How Computational Tools and Advanced Manufacturing are Driving the Next Generation of Lighter, More Efficient Vehicles

This technical brief is based on the academic paper "Recent advances in light metals and manufacturing for automotive applications" by A. A. Luo, published in CIM Journal (2021). It is summarized and analyzed for industry professionals by the experts at CASTMAN.

Keywords

- Primary Keyword: Automotive lightweighting

- Secondary Keywords: Light metals, aluminum alloys, magnesium alloys, titanium alloys, CALPHAD, Integrated Computational Materials Engineering (ICME), advanced manufacturing

Executive Summary

- The Challenge: The automotive industry faces intense pressure to reduce vehicle weight to improve fuel economy and, for electric vehicles, extend driving range. A 10% weight reduction can yield a 6-14% efficiency improvement.

- The Method: The research reviews the use of advanced computational tools, specifically CALPHAD (CALculation of PHAse Diagrams) and the broader ICME (Integrated Computational Materials Engineering) framework, to design and develop new, high-performance aluminum, magnesium, and titanium alloys.

- The Key Breakthrough: The paper demonstrates successful, data-driven alloy design, including a new Mg-Zn-Ca-Ce sheet alloy with excellent ductility, a creep-resistant AE44 magnesium alloy for engine components, and a cost-effective Ti-6Al-5Fe titanium alloy that replaces expensive vanadium with iron without sacrificing strength.

- The Bottom Line: Combining computational materials design with advanced manufacturing processes like high-vacuum die casting and warm forming provides a powerful, accelerated pathway for implementing affordable, high-performance lightweight components in next-generation vehicles.

The Challenge: Why This Research Matters for HPDC Professionals

For decades, engineers have pursued vehicle lightweighting to meet ever-stricter efficiency and performance targets. As the paper highlights, a 10% reduction in vehicle weight delivers a 6% fuel economy improvement for conventional cars and a significant 14% range extension for battery-electric vehicles (Joost, 2015; Schutte & Joost, 2014). While light metals like aluminum, magnesium, and titanium are primary candidates for replacing steel, their widespread adoption is often limited by factors such as cost, formability, and the need for specialized manufacturing processes. This research directly addresses these hurdles by showcasing a modern, integrated approach to developing both the materials and the manufacturing techniques needed to make lightweighting a practical reality.

The Approach: Unpacking the Methodology

The study moves beyond traditional trial-and-error material development. The core of its approach is the use of Integrated Computational Materials Engineering (ICME), a framework that links material models, manufacturing process simulations, and product performance analysis. A key tool within this framework is CALPHAD (CALculation of PHAse Diagrams) modeling. As the paper details, researchers used CALPHAD to:

- Predict phase formation in new alloy systems.

- Optimize alloy compositions to achieve desired properties (e.g., strength, creep resistance, ductility).

- Reduce the number of expensive and time-consuming physical experiments.

This computational approach was then validated with experimental testing, creating a powerful feedback loop that accelerates the development of new, application-specific light metal alloys. The paper presents this methodology as a strategic tool for designing materials and processes concurrently, ensuring that new alloys are not just theoretically superior but also manufacturable at scale.

The Breakthrough: Key Findings & Data

The paper presents several compelling examples of how this integrated approach yields tangible results across different light metals.

- Optimizing Recycled Aluminum: Iron (Fe) is a common impurity in recycled aluminum that forms brittle phases, harming ductility. By using CALPHAD modeling and experimental validation, researchers created a formation map (Figure 2) that shows how to control the Fe/Mn ratio and cooling rate to promote the formation of less harmful intermetallic phases. This finding is critical for increasing the use of cost-effective, sustainable recycled aluminum in structural castings.

