Boosting HPDC Profitability: How Additive Manufacturing Slashes Scrap Rates and Cycle Times

This technical summary is based on the academic paper "INCREASING COMPETITIVENESS IN HIGH PRESSURE DIE CASTING WITH ADDITIVE MANUFACTURING" by Armin WIEDENEGGER, Günther PRUNNER, and Bostjan NOTAR, published in INDUSTRIJSKI FORUM IRT (2021).

Keywords

- Primary Keyword: High Pressure Die Casting (HPDC)

- Secondary Keywords: Additive Manufacturing, Conformal Cooling, Hot Work Tool Steel, Cycle Time Reduction, Scrap Rate

Executive Summary

- The Challenge: High scrap rates and long cycle times in cost-intensive High Pressure Die Casting (HPDC) processes significantly impact profitability and increase the carbon footprint.

- The Method: The study compares the performance of conventionally manufactured and additively manufactured (AM) hot work tool steels and presents a case study of an AM tool insert featuring conformal cooling.

- The Key Breakthrough: Additively manufactured inserts from advanced hot work tool steel (BÖHLER W360 AMPO) outperform conventional materials in thermo-chemical and thermo-mechanical resistance, enabling a significant reduction in the total scrap rate from 7.1% to 3.74% in an industrial application.

- The Bottom Line: Integrating Additive Manufacturing with conformal cooling and advanced tool steels into HPDC tooling is a proven strategy to reduce operational costs, lower energy consumption, and increase overall competitiveness.

The Challenge: Why This Research Matters for HPDC Professionals

High Pressure Die Casting (HPDC) is a highly efficient process for high-volume production, but it is not without its challenges. The process is cost-intensive, and profitability hinges on minimizing cycle times and scrap rates. The tooling itself is a significant investment and must withstand harsh conditions, including temperatures cycling up to 700°C and pressures up to 100 MPa.

While Additive Manufacturing (AM) is often associated with rapid prototyping or complex, low-volume parts, its potential in high-volume tooling has been underexplored. Toolmakers have begun using AM to build inserts with complex conformal cooling channels, but questions remain about the performance of printed materials under real-world HPDC conditions. This research was necessary to validate the performance of new AM-specific tool steel grades and quantify the economic and environmental benefits of adopting this technology for demanding HPDC applications.

The Approach: Unpacking the Methodology

To provide a comprehensive evaluation, the researchers conducted a detailed study supported by the voestalpine High Performance Metals Division, comparing several material grades under simulated HPDC conditions.

Materials Tested:

- Maraging Steel 1.2709 (Bulk and AM): A commonly used material for AM tooling.

- Hot Work Steel 1.2343 (Bulk): A widely used "gold standard" material serving as the reference.

- High-Performance Hot Work Steel W360 (Bulk and AM): A premium martensitic hot work steel characterized by high hot hardness, toughness, and temper resistance.

Equipment Used:

- AM samples of 1.2709 were printed on an EOS M 290 system.

- AM samples of W360 were printed on a Renishaw AM500Q system with a preheated chamber.

Key Tests:

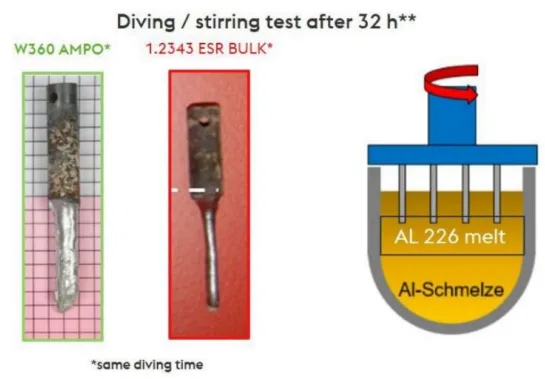

- Thermo-chemical Resistance Test: Test bars were submerged in a 226 aluminum melt for 32 hours to simulate the chemical interaction and corrosion that occurs over approximately 120,000 shots. Material loss was measured to evaluate resistance.

- Thermo-mechanical Performance Test: Notched samples were cyclically immersed in molten aluminum and then transferred to water to simulate the thermal shock of the HPDC process. After up to 50,000 cycles, samples were analyzed for surface cracks (a measure of notch-crack resistance) and volume cracks (a measure of general tool lifetime).

This rigorous testing was complemented by an industrial case study to validate the findings in a real-world production environment.

The Breakthrough: Key Findings & Data

The study delivered clear, data-driven evidence of the superiority of additively manufactured, high-performance tool steels for HPDC applications.

