This introduction paper is based on the paper "Microstructures of Mg-Al-Zn and Al-Si-Cu cast alloys" published by "Journal of Achievements in Materials and Manufacturing Engineering".

1. Overview:

- Title: Microstructures of Mg-Al-Zn and Al-Si-Cu cast alloys

- Author: T. Tański, L.A. Dobrzański, R. Maniara

- Year of publication: 2010

- Journal/academic society of publication: Journal of Achievements in Materials and Manufacturing Engineering

- Keywords: Metallography; Magnesium alloys; Aluminium alloys, Structure

2. Abstract:

Purpose: The aim of this paper was to investigate the structure of the MCMgAl6Zn1 magnesium and ACAlSi9Cu aluminium cast alloy in as-cast state.

Design/methodology/approach: The following results concern the microstructure of the cast magnesium and aluminium alloys using ZEISS SUPRA 25, Opton DSM-940 scanning and LEICA MEF4A light microscopy, X-ray qualitative microanalysis as well as X-ray analysis.

Findings: The analysis of the structure magnesium alloy consists of the solid solution α – Mg (matrix) of the secondary phase γ – Mg17Al12 evenly located in the structure. The structure creates agglomerates in the form of needle precipitations, partially coherent with the matrix placed mostly at the grain boundaries. The AC AlSi9Cu and AC AlSi9Cu4 cast aluminium alloys are characterised by a dendritic structure of the α solid solution – as the alloy matrix, as well are characterised by a discontinuous β-Si phase forming the α+β eutectic grains, with a morphology depending on the silicon and copper mass concentration.

Research limitations/implications: Taking into account the fact that some of the properties are of great importance only for the surface of the material, the future investigation will concern modelling of the alloy surface using surface layers deposition methods like physical vapour deposition methods.

Practical implications: A desire to create as light vehicle constructions as possible and connected low fuel consumption have made it possible to make use of magnesium and aluminium alloys as constructional material in automotive industry.

Originality/value: Contemporary materials should possess high mechanical properties, physical and chemical, as well as technological ones, to ensure long and reliable use. The above mentioned requirements and expectations regarding the contemporary materials are met by the non-ferrous metals alloys used nowadays, including the magnesium and aluminium alloys.