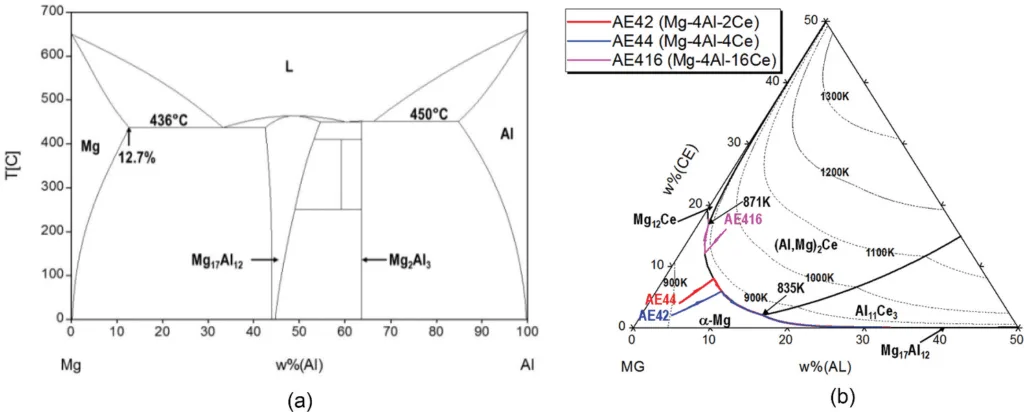

- Designing High-Performance Magnesium Alloys: To overcome the poor high-temperature performance of standard Mg-Al alloys, CALPHAD was used to design the AE44 (Mg-4Al-4RE) alloy. As shown in the calculated phase diagrams (Figure 3), the addition of rare-earth elements (RE) suppresses the formation of the low-melting-point Mg17Al12 phase, enabling the alloy to be used in higher-temperature applications like the Corvette engine cradle. Furthermore, a new ZXEM2000 magnesium sheet alloy was developed with an exceptional combination of strength and ductility (29% elongation), attributed to a fine grain structure and nanoscale precipitates (Figure 4).

- Developing Cost-Effective Titanium: Titanium's high cost is a major barrier to its use in automotive. The research details the design of a new castable alloy, Ti-6Al-5Fe-0.05B-0.05C, which replaces expensive vanadium (V) with low-cost iron (Fe). CALPHAD calculations (Figure 5a) confirmed the viability of this substitution. The resulting alloy exhibits exceptionally high strength (1136 MPa UTS) due to a very fine microstructure (Figure 5b), making it a promising candidate for components like connecting rods.

- Innovating Manufacturing Processes: The paper also highlights advances in manufacturing. Warm gas forming of magnesium tubes (Figure 6b) demonstrates how to overcome the material's poor room-temperature formability. The development of high-integrity casting processes, including a permanent mold casting system for titanium (Figure 8), shows a path toward high-volume production of complex light metal parts.

Practical Implications for Your HPDC Operations

The findings presented in this paper offer direct, actionable insights for engineers and managers in the automotive and manufacturing sectors.

- For Process Engineers: The research on warm forming of magnesium (Figure 6) and high-vacuum die casting for aluminum suggests that adopting advanced thermal and process controls can enable the production of more complex, higher-integrity components from light alloys. The formation map for recycled aluminum (Figure 2) provides a practical guide for optimizing melt chemistry and cooling parameters to improve casting quality.

- For Materials and Alloy Development: The success of the CALPHAD-driven approach in designing new Mg and Ti alloys (Figures 3, 4, and 5) validates the use of computational tools to drastically shorten development cycles and reduce R&D costs. This methodology allows for the creation of tailored alloys that meet specific performance and cost targets.

- For R&D and Strategy Managers: The ICME framework (Figure 9) presents a clear strategic model for innovation. By integrating material design, manufacturing simulation, and performance analysis, companies can de-risk the adoption of new materials and accelerate their path from the lab to the production line, creating a significant competitive advantage.

