This article introduces the paper ['Warm forming of High-strength Aluminum alloys for the Automotive industry'] published by ['Politecnico di Torino'].

1. Overview:

- Title: Warm forming of High-strength Aluminum alloys for the Automotive industry

- Author: Wang Xuanye

- Publication Year: 2021/2022

- Publishing Journal/Academic Society: Politecnico di Torino

- Keywords: Aluminum alloy, warm forming, mechanical properties, automotive manufacturing

2. Abstracts or Introduction

The aim of this thesis is to give a brief overview of some experiments on the high-

strength aluminum alloys of the 6xxx and 7xxx series and to analyse their main

mechanical properties in the light of the test results. Firstly, a literature presentation on

aluminum, aluminum alloys and their warm forming is given, followed by an overview

of the current applications (with emphasis on the automotive sector), properties and

problems of aluminum alloys. In the next sections, which form the main part of this

report, suitable thermoformable aluminum alloys AA6016, AA7021 and AA7046 are

selected for detailed experimental descriptions, showing the results of individual

experiments including data and figures, including tensile tests, hardness tests,

metallography and finally conclusions are drawn.

3. Research Background:

Background of the Research Topic:

In recent years, the greenhouse effect is getting more and more attention, and almost every government is or has made new policies and decrees to try to stop the rapid rise of carbon dioxide emissions and strive to reach carbon neutrality. The energy emission of automobiles is a point that needs special attention. Automotive light weighting technology is the most important, simple and effective method for sustainable development of the automotive industry, which can improve fuel economy and reduce exhaust emissions. Among all the materials available for automotive applications, aluminum alloy is undoubtedly a good compromise between cost and weight reduction. Aluminum alloys are widely used for automotive light weighting due to their low density, good corrosion resistance and easy processability.

Status of Existing Research:

As the AA7XXX series is the most popular high-strength aluminum alloy, many studies have focused on the heat treatment process. For example, Suleiman E. Al-lubani et al. studied the heat treatment of AA7449 in 2015 [4] and R. RANGANATHA1 et al. studied the multi-step heat treatment of AA7049 in 2013. [5]. As early as 1946, FINCH et al. conducted a study on warm forming of aluminum alloy sheets, and the results showed that the tensile properties were significantly improved when forming in the warm state. In 1978, a paper by F. Shehata et al. reported the finding: commercial aluminum alloys undergo a corresponding change in strain of 0 to 6.6% at temperatures between 20 and 300°C, that is, the higher the temperature, the greater the elongation [20].

Necessity of the Research:

Due to the low strength of AA6XXX series, it is difficult to realize the light weight of side impact beams and A-pillar and B-pillar load-bearing structural parts. Therefore, from the consideration of service safety, high strength 7000 series aluminum alloys (Al-Zn-Mg-Cu) are becoming more and more popular among OEMs, and their high strength can meet the strength requirements of automotive load-bearing structural members, but the application of high strength AA7XXX series in automotive is still limited. Warm forming processes are therefore expected to solve this problem for high strength aluminum alloys.

4. Research Purpose and Research Questions:

Research Purpose:

The aim of this thesis is to give a brief overview of some experiments on the high-strength aluminum alloys of the 6xxx and 7xxx series and to analyse their main mechanical properties in the light of the test results.

Key Research:

Suitable thermoformable aluminum alloys AA6016, AA7021 and AA7046 are selected for detailed experimental descriptions, showing the results of individual experiments including data and figures, including tensile tests, hardness tests, metallography and finally conclusions are drawn.

Research Hypotheses:

This study aims to verify the applicability of the warm forming process in the automotive industry. It is designed to investigate the effect of warm forming on the mechanical properties of AA6016, AA7021, and AA7046 aluminum alloys, and to compare the properties of pre-aged and non-pre-aged materials under warm forming conditions.

5. Research Methodology

Research Design:

This research employed an experimental design to evaluate the effects of warm forming and heat treatments on the mechanical properties of aluminum alloys. The study included tensile tests at room and elevated temperatures, micro-hardness testing, and metallographic analysis.

Data Collection Method:

- Tensile Test: Conducted using an universal testing machine (Z050, Zwick Roell) to measure tensile properties at room temperature and warm forming temperatures (175°C, 200°C, 225°C).

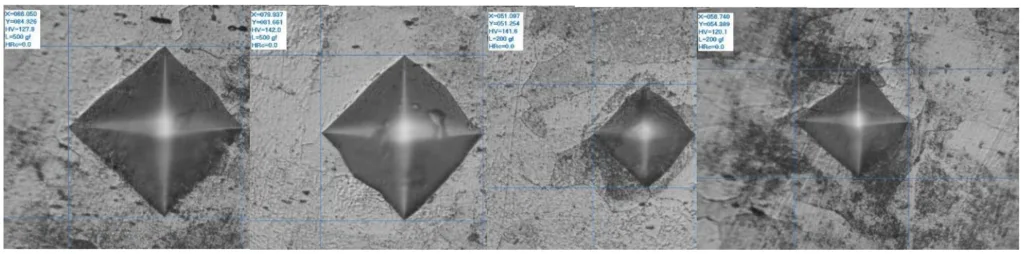

- Micro-hardness Testing: Performed using a Micro-Vickers hardness tester with test loads of 200 gf and 500 gf to assess the hardness of the samples.

- Metallography: Optical microscopy was used to observe and analyze the microstructure of AA7046 samples after different heat treatments.

- Fractography: Fracture surfaces of tensile tested samples were examined using optical microscopy to measure fracture angles and analyze fracture modes.

Analysis Method:

- Tensile Test Data Analysis: Stress-strain curves were generated, and parameters such as Yield Strength (Rp0.2), Ultimate Tensile Strength (UTS), and fracture strain were determined and compared. True stress and true strain were calculated using formula 1 and formula 2:

- formula 1: Otrue = σο × (1 + €0)

- formula 2: Etrue = ln(1+ €0)

- Micro-hardness Data Analysis: Vickers hardness values (HV) were measured and compared for different alloys and heat treatment conditions.

- Metallographic Image Analysis: Microstructural features, including grain boundaries and precipitates, were observed and analyzed from optical micrographs.

- Fractography Analysis: Fracture surface angles were measured using image analysis software "imagej" to evaluate the fracture characteristics.

Research Subjects and Scope:

The research focused on three different high-strength aluminum alloys: AA6016, AA7021, and AA7046. The study investigated the effects of different heat treatments (solubilization, pre-aging) and warm forming temperatures on the mechanical properties of these alloys. The scope was limited to experimental investigation of tensile behavior, hardness, and microstructure under specific warm forming conditions relevant to automotive applications.

6. Main Research Results:

Key Research Results:

- AA6016: Warm forming at 200 °C and 225 °C did not significantly change the final tensile strength. However, the value of final Rp0.2 slightly decreased as the tensile test temperature increased. The strain capacity of AA6016 is notable, but its strength remains relatively low even after warm temperature ageing.

- AA7021: In the high temperature tensile test at 175°C, the yield strength of the room temperature aged AA7021 alloy was slightly higher than that of the high temperature aged (100°C, 20 minutes) alloy. After air cooling to room temperature, both groups showed similar yield strengths in the second tensile test.

- AA7046: The high temperature pre-aged AA7046 alloy exhibited a higher final tensile strength and UTS compared to non-pre-aged alloy. In tensile tests at 175°C, yield strengths were approximately 230-240 MPa, and re-tensile tests at room temperature increased the yield strength by approximately 50%. Micro-hardness tests indicated that heat treatment decreased the hardness of AA7046.

- Fractography: Fracture surfaces were generally ductile. AA7021 samples showed smaller side view angles and obvious necking shrinkage in pre-aged conditions. AA6016 exhibited larger fracture angles and obvious necking.

Analysis of presented data:

The data presented includes stress-strain curves, tables of tensile test results (Table 10, Table 11, Table 12), micro-hardness values (Table 13, Table 14), and fracture angle measurements (Table 15). Analysis of tensile test data for AA6016 indicated that while warm forming did not significantly enhance strength, it maintained ductility. For AA7021 and AA7046, pre-aging showed a positive effect on tensile strength, particularly for AA7046. Micro-hardness results suggested a decrease in hardness after heat treatment for AA7046. Fractography provided qualitative insights into the fracture behavior of the alloys under different conditions.

