How to Extend Die Life: A Data-Driven Approach to Cooling System and Gating Design in HPDC

This technical summary is based on the academic paper "Design and optimization of gating system, modification of cooling system position and flow simulation for cold chamber high pressure die casting machine" published by A.R. Jadhav, D.P. Hujare and P.P. Hujare in Materials Today: Proceedings (2021). It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: Die life optimization HPDC

- Secondary Keywords: Cooling system design die casting, Gating system optimization, HPDC simulation, ANSYS stress analysis, MAGMA flow simulation, ADC12 aluminum alloy, H13 tool steel

Executive Summary

- The Challenge: Premature die failure in High-Pressure Die Casting (HPDC) is a significant cost driver, often caused by high thermal and mechanical stresses that exceed the die material's limits. A primary, yet often overlooked, contributor is the suboptimal design of the die's cooling system.

- The Method: Researchers used a powerful combination of Finite Element Analysis (ANSYS) for stress analysis and flow simulation (MAGMA) to redesign and optimize the cooling and gating systems for an H13 tool steel die casting an ADC12 aluminum component.

- The Key Breakthrough: The study proved that the position of the cooling channels is a critical factor in managing die stress. By strategically moving the cooling channels from 10 mm to an optimal 30 mm away from the cavity surface, the maximum stress on the die was reduced from a critical 4098.7 MPa to a safe 1618.4 MPa.

- The Bottom Line: This research provides a clear, data-backed methodology for extending die life. By optimizing cooling channel placement and using flow simulation to refine the gating system during the initial design stage, manufacturers can significantly reduce die failure, improve casting quality, and lower operational costs.

The Challenge: Why This Research Matters for HPDC Professionals

In the demanding world of HPDC, die failure is not just an inconvenience; it's a major threat to productivity and profitability. Dies are subjected to immense cyclic thermal and mechanical loads, leading to common failure modes like heat checks and cracks. As the paper highlights, these failures often occur when stresses generated during the casting cycle surpass the die material's yield strength.

The cooling system is a double-edged sword. While essential for proper solidification and maintaining die temperature, an improperly located cooling system can create severe thermal gradients, leading to concentrated stress points on the die surface. The core problem this research tackles is the lack of a systematic, data-driven approach to positioning these cooling channels to minimize stress and maximize die life from the very beginning of the design process.

The Approach: Unpacking the Methodology

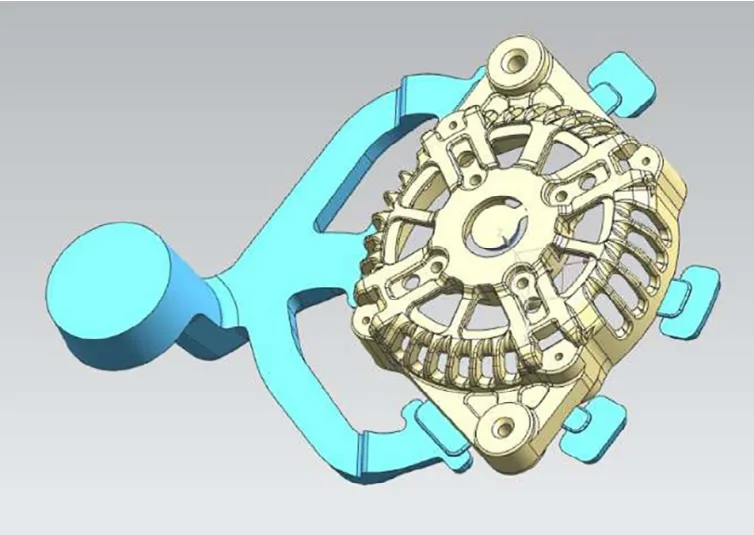

To solve this critical issue, the researchers employed a two-pronged digital engineering approach for a die designed to produce an ADC12 aluminum alloy "DE Bracket" on a 160 Tonne Cold Chamber HPDC machine.

- Stress Analysis (ANSYS): The team first modeled the H13 tool steel die inserts and performed a steady-state thermal and static structural analysis using ANSYS Workbench. They simulated the thermal load from the 660°C molten metal and the mechanical load from the 160T clamping force. The key variable in their analysis was the distance of the cooling channels from the cavity surface.

- Flow Simulation (MAGMA): After optimizing the die design for stress, the researchers used MAGMA software to simulate the molten metal filling process. This allowed them to analyze and refine critical gating system parameters like gate velocity, filling time, and the plunger's switchover point to prevent defects like die erosion and air entrapment.

This combined simulation approach allowed the team to predict and solve potential problems digitally before any steel was cut, demonstrating a modern, efficient workflow for die design.