Finding 1: Superior Material Performance with AM Hot Work Steel

The additively manufactured W360 AMPO grade demonstrated exceptional performance, surpassing not only the conventional reference material but also its own conventionally manufactured counterpart.

- Thermo-chemical Resistance: In the 32-hour aluminum melt immersion test, the maraging steel (1.2709) samples dissolved within 4-8 hours. In contrast, the AM W360 test bar outperformed all other samples, including the 1.2343 reference and bulk W360 (Figure 2).

- Thermo-mechanical Resistance: The AM W360 grade showed the best performance in resisting cracks. As shown in Figure 4, its notch-crack resistance was significantly higher than the 1.2343 reference. Similarly, Figure 5 shows its heat-checking resistance, a key indicator of tool lifetime, was the highest among all tested materials.

Finding 2: Drastic Scrap Rate Reduction and Cost Savings in a Real-World Application

A case study conducted with Druckguss Heidenau, producing 600,000 aluminum parts per year, confirmed the practical benefits of AM tooling.

- Scrap Rate Reduction: The conventional tool insert had a total scrap rate of 7.1% (3.8% in the foundry and 3.3% in rework). By implementing an additively manufactured insert with optimized conformal cooling, the total scrap rate was reduced to just 3.74%.

- Economic Impact: This 3.36% reduction in scrap translated to a savings of approximately €194,000 per year in raw casting costs alone (Figure 8). After accounting for the higher initial cost of the AM inserts (€20,000 for 10 inserts), the net annual savings were €174,000 (Table 1).

- Environmental Impact: The reduction in scrap led to an annual energy saving of approximately 160,000 kWh, corresponding to a reduction of 80 tons of CO2 emissions (Figure 9).

Practical Implications for R&D and Operations

The findings from this paper provide actionable insights for various roles within a manufacturing organization.

- For Process Engineers: This study suggests that implementing AM tool inserts with conformal cooling can directly reduce scrap rates (from 7.1% to 3.74% in the case study) and offers a clear pathway to reduce cycle times. A modeled 5-second cycle time reduction showed the potential for an additional €384,000 in annual savings.

- For Quality Control Teams: The data in Figure 4 and Figure 5, showing the superior heat-checking and notch-crack resistance of W360 AMPO, indicates that tools made from this material may require less frequent maintenance and exhibit a longer, more predictable lifetime, impacting maintenance schedules and part quality consistency.

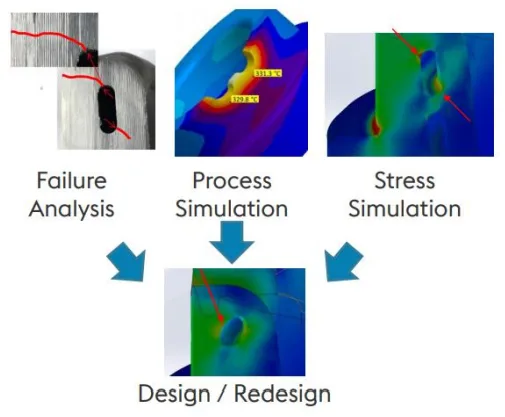

- For Design Engineers: The findings indicate that simply applying conventional design rules to conformal cooling channels is insufficient. A holistic design approach, incorporating failure analysis, process simulation, and stress simulation (as shown in Figure 6), is essential to fully exploit the potential of AM and prevent premature tool failure.

Paper Details

INCREASING COMPETITIVENESS IN HIGH PRESSURE DIE CASTING WITH ADDITIVE MANUFACTURING

1. Overview:

- Title: INCREASING COMPETITIVENESS IN HIGH PRESSURE DIE CASTING WITH ADDITIVE MANUFACTURING

- Author: Armin WIEDENEGGER¹, Günther PRUNNER², Bostjan NOTAR³

- Year of publication: 2021

- Journal/academic society of publication: INDUSTRIJSKI FORUM IRT

- Keywords: Additive manufacturing, Hot work tool steel, High pressure die casting, Powder bed fusion, Conformal cooling.

2. Abstract:

In a cost-intensive process, such as high pressure aluminum die casting, reducing the cycle time and scrap rate has a significant influence on profitability. By using advanced conformal cooling design and state-of-the-art BÖHLER hot work tool steels, the cycle time for molding tools can be reduced and tool life can be increased. This means that not only the component quality in functional areas increases, but also the overall process quality. These innovative solutions can only be realized if the restrictions of additive manufacturing (AM) are understood. Only then can the potential of AM be exploited to develop novel tool concepts from a holistic understanding of component and process requirements. Thermal management then becomes the focus of the entire process chain. In addition to an increasing component quality, the optimization of thermal management leads to significant cost savings and thus to an increase in the competitiveness of this production process. Likewise, AM tools also contribute to the reduction of energy consumption and hence CO2 emissions which will play an ever increasing role in future (automotive) production processes.

3. Introduction:

Typically, the first thoughts when discussing additive manufacturing (AM) are not about economically efficient high-volume production or even the possible reduction of carbon dioxide emissions. AM is usually associated with rapid prototyping, complex components, or bespoke medical components. Due to the tremendous speed of developments in this segment, the production of small batch sizes (up to a few thousands) is getting more and more competitive. Traditional processes, like plastic injection molding (PIM) or high-pressure die casting (HPDC), are highly efficient for high volume production but require costly tooling as a starting point. Thus, plastic or even metal AM can be more economical depending on the total amount of produced parts. One may be tempted to conclude that tool makers for PIM and HPDC molds are directly competing with laser AM technologies of steel parts – this is a premature conclusion. In recent years many toolmakers have in fact been employing laser AM technologies to build inserts with complex conformal cooling channels for PIM and HPDC applications to complement their traditional toolmaking. This novel approach allows a huge degree of freedom when designing cooling channels and paves the way for an unprecedented cooling performance. Together with the latest developments in tool steel powder grades, a new generation of tools for PIM and HPDC processes will be widely introduced in the next years. The conformal cooling approach enables lower cycle times and lower scrap rates. Although tools produced with laser AM are more expensive than conventionally manufactured tools, the economic benefits of the enhanced cooling performance can very often easily outweigh these costs for high volume production. Interestingly, the advantages of laser AM tools can also have a significant impact on the CO2 emission during production, especially for energy-intensive production processes like HPDC. Scrap rates of increasingly complex cast aluminum parts can be significantly reduced when a conformal cooling concept is applied. Every cast part that fails the quality control adds to the CO2 footprint of the production. Consequently, lower scrap rates in HPDC processes through the employment of AM tools can contribute to the demanded reduction of the total CO2 footprint in car production [1, 2].

4. Summary of the study:

Background of the research topic:

High-volume HPDC is an efficient but cost-intensive process where profitability is highly dependent on tooling performance, cycle time, and scrap rate. Additive Manufacturing has traditionally been viewed as a technology for prototyping rather than for producing robust tooling for high-volume manufacturing.

Status of previous research:

Toolmakers have started using laser AM to create tool inserts with conformal cooling. However, the printability of traditional hot work steel grades (like 1.2343) is challenging due to high carbon content. This led to the widespread use of maraging steels (like 1.2709) for AM tools, but their performance under the harsh thermo-mechanical conditions of HPDC has been a limiting factor.

Purpose of the study:

The study aims to demonstrate that current state-of-the-art laser AM technology, combined with newly developed hot work steel powders, can produce high-quality HPDC tools. The goal is to prove that these advanced tools can significantly increase competitiveness by reducing scrap rates and cycle times, leading to economic and ecological benefits.

Core study:

The research consists of two main parts: 1) A comparative performance evaluation of different tool steel grades (maraging 1.2709, standard hot work 1.2343, and high-performance W360) in both conventional (bulk) and additively manufactured (AM) forms. 2) An industrial case study to quantify the real-world economic and environmental impact of using an AM tool insert with conformal cooling in a high-volume aluminum HPDC process.

5. Research Methodology

Research Design:

The study employed a mixed-method approach, combining a comparative laboratory experiment with a single-case industrial application study. The experimental part compared materials under controlled, simulated HPDC conditions, while the case study provided validation in a real production environment.

Data Collection and Analysis Methods:

Data was collected through physical testing and analysis of production data. Thermo-chemical resistance was measured by material loss after immersion in molten aluminum. Thermo-mechanical performance was evaluated by analyzing surface and volume cracks using optical and scanning electron microscopy after thermal cycling. The case study collected data on production volume, scrap rates, and operational costs to perform an economic and environmental impact analysis.

Research Topics and Scope:

The research is focused on the application of additively manufactured hot work tool steels for high pressure die casting of aluminum alloys. The scope includes material performance testing (thermo-chemical and thermo-mechanical) and an analysis of the economic and environmental benefits derived from scrap rate reduction and potential cycle time improvements.

6. Key Results:

Key Results:

- The additively manufactured W360 AMPO grade demonstrated the highest thermo-chemical resistance, outperforming the 1.2343 reference material and even its own bulk counterpart (Figure 2).