3. Introduction:

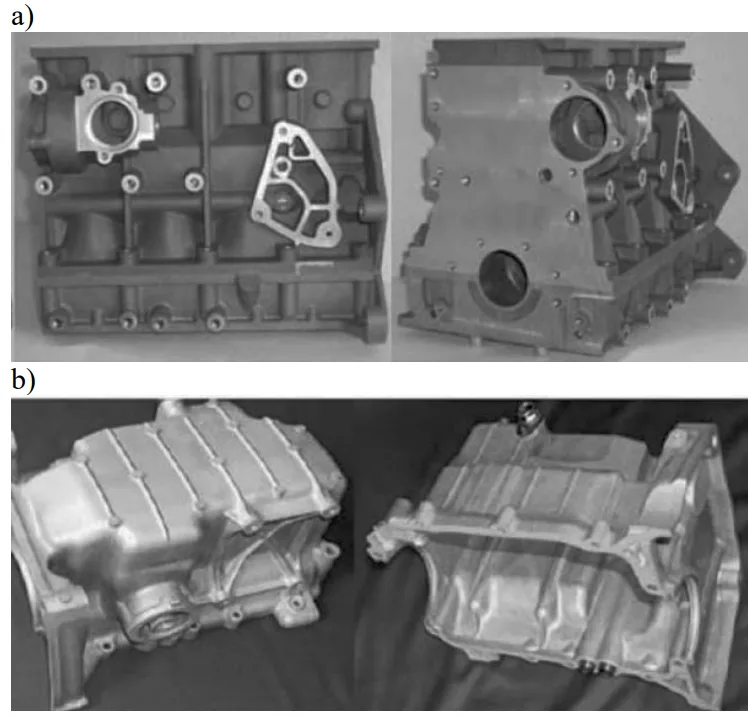

Recent dynamic development in the automobile industry is largely based on innovative constructional solutions and modern materials, which directly influence vehicle mass, performance, and fuel consumption. Magnesium and aluminium alloys are fundamental groups of metal alloys that enable these advancements. Magnesium alloys are noted for their excellent strength-to-density ratio (yield strength Rp0.2 to density) and good vibration damping ability, making them suitable for sports equipment and automotive components. They also offer good castability for thin-walled, large surface elements with high dimensional stability and extraordinary machinability. The demand for magnesium cast alloys, such as those used by General Motors, Ford, VW, Audi, and Alfa Romeo, is increasing due to their low density (1700-1900 kg/m³) and mechanical properties similar to aluminium casting alloys. Alloy additions can counteract shrinkage porosities or hot micro-cracks and influence mechanical properties or corrosion resistance. Advances in casting technologies (e.g., moulding in liquid and solid-liquid state, vacuum casting, pressure die casting) have improved processing costs and material properties, with a general trend towards increased plasticity and resistance.

Aluminium alloys are also widely used in automotive and aviation industries due to their low density (2689 kg/m³), good mechanical properties, corrosion resistance, and machinability. These properties make them suitable for engine bodies, gearbox housings, clutches, water pumps, and rear axles, contributing to reduced operating expenses and fuel consumption. Recent trends include a return to aluminium alloy sand casting using high-efficiency automated production lines (e.g., Cosworth, CPS, BAXI, HWS) that ensure good form filling and reduced oxidation.

4. Summary of the study:

Background of the research topic:

The automotive industry's continuous drive for lighter vehicle constructions to improve fuel efficiency and performance necessitates the use of advanced lightweight materials. Magnesium and aluminium alloys are key candidates due to their favorable physical and mechanical properties.

Status of previous research:

Previous research and industrial applications have established magnesium and aluminium alloys as viable constructional materials. Various casting technologies have been developed to optimize their production and properties. The general characteristics, advantages (e.g., low density, good machinability), and some limitations (e.g., need for alloy additions to control casting defects in Mg alloys) are known.

Purpose of the study:

The goal of this paper is to present the investigation results of the microstructure of MCMgAl9Zn1, MCMgAl6Zn1 magnesium alloys and ACAlSi9Cu, ACAlSi9Cu4 aluminium alloys in their as-cast state.

Core study:

The core of the study involved detailed microstructural characterization of four specific cast alloys: two magnesium alloys (MCMgAl9Zn1, MCMgAl6Zn1) and two aluminium alloys (ACAlSi9Cu, ACAlSi9Cu4) in their as-cast condition. This was achieved through metallographic examinations using light and scanning electron microscopy, coupled with X-ray qualitative microanalysis and X-ray analysis to identify phases and elemental distributions.

5. Research Methodology

Research Design:

The research was designed as an experimental investigation to characterize the as-cast microstructures of selected magnesium and aluminium alloys. Test samples of MCMgAl9Zn1, MCMgAl6Zn1, ACAlSi9Cu, and ACAlSi9Cu4 alloys were prepared and examined.

Data Collection and Analysis Methods:

Metallographic examinations were conducted on cast alloy specimens mounted in thermohardening resins. Etching reagents (5% molybdenic acid and 1% HBF4 acid) were used to reveal grain boundaries and microstructures.

Microstructural observations were made using:

- LEICA MEF4A light microscope.

- Opton DSM-940 scanning electron microscope (SEM).

- ZEISS SUPRA 25 SEM, using secondary electron detection.

X-ray qualitative and quantitative microanalysis, and surface distribution analysis of elements were performed using: - ZEISS SUPRA 25 and Opton DSM-940 SEM equipped with an Oxford EDS LINK ISIS dispersive radiation spectrometer (accelerating voltage of 15 kV).

- JEOL JCXA 733 X-ray microanalyser.

Research Topics and Scope:

The study focused on the microstructure of the following alloys in their as-cast state:

- Magnesium alloys: MCMgAl9Zn1, MCMgAl6Zn1 (chemical compositions detailed in Table 1 of the original paper).

- Aluminium alloys: ACAlSi9Cu, ACAlSi9Cu4 (chemical compositions detailed in Table 2 of the original paper).

The investigation aimed to identify the constituent phases, their morphology, and distribution within the as-cast structure.

6. Key Results:

Key Results:

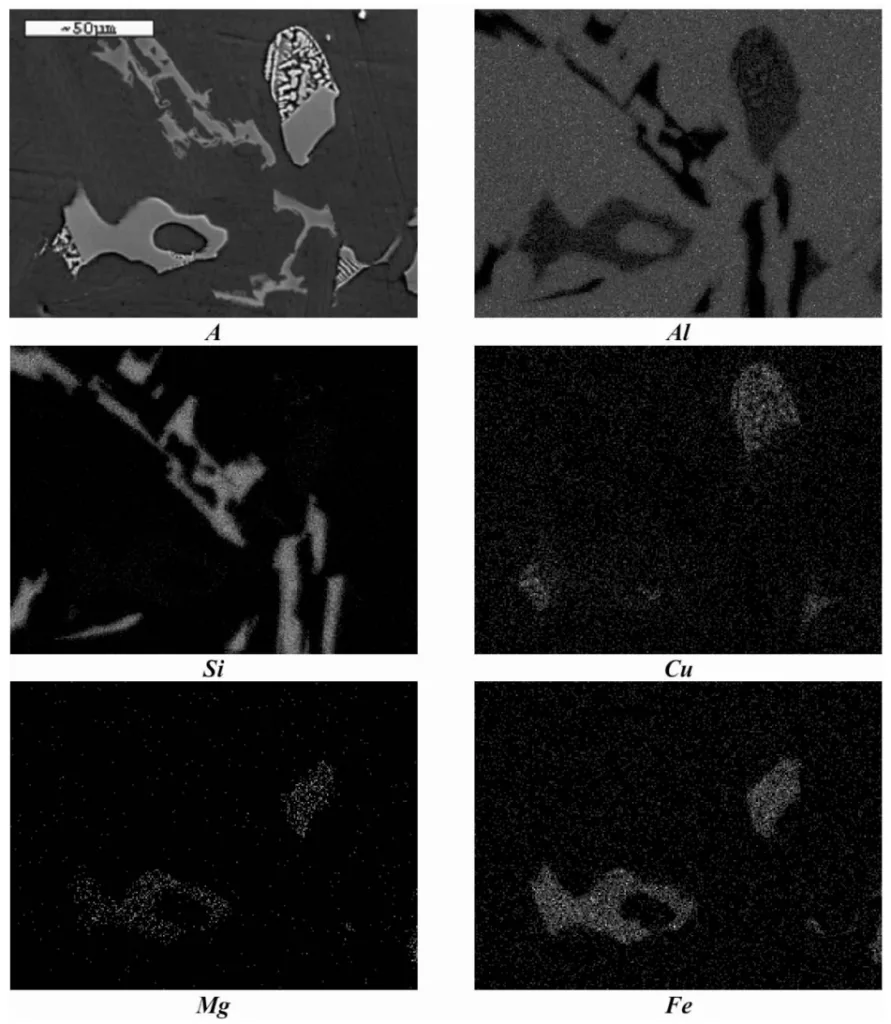

Magnesium Alloys (MCMgAl9Zn1 and MCMgAl6Zn1):

- The microstructure of the MCMgAl9Zn1 alloy in the cast state is characterized by a solid solution α (alloy matrix) and the γ-Mg17Al12 discontinuous intermetallic phase, typically in the form of plates located mostly at grain boundaries.

- In the vicinity of the γ intermetallic phase, needle-like eutectics (α + γ) were observed.

- Both examined magnesium cast alloys (MCMgAl9Zn1 and MCMgAl6Zn1) showed, apart from Mg17Al12 precipitations, grey-green phases with angular contours and smooth edges, identified as the Mg2Si compound, which increases casting hardness.

- Surface decomposition and X-ray quantitative microanalysis confirmed the presence of main alloy additions (Mg, Al, Mn, Zn) and also Fe and Si. Phases with high Mn and Al concentrations, often irregular or in block/needle forms, were also noted.

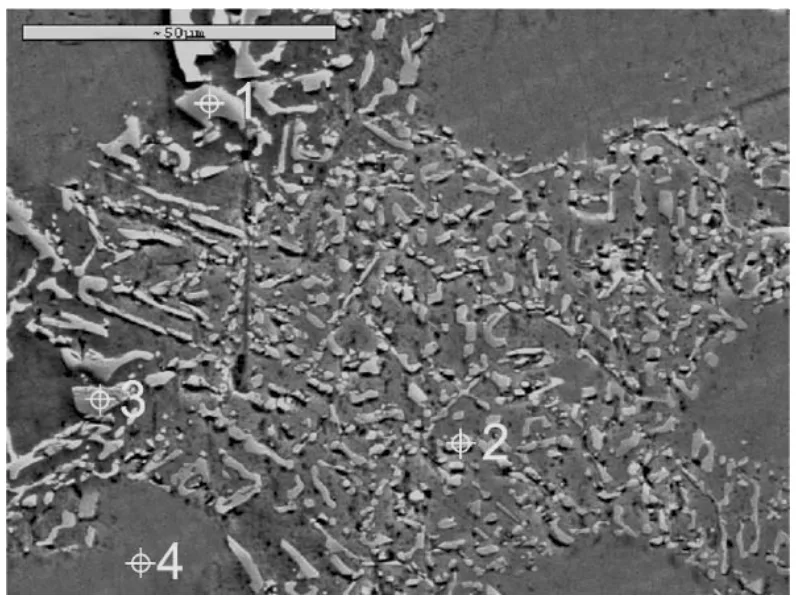

Aluminium Alloys (ACAlSi9Cu and ACAlSi9Cu4):

- The ACAlSi9Cu and ACAlSi9Cu4 cast aluminium alloys are characterized by a dendritic structure of the α solid solution (alloy matrix).

- They also feature a discontinuous β-Si phase forming α+β eutectic grains, with morphology depending on silicon and copper mass concentration. The β-Si phase occurred as big irregular plates with sharply ending corners.

- The microstructure includes needle-shaped precipitations of the Al5FeSi phase, usually near α+Al₂Cu+AlCuMgSi+β eutectics.

- The Al₂Cu phase occurs as a compound of the triple eutectic and as separate, irregular, brown-coloured precipitates, sometimes of the "Chinese character" type.

- Quantitative EDS analysis confirmed the presence of basic alloying additives (Si, Cu, Mg) and Fe. Copper, silicon, and magnesium were found in higher concentrations in eutectic regions and the alloy matrix.

- The presence of α+β eutectics and triple α+Al2Cu+β eutectics was confirmed.

Figure Name List:

- Fig. 1. Examples of automotive components made of Mg alloys a) engine block, b) oil pump

- Fig. 2. a), b) Microstructure of MCMgAl6Zn1 magnesium alloys in as-cast state

- Fig. 3. a), b) Microstructure of MCMgAl9Zn1 magnesium alloys in as-cast state

- Fig. 4. The area analysis of chemical elements alloy MCMgAl6Zn1 in as-cast state: image of the secondary electrons (A) and maps of elements’ distribution

- Fig. 5. a), b) Microstructure of ACAlSi9Cu casting alloy

- Fig. 6. Microstructure of ACAlSi9Cu4 casting alloy

- Fig. 7. Microstructure of ACAlSi9Cu4 casting alloy

- Fig. 8. The area analysis of chemical elements alloy ACAlSi9Cu4: image of secondary electrons (A) and maps of elements’ distribution

- Fig. 9. Microstructure of ACAlSi9Cu casting alloys

7. Conclusion:

The metallographic examinations confirmed that the magnesium cast alloy MCMgAl9Zn1 is characterized by a microstructure of the α solid solution (matrix) and the γ–Mg17Al12 discontinuous intermetallic phase, mainly as plates at grain boundaries. Needle eutectics (α + γ) were found near the γ phase. Chemical analysis confirmed concentrations of magnesium, silicon, aluminium, manganese, and iron, suggesting Mg and Si precipitations with angular contours, and phases with high Mn and Al, often as blocks or needles.