The Breakthrough: Key Findings & Data

The study yielded clear, actionable results that directly link design choices to die performance and longevity.

Finding 1: The Danger of "Too Close" Cooling: The initial design placed the cooling channels just 10 mm from the cavity surface. Stress analysis revealed this generated a maximum stress of 4098.7 MPa on the moving die half (Figure 6). This value is far beyond the typical yield strength of H13 tool steel (~1650 MPa), guaranteeing premature failure.

Finding 2: The "Sweet Spot" for Cooling Channel Placement: By systematically analyzing different positions, the researchers found that the stress on the die decreased as the cooling channels were moved further from the cavity. The optimal position was determined to be 30 mm from the surface. At this distance, the maximum stress dropped to 1618.4 MPa (Figure 8), a value safely below the material's yield strength. The relationship between cooling channel location and stress is clearly visualized in Figure 10.

Finding 3: Gating System Optimization for Quality: The MAGMA flow simulation identified that the initial design would result in a gate velocity of 40 m/s, which could lead to die erosion. To mitigate this, the gate thickness was increased from 1.2 mm to 1.8 mm, and the target velocity was successfully reduced to a safer 35 m/s.

Finding 4: Fine-Tuning the Shot Profile: The simulation also revealed that the plunger's switchover point (from slow to fast phase) could be improved. By modifying the slow phase length to 203 mm and the slow phase velocity to 0.30 m/s, a smoother, more controlled fill was achieved, reducing the risk of air entrapment, which was confirmed to be within the acceptable 15% limit (Figure 15).

Practical Implications for HPDC Products

This research offers valuable insights that can be directly applied to real-world HPDC operations to improve die life and part quality.

For Die Design Engineers: The study provides a compelling, data-driven case for making cooling channel placement a primary consideration in the initial design phase. The graph in Figure 10 serves as a powerful conceptual guide: moving cooling channels further from the cavity surface reduces thermal stress. Instead of relying on rules of thumb, designers can use simulation to find the optimal balance between cooling efficiency and die stress for each unique part geometry.

For Process Engineers: The findings on gating and plunger parameters underscore the importance of a well-defined shot profile. The optimization of the switchover point and slow-phase velocity (as shown in Figure 11 and Figure 12) demonstrates that small adjustments, guided by simulation, can significantly improve metal flow, reduce turbulence, and minimize defects like porosity caused by air entrapment.

For Quality Control: The correlation between gate velocity and die erosion is a critical takeaway. Monitoring for signs of erosion near the gate area can be an early indicator of a process that is too aggressive, potentially leading to casting defects and premature die wear. The study reinforces that maintaining air entrapment below 15% (Figure 15) is a key benchmark for producing high-integrity castings.

Paper Details

Design and optimization of gating system, modification of cooling system position and flow simulation for cold chamber high pressure die casting machine

1. Overview:

- Title: Design and optimization of gating system, modification of cooling system position and flow simulation for cold chamber high pressure die casting machine

- Author: Amol R. Jadhav, Deepak P. Hujare, Pravin P. Hujare

- Year of publication: 2021 (Available online 2020)

- Journal/academic society of publication: Materials Today: Proceedings

- Keywords: Gating design, Cooling system, Filling simulation, Cold chamber die casting, MAGMA

2. Abstract:

The failure of dies and its repairing options are very important in die casting industries. Of all the casting processes available, pressure die casting finds wide applications in large scale production of complex shaped objects with intricate geometries that require good surface finish and dimensional stability. The cooling system employed in the die not only facilitates proper solidification of the cast components but also helps in maintaining the die temperature and controlling the stresses generated during the cyclic operation. The research work focuses on designing a die of H13 material for ADC12 cast part that is to be operated on 160 Tonne Cold Chamber HPDC machine. The effect of cooling system location on the stresses produced in die is analysed and their optimum location is determined by ANSYS. Further, filling simulation of the modified design was carried out and minor modifications are made to optimize the filling operation using MAGMA Software. The research work proves to be useful in increasing the die life by considering the optimization of cooling channel position along with the gating system design in the design stage.

3. Introduction:

Pressure die casting is a widely used process for mass-producing complex, thin-walled components from non-ferrous alloys like aluminum, magnesium, and zinc. Its high production rate and dimensional precision make it popular in the automotive and communication industries. However, the process is not without its challenges. Porosity, caused by air entrapment during high-speed injection, is a major defect. Furthermore, the dies themselves are subject to failure. This study focuses on addressing die failure by optimizing the design of the gating and cooling systems for a cold chamber HPDC process.

4. Summary of the study:

Background of the research topic:

Die failure in HPDC is a significant operational issue. Stresses from mechanical loading and severe temperature gradients are a common cause of cracks and heat checks on the die surface. The location of the cooling system plays a crucial role in managing these thermal stresses. An improper location can exacerbate stress concentrations, leading to a reduced die life.

Status of previous research:

Previous studies have established H11 and H13 as suitable hot work tool steels for HPDC dies (Ref. [1]). Research has also highlighted the use of simulation software like MAGMAsoft for predicting filling patterns and defects (Ref. [2], [7]). Other work has investigated the influence of different gating system designs (Ref. [3], [4]) and the causes of die failure, noting that thermal gradients from cooling channels contribute to mechanical fatigue (Ref. [5]). This study builds upon this foundation by directly linking the cooling channel position to stress levels and combining it with gating system optimization.

Purpose of the study:

The primary objectives of this research were:

- To design a die for an ADC12 component for a Cold Chamber HPDC machine.

- To perform a stress analysis to determine the optimum position of the cooling system to minimize stress and increase die life.

- To use MAGMA software for flow simulation and optimization of the gating system to ensure good quality casting.

Core study:

The core of the study involved a multi-step optimization process. First, a die for an automotive DE Bracket was designed. An initial stress analysis was performed in ANSYS with the cooling channels positioned 10 mm from the cavity surface. After finding the stresses were unacceptably high, the analysis was repeated with the channels at different distances until an optimal position (30 mm) was found that kept stresses within the material's limits. Following this structural optimization, the gating system was analyzed using MAGMA. The simulation identified potential issues with gate velocity and the plunger's shot profile, which were then modified to improve the filling process and reduce the risk of defects.

5. Research Methodology

Research Design:

The research followed a sequential simulation-based design and optimization workflow.

- Component and Die Design: A 3D model of the ADC12 cast part and the H13 die was created using NX-10 software.

- Stress Analysis: A steady-state thermal and static structural analysis was conducted using ANSYS Workbench 14.5. The analysis simulated the operating conditions of a 160T HPDC machine. The key parameter varied was the distance of the cooling channels from the die cavity (trials from 10 mm to 30 mm).

- Flow Simulation: The optimized die and gating system design was then imported into MAGMA software. A filling simulation was performed to analyze metal flow, velocity, temperature, and air entrapment.

Data Collection and Analysis Methods:

Data was generated and collected through the simulation software. In ANSYS, the primary output data was the Equivalent (von-Mises) Stress distribution on the die surface. In MAGMA, the output data included metal velocity at the gate, filling patterns over time, temperature distribution, and percentage of air entrapment in the final casting.

Research Topics and Scope:

The research was scoped to the design and optimization of a specific die for an ADC12 aluminum component on a 160 Tonne cold chamber HPDC machine. It focused specifically on two key areas:

- The impact of cooling channel location on thermally induced stresses in the H13 die.

- The optimization of the gating system (gate velocity, thickness) and shot parameters (plunger velocity, switchover point) to ensure a defect-free filling process.

6. Key Results:

Key Results:

- The initial design with cooling channels 10 mm from the cavity resulted in a maximum von-Mises stress of 4098.7 MPa on the moving die, far exceeding the H13 material's yield strength of 1650 MPa.

- The optimal cooling channel position was found to be 30 mm from the cavity surface, which reduced the maximum stress to a safe level of 1618.4 MPa.

- Flow simulation indicated the initial gate velocity of 40 m/s was too high. It was optimized to 35 m/s by modifying the gate thickness to 1.8 mm.

- The plunger's slow phase length was modified to 203 mm and the slow phase velocity to 0.30 m/s for smoother metal flow.

- The final optimized design resulted in air entrapment within the acceptable limit of 15%.

Figure Name List:

- Fig. 1. Cast Part Model.

- Fig. 2. Transparent view of die assembly.

- Fig. 3. Shot Model.

- Fig. 4. Temperature result (Moving Side Die - Existing Design).

- Fig. 5. Temperature result (Fixed side die - Existing design).

- Fig. 6. Moving side die (Stresses).

- Fig. 7. Fixed side die (Stresses).

- Fig. 8. Moving side die (Stresses).

- Fig. 9. Fixed side die (Stresses).

- Fig. 10. Graph of stress variation.

- Fig. 11. Switch over point during filling.

- Fig. 12. Switch over point during filling (after modification).

- Fig. 13. Metal velocity result (before modification).

- Fig. 14. Metal velocity result (after modification).

- Fig. 15. Air Entrapment.

7. Conclusion:

The design of the gating system forms a crucial part of the die design operation. The cooling system employed in the die not only helps in the solidification of the cast component but also facilitates in proper maintenance of die temperature during the cyclic operation. Optimization of the cooling channel position in the design stage proves to be helpful in increasing the die life and can be done in the design stage. Flow simulation using MAGMA Software helps to optimize the gating system design so as to have proper filling of the die cavity and to ensure good quality casting.

8. References:

- [1] A. Long, D. Thornhill, C. Armstrong, D. Watson, Predicting die life from die temperature for high pressure die castings, Appl. Therm. Eng. 44 (2012) 100-107.

- [2] I. Lokeswar Patnaik, Saravanan, Sunil Kumar, "Die casting parameters and simulations for crankcase of automobile using MAGMAsoft", Mater. Today:. Proc. 22 (2020) 563–571.

- [3] B.H. Hu, K.K. Tong, X.P. Niu, I. Pinwill, Design and optimization of runner and gating systems for the die casting of thin walled magnesium telecommunication parts through numerical simulation, J. Mater. Process. Technol. 105 (2000) 128–133.

- [4] B. Vijaya Ramnath, C. Elanchezhian, A. Vishal Chandrashekhar, A. Kumar, et al., Analysis and optimization of gating system for commutator end bracket, Procedia Mater. Sci. 6 (2014) 1312–1328.

- [5] S. Jhavar, C.P. Paul, N.K. Jain, Causes of failure and repairing options for dies and molds: A review, Eng. Fail. Anal. 34 (2013) 519–535.

- [6] , Comput. Mater. Sci. 43 (2008) 1147–1154.

- [7] Paul Cleary, Joseph Ha a, Vladimir Alguine b, Thang Nguyen "Flow modelling in casting processes", Applied Mathematical Modelling 26 (2002) 171–190

- [8] T. Kimura, H. Yamagata and S. Tanikawa, "FEM stress analysis of the cooling hole of an HPDC die", IOP Conf. Series: Materials Science and Engineering 84 (2015) 012052 doi:10.1088/1757-899X/84/1/012052

- [9] Radhika Chavan, P.S. Kulkarni "Die design and optimization of cooling channel position for cold chamber high pressure die casting machine", IOP Conf. Series: Materials Science and Engineering 810 (2020) 012017

Expert Q&A: Your Top Questions Answered

Q1: What was the main cause of the high stress in the initial die design?

A1: The main cause was the proximity of the cooling channels to the die cavity surface. The initial design placed them only 10 mm away, creating a very steep thermal gradient. This rapid temperature change between the hot cavity surface and the cool channel induced massive thermal stresses, which, when combined with mechanical clamping forces, reached a critical level of 4098.7 MPa (Figure 6).

Q2: How much was the stress reduced by optimizing the cooling channel position?

A2: The stress was reduced dramatically. By moving the cooling channels from 10 mm to an optimal 30 mm away from the cavity surface, the maximum von-Mises stress on the moving die was reduced from 4098.7 MPa to 1618.4 MPa. This is a reduction of over 60% and brought the stress level safely below the H13 tool steel's yield strength of 1650 MPa (Figure 10).

Q3: Why is gate velocity so important in this study?

A3: Gate velocity is critical because excessively high velocity (initially 40 m/s) can cause erosion of the steel die at the gate, leading to dimensional inaccuracies in the casting and premature die failure. The MAGMA simulation allowed the researchers to identify this risk and modify the gate design to achieve a safer velocity of 35 m/s, ensuring both part quality and die longevity (Figure 13, Figure 14).

Q4: What specific software tools were used, and what were their roles?

A4: The study used two key software tools. ANSYS Workbench 14.5 was used for Finite Element Analysis (FEA) to calculate the thermal and mechanical stresses on the die. Its role was to determine the optimal location for the cooling channels to minimize stress. MAGMA Software was used for casting process simulation to analyze the molten metal flow, identify potential filling problems like high velocity and air entrapment, and optimize the gating system and shot parameters.

Q5: What are the key material properties to consider for the die and the cast part in this context?

A5: For the die, made of H13 tool steel, the most critical properties are its yield strength (~1650 MPa) and ultimate tensile strength (~1990 MPa), as the induced stresses must remain below these values to prevent failure. For the cast part, made of ADC12 aluminum alloy, the key properties are its melting temperature (650-700°C) and liquidus temperature (580°C), which are essential inputs for calculating fill time and simulating thermal loads on the die.

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing die life and part quality in HPDC. By moving beyond traditional design rules and embracing a simulation-driven approach, the findings offer a clear, data-backed path toward engineering more robust and reliable tooling. The direct correlation established between cooling channel position and die stress is a powerful principle that can be applied to virtually any die design project.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues of die life, stress management, and filling quality discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "A.R. Jadhav, D.P. Hujare and P.P. Hujare". Based on "Design and optimization of gating system, modification of cooling system position and flow simulation for cold chamber high pressure die casting machine".

- Source of the paper: https://doi.org/10.1016/j.matpr.2020.11.346

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.