Boost Casting Quality: A Simulation-Driven Guide to Casting Process Optimization

This technical summary is based on the academic paper "Thermal-Induced Defects and Optimization of Casting Process" by S. Sulaiman, M. Aljermi, M. I. S. Ismail and M.F. Fadzil, published in International Journal of Mechanical Engineering and Robotics Research (2019).

Keywords

- Primary Keyword: Casting Process Optimization

- Secondary Keywords: Casting Defect, Casting Simulation, Thermal Defect, Flow Analysis, Porosity, Shrinkage

Executive Summary

- The Challenge: The casting process is frequently plagued by thermal-induced defects like porosity and shrinkage, which degrade product quality and operational performance.

- The Method: Researchers employed computer-aided simulation to analyze and optimize the casting of a standard Globe Valve, systematically testing variables such as melt temperature, gate design, and material type.

- The Key Breakthrough: The study revealed that modifying the gating system (Case07) and changing the casting material (Case06) were the most effective strategies for simultaneously reducing production time and minimizing defects.

- The Bottom Line: Simulation-driven optimization of casting parameters is a powerful and cost-effective method for mitigating thermal defects, enhancing final product quality, and improving manufacturing efficiency.

The Challenge: Why This Research Matters for HPDC Professionals

In the foundry industry, particularly in automotive and heavy industries, producing high-quality cast parts in mass quantities is paramount. However, the very nature of pouring liquid metal into molds introduces a persistent problem: thermal defects. As described in the paper, factors related to temperature and material flow are the primary cause of flaws like porosity and shrinkage.

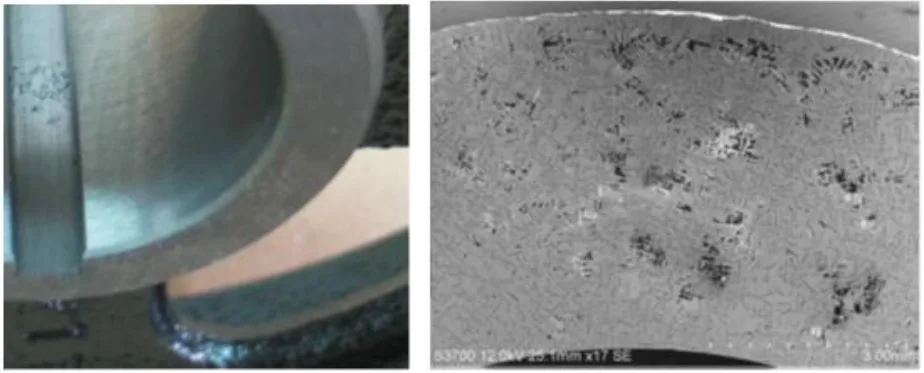

Porosity, caused by trapped gases (as shown in Fig. 1), and shrinkage, a volume change that occurs as metal solidifies (Fig. 2), can create voids and cavities. These defects are not merely cosmetic; they are major quality issues that can lead to a significant drop in product performance and reliability during operation. For engineers and toolmakers, predicting and compensating for these thermal variations is a critical but challenging aspect of quality control, making this research into simulation-based solutions highly relevant.

The Approach: Unpacking the Methodology

The research team conducted a systematic study to analyze and reduce thermal-based defects using advanced simulation technologies.

Method 1: Model Development and Simulation Setup

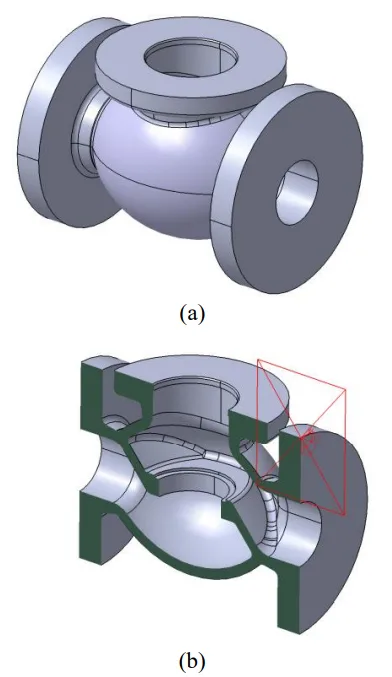

The researchers began with a standard geometrical model of a Globe Valve (JIS 10K-50), preparing it for analysis using CATIA V5 CAD software. This involved simplifying the model by removing non-essential features like engravings and mounting holes to focus on the casting process itself. The baseline analysis used Cast Iron GGG-50 as the melt material, with a Green Sand mold.

Method 2: Process Analysis and Optimization

Using casting simulation software (Click2Cast), the team established a benchmark process. They then ran a series of seven distinct optimization studies, each modifying a single key parameter to isolate its effect on the final casting. The parameters adjusted included:

- Melt temperature

- Mold temperature

- Ingate shape and size

- Melt flow velocity

- Casting material

- Number of ingates

The simulation recorded critical data for each case, including mold filling time, solidification time, temperature distribution, and the resulting volume and percentage of porosity.