Paper Details

Recent advances in light metals and manufacturing for automotive applications

1. Overview:

- Title: Recent advances in light metals and manufacturing for automotive applications

- Author: A. A. Luo

- Year of publication: 2021

- Journal/academic society of publication: CIM Journal

- Keywords: Aluminum, Automotive lightweighting, Casting, Forming, Integrated Computational Materials Engineering, Magnesium, Titanium

2. Abstract:

Advanced light metals, including aluminum, magnesium, and titanium alloys, are increasingly being used in the automotive industry for weight reduction and structural efficiency. This paper provides examples of designing and developing new aluminum, magnesium, and titanium alloys using CALPHAD (CALculation of PHAse Diagrams) modeling and experimental validation. The paper also summarizes some of the latest process innovations in casting and forming processes for light alloys. Integrated Computational Materials Engineering (ICME) is defined as the integration of materials information, captured in computational tools, with engineering product performance analysis and manufacturing process simulation. This paper highlights some examples of alloy development and advanced processing of light alloys using CALPHAD and ICME tools and future challenges of light metal research for automotive lightweighting.

3. Introduction:

The paper establishes the strong incentive for automotive lightweighting: a 10% weight reduction can improve fuel economy by 6% in conventional vehicles and increase the range of electric vehicles by approximately 14%. This has driven the adoption of light metals. The Ford F-150's aluminum-intensive architecture and the Cadillac ATS's use of aluminum and magnesium components are cited as key examples. The paper states that vehicle weight reduction is achieved through design optimization and material substitution, and this review will focus on the latter, specifically the development of advanced light metals and their associated manufacturing processes.

4. Summary of the study:

Background of the research topic:

The automotive industry's continuous push for improved fuel economy and performance, especially with the rise of heavier electric vehicles, necessitates significant vehicle weight reduction. Light metals like aluminum, magnesium, and titanium offer high strength-to-weight ratios, making them ideal for this purpose. However, challenges related to cost, manufacturability, and performance in specific applications have historically limited their use.

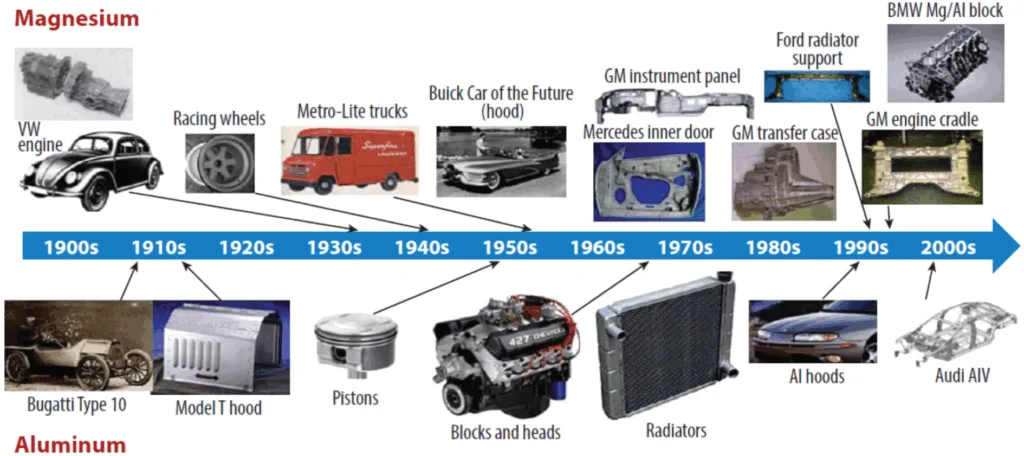

Status of previous research:

The paper builds upon a long history of using aluminum and magnesium in cars, which saw steady growth since the 1970s. It acknowledges existing work on modifying aluminum alloys to tolerate impurities, improving the creep resistance of magnesium alloys, and developing forming technologies for these materials. The paper positions its contribution as a review of the latest advances, with a particular focus on the role of modern computational tools like CALPHAD and the ICME framework in accelerating these developments.

Purpose of the study:

The purpose of this paper is to provide an overview of recent, significant progress in the field of light metals for automotive applications. It aims to:

- Provide examples of designing and developing new aluminum, magnesium, and titanium alloys using CALPHAD modeling.

- Summarize recent innovations in casting and forming processes for these light alloys.

- Highlight the role and importance of the Integrated Computational Materials Engineering (ICME) framework in future research and development for automotive lightweighting.

Core study:

The core of the study is a review and synthesis of recent breakthroughs in three key areas:

- Alloy Development: It details the computational design and experimental validation of new alloys. This includes managing iron in recycled aluminum, enhancing the high-temperature performance of magnesium alloys, and creating a low-cost, high-strength cast titanium alloy.

- Process Innovations: It examines advanced manufacturing techniques that enable the use of these alloys in complex components. This includes advanced sheet forming (warm forming), tube hydroforming/gas forming, and high-integrity casting processes (e.g., high vacuum die-casting, permanent mold casting for titanium).

- Integrated Framework: It champions the ICME approach as the unifying methodology that connects alloy design, manufacturing, and final component performance, proposing it as the key to future progress.

5. Research Methodology

Research Design:

The paper is a review article. Its methodology consists of synthesizing and analyzing recent research from the author and the broader scientific community. The research examples cited within the paper follow a consistent design:

- Problem Identification: A specific material limitation is identified (e.g., poor creep resistance in Mg, high cost of Ti).

- Computational Modeling: CALPHAD is used to predict phase equilibria and guide the design of new alloy compositions.

- Experimental Validation: The newly designed alloys are physically produced and tested (e.g., tensile tests, microstructural analysis) to confirm the model's predictions and evaluate performance.

- Process Development: Manufacturing processes are developed or adapted to produce components from the new materials.

Data Collection and Analysis Methods:

The data presented is collected from a variety of sources described in the paper, including:

- CALPHAD Software: To generate phase diagrams and liquidus projections (e.g., Figure 3, Figure 5a).

- Microscopy: Optical and Scanning Electron Microscopy (SEM) to characterize microstructures, grain sizes, and precipitate phases (e.g., Figures 2, 4, 5b).

- Mechanical Testing: Tensile testing machines to generate stress-strain curves and determine properties like yield strength, ultimate tensile strength, and elongation (e.g., Figure 4a, Table 2).

- Process Simulation: Casting simulation software to optimize processes and predict fill patterns (e.g., Figure 7).

Research Topics and Scope:

The scope of the paper covers recent advances in light metals specifically for automotive applications. The primary topics are:

- Light Metals: Aluminum, Magnesium, and Titanium alloys.

- Alloy Development: Focusing on the use of CALPHAD for designing new compositions with improved properties (strength, ductility, creep resistance) and lower cost.

- Manufacturing Processes: Innovations in casting (high-vacuum die casting, permanent mold) and forming (warm forming, hydroforming).

- Computational Framework: The application and future importance of the ICME framework.

6. Key Results:

Key Results:

The key results are organized by material and process:

- Aluminum: A formation map for iron-containing intermetallic phases was developed (Figure 2), providing a guide to control microstructure and improve ductility in recycled cast aluminum alloys by managing the Fe/Mn ratio and cooling rate.

- Magnesium: A new creep-resistant alloy (AE44) was developed for higher-temperature applications by using Ce additions to suppress the undesirable Mg17Al12 phase (Figure 3). A new sheet alloy (ZXEM2000) was also developed, exhibiting an excellent combination of 157 MPa yield strength and ~29% elongation (Figure 4).

- Titanium: A cost-effective cast titanium alloy (Ti-6Al-5Fe-0.05B-0.05C) was designed by replacing expensive vanadium with iron. This alloy achieved exceptionally high strength (1023 MPa YS, 1136 MPa UTS) and reasonable ductility (Table 2, Figure 5).

- Manufacturing: Successful warm gas forming of AZ31 magnesium tubes (Figure 6b) and the development of a permanent mold casting process for titanium connecting rods (Figure 8c) demonstrated viable pathways for high-volume production of complex lightweight components.

- ICME Framework: The paper proposes an ICME framework (Figure 9) as a critical tool to accelerate future development by integrating material, process, and performance models.

Figure Name List:

- Figure 1. Timeline of key aluminum and magnesium automobile applications; AIV, aluminum-intensive vehicle (Krajewski, Sachdev, Luo, Carsley & Schroth, 2009)

- Figure 2. The formation map of Fe-containing intermetallic phases effect of cooling rate on the solidification behavior of Al-Si-Mg casting alloys with high Fe content (Cinkilic, Ridgeway, Yan & Luo, 2019)

- Figure 3. (a) Calculated Mg-Al phase diagram (Luo, 2015). (b) Calculated Mg-Al-Ce liquidus projection and solidification paths of experimental Mg-Al-Ce alloys (Luo, 2015)

- Figure 4. (a) Tensile curves at room temperature; (b) optical micrograph; and (c) STEM-EDS map for solute elements (Ca-green, Zn-blue and Mn-Magenta) of ZXEM2000 alloy (Shi, Miao & Luo, 2019)

- Figure 5. (a) Comparison of calculated isopleths of Ti-6Al-xV (blue) and Ti-6Al-xFe (red); and (b) tensile curve of Ti-6Al-5Fe-0.05B-0.05C alloy with an insert of SEM image showing very fine secondary α phase (in addition to the primary α platelets) in this α-β titanium casting alloy (Liang et al., 2018)

- Figure 6. (a) Hydroformed aluminum rail for Corvette Z06 shown immediately after forming (Luo & Sachdev, 2008). (b) AZ31 magnesium tube gas-formed at 350°C showing 80% circumference expansion (Luo & Sachdev, 2008)

- Figure 7. Achieving thin-wall aluminum and magnesium die casting through alloy optimization and process simulation (Cinkilic et al., 2018)

- Figure 8. Titanium permanent mold casting system at OSU: (a) overall view including all control, power cabinets, and vacuum chamber; and (b) in-chamber view including ISM crucible and mold heater. The ISM crucible can be tilted with a mechanical lever outside of chamber for tilt-pouring. (c) an example casting of connecting rod (Luo, Liang, Miao, Sachdev & Williams, 2019)

- Figure 9. ICME framework for new application development (Luo, 2015)

7. Conclusion:

The paper concludes that significant progress has been made in developing and implementing light metals for automotive lightweighting. The use of computational tools like CALPHAD and the overarching ICME framework has proven to be a highly effective strategy for accelerating the design of new alloys with tailored properties and for optimizing manufacturing processes. While challenges remain, particularly in developing cost-effective, high-integrity manufacturing and joining processes, the author firmly believes that the ICME approach will be critical in developing the next generation of affordable, lightweight vehicle structures.

8. References:

- [The full list of references from page 9 and 10 of the paper is included here, starting with Banerjee, D., & Williams, J. C. (2013) and ending with Xia, L. (2016).]

- Banerjee, D., & Williams, J. C. (2013). Perspectives on titanium science and technology. Acta Materialia, 61(3), 844-879. https://doi.org/10.1016/j.actamat.2012.10.043

- Brown, Z., Szymanowski, B., Musser, M., Saha, D., & Seaver, S. (2009). Development of super-vacuum die casting process for magnesium alloys. North American Die Casting Association Transmission. http://www.diecasting.org/archive/transactions/T09-043.pdf

- Carter, J. T., Krajewski, P. E., & Verma, R. (2008). The hot blow forming of AZ31 Mg sheet: Formability assessment and application development. JOM, 60(11), 77. https://doi.org/10.1007/s11837-008-0153-5

- ... [and all other references as listed in the original document] ...

- Twarog, D., Apelian, D., & Luo, A. (2016). High integrity casting of lightweight components. North American Die Casting Association.

- Xia, L. (2016). Multiscale structural topology optimization. Elsevier Ltd.

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing automotive lightweighting through the integrated development of materials and manufacturing processes. The findings offer a clear, data-driven path toward improving component performance, increasing the use of sustainable materials, and optimizing production.