Figure Name List:

- Figure 1: Aluminum in our life

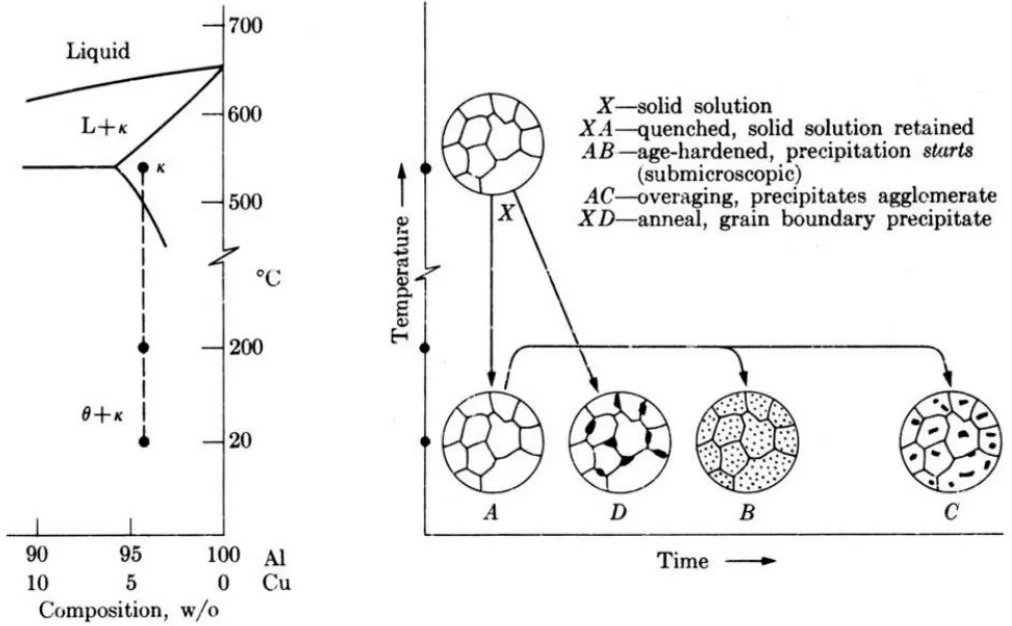

- Figure 2: heat treatment process

- Figure 3: Common aluminum alloy of 7xxx series

- Figure 4: Common aluminum alloy of 6xxx series

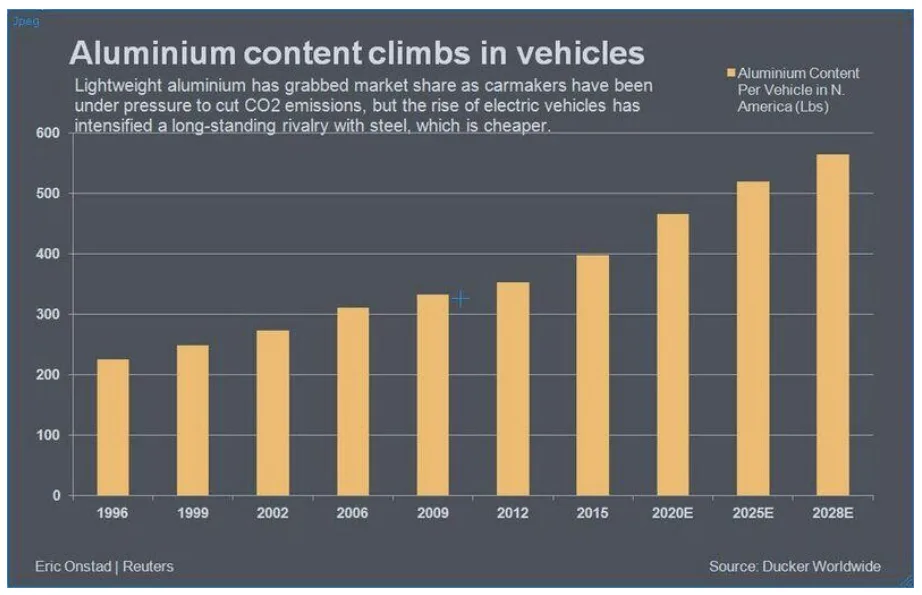

- Figure 5: Latest Trends for Aluminum Demand in Automotive Industry

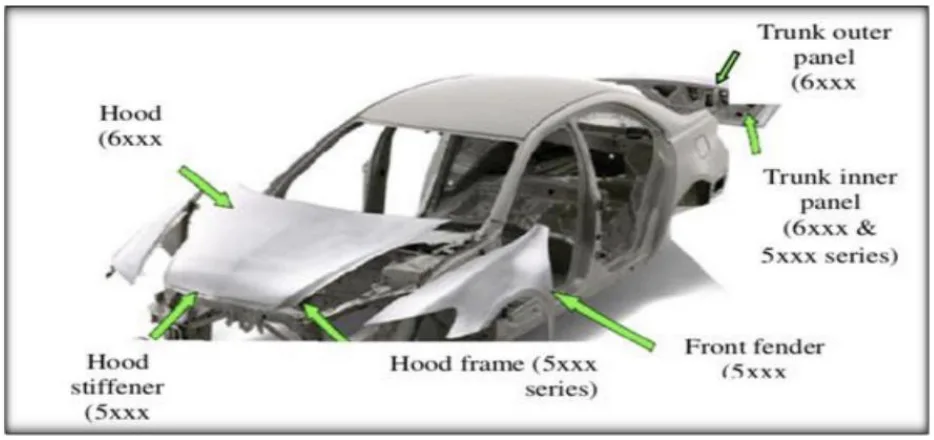

- Figure 6: the typical applications of different alloys in a vehicle

- Figure 7: AA5xxx and AA6xxx series in vehicle

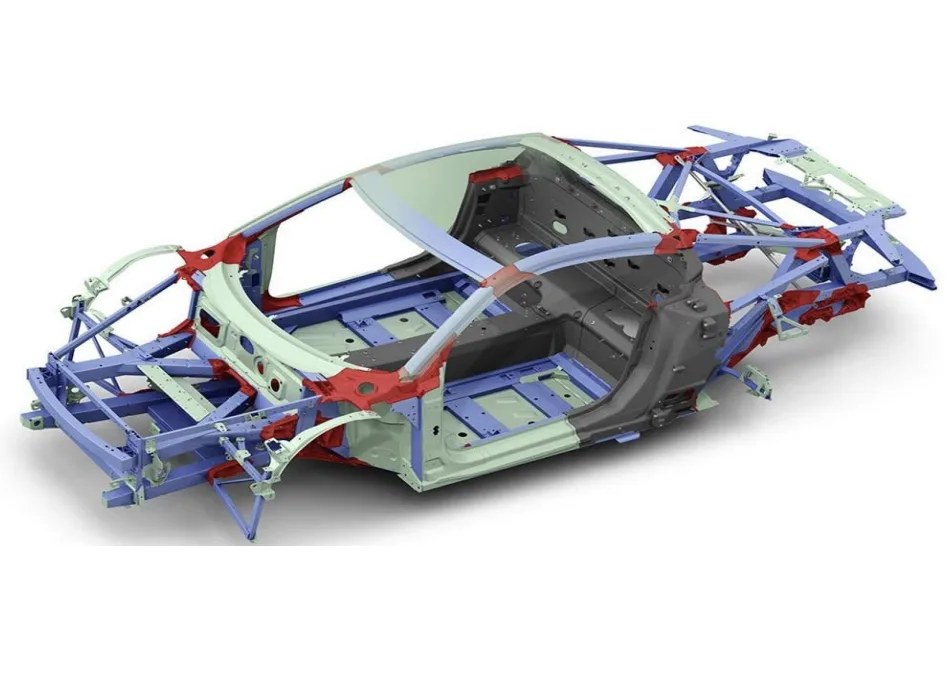

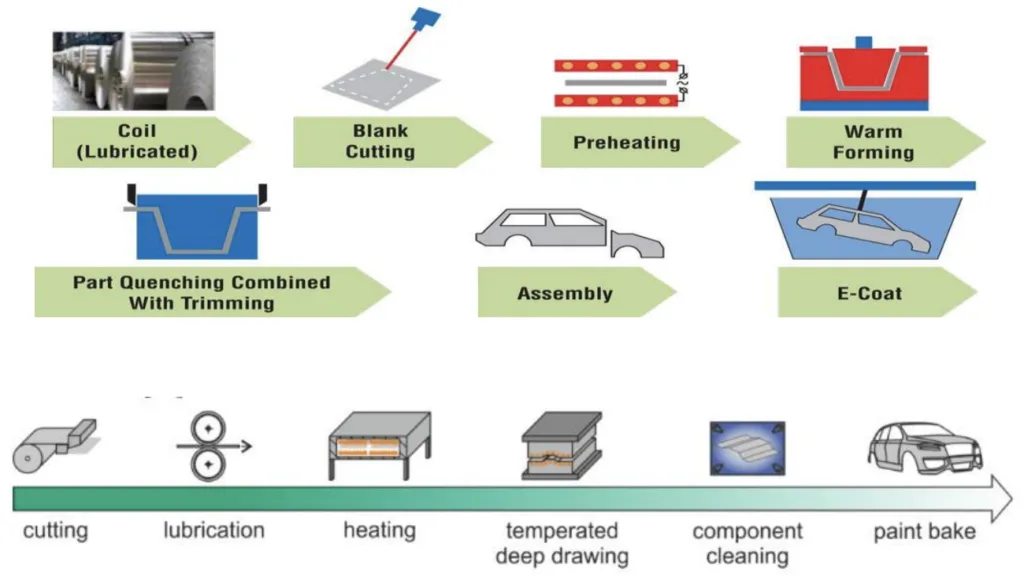

- Figure 8: Warm forming method for vehicle body

- Figure 9: One classical non-isothermal forming

- Figure 10: Heating system of forming

- Figure 11: The effect of punching temperature on the ultimate stretch rate

- Figure 12: The relationship between molding speed and formability (left); The relationship between molding speed/temperature and formability (right)

