This technical brief is based on the academic paper "Optimizing the Structural Design of Computing Units in Autonomous Driving Systems and Electric Vehicles to Enhance Overall Performance Stability" by Zhong, Yao-Nian, published in International Journal of Advance in Applied Science Research (2024). It is summarized and analyzed for HPDC professionals by the experts at CASTMAN.

Executive Summary

- The Challenge: The computing units in electric vehicles (EVs) and autonomous driving (AD) systems generate immense heat but often require sealed, fanless enclosures. Standard aluminum alloy die-castings with fins are reaching their thermal limits.

- The Method: The research analyzes a multi-stage thermal management strategy, starting with optimized fin design on aluminum alloy casings, followed by a novel "disassembly" concept that integrates high-conductivity copper blocks into the die-cast structure for localized cooling.

- The Key Breakthrough: Thermal simulations showed that strategically embedding copper blocks into an aluminum alloy casing can reduce the temperature of high-heat electronic components by at least 5 °C, enhancing system stability and lifespan.

- The Bottom Line: A hybrid copper-aluminum HPDC design offers a superior, practical solution for managing extreme heat in modern automotive electronics, balancing performance, cost, and weight.

The Challenge: Why This Research Matters for HPDC Professionals

As computing power in EVs and AD systems skyrockets, so does the heat generated. For decades, engineers have relied on High-Pressure Die Casting (HPDC) to produce lightweight, complex aluminum alloy enclosures with integrated heat dissipation fins. This has been a successful strategy. However, the increasing computational density and the need for sealed, fanless designs to protect against dust and moisture are pushing traditional fin-only designs to their thermal breaking point.

Overheating can compromise vehicle safety and operational stability by degrading performance or causing system failure. The industry urgently needs a cost-effective evolution in thermal management that can be realized through advanced die casting. This study, as detailed in its Introduction, tackles this exact problem by exploring how to enhance the heat dissipation efficiency of computing unit enclosures through optimized structural and material design.

The Approach: Unpacking the Methodology

The research outlines a progressive, multi-layered approach to thermal management. The study begins by reaffirming the value of aluminum alloys for their high thermal conductivity (90–130 W/m·K), light weight, and excellent processability via die-casting.

The core of the investigation focuses on two key areas:

- Fin Optimization: The study first analyzes the fundamental principles of fin design for die-cast parts, considering material thickness, fin width, height, and spacing to maximize the surface area for air convection without compromising the die-casting process.

- Hybrid Material Design: When fin optimization alone is insufficient, the paper proposes a "disassembly" design concept. This involves creating a hybrid cooling module where copper blocks, prized for their superior thermal conductivity, are integrated into an aluminum alloy casing specifically at high-heat-generating spots. The performance of this improved structure was then validated using thermal simulation software.

The Breakthrough: Key Findings & Data

The study yielded several critical findings that directly inform next-generation HPDC design for thermal applications.

- Finding 1: Fin Design is a Balancing Act: The research reiterates that while more fins increase surface area, density must be carefully controlled. Fin spacing of 2-5 mm is recommended to prevent hindering airflow. Fin height should be between 10-25 mm to provide sufficient area without negatively impacting the fluidity of molten aluminum during die-casting.

- Finding 2: Hybrid Copper-Aluminum Modules Significantly Boost Cooling: The most innovative finding is the effectiveness of the hybrid material approach. By placing copper blocks close to the heat-generating electronic components, heat is rapidly absorbed and transferred to the larger aluminum alloy casing for dissipation.

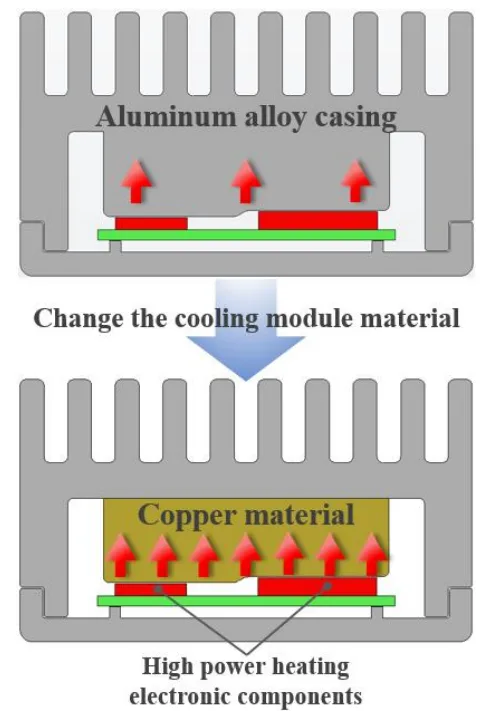

- Finding 3: Quantifiable Performance Gains: As shown in Figure 1, changing the cooling module material from a monolithic aluminum design to a hybrid copper-aluminum structure provides a targeted and highly effective cooling solution. The paper’s thermal simulations confirmed that this method could reduce the temperature of critical components by at least 5 °C, a significant margin for improving electronic component lifespan and reliability.

Practical Implications for Your HPDC Products

This research provides actionable insights for improving the design and manufacture of high-performance thermal management components.

- For Process Engineers: The specifications in section

2.4 Considerations for Fin Size Designoffer a clear design guide. Adhering to the recommended material thickness (1.5–4 mm) and fin geometry (1–3 mm width, 10–25 mm height, 2–5 mm spacing) can help balance heat dissipation efficiency with manufacturability, avoiding molding defects like shrinkage cavities and ensuring stable production cycles. - For Quality Control: The study highlights that overly thick sections can increase cooling time and lead to defects, while fins that are too thin risk deformation. The correlation shown in Figure 1 and the accompanying analysis implies that integrating copper blocks post-casting (or via insert-molding) could be a more reliable QC strategy than attempting to cast increasingly complex and risky monolithic fin structures.

- For Die Design: The "disassembly" concept detailed in section

3. Design Optimization for Cooling Modulesis a paradigm shift. It suggests that die designers should focus on creating aluminum casings with precision-machined pockets or interfaces to accept copper blocks. This modular approach allows for optimized cooling where it's needed most, without compromising the integrity of the overall HPDC part. It transforms the die from a single-purpose tool into a platform for a multi-material, high-performance assembly.

Paper Details

Optimizing the Structural Design of Computing Units in Autonomous Driving Systems and Electric Vehicles to Enhance Overall Performance Stability

1. Overview:

- Title: Optimizing the Structural Design of Computing Units in Autonomous Driving Systems and Electric Vehicles to Enhance Overall Performance Stability

- Author: Zhong, Yao-Nian

- Year of publication: 2024

- Journal/academic society of publication: International Journal of Advance in Applied Science Research

- Keywords: Autonomous driving systems; Electric vehicles; Computing units; Heat dissipation; Structural design.

2. Abstract:

In the rapid development of autonomous driving systems and electric vehicles, the thermal management of computing units has become a key factor affecting system performance and stability. This article explores how to enhance the heat dissipation efficiency of computing units through optimized structural design, thereby enhancing the overall performance stability. Firstly, aluminum alloy casings are an ideal material choice for computing units due to their excellent thermal conductivity, lightweight characteristics, and processing flexibility. We analyze the heat conduction mechanisms in detail and consider design based on thermal conductivity formulas. To improve heat dissipation efficiency, we adopt a fin design that increases the heat dissipation surface area, utilizing air convection to accelerate heat dissipation. We also discuss the design of fin sizes and spacing, aiming to balance the molding process's feasibility and heat dissipation efficiency. Secondly, the structural optimization of the heat dissipation module is conducted by integrating the material characteristics of copper blocks with those of aluminum alloy casings. We propose a "disassembly" design concept, considering the use of localized materials to enhance thermal conduction efficiency. For areas with high heat generation from electronic components, the high thermal conductivity of copper blocks quickly transfers heat to the aluminum alloy casing, achieving a cooling effect. Furthermore, when the aforementioned heat dissipation methods are insufficient to meet higher cooling demands, liquid cold plate technology may become an effective cooling solution. By integrating the liquid cooling system of the computing unit with the cooling system of the electric vehicle battery pack, we can achieve thermal load balancing, enhancing the system's energy efficiency and stability. This multifunctional cooling system maximizes the utilization of internal vehicle space while improving thermal management efficiency, catering to the high-performance demands of electric vehicles and autonomous driving systems. This study proposes diversified solutions for the thermal design of computing units in autonomous driving systems and electric vehicles, aiming to enhance the performance and stability of the computing units. Through the integrated use of fin design, optimization of cooling modules, and liquid cold plate technology, it provides effective and economical management strategies for the thermal management of future electronic devices, with broad application prospects.

3. Introduction:

As the demand for autonomous driving systems continues to rise, various sensors, radars, cameras, and other perception devices installed in vehicles generate a large amount of data that needs to be processed in real-time to support the safety and accuracy of autonomous driving. This requires powerful processing capabilities and stable thermal management. With increasing computing density, the heat generated has significantly increased, presenting new challenges for heat dissipation. In hot environments, these devices are prone to overheating, which can affect operational stability and compromise vehicle safety. Computing units in autonomous driving systems and electric vehicles often use aluminum alloy metal casings due to their superior thermal conductivity, lightweight advantages, and mechanical strength. This study explores fin design, cooling module optimization, and liquid cold plate technology to enhance heat dissipation efficiency.

4. Summary of the study:

Background of the research topic:

The performance and stability of computing units in autonomous driving systems and electric vehicles are critically dependent on thermal management. Increasing computational demands lead to higher heat generation, which must be dissipated effectively to prevent performance degradation and ensure safety.

Status of previous research:

Previous methods have relied on aluminum alloy casings with fins for heat dissipation. While effective, these methods are reaching their limits with increasing power densities. Researchers have explored optimizing fin geometry (Refs. [1], [2]), but new approaches are needed for next-generation systems.

Purpose of the study:

This study aims to propose and analyze diversified solutions for the thermal design of computing units to enhance their performance and stability. The research explores optimizing fin design, integrating different materials like copper, and applying liquid cold plate technology.

Core study:

The core of the study is a multi-pronged approach to improve heat dissipation. It begins with optimizing traditional fin structures on aluminum alloy casings. It then introduces a "disassembly" concept, where high-conductivity copper blocks are integrated into the aluminum casing to target high-heat areas. Finally, it discusses the potential of liquid cold plate technology for even higher cooling demands, including a shared system with the vehicle's battery pack.

5. Research Methodology

Research Design:

The study employs a theoretical and conceptual design methodology. It first establishes the physical principles of heat transfer and the material properties of aluminum and copper. It then proposes optimized designs for fin structures and hybrid cooling modules.

Data Collection and Analysis Methods:

The study references established thermal conductivity formulas and design principles. The effectiveness of the proposed hybrid copper-aluminum cooling module was tested and analyzed using thermal simulation software to quantify the temperature reduction.

Research Topics and Scope:

The research covers three main topics: 1) The design of heat dissipation fins on aluminum die-cast parts. 2) The design optimization of cooling modules using a hybrid copper-aluminum structure. 3) The application of liquid cold plates technology as an advanced cooling solution. The scope is focused on computing units for autonomous driving systems and electric vehicles.

6. Key Results:

Key Results:

- Aluminum alloys are ideal for die-cast enclosures due to thermal conductivity (90-130 W/m·K), light weight, and processability.

- Optimal fin design requires a balance: 1.5–4 mm material thickness, 1–3 mm fin width, 10–25 mm fin height, and 2–5 mm fin spacing.

- A hybrid "disassembly" design integrating copper blocks into an aluminum alloy casing provides superior localized cooling.

- Thermal simulations show this hybrid design can reduce electronic component temperatures by at least 5 °C.

- For ultimate performance, integrating the computing unit's liquid cooling system with the vehicle's battery pack cooling system offers significant benefits in efficiency, space, and thermal load balancing.

Figure Name List:

- Figure 1: Diagram of changing the cooling module material.

7. Conclusion:

The study concludes that a multi-faceted approach is essential for modern automotive thermal management. It proposes a combination of optimized finned aluminum alloy casings with integrated copper blocks as an innovative and effective solution for fanless, sealed computing units. This hybrid design balances cost, weight, and performance. Looking ahead, the paper suggests that liquid cold plate technology, potentially integrated with other vehicle systems, will be a key solution for future high-demand applications. Future research should focus on optimizing liquid cold plate flow channels and coolant flow rates.

8. References:

- [1] Kou, H. S., Lee, J. J., Lai, C. Y., Thermal Analysis and Optimum Fin Length of a Heat Sink, J. Heat Transfer Engineering, 2003, 24 (2): 18-29.

- [2] Chi-Yuan Lai, Hong-Sen Kou, Ji-Jen Lee, Optimum thermal analysis of annular fin heat sink by adjusting outer radius and fin number, J. Applied Thermal Engineering, 2006, 26 (8-9): 927-936.

- [3] Yaonian Zhong, Enhancing the Heat Dissipation Efficiency of Computing Units Within Autonomous Driving Systems and Electric Vehicles, J. World Journal of Innovation and Modern Technology, 2024, 7 (5): 100-104.

Expert Q&A: Your Top Questions Answered

Q1: What was the single most critical factor identified in this study for improving heat dissipation in a fanless enclosure?

A1: The study concluded that for applications where fin-only designs are insufficient, the most critical factor is the hybrid "disassembly" design. Integrating high-conductivity copper blocks at localized high-heat areas was shown via simulation to reduce component temperatures by at least 5 °C, a key finding detailed in section 3. Design Optimization for Cooling Modules.

Q2: How does this research compare to traditional methods for addressing heat dissipation in die-cast parts?

A2: The paper's Introduction and Section 3 explain that while traditional methods focus on optimizing fin geometry on a monolithic aluminum alloy casting, this research proposes a more advanced solution by combining materials (copper and aluminum) to overcome the physical limits of a single material, a concept supported by the analysis in Figure 1.

Q3: Is this finding applicable to all types of alloys, or a specific one?

A3: The research, as described in section 1. Introduction, discusses "die-cast aluminum alloys" in general, citing their typical thermal conductivity range of 90 ~ 130 W/m·K. It does not limit the findings to a single, specific alloy, suggesting the principles are broadly applicable across common die-casting alloys.

Q4: What specific measurement or simulation technique did the researchers use to arrive at this conclusion?

A4: The researchers utilized "thermal simulation software" to test and analyze the improved structure with integrated copper blocks, as explained in Section 3. This simulation quantified the cooling effect and confirmed the temperature reduction.

Q5: According to the paper, what is the main limitation or area for future research?

A5: The authors state in the 5. Conclusion and Outlook that while the hybrid module is effective, liquid cooling technology is the key for future high-demand systems. They suggest future research should focus on "the design of flow channels for liquid cold plates, optimization of coolant flow rates, and exploring ways to improve the cooling efficiency of liquid cold plates."

Q6: What is the direct, practical takeaway from this paper for a die casting facility?

A6: The core takeaway is that by adopting a hybrid manufacturing approach—producing an HPDC aluminum casing designed to integrate with a copper cooling block—a facility can offer a superior thermal management solution for high-power electronics. This shifts the focus from simply casting fins to creating a platform for a multi-material assembly, as concluded in the paper, "Optimizing the Structural Design of Computing Units…".

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing thermal management in HPDC components. The findings offer a clear, data-driven path toward improving quality by moving beyond traditional fin designs to innovative, hybrid material solutions that meet the extreme demands of the EV and autonomous vehicle markets.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "Zhong, Yao-Nian". Based on "Optimizing the Structural Design of Computing Units in Autonomous Driving Systems and Electric Vehicles to Enhance Overall Performance Stability".

- Source of the paper: https://h-tsp.com/ (General journal URL from paper)

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.