- The maraging steel 1.2709 showed poor thermo-chemical resistance, dissolving in the aluminum melt in a fraction of the test time.

- In thermo-mechanical tests, W360 AMPO exhibited the best notch-crack resistance (Figure 4) and heat-checking resistance (Figure 5), indicating superior durability and a longer potential tool life.

- The industrial case study proved that an AM insert could reduce the total scrap rate from 7.1% to 3.74%.

- This scrap reduction resulted in net annual savings of €174,000, even after accounting for the higher cost of the AM inserts (Table 1).

- The process improvement led to an annual energy saving of ~160,000 kWh and a reduction of ~80 tons of CO2 emissions (Figure 9).

- A modeled 5-second reduction in cycle time showed the potential for an additional €384,000 in savings, bringing the total potential annual savings to €523,000 (Table 2).

Figure Name List:

- Figure 1: Test bars are put into an aluminum 226 melt for a total time of 32 hours to evaluate the thermo-chemical resistance.

- Figure 2: Comparison of the thermo-chemical resistance after 32 hours of diving time in the aluminum melt.

- Figure 3: For testing, the thermo-mechanical resistance machined samples were alternately immersed between liquid aluminum and a cooling medium. Transverse and longitudinal cross-sections were analyzed for surface and bulk cracks.

- Figure 4: Comparison of the notch-crack resistance. The notch crack resistance is also a measure for cracks starting from the conformal cooling channel and hence a tool failure due to macroscopic cracks.

- Figure 5: Comparison of the heat-checking resistance. The heat-checking resistance is a general measure on for the overall tool lifetime and required maintenance intervals.

- Figure 6: Development of an optimized design based on failure analysis, process, and stress simulation.

- Figure 7: Comparison of the temperatures of the tool insert before spraying (Left picture: conventional; central & right picture: additive) [9].

- Figure 8: Aluminum part costs and scrap rate costs.

- Figure 9: Energy consumption of high pressure die casting process [9].

- Figure 10: Costs for Al-parts and scrap rate costs.

![Figure 7: Comparison of the temperatures of the tool insert before spraying (Left picture: conventional; central & right picture: additive) [9].](https://castman.co.kr/wp-content/uploads/image-3078.webp)

7. Conclusion:

By using additive manufacturing inserts in an energy-intensive process such as high pressure aluminum die casting, the scrap rate has a significant influence on the CO2 savings potential and profitability. This can be further improved by using state-of-the-art hot work tool steels, which leads to a cycle time reduction and an increased tool life. While the initial costs for additive manufacturing are higher compared to conventional tool fabrication, the resulting increase in aluminum part quality and the optimization of thermal management lead to significant cost savings and thus to an increase in the competitiveness of this manufacturing process. The use of additively manufactured die inserts in the die casting process brings significant technical advantages and both economically and ecologically.

8. References:

네, 요청하신 참고 문헌 목록을 마크다운 리스트 형식으로 정리해 드릴게요.

- Lee, K.-H.: Integrating carbon footprint into supply chain management: The case of Hyundai Motor Company (HMC) in the automobile industry, Journal of Cleaner Production, July 2011, 19(11), pp 1216-1223

- https://www.volkswagenag.com/en/news/stories/2019/02/clean-mobility-starts-with-suppliers.html# (24.3.2021)

- Over, C.: Generative Fertigung von Bauteilen aus Werkzeugstahl X38CrMoV5-1 und Titan TiAl6V4 mit 'Selective Laser Melting', Dissertation, RWTH Aachen, 2003

- Klocke, F.; Arntz, K.; Teli, M.; Winands, K.; Wegener, M.; Oliari, S.: State-of-the-art Laser Additive Manufacturing for Hot-work Tool Steels, Procedia CIRP, 63 (2017), pp 58-63

- Andersson, H.: Thermal fatigue and soldering experiments of additively manufactured hot work tool steel, Master-thesis, Faculty of Health, Science and Technology, Karlstads University, 2018

- Berbić, M.; Hofer-Hauser, P.; Gschwandtner, R.; Ognianov, M.; Leuders, S.: Glatz, S.: Lochbichler, C.; Mangelberger, M.: Thermomechanical and thermochemical endurance of hot work tool steels and PVD-coatings for high pressure die casting, 60th IFC Portorož, 2020

- voestalpine BÖHLER Edelstahl GmbH & Co KG: Product description BÖHLER W360 ISOBLOC, https://www.bohler.at/app/uploads/sites/92/2020/02/productdb/api/w360de.pdf, 2021 (24.3.2021)

