This technical summary is based on the academic paper "Development And Characterization Of Copper-Coated Basalt Fiber Reinforced Aluminium Alloy Composites" published by S. Ezhil Vannan and S. Paul Vizhian in the International Journal of Engineering Research & Technology (IJERT) (2013). It was analyzed and summarized for HPDC experts by CASTMAN with the support of AI.

Keywords

- Primary Keyword: Aluminum Metal Matrix Composites

- Secondary Keywords: Basalt fiber reinforcement, Squeeze casting technique, Electroless copper coating, Mechanical properties of composites, Interfacial bonding, Wettability improvement

Executive Summary

- The Challenge: The performance of fiber-reinforced aluminum composites is often limited by poor wettability and weak interfacial bonding between the aluminum matrix and the reinforcement fibers, leading to inconsistent material properties and defects.

- The Method: Researchers applied an electroless copper coating to short basalt fibers before incorporating them into an Al 7075 alloy matrix. Composites with 2.5, 5, 7.5, and 10 wt. % of fibers were fabricated using a high-pressure squeeze casting technique.

- The Key Breakthrough: The copper coating dramatically improved the wettability of the fibers. This resulted in a more homogenous fiber distribution, stronger interfacial bonding, and significant improvements in mechanical properties, including a 13.26% increase in Young's modulus and a UTS increase of up to 28.7%.

- The Bottom Line: This study demonstrates that surface modification of reinforcements is a highly effective strategy to overcome key manufacturing challenges in Aluminum Metal Matrix Composites. The findings provide a clear pathway for producing stronger, more reliable, and uniformly performing cast components for demanding applications.

The Challenge: Why This Research Matters for HPDC Professionals

In the world of high-performance casting, creating strong, lightweight components is the ultimate goal. Aluminum Metal Matrix Composites (MMCs) reinforced with fibers promise exceptional strength-to-weight ratios. However, a fundamental problem often stands in the way: liquid aluminum doesn't like to "wet" or bond with reinforcement materials like basalt fibers.

As the paper's introduction highlights, this poor wettability leads to several critical issues in production:

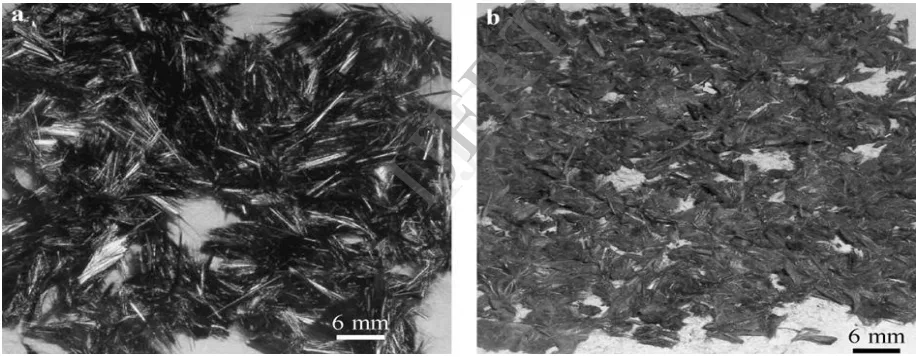

- Fiber Segregation: Uncoated fibers are often pushed aside by the solidifying metal front, leading to clumping and uneven distribution (Fig. 3(a)). This creates weak spots in the final component.

- Weak Interfacial Bonding: A poor bond between the fiber and the matrix means that stress cannot be effectively transferred from the aluminum to the strong fibers, undermining the very purpose of the reinforcement.

- Porosity and Voids: The lack of good wetting can trap gases and create voids at the fiber-matrix interface, further compromising the material's integrity.

For any HPDC professional, these issues translate to inconsistent part quality, unpredictable mechanical performance, and a high scrap rate. This research directly tackles this core manufacturing challenge.