- Figure 13: Sketch of warm water forming

- Figure 14: Brief view of the steps of preforming, annealing and finishing forming

- Figure 15: schema of Quick Plastic Forming (QPF)

- Figure 16: standard plan view of sample

- Figure 17: heat treatment process

- Figure 17: Metallographic cut-off machine.

- Figure 18: Embedded samples

- Figure 19: Metallographic images of 2nd etched

- Figure 20: the picture of tensile test machine

- Figure 21: All samples after the experiment (after breakage)

- Figure 22: AA6016 225 °C up to 10% full test

- Figure 23: AA6016 200°C up to 10% full test

- Figure 24: AA6016 in different temperature

- Figure 25: Comparison of tensile test in different pre-aged condition in

- Figure 26: Comparison of warm tensile test and room temperature full tensile test of no pre-aged AA7021

- Figure 27: Comparison of warm tensile test and room temperature full tensile test of pre aged AA7021

- Figure 28: Comparison of warm tensile test and room temperature full tensile test of AA7046 with pre-aged

- Figure 29: Comparison of "warm tensile test then room temperature full tensile test” and “ONLY full warm tensile test” of AA7046 with pre-aged

- Figure 30: Comparison of warm tensile test and room temperature full tensile test of AA7046 with pre-aged

- Figure 31: micro-hardness

- Figure 32: Hardness testing machines

- Figure 33: Hardness test results

- Figure 34: Microscope used for the experiment

7. Conclusion:

Summary of Key Findings:

- For AA6016, warm forming at 200 °C and 225 °C did not show significant improvements in final strength.

- For AA7046, pre-aging treatment resulted in a higher final tensile strength.

- For AA7021, pre-aging did not significantly affect the final tensile strength.

- Microstructural analysis of AA7046 using light microscopy showed similar results for pre-aged and non-pre-aged samples.

- Hardness tests did not reveal major differences between different aging conditions for the tested aluminum alloys.

Academic Significance of the Study:

This study contributes to the existing body of knowledge on warm forming of high-strength aluminum alloys, specifically focusing on AA6016, AA7021, and AA7046. The experimental results provide valuable data on the effects of warm forming and pre-aging on the tensile properties, hardness, and microstructure of these alloys. The observation of the Portevin-Le Chatalier (PLC) effect in AA7XXX alloys during room temperature tensile tests adds to the academic understanding of deformation mechanisms in these materials.

Practical Implications:

The findings suggest that warm forming can be a viable technique for processing AA7XXX series aluminum alloys for automotive applications, particularly for AA7046 where pre-aging in combination with warm forming enhances tensile strength. However, for AA6016, warm forming within the tested temperature range may not offer significant strength benefits. The study highlights the importance of alloy-specific optimization of warm forming parameters and heat treatments to achieve desired mechanical properties for automotive components.

Limitations of the Study and Areas for Future Research:

The study is limited by the specific alloys and warm forming conditions tested. Further research could explore a wider range of warm forming temperatures, strain rates, and pre-aging parameters to optimize the process for each alloy. More sophisticated microstructural analysis techniques, such as TEM, could be employed to better understand the precipitation behavior and its correlation with mechanical properties. The investigation of lubricant performance and interfacial friction in warm forming of aluminum alloys is also a crucial area for future research to address the practical challenges in industrial implementation.

8. References:

- [1] https://www.aluminum.org/Recycling

- [2] HAMEDI, Emilia. Electrical connection for aluminium conductors in automotive applications: Prestudy of available solutions for electrical connection methods of aluminium cables. 2017.

- [3] ASM Handbook, Volume 4: Heat Treating ASM Handbook Committee, p 841-879 DOI: 10.1361/asmhba0001205

- [4] AL-LUBANI, Suleiman E., et al. Heat Treatment of Aluminum Alloy 7449. International Journal of Materials and Metallurgical Engineering, 2013, 7.8: 591-596.

- [5] RANGANATHA, R., et al. Multi-stage heat treatment of aluminum alloy AA7049. Transactions of Nonferrous Metals Society of China, 2013, 23.6: 1570-1575.

- [6] Copyright© 2001 ASM International® Alloying: Understanding the Basics, J.R. Davis, p351-416 DOI:10.1361/autb2001p351

- [7] CAMPBELL JR, Flake C. Manufacturing technology for aerospace structural materials. Elsevier, 2011.

- [8] HIRSCH, J. Automotive trends in aluminum-The European perspective. In: Materials Forum. 2004. p. 15-23.

- [9] Summary briefing on four major new mass-reduction assessment for light-duty vehicles

- [10] NODER, Jacqueline. Characterization and simulation of warm forming of 6xxx and 7xxx series aluminum alloys. 2017. Master's Thesis. University of Waterloo.

- [11] Cheng Yan, Discussion on the production process technology and development of aluminum alloy body sheet, 2022

- [12] BOTTEMA, J., et al. Recent developments in AA6016 aluminum type body sheet product. SAE transactions, 1998, 900-907.

- [13] 2004 ASM International. All Rights Reserved. Tensile Testing, Second Edition (#05106G)

- [14] CHOI, Sung-Hwan, et al. High temperature tensile deformation behavior of new heat resistant aluminum alloy. Procedia Engineering, 2011, 10: 159-164.

- [15] EGBU, R. N. Effect of Temperature on the Tensile Strength and Thermoelectric emf Values of Aluminum Alloy. Journal of Applied Sciences and Environmental Management, 2007, 11.2.

- [16] CHEN, Dyi-Cheng; YOU, Ci-Syong; GAO, Fu-Yuan. Analysis and experiment of 7075 aluminum alloy tensile test. Procedia Engineering, 2014, 81: 1252-1258.

- [17] SCHARIFI, Emad, et al. Dynamic Tensile Deformation of High Strength Aluminum Alloys Processed Following Novel Thermomechanical Treatment Strategies. Advanced Engineering Materials, 2020, 22.8: 2000193.