The Breakthrough: Key Findings & Data

The simulation results provided clear, quantitative data on how each parameter change impacted casting quality. The most significant findings demonstrate that not all optimization strategies are equal.

Finding 1: Adjusting Gating System Delivers the Best Defect Reduction

The most effective optimization was achieved in Case07, where the number of ingates was modified. As shown in Table I, this single change produced a dramatic improvement across multiple metrics compared to the benchmark.

- Melt Fill Time was reduced by 45%, from 0.3855 s to just 0.2118 s.

- Melt Solidify Time decreased by 24%, from 82.07 s to 61.97 s.

- Most importantly, Porosity Percentage dropped from 1.87% to 1.63%, representing the lowest defect rate among all tested cases.

Finding 2: Some Optimizations Offer Trade-offs, Not Universal Improvements

The study also revealed that certain adjustments can create a trade-off between speed and quality. For example, in Case01-1, lowering the melt temperature increased the porosity percentage to 2.41% (the highest of any case), even though it reduced solidification time. This highlights the critical need for simulation to find the "sweet spot" rather than relying on intuition. As the authors note, "The results are varied with improvement in one area, but might worsen in another area."

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the gating system (specifically the number of gates, as in Case07) and material selection (Case06) may contribute most effectively to reducing porosity and improving production cycle time.

- For Quality Control Teams: The data in Figure 8 of the paper, which visualizes shrinkage porosity volume, illustrates how simulation can predict the location and severity of defects. This can inform new, more targeted quality inspection criteria for high-risk areas.

- For Design Engineers: The findings indicate that gating strategy is not just a manufacturing concern but a critical design consideration. The number and location of ingates significantly influence defect formation, suggesting this should be evaluated early in the component design phase.

Paper Details

Thermal-Induced Defects and Optimization of Casting Process

1. Overview:

- Title: Thermal-Induced Defects and Optimization of Casting Process

- Author: S. Sulaiman, M. Aljermi, M. I. S. Ismail and M.F. Fadzil

- Year of publication: 2019

- Journal/academic society of publication: International Journal of Mechanical Engineering and Robotics Research Vol. 8, No. 6, November 2019

- Keywords: Casting, Casting defect, Casting simulation, Thermal and flow analysis, Casting optimization, Thermal defect.

2. Abstract:

A casting process in the general industry is prone to produce varied defective parts, which happens majorly due to the factor of thermal and flow. These factors can cause major quality problems and drop in product performance during operational condition if left untreated. Thus, this paper presents these type of problems encountered in casting by applying analytical technique to forecast the behaviors of inclusions in molten material in a mold, determining the effect of parameter and process change during pouring, and analyze the pattern and provide the best decision in regards to the process of manufacturing. The use of computer-aided tool, also known as Manufacturing Analysis (in this case, an analysis of solidification and fluidity of molten material) technologies, is developed and utilized to enable a study on reduction of thermal-based defects in manufacturing on a casting product. Assessment is made based on temperature distribution, filling and solidification time, and the presence of porosity in a sample product, while optimization is performed on the same product but with different process parameters such as gate size, location, melt temperature and such. The results are varied with improvement in one area, but might worsen in another area. Thus, the final outcome is discussed and measured for its feasibility and possibility for multiple improvement process to be integrated together.

3. Introduction:

The foundry industry, particularly in the automotive and heavy industry sectors, requires the mass production of high-quality cast parts. The casting process, while convenient, is susceptible to thermal defects induced by the manipulation of temperature and related thermal factors. These defects, such as porosity from trapped gas and shrinkage from volume changes during solidification, can lead to significant quality control issues and compromise product performance. To counter these challenges, foundries are increasingly integrating computer simulation with experience-based approaches. Simulation software provides capabilities for thermal and flow modeling, enabling the prediction of grain structure, porosity, hot tearing, and other phenomena, thereby helping to optimize the mold design and process parameters in a cost-effective manner.

4. Summary of the study:

Background of the research topic:

The research addresses the persistent issue of thermal-induced defects, such as porosity and shrinkage, in industrial casting processes. These defects compromise the quality and performance of cast components, necessitating effective methods for their prediction and reduction.

Status of previous research:

The paper acknowledges the established use of computer simulation tools by foundry engineers to bridge the gap between design and manufacturing. It notes that such software is available not only for thermal and flow modeling but also for predicting specific defects and material structures, representing a shift from purely experience-based approaches to more analytical, data-driven methods.

Purpose of the study:

The purpose of this study is to demonstrate the application of an analytical technique, specifically computer-aided manufacturing analysis, to forecast material behavior, assess the impact of process parameter changes, and ultimately optimize the casting process to reduce thermal-based defects.

Core study:

The core of the study is a simulation-based analysis of the casting process for a standard Globe Valve. A baseline model using Cast Iron GGG-50 was established. Subsequently, seven optimization cases were simulated, each varying a single process parameter: melt temperature, mold temperature, ingate shape, ingate size, melt flow velocity, material, and number of ingates. The performance of each case was evaluated by analyzing the resulting mold filