Simulating Success: How Low Pressure Die Casting Simulation Prevents Defects in Automotive MMC Wheels

This technical summary is based on the academic paper "Design Simulation of Filing Sequence and Solidification Time for Cast Metal Matrix Composite by Low Pressure Die Casting" by R. S. Taufik, S. Shamsuddin, K. K. Mak, A. A. Tajul, M. A. M. Khairul Anuar, B. B. T. Hang Tuah, published in International Review of Mechanical Engineering (2011). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Low Pressure Die Casting Simulation

- Secondary Keywords: Metal Matrix Composite, Automotive Wheel Casting, Solidification Time, Filling Sequence, A356 Aluminum Alloy, Casting Defects, AnyCasting software

Executive Summary

A 30-second overview for busy professionals.

- The Challenge: Developing defect-free, high-performance Metal Matrix Composite (MMC) automotive components without costly and time-consuming physical prototyping.

- The Method: A theoretical and simulation-based approach using AnyCasting software to model the Low Pressure Die Casting (LPDC) of an automotive wheel made from A356 aluminum alloy reinforced with silicon carbide.

- The Key Breakthrough: The simulation precisely identified a critical flow velocity exceeding 50 cm/s in the gating system, a known cause of oxidation and air entrapment defects.

- The Bottom Line: Low Pressure Die Casting Simulation is an essential tool for predicting and mitigating manufacturing defects by optimizing filling sequences and solidification, saving significant time and cost before production begins.

The Challenge: Why This Research Matters for HPDC Professionals

In the automotive and aerospace industries, the demand for lightweight, high-strength materials is relentless. Metal Matrix Composites (MMCs), such as aluminum reinforced with silicon carbide (SiC), offer superior strength, wear resistance, and performance at elevated temperatures. However, casting these advanced materials presents significant challenges.

Traditionally, optimizing a casting process for MMCs involves fabricating multiple physical specimens to analyze microstructure and mechanical behavior. This trial-and-error approach is expensive, time-consuming, and often fails to reveal the complex interplay of temperature and fluid dynamics during the casting process. The core industrial problem is the need to design a robust and reliable casting process that minimizes defects like air entrapment and oxidation without resorting to costly physical prototypes. This research demonstrates how simulation provides a powerful solution.

The Approach: Unpacking the Methodology

This study focused on simulating the Low Pressure Die Casting (LPDC) process for a high-performance automotive wheel. The methodology combined theoretical formulation with advanced simulation software to create a detailed virtual model of the entire casting process.

- Material: The component was designed using A356 aluminum alloy as the matrix material, reinforced with 20% wt. silicon carbide (SiC) dispersion particles (Duralcan F3S.20S-T6). This combination was chosen for its ability to significantly improve yield strength over the base alloy, as shown in Table I of the paper. The mould was modeled using SKD61 cast steel.

- Process Simulation: The researchers used AnyCasting software to model the entire LPDC process, from the filling sequence to the final solidification. The simulation was based on a 3D model of the wheel, gating system, and mould.

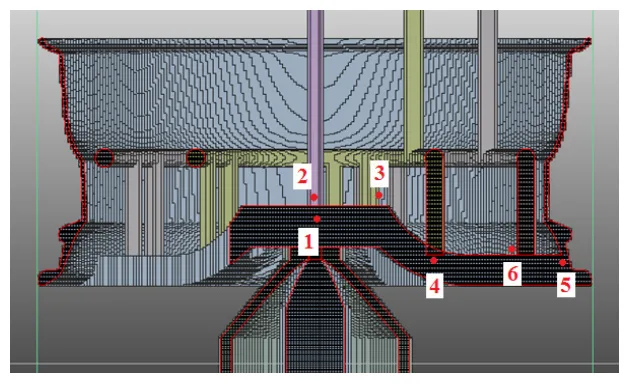

- Virtual Sensing & Cooling: To monitor the process, six virtual sensors were placed in key areas of the cavity (core, spoke, rim) and mould. The design also incorporated three distinct cooling channels for the core, hub, and spoke, using a combination of water and air as cooling media to manage thermal gradients effectively (Table II). Key process parameters like cutting speed (200 m/min) and pouring temperature (680°C) were kept constant.

The Breakthrough: Key Findings & Data

The simulation provided critical, actionable data on the filling and solidification dynamics, highlighting potential sources of defects that would be difficult to observe in a physical trial.

Finding 1: Critical Flow Velocity Predicts Defect Formation

The simulation revealed that the molten metal flow reached a peak velocity of over 58.2 cm/s as it passed through the small feed cross-section at the center of the hub. As cited in the paper, flow speeds higher than 50 cm/s can break up the melt flow, leading to severe defects such as oxidation, inclusion of oxide films, and air entrapment. In contrast, the flow velocities in the spoke and rim areas were well within the safe limits at 35.9 cm/s and 28.6 cm/s, respectively (Figures 6, 7, and 8). This finding pinpoints the exact location and cause of potential quality issues, allowing engineers to redesign the gating system to reduce velocity before tooling is ever produced.

Finding 2: Precise Mapping of Solidification for Microstructure Control

The simulation accurately predicted a total solidification time of 381.826 seconds. The visualization in Figure 5 shows that solidification begins at the rim body and the outer surface of the wheel spokes during the first 5.121 seconds, progressing inward toward the feeder and ingate. This detailed solidification map is invaluable for predicting the final microstructure and mechanical properties of the wheel. It allows engineers to optimize the cooling channel design and cycle time to ensure complete and uniform solidification, preventing defects and ensuring the component meets its performance specifications.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that the gating system, specifically the ingate at the hub, must be redesigned to reduce the molten metal velocity below the 50 cm/s threshold to prevent oxidation and air entrapment.

- For Quality Control Teams: The data in Figures 6 and 9 of the paper illustrates that the center of the hub is a high-risk area for flow-related defects and thermal turbulence. This could inform new, targeted quality inspection criteria for first-article components.

- For Design Engineers: The findings indicate that the geometry of the feed cross-section directly influences defect formation. This highlights the importance of co-designing the component and the gating system in the early stages to ensure manufacturability.

Paper Details

Design Simulation of Filing Sequence and Solidification Time for Cast Metal Matrix Composite by Low Pressure Die Casting

1. Overview:

- Title: Design Simulation of Filing Sequence and Solidification Time for Cast Metal Matrix Composite by Low Pressure Die Casting

- Author: R. S. Taufik, S. Shamsuddin, K. K. Mak, A. A. Tajul, M. A. M. Khairul Anuar, B. B. T. Hang Tuah

- Year of publication: 2011

- Journal/academic society of publication: International Review of Mechanical Engineering (I.RE.M.E.), Vol. 5, N. 2

- Keywords: Design, Simulation, Low Pressure Die Casting

2. Abstract:

This research presents the design simulation of aluminum silicon carbide by Low Pressure Die Casting (LPDC). The theoretical formulation was presented for determining the filling sequence and solidification time. The simulation is presented in order to study the velocity and temperature patterns by applying sensor to the mould and cavity. As a result, an application of A356 aluminum alloy was used as a matrix material and silicon carbide was added as reinforcement particles in designing of automotive wheel were presented.

3. Introduction:

Metal matrix composites (MMC’s), has showed significant success in industries such as automotive, aerospace and electronics because an evolutionary composite material for reinforcement and weight reduction in casting products. In recent years, researchers have viewed metal matrix composite (MMC) for potential increasing the overall performance of materials. Among the several metal matrix composites, aluminum silicon carbide which utilizes the mechanical properties has been receiving attention because of its advantages such as elevated temperature, weight reduction and fatigue life improvement. However, the actual cast specimens or products are needed to be fabricated in order to analyze the mechanical properties of cast metal matrix such as impact strength and yield strength. The purpose is to ensure cast aluminum silicon carbide to meet the expected strength and fatigue life. This lead to higher cost consumption and lead time in the design stage. Therefore, the composition between matrix material and composite reinforced of aluminum silicon carbide must be further studied.

4. Summary of the study:

Background of the research topic:

The study addresses the manufacturing of Cast Metal Matrix Composites (MMCs), specifically for automotive wheels, using Low Pressure Die Casting (LPDC). MMCs are valued for their superior mechanical properties, but their casting process is complex and costly to develop through physical trials.

Status of previous research:

Previous research into MMCs often required the fabrication of physical specimens to analyze microstructures and mechanical behavior. This conventional approach is costly and time-consuming. The paper notes that while thermal expansion models for MMCs have been studied, a simulation-based approach to filling sequence and solidification for a specific product like an automotive wheel is a valuable area of investigation.

Purpose of the study:

The primary purpose is to develop and analyze a design simulation for an automotive wheel made from A356 aluminum alloy reinforced with silicon carbide (SiC) particles using the LPDC process. The goal is to study the filling sequence, flow velocity, and solidification time to predict and prevent potential manufacturing defects before physical prototyping.

Core study:

The core of the study involves creating a detailed 3D simulation model of an automotive wheel casting process in AnyCasting software. This includes defining the material properties (A356 Al-SiC composite), the process parameters (LPDC), the geometry of the gating system, and the placement of virtual sensors and cooling channels. The simulation results for flow velocity and temperature patterns during filling and solidification are then analyzed to assess the manufacturability of the design.

5. Research Methodology

Research Design:

The research employed a design simulation methodology. A theoretical formulation for the filling rate in LPDC was established using Bernoulli's equation. This was followed by the creation of a comprehensive 3D Finite Element Model (FEM) of an automotive wheel, mould, and gating system.

Data Collection and Analysis Methods:

Data was generated virtually using AnyCasting simulation software. Six sensors were placed in the model to record temperature and velocity data over time at specific points in the cavity and mould. The simulation output included visualizations of the filling sequence, solidification patterns, and graphs of velocity and temperature versus time. This data was then analyzed to identify process characteristics, such as peak flow velocity and total solidification time, and to pinpoint potential defect-prone areas.

Research Topics and Scope:

The research focused on the LPDC of an automotive wheel using A356/SiC MMC. The scope included:

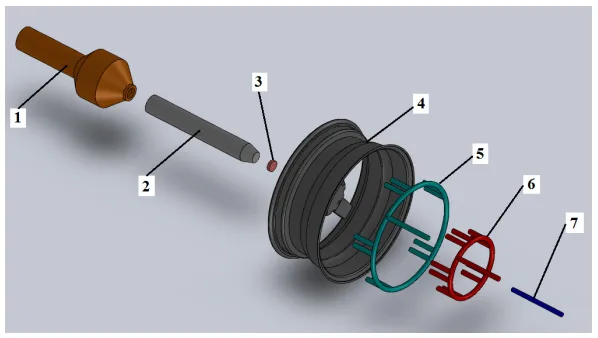

1. Design of the gating system (stalk, ingate, cooling channels).

2. Simulation of the mould filling sequence.

3. Analysis of molten metal flow velocity at the hub, spoke, and rim.

4. Simulation of the solidification time and pattern.

5. Analysis of temperature distribution in the cavity and mould during the process.

6. Key Results:

Key Results:

- The total filling time for the wheel cavity was 11.7583 seconds.

- The total solidification time was 381.826 seconds, with solidification initiating at the rim and outer spoke surfaces.

- The peak flow velocity at the center of the hub was 58.2 cm/s, which exceeds the recommended maximum of 50 cm/s and indicates a high risk of defects like oxidation and air entrapment.

- Flow velocities at the spoke (35.9 cm/s) and rim (28.6 cm/s) were within acceptable limits.

- The maximum temperature in the cavity reached the pouring temperature of 680°C, with only minor turbulence observed, suggesting the temperature profile was generally stable.

Figure Name List:

- Fig. 1. The filling rate process

- Fig. 2. Exploded view showing components of Gating System

- Fig. 3. Sensors placement in the cast model

- Fig. 4. Filling Sequence

- Fig. 5. Regions that solidify during 5.121s

- Fig. 6. Velocity VS. Time Graph (Sensor 1, Center of Hub)

- Fig. 7. Velocity VS. Time Graph (Sensor 4, Spoke)

- Fig. 8. Velocity VS. Time Graph (Sensor 6, Rim)

- Fig. 9. Temperature vs. Time Graph – Sensor 1 (cavity, core)

- Fig. 10. Temperature vs. Time Graph – Sensor 4 (cavity, spoke)

- Fig. 11. Temperature vs. Time Graph – Sensor 5 (cavity, rim)

- Fig. 12. Temperature vs. Time Graph – Sensor 2 (mould, center of hub)

- Fig. 13. Temperature vs. Time Graph – Sensor 3 (mould, side of hub)

- Fig. 14. Temperature vs. Time Graph – Sensor 6 (mould, spoke)

- Figs. 16. Simulation results for cutting speed of 200 m/min, rake angle of 20 deg and clearance angle of 5 deg), a) Displacement, b) Effective stress, c) Effective Strain and c) Generated temperature

- Fig. 17. Sticking and sliding areas in secondary deformation zone

7. Conclusion:

In this work, a novel of cast metal matrix composites were successfully designed for an automotive wheel using low pressure dies casting. The approach combines the formulation theoretical and simulation for Aluminum Silicon Carbide Duralcan F3S.20S-T6 (A356-20% SiC) and were analyzed the filling sequence, flow velocity, and solidification time. Based on the simulation result, the maximum flow accelerates of 50 cm/s as the molten metal matrix composite passes through the small feed cross section in order to circumvent the oxidation, oxide films, and air entrapment. In addition, simulation results experienced to minor turbulence due to maximum pouring temperature of 680°C. Therefore, the metal matrix composite is prospective material for low-pressure die cast wheel.

8. References:

- [1] L. J. Vendra, A. Rabiei, A study on aluminum-steel composite metal foam composite by casting, Journal of Material Science & Engineering, vol. A. 465, pp. 59-67, 2007.

- [2] R.K. Gupta, S.P. Mehrotra, S.P. Gupta, Evaluation and optimization of metal matrix composite strip produced by single roll continous strip casting method, Journal of Material Science & Engineering, vol. A. 465, pp. 116-123, 2007.

- [3] S. Sulaiman, M Sayuti, R. Samin, Mechanical properties of the as cast quartz particulate reinforced LM6 alloy matrix composite, Journal of Materials Processing Technology, vol. 201, pp. 731-73, 2008.

- [4] K. Aldas, M.D. Mat, Experimental and theoritical analysis of particle distribution in particulate metal matrix composite, Journal of Materials Processing Technology, vol. 160, pp. 289-285, 2008.

- [5] S. Naher, D. Brabazon, L. Looney, Development and assesment of new quick quench stir caster design for the production of metal matrix composites, Journal of Materials Processing Technology, vol. 166, pp. 430-439, 2004.

- [6] N. Altinkok, R. Koker, Modelling of the prediction of tensile and density properties in particle reinforced metral matrix composite, Journal of Materials & Design, vol. 27, pp. 625-631, 2006.

- [7] R. Koker, N. Altinkok, A. Demir, Neural network based prediction of mechanical properties of particulate reinforced metal matrix compostes using various training algorithm, Journal of Materials & Design, vol. 28, pp. 616-627, 2007.

- [8] K.R. Ravi, V.M. Sreekumar, R.M. Pillai, C. Mahato, K.R. Amaranathan, R.A. Kumar, B.C. Pai, Optimization of mixing parameters through a water model for metal matrix composites synthesis, Journal of Materials & Design, vol. 28, pp. 871-881, 2007.

- [9] T.R Vijayaram, S. Sulaiman, A.M.S. Hamouda, M.H.M. Ahmad, Fabrication of fiber reinforced metal matrix composites by squeeze casting technology, Journal of Materials & Design, vol. 178, pp. 34-38, 2006.

- [10] H. Yamagata, H. Kurita, M. Aniolek, W. Kasprzak, J.H. Sokolowski, Thermal and metallographic characteristics of the Al 20% Si high pressure die casting alloy for monolithic cylinder block, Journal of Materials Processing Technology, vol. 199, pp. 84-90, 2008.

- [11] M.T. Smith, D.R., Herling & J.A. Carpenter, Low Cost Cast Aluminium Metal Matrix Composites, 2001 Annual Progress Report of Automotive Lightweighting Material. USA: U.S. Department of Energy, 2001.

- [12] M. Merlin, G. Timeli, F. Bonollo, & G.L. Garagnani, Impact Behavior of A356 Alloy for Low-pressure Die Casting Automotive Wheels, Journal of Materials Processing Technology. vol. 209, pp. 1060-1073. 2009.

- [13] K. L. Edwards, Strategic Substitution of New Materials for Old: Applications in Automotive Product Development, Journals of Materials and Design, vol. 25, pp. 529-533, 2004.

- [14] G. Sala, Technology-driven Design of MMC Squeeze Cast Connecting Rods, Science and Technology of Advanced Materials, vol. 3, pp. 45-57, 2002.

- [15] J.W. Kaczmar, K. Pietrzak, & W. Wlosińki, The Production and Application of Metal Matrix Composite Materials, Journal of Materials Processing Technology, vol. 106, pp. 58-67, 2000.

- [16] W.D. Callister. Jr., Materials Science and Engineering an Introduction" (6th edition, Wiley, 2003).

- [17] C.Y., Chia, & L.H. Yeh, Computer Simulation of Casting Process of Aluminum Wheels - A Case Study, Journal of Engineering Manufacture, vol. 220, part B. 2005.

Expert Q&A: Your Top Questions Answered

Q1: Why was A356 aluminum alloy with 20% SiC reinforcement chosen for this automotive wheel study?

A1: The paper selected this MMC for its significant advantages in automotive applications. As shown in Table I, reinforcing A356 alloy with 20% SiC particles (Duralcan F3S.20S) dramatically increases the yield strength from 164 MPa to 310 MPa. This provides the high strength required for a durable automotive wheel while maintaining a low weight, which is critical for improving vehicle fuel efficiency and performance.

Q2: The paper flags the peak velocity of 58.2 cm/s as a major risk. What specific defects does this cause and why?

A2: According to the paper, a flow velocity higher than 50 cm/s can cause the molten metal stream to break up. This violent, turbulent flow introduces defects in three primary ways: 1) Oxidation, where the turbulent metal reacts with air in the cavity; 2) Oxide Film Inclusion, where these newly formed oxides get trapped inside the final casting; and 3) Air Entrapment, where pockets of air are folded into the metal during the chaotic filling. These defects create weak points in the final component, compromising its structural integrity and fatigue life.

Q3: How did the simulation model the cooling process, and what was its impact on the mould temperature?

A3: The simulation incorporated a sophisticated cooling system with three separate channels targeting the core, hub, and spoke of the wheel. As detailed in Table II, the core channel used water, while the hub and spoke channels used air. Figure 12 clearly shows the impact: the sensor on the mould core experienced a sharp, rapid temperature drop at 280 seconds when the water cooling was activated. This demonstrates how simulation can be used to fine-tune cooling strategies to control solidification and reduce cycle times.

Q4: The total solidification time was predicted to be 381.826 seconds. How can a process engineer use this specific information?

A4: This precise solidification time is crucial for optimizing the production cycle. Knowing the exact moment the entire part, including the thickest sections near the feeder, becomes solid allows engineers to set the minimum possible cycle time. This ensures the component is fully solidified before it is ejected from the mould, preventing defects like deformation or hot tears, while maximizing production throughput. The solidification pattern shown in Figure 5 also helps confirm that the part cools uniformly.

Q5: What is the main advantage of using a simulation tool like AnyCasting over traditional physical prototyping for this application?

A5: The primary advantage is the ability to predict and solve complex manufacturing problems before committing to expensive tooling and materials. In this study, the simulation identified a critical flaw in the gating design (the high-velocity flow) that would have likely caused defects in a physical part. With simulation, engineers can test multiple design iterations of the gating and cooling systems virtually, at a fraction of the cost and time, to arrive at an optimized process that produces high-quality, defect-free components from the very first shot.

Conclusion: Paving the Way for Higher Quality and Productivity

This research underscores the indispensable role of Low Pressure Die Casting Simulation in the modern manufacturing of advanced materials. By providing a detailed, data-driven view into the complex dynamics of mould filling and solidification, simulation transforms product development from a process of trial-and-error into one of predictive engineering. The key breakthrough—identifying excessive flow velocity as a direct cause of potential defects—allows for targeted design improvements that enhance quality and reduce scrap.

For manufacturers of high-performance MMC components, these insights are invaluable. They enable the optimization of gating systems, cooling strategies, and cycle times, leading directly to higher productivity and more reliable, defect-free products.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "Design Simulation of Filing Sequence and Solidification Time for Cast Metal Matrix Composite by Low Pressure Die Casting" by "R. S. Taufik, S. Shamsuddin, K. K. Mak, A. A. Tajul, M. A. M. Khairul Anuar, B. B. T. Hang Tuah".

- Source: International Review of Mechanical Engineering (I.RE.M.E.), Vol. 5, N. 2, February 2011

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.