The ACAlSi9Cu and ACAlSi9Cu4 cast aluminium alloys exhibit a dendritic α solid solution structure (matrix) and a discontinuous β-Si phase in large, irregular plates forming α+β eutectic grains. The occurrence of α+Al₂Cu+β, α+Al₂Cu+AlCuMgSi+β eutectics, and the Al5FeSi phase (usually near these eutectics) was also noted in the investigated alloys.

8. References:

- [1] E.F. Horst, B.L. Mordike, Magnesium Technology. Metallurgy, Design Data, Application, Springer-Verlag, Berlin Heidelberg 2006.

- [2] A. Fajkiel, P. Dudek, G. Sęk-Sas, Foundry engineering XXI c. Directions of metallurgy development and Ligot alloys casting, Publishers Institute of Foundry engineering, Cracow, 2002.

- [3] K.U. Kainem, Magnesium – Alloys and Technology, Wiley-VH, Weinheim, Germany, 2003.

- [4] H. Westengen, Magnesium Alloys: Properties and Applications Encyclopaedia of Materials: Science and Technology, 2008, 4746-4753.

- [5] M. Greger, R. Kocich, L. Čížek, L.A. Dobrzański, I. Juřička, Possibilities of mechanical properties and microstructure improvement of magnesium alloys, Archives of Materials Science and Engineering 28/2 (2007) 83-90.

- [6] W. Kasprzak, J.H. Sokołowski, M. Sahoo, L.A. Dobrzański, Thermal characteristic of the AM50 magnesium alloys, Journal of Achievements in Materials and Manufacturing Engineering 29/2 (2008) 179-182.

- [7] L.A. Dobrzański, T. Tański, Influence of aluminium content on behaviour of magnesium cast alloys in bentonite sand mould, Solid State Phenomena 147-149 (2009) 764-769.

- [8] L.A. Dobrzański, M. Król, T. Tański, R. Maniara, Effect of cooling rate on the solidification behaviour of magnesium alloys, Archives of Computational Materials Science and Surface Engineering 1/1 (2009) 21-24.

- [9] L.A. Dobrzański, T. Tański, J. Trzaska, Optimization of heat treatment conditions of magnesium cast alloys, Materials Science Forum 638-642 (2010) 1488-1493.

- [10] Z. Górny, J. Sobczak, Non-ferrous metals based novel materials in foundry practice, ZA-PIS, Cracow, 2005.

- [11] J.G. Kauffman, E. L. Rooy, Aluminum Alloy Castings, ASM International, Ohio, 2005.

- [12] A.K. Dahle, K. Nogita, S.D. McDonald, C. Dinnis, L. Lu, Eutectic Modification on Microstructure Development in Al-Si Alloys, Materials Science and Engineering A 413 (2005) 243-248.

- [13] Z. Muzaffer, Effect of copper and silicon content on mechanical properties in Al-Cu-Si-Mg alloys, Journal of Materials Processing Technology 169 (2005) 292-298.

- [14] P. Ouellet, F.H. Samuel, Effect of Mg on the ageing behaviour of Al-Si-Cu 319 type aluminium casting alloys, Journal of Materials Science 34 (1999) 4671 - 4697.

- [15] P.D. Lee, A. Chirazi, R.C. Atwood, W. Wan, Multiscale modelling of solidification microstructures, including microsegregation and microporosity, in an Al-Si-Cu alloy, Materials Science and Engineering A365 (2004) 57-65.

- [16] ASM Handbook, Aluminum and Aluminum Alloys, ASM International, Ohio, 1993.

- [17] L. Bäckerud, G. Chai, J. Tamminen, Solidification Characteristics of Aluminum Alloys, Vol. 2, AFS/SKANALUMINIUM, Illinois, 1990.

9. Copyright:

- This material is a paper by "T. Tański, L.A. Dobrzański, R. Maniara". Based on "Microstructures of Mg-Al-Zn and Al-Si-Cu cast alloys".

- Source of the paper: DOI URL: Not available in the provided document. (The paper is from Journal of Achievements in Materials and Manufacturing Engineering, Volume 38, Issue 1, January 2010, pp. 64-71)

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.