- voestalpine BÖHLER Edelstahl GmbH & Co KG. Product description BÖHLER W360 AMPO https://www.bohler-edelstahl.com/de/products/w360-ampo/, 2021 (24.3.2021)

- Sieger, A.; Nitsch, M.: "ADDITIVE MANUFACTURING OF TOOLS – OPPORTUNITIES AND RISKS", Euroguss 2020, Nürnberg, 2020

- Favi, C.; Germani, M.; Mandolini, M.: Analytical Cost Estimation Model in High Pressure Die Casting, Procedia Manufacturing, 11 (2017), pp 526-535

- Boos, W.; Pitsch, M.; Salmen, M.; Wiese, J.; Kelzenberg, C.; Lange, J. d.: "Successful Calculation in Tool Making", WZL & WBA Aachen, 2016

- https://www.custompartnet.com/estimate/die-casting-std/ (Retrieval: 24.03.2021)

Expert Q&A: Your Top Questions Answered

Q1: Why was the W360 steel printed using a machine with a preheated chamber?

A1: The paper specifies that the W360 samples were printed on a Renishaw AM500Q in a preheated chamber. While not explicitly stated why, high-performance hot work steels like W360 have higher carbon content than maraging steels, making them more susceptible to cracking from thermal stresses during the rapid heating and cooling of the laser powder bed fusion process. Using a preheated chamber helps to reduce the thermal gradient, minimize residual stress, and ensure a high-quality, crack-free printed part.

Q2: The paper states AM W360 outperformed its bulk counterpart in the thermo-chemical test (Figure 2). What could explain this surprising result?

A2: The paper reports this remarkable finding in Figure 2 but does not delve into the specific metallurgical reasons. This superior performance is noteworthy because AM parts are sometimes perceived as being inferior to wrought materials. The improved resistance could potentially be related to the very fine-grained and homogenous microstructure typically achieved through the rapid solidification inherent in the L-PBF process, which may enhance its resistance to corrosion from molten aluminum.

Q3: How significant was the underperformance of the maraging steel 1.2709 in these HPDC-specific tests?

A3: The underperformance was highly significant and confirms why specialized hot work steels are necessary for HPDC tooling. In the thermo-chemical test, the 1.2709 test bars completely dissolved between 4-8 hours, whereas the W360 and 1.2343 grades lasted the full 32 hours. It also performed poorly in the thermo-mechanical tests for crack resistance. This demonstrates that while 1.2709 has been a preferred material for general AM tooling due to its good printability, it lacks the required properties for longevity in a demanding HPDC environment.

Q4: What was the total additional investment required in the case study to achieve the total potential savings of €523,000?

A4: According to Table 2, the financial model for achieving the total potential savings (from both scrap reduction and cycle time reduction) included an additional cost of €20,000 for the AM inserts and €35,000 for an AM distributor. This represents a total additional investment of €55,000 compared to the conventional tooling approach to unlock over half a million Euros in annual savings.

Q5: The paper mentions that designers should not apply "conventional or traditional design rules" to conformal cooling. What does this imply?

A5: This implies that designing for AM is a fundamentally different discipline than designing for conventional manufacturing. The paper identifies common problems where designers are unaware of AM-specific rules or the unique mechanical loads on the tool. For conformal cooling, this means designers must consider factors like minimum channel diameter, self-supporting angles to avoid the need for internal supports that cannot be removed, the optimal distance of the channel from the mold surface to balance cooling efficiency and tool strength, and how to design smooth channel paths to minimize pressure drop and prevent erosion.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides compelling evidence that the strategic use of Additive Manufacturing is no longer confined to prototypes but is a viable, profitable solution for high-volume High Pressure Die Casting (HPDC). By pairing advanced, AM-specific hot work tool steels like W360 AMPO with intelligently designed conformal cooling channels, manufacturers can achieve dramatic reductions in scrap rates and cycle times. The result is not just a significant improvement in profitability but also a tangible reduction in energy consumption and CO2 emissions. The initial higher cost of AM tooling is shown to be a smart investment, delivering substantial returns through enhanced operational efficiency and superior part quality.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "INCREASING COMPETITIVENESS IN HIGH PRESSURE DIE CASTING WITH ADDITIVE MANUFACTURING" by "Armin WIEDENEGGER, Günther PRUNNER, Bostjan NOTAR".

- Source: INDUSTRIJSKI FORUM IRT, Portorož, 21. in 22. junij 2021

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.