The Approach: Unpacking the Methodology

The researchers took a systematic approach to solve the wettability problem. The process, relevant to high-pressure casting operations, involved several key stages:

- Fiber Preparation: Continuous basalt fibers (average diameter 6 µm) were chopped into short fibers (1-2 mm length). They were heat-treated at 500°C to remove any surface contaminants.

- Electroless Copper Coating: A multi-step electroless coating process was used to deposit a thin, uniform layer of copper onto the basalt fibers. This process involved sensitization with stannous chloride and activation with palladium chloride before metallization in a copper sulfate solution (Table 2). The goal was to create a metallic surface on the non-metallic fiber that would be readily accepted by the molten aluminum.

- Composite Fabrication: The copper-coated fibers were mixed with Al 7075 alloy to create MMCs with varying fiber content: 2.5, 5, 7.5, and 10 wt. %.

- Squeeze Casting: The composites were fabricated using a squeeze casting technique. This high-pressure process involves preheating the die (300-400°C), pouring the molten metal, and applying high pressure (20 to 30 MPa) during solidification. This method ensures intimate contact between the matrix and fibers, minimizing porosity.

The resulting composites (both coated and uncoated for comparison) were then subjected to rigorous testing for mechanical properties and microstructural analysis as per ASTM standards.

The Breakthrough: Key Findings & Data

The results clearly demonstrate the profound impact of the copper coating on the final composite's quality and performance.

- Finding 1: Drastic Improvement in Strength and Stiffness

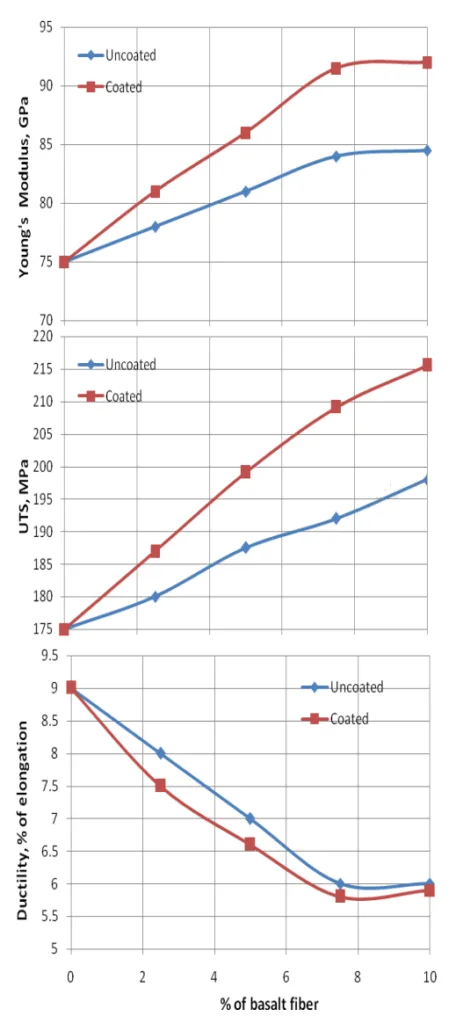

The copper-coated fibers led to a marked increase in both Young's Modulus and Ultimate Tensile Strength (UTS). As the coated fiber content increased from 2.5 to 10 wt. %, the UTS saw a significant jump from 15.5% to 28.7% compared to the uncoated counterparts. Similarly, the Young's Modulus improved by 13.26% over the same range. This is attributed to better stress transfer due to the strong interfacial bond and matrix strengthening effects. (Fig. 5 (a) and (b)). - Finding 2: Uniform Fiber Distribution Achieved