STI C&D is committed to applying cutting-edge industry research to solve our customers’ most challenging technical problems. If the challenges discussed in this paper align with your goals, please contact our engineering team to discuss how we can help you apply these advanced principles to your projects.

Expert Q&A:

- Q1: What is the primary motivation for using advanced light metals in the automotive industry? A: The primary motivation is vehicle weight reduction. According to the paper, a 10% weight reduction delivers a 6% fuel economy improvement in conventional cars and a 14% increase in driving range for electric vehicles, which is critical for offsetting the heavy weight of battery systems. (Source: "Recent advances in light metals and manufacturing for automotive applications", Introduction section).

- Q2: How can the negative effects of iron in recycled aluminum be managed during casting? A: The paper suggests that the negative effects of iron, which forms brittle β-Al5FeSi phases, can be managed by adding manganese (Mn) and controlling the cooling rate. The formation map in Figure 2 shows that by adjusting the Fe/Mn ratio and using faster cooling, the formation of the brittle phase can be suppressed in favor of less harmful, more compact α-Al15(Fe,Mn)3Si2 phases, thus improving the ductility of castings made from recycled aluminum. (Source: "Recent advances in light metals and manufacturing for automotive applications", Aluminum alloy development section).

- Q3: What is a key limitation of traditional magnesium-aluminum alloys and how was it overcome for the Corvette engine cradle? A: A key limitation is poor creep resistance at temperatures above 125°C, caused by the formation of a low-melting-point Mg17Al12 phase. This was overcome in the AE44 (Mg-4Al-4RE) alloy by adding rare-earth (RE) elements. As shown in the calculated liquidus projection in Figure 3b, the RE additions promote the formation of more stable, higher-temperature phases like Al11Ce3, suppressing the Mg17Al12 phase and allowing the alloy to be used at operating temperatures up to 150°C, as required for the engine cradle. (Source: "Recent advances in light metals and manufacturing for automotive applications", Magnesium alloy development section).

- Q4: How did the researchers develop a more cost-effective high-strength titanium alloy? A: They designed a new alloy, Ti-6Al-5Fe-0.05B-0.05C, by substituting the expensive alloying element vanadium (V) with low-cost iron (Fe). CALPHAD modeling, shown in Figure 5a, confirmed this was a viable strategy. The resulting alloy achieved exceptionally high strength (1136 MPa UTS), making it a promising, lower-cost alternative to traditional Ti-6Al-4V for automotive applications like connecting rods. (Source: "Recent advances in light metals and manufacturing for automotive applications", Titanium alloy development section).

- Q5: What is Integrated Computational Materials Engineering (ICME) and why is it considered so important for the future? A: ICME is defined as the integration of materials information, captured in computational tools, with engineering product performance analysis and manufacturing process simulation. It is considered crucial because it can greatly accelerate the design and development of new, affordable lightweight structures. The ICME framework, illustrated in Figure 9, connects material design (e.g., CALPHAD), manufacturing models, and final product performance (e.g., FEA) into a single, cohesive workflow, reducing the time and cost of innovation. (Source: "Recent advances in light metals and manufacturing for automotive applications", Abstract and Future Outlook sections).

- Q6: What is an example of an advanced forming process that enables the use of magnesium for complex parts? A: The paper highlights warm gas forming as a key enabling technology. Magnesium has very limited formability at room temperature, but it can be successfully formed at elevated temperatures. Figure 6b shows a magnesium alloy AZ31 tube that was successfully gas-formed at 350°C, achieving an 80% circumference expansion, a feat not possible with cold forming. This demonstrates a viable manufacturing route for complex magnesium components. (Source: "Recent advances in light metals and manufacturing for automotive applications", Tube hydroforming and gas forming section).

Copyright

- This material is an analysis of the paper "Recent advances in light metals and manufacturing for automotive applications" by A. A. Luo.

- Source of the paper: https://doi.org/10.1080/19236026.2021.1947088

- This material is for informational purposes only. Unauthorized commercial use is prohibited.

- Copyright © 2025 STI C&D. All rights reserved.