- [18] ALTAN, Taylan; TEKKAYA, A. Erman (ed.). Sheet metal forming: processes and applications. ASM international, 2012.

- [19] https://www.mechtechguru.com/2020/04/cold-working-warm-working-hot-working.html

- [20] LI, Daoming; GHOSH, Amit. Tensile deformation behavior of aluminum alloys at warm forming temperatures. Materials Science and Engineering: A, 2003, 352.1-2: 279-286.

- [21] LIU, Chin-Wei, et al. Dimensional accuracy in quick plastic forming of aluminum alloy using demolding mechanism. Advances in Mechanical Engineering, 2021, 13.6: 16878140211021731.

- [22] TAKATA, Ken. Warm forming of aluminum alloys. Nippon Steel Technical Report, 2013, 103.

- [23] HUI, W. A. N. G., et al. Warm forming behavior of high strength aluminum alloy AA7075. Transactions of Nonferrous Metals Society of China, 2012, 22.1: 1-7.

- [24] BEHRENS, Bernd-Arno; HÜBNER, S.; VOGT, H. Formability of 7000 aluminum alloys in warm and hot forming condition. In: IOP Conference Series: Materials Science and Engineering. IOP Publishing, 2018. p. 012027.

- [25] ANYASODOR, Gerald; KOROSCHETZ, Christian. Industrial based volume manufacturing of lightweight aluminum alloy panel components with high-strength and complex-shape for car body and chassis structures. In: Journal of Physics: Conference Series. IOP Publishing, 2017. p. 012093.

- [26] TÜRKÖZ, Mevlüt, et al. Manufacturing of Cups by Warm Hydroforming Process. 2016.

- [27] ZHENG, Kailun, et al. A review on forming techniques for manufacturing lightweight complex-shaped aluminum panel components. International Journal of Lightweight Materials and Manufacture, 2018, 1.2: 55-80.

- [28] ISMAIL, A.; MOHAMED, M. S. Review on sheet metal forming process of aluminum alloys. In: The International Conference on Applied Mechanics and Mechanical Engineering. Military Technical College, 2016. p. 1-13.

- [29] https://www.thefabricator.com/stampingjournal/article/stamping/warm-forming-of-alloys-in-the-auto-industry

- [30] LIU, Chin-Wei, et al. Dimensional accuracy in quick plastic forming of aluminum alloy using demolding mechanism. Advances in Mechanical Engineering, 2021, 13.6: 16878140211021731.

- [31] BOISSIERE, R., et al. Quick-plastic forming: Similarities and differences with super-plastic forming. In: EuroSPF08. 2008.

- [32] WINTER, Lisa, et al. Influence of Pre-Aging on the Artificial Aging Behavior of a 6056 Aluminum Alloy after Conventional Extrusion. Metals, 2021, 11.3: 385.

- [33] Etching and Microscopical Examination

- [34] Wang minye, Warm Aluminum Formability, 2015

- [35] FRIBOURG, Guillaume. Precipitation and plasticity couplings in a 7xxx aluminium alloy: application to thermomechanical treatments for distortion correction of aerospace component. 2009. PhD Thesis. Institut National Polytechnique de Grenoble-INPG.

- [36] SOTIROV, N., et al. Improved formability of AA5182 aluminium alloy sheet at cryogenic temperatures. Materials Today: Proceedings, 2015, 2: S113-S118.

- [37] R.E. Smallman, A.H.W. Ngan, in Modern Physical Metallurgy (Eighth Edition), 2014

- [38] MATTEIS, Paolo; UBERTALLI, Graziano; CHEN, Minye. Warm forming processes for high-performance aluminum alloys for the automotive industry. 2021.

- [39] NASA website “Microhardness Testing of Aluminum Alloy Welds"

- [40] MATTEIS, Paolo; UBERTALLI, Graziano; DELLA PORTA, Francesco Pio.

9. Copyright:

- This material is "Wang Xuanye"'s paper: Based on "Warm forming of High-strength Aluminum alloys for the Automotive industry".

- Paper Source: [No DOI URL provided in the document, please add DOI URL if available]

This material was summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.