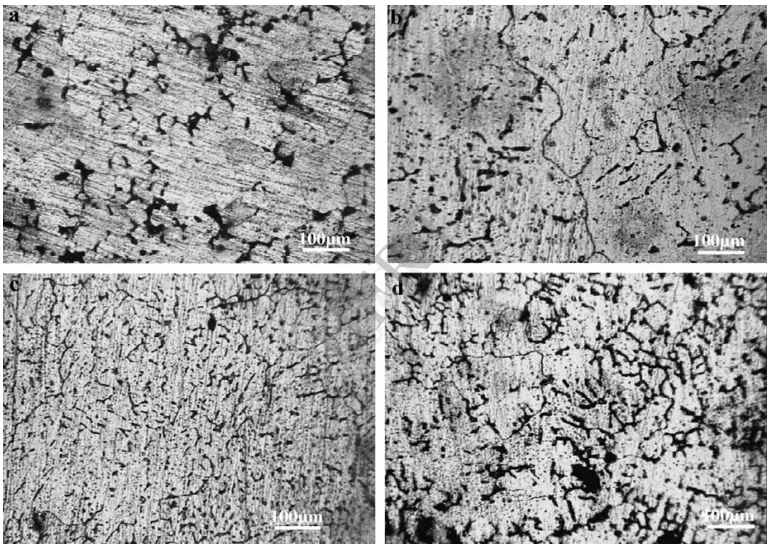

Microstructural analysis revealed a stark difference. In uncoated composites, fibers were pushed into interdendritic spaces (Fig. 3(a)). In contrast, the copper-coated fibers were uniformly distributed throughout the matrix, especially up to 7.5 wt. % (Fig. 4). This homogeneity is critical for achieving predictable and reliable mechanical properties across the entire component. - Finding 3: A Trade-Off in Ductility

As is common with high-strength materials, the increase in strength came at the cost of ductility. The study found that ductility decreased by about 35.9% as the coated fiber content increased to 10 wt. % (Fig. 5 (c)). The paper attributes this to the presence of voids, which can nucleate during plastic strain. This is a crucial design consideration for engineers.

Practical Implications for HPDC Products

This research offers valuable insights for manufacturers working with reinforced alloys in high-pressure casting environments.

- For Process Engineers: The study suggests that pre-treating reinforcements with a metallic coating can be a game-changer for process stability. The improved wettability indicated by the results could lead to better die filling, reduced segregation of reinforcements, and a more consistent casting process, especially for complex geometries.

- For Quality Control: The findings highlight a direct link between microstructure and performance. The uniform fiber distribution seen in Figure 4 is a key quality indicator for achieving the high tensile strength shown in Figure 5. This suggests that microscopic examination is essential for validating the quality of reinforced components. The inverse relationship between strength and ductility must also be factored into quality specifications.

- For Die Design: The study's success in creating uniformly distributed composites using a high-pressure process indicates the potential for designing more ambitious HPDC components. With improved material flow and reduced fiber agglomeration, it may be possible to design parts with thinner walls or more intricate features that incorporate reinforcement for localized strength, without compromising structural integrity.

Paper Details

1. Overview:

- Title: Development And Characterization Of Copper-Coated Basalt Fiber Reinforced Aluminium Alloy Composites

- Author: S. Ezhil Vannan, S. Paul Vizhian

- Year of publication: 2013

- Journal/academic society of publication: International Journal of Engineering Research & Technology (IJERT), Vol. 2 Issue 8, August - 2013

- Keywords: Metal matrix composite (MMCs), Basalt fibers, Short fiber composites, Electroless coating, squeeze casting technique.

2. Abstract:

The aim of the work was to investigate the effect of copper coated basalt short fiber reinforced Al alloy composites and was compared with uncoated basalt short fiber Al metal matrix composites (MMCs). Five different wt. % of basalt short fiber reinforced Al MMCs were prepared by squeeze casting technique 2.5, 5, 7.5 and 10% basalt short fiber MMCs. Both type of MMCs (coated and uncoated basalt fiber reinforced Al MMCs) were tested for elastic modulus, ultimate tensile strength and ductility along with microstructural change as per ASTM standard. The result shows the coating of Cu on basalt short fiber increases the Young's modulus, due to the homogenous distribution of basalt short fiber and the alignment of these fibers parallel to the axis with minimum segregation in the alloys, the ultimate tensile strength also increased due to their matrix strengthening and reduction in the alloy grain size, but the ductility significantly decreases due to the voids. The microstructure and fracture surfaces of both MMCs were examined using optical and SEM micrographs respectively. The lack of observed fiber pull-out on fracture and improved mechanical properties resulted due to the good wetting of the fibers by the liquid alloy.

3. Introduction:

Metal matrix composites (MMCs) properties are strongly dependent on the interfacial phenomena between the metal matrix and fiber surfaces. The interface plays a vital role in the overall performance. The wettability of reinforcement by liquid metal is the key factor to achieve high interface bonding strength. While several methods exist to improve bonding, modifying the fiber surface with a metal coating is a prominent technique. Electroless copper coating is highly preferable due to its simple, low-cost, and easy-to-use process. It helps prevent undesired interfacial reactions and promotes wettability. This study investigates the effect of copper coating on basalt fiber reinforced aluminum alloy composites prepared by squeeze casting.

4. Summary of the study:

This study systematically investigates the benefits of applying an electroless copper coating to short basalt fibers used as reinforcement in an Al 7075 alloy matrix. The researchers fabricated composites with 2.5%, 5%, 7.5%, and 10% weight fractions of both coated and uncoated fibers using a squeeze casting method. They then conducted comprehensive mechanical testing (tensile strength, Young's modulus, ductility) and microstructural analysis (optical and SEM) to compare the two types of composites. The core finding is that the copper coating significantly enhances the distribution of fibers and their bond with the aluminum matrix, leading to substantial improvements in strength and stiffness, albeit with a reduction in ductility.

5. Methodology

The study utilized Al 7075 alloy as the matrix and short basalt fibers (1-2 mm length, 6 µm diameter) as reinforcement. The key methodological steps were:

- Pre-procedure: Basalt fibers were heat-treated at 500°C for 10 minutes to remove pyrolytic coatings.

- Electroless Coating: A three-stage process was employed:

- Sensitization: Fibers were treated with stannous chloride (SnCl2) to prepare the surface.

- Activation: Catalytic palladium (Pd) sites were created on the fiber surface using palladium chloride (PdCl2).

- Metallization: The activated fibers were immersed in a solution containing copper sulfate (CuSO4) to deposit a uniform copper layer. Process parameters like pH, temperature, and time were carefully controlled (Table 2).

- Squeeze Casting: Composites were prepared by squeeze casting. The process involved preheating a die to 300-400°C, pouring the molten metal-fiber mixture, and applying 20-30 MPa of pressure during solidification to ensure full infiltration and minimal porosity.

- Characterization: Mechanical properties were tested using a Shimuzu universal testing machine per ASTM E8-82. Microstructures and fracture surfaces were analyzed using optical microscopy and Scanning Electron Microscopy (SEM).

6. Key Results:

Key Results:

- A uniform and continuous copper coating was successfully applied to over 90% of the chopped basalt fibers using the electroless technique (Fig. 1).

- The copper coating significantly improved the distribution of fibers within the aluminum matrix. Coated fibers were uniformly distributed up to 7.5 wt.%, whereas uncoated fibers showed heterogeneous distribution and were pushed away by the solidification front (Fig. 3, Fig. 4).

- The Young's modulus of the composite with coated fibers showed an improvement of 13.26% as fiber content increased from 2.5 to 10 wt.% (Fig. 5a).

- The Ultimate Tensile Strength (UTS) increased markedly, with an improvement ranging from 15.5% to 28.7% as the coated fiber content was increased from 2.5 to 10 wt.% (Fig. 5b).

- Ductility decreased significantly with increasing fiber content, showing a decrease of about 35.9% for the coated fiber MMCs compared to uncoated ones (Fig. 5c).

- Fracture analysis showed good wetting and strong bonding, with a lack of significant fiber pull-out, indicating that failure occurred primarily within the matrix or at the fiber itself, not at the interface (Fig. 6).

Figure Name List:

- Fig. 1 - Photographs of (a) un-coated basalt fibers and (b) coated basalt fibers.

- Fig. 1 (c) SEM Micrographs of coated basalt fibers

- Fig. 1 (d) SEM Micrographs of coated basalt fibers

- Fig. 1 (e) SEM Micrographs of coated basalt fibers

- Fig. 1 (f) SEM Micrographs of coated basalt fibers

- Fig. 3 Microstructure of the Al/10 % basalt short fiber MMCs uncoated (a) and coated (b) conditions.

- Fig. 4 - Optical micrographs of copper-coated basalt fiber reinforced composites. (a) 2.5 wt%, (b) 5 wt%, (c) 7.5 wt% and (d) 10 wt% fiber reinforcements.

- Fig. 5 Effect of Cu coating on basalt short fiber reinforced Al MMCs a. Young's modulus, b) UTS and c) Ductility

- Figure 6 (a) Fractrographs of the tensile specimen shows (a) fractured short Basalt fibers and (b) fiber pullout from the

- Figure 6 (b) Fractographs of the tensile specimen unreinforced shows uneven distribution of the large dimples

7. Conclusion:

- A fairly uniform and continuous coating of copper on short basalt fibers can be prepared successfully by electroless technique. Around 95% of the fiber had a continuous coating with a fine crystallite-type deposition of copper was found over continuously coated copper.

- The low wettability of high modulus basalt fibers by molten aluminium has a marked effect on the subsequent final solidification of the composite, determining not only heterogeneous distribution of the short basalt fibers in the aluminium matrix but also favouring the microsegregation of alloying elements (i.e. magnesium) in the matrix/fiber interfaces.

- The copper-coated fibers, up to 7.5 wt%, are uniformly distributed in the matrix with little agglomeration.

- The tensile strength increases with increase in Cu coated reinforcement content, an increase in UTS from 15.5 to 28.7% was observed.

- The Young's modulus and UTS of the composite material increases with increase in fiber wt %, an improvement in Young's modulus of 13.26% has been observed.

- The ductility of the MMC decreases gradually with increase in fiber wt %.

8. References:

- T.P.D. Rajan, R.M. Pillai, B.C. Pai, J. Review Reinforcement coatings and interfaces

in aluminium metal matrix composites, Mater. Sci.33 (1998) 3491-3501 - Delannay, F., Froyen, L., Deruyttere, A., 1987. Review: The wetting of solids by

molten metals and its relation to the preparation of metal-matrix composites. J. Mater.

Sci. 22, 1–16. - Baker, A.A., Shipman, C., Jackson, P.W., 1972. Short-term compatibility of carbon

fibres with aluminium. Fibre Sci. Technol. 5, 213–218. - A.M Davidson, D.Regener , A Comparison of Aluminium-Based Metal Matrix

Composites Reinforced With Coated and Uncoated Particlulate Silicon Carbide,

Composite Science And Technology Vol.107(6),2000, pp 865-869 - G.O. Mallory, J.B. Hadju, Electroless plating: fundamentals and applications, AESF,

Orlando, 1991. - F. Dalannay, L. Froyen and A. Deruythere J. Material Science, 22 (1987) 1.

- Baker, A.A., Shipman, C., Jackson, P.W., 1972. Short-term compatibility of carbon

fibres with aluminium. Fibre Sci.Technol. 5, 213–218. - Baker, S.J., Bonfield, W., 1978. Fracture of aluminium-coated carbon fibres. J. Mater.

Sci. 13, 1329–1334. - Abraham, S., Pai, B.C., Satyanarayana, K.G., Vaidyan, V.K., 1992.Copper coating on

carbon fibres and their composites with aluminium matrix. J. Mater. Sci. 27,3479–

3486. - Sukumaran, K., Pillai, S.G.K., Pillai, R.M., Kelukutty, V.S., Pai, B.C., 1995. The

effects of magnesium additions on the structure and properties of Al-7 Si-10 SiC

particle composites. J. Mater.Sci. 30, 1469–1472.

Expert Q&A: Your Top Questions Answered

Q1: What was the primary reason for the significant increase in UTS for the copper-coated fiber composites?

A1: The primary reason was the enhanced interfacial bonding between the fiber and the aluminum matrix, facilitated by the copper coating. This strong bond allows for efficient load transfer from the softer aluminum matrix to the much stronger basalt fibers. The paper also notes that matrix strengthening due to a reduction in alloy grain size and an increase in dislocation density contributed to the overall increase in UTS, as shown in Figure 5(b).

Q2: The paper mentions a decrease in ductility. Why does this happen, and what is the practical implication for engineers?

A2: The decrease in ductility, shown in Figure 5(c), is a common trade-off when reinforcing a metal matrix. The hard, brittle ceramic fibers act as stress concentration points and limit the plastic flow of the surrounding aluminum matrix. The paper suggests this behavior is likely due to voids that nucleate during plastic strain at the reinforcement interface. For engineers, this means that while these composites are stronger and stiffer, they are less forgiving and will fracture with less warning, a critical factor for designing components subjected to impact or overload conditions.

Q3: How does the copper coating actually improve wettability during the casting process?

A3: The copper coating transforms the non-metallic, chemically inert surface of the basalt fiber into a metallic one. Molten aluminum has much better wettability with metallic copper than with basalt. As stated in the introduction, this prevents the repulsion between the negative electrons of the reinforcement and the negative oxygen anion monolayer on the aluminum surface. During casting, the copper layer readily interacts with the molten aluminum, allowing the liquid metal to flow around and bond intimately with each fiber.

Q4: The study used squeeze casting. How might these findings translate to traditional High-Pressure Die Casting (HPDC)?

A4: Squeeze casting and HPDC are both high-pressure processes, so the findings are highly relevant. The core benefit—improved wettability from the copper coating—would likely translate directly to HPDC, helping to prevent fiber segregation during the rapid injection and solidification phases. This could enable the successful casting of more complex reinforced components via HPDC. However, the high shear forces in HPDC might pose a risk to the integrity of the coating or the fibers themselves, which would require further investigation.

Q5: What was the optimal weight percentage of basalt fiber according to the study's results?

A5: The study suggests that 7.5 wt.% is an optimal balance. The microstructures in Figure 4 show that up to 7.5 wt.%, the coated fibers remain uniformly distributed. Beyond this point, at 10 wt.%, the paper notes that the uniformity of distribution slightly decreases, and agglomeration begins to occur, along with the presence of voids. While mechanical properties continued to increase up to 10 wt.%, the onset of these microstructural defects at higher percentages could lead to less reliable performance.

Q6: The paper mentions avoiding dendritic growth of the copper coating. Why is this important for the coating's effectiveness?

A6: Dendritic growth refers to the formation of tree-like, irregular crystal structures in the coating, which is promoted by higher temperatures (above 45°C) as mentioned in Section 3.1. A smooth, continuous, and homogeneous coating is essential for ensuring consistent wetting and bonding with the aluminum matrix. A dendritic, uneven coating would create stress concentration points, potential voids, and an inconsistent interface, which would compromise the mechanical properties of the final composite.

Conclusion & Next Steps

This research effectively demonstrates that the primary obstacle to creating high-performance Aluminum Metal Matrix Composites—poor interfacial bonding—can be overcome through intelligent surface engineering of the reinforcement. By applying a simple electroless copper coating to basalt fibers, the study achieved significant gains in strength and stiffness, paving the way for more reliable and robust lightweight components. The trade-off in ductility is a critical design parameter, but for applications where stiffness and ultimate strength are paramount, this method holds immense promise.

At CASTMAN, we are committed to applying the latest industry research to help customers achieve higher productivity and quality. If the issues discussed in this paper align with your operational goals, contact our engineering team to explore how we can implement these principles in your HPDC components.

Copyright

- This material is a paper by "S. Ezhil Vannan, S. Paul Vizhian". Based on "Development And Characterization Of Copper-Coated Basalt Fiber Reinforced Aluminium Alloy Composites".

- Source: https://core.ac.uk/display/11699054

- Copyright © 2025 CASTMAN. All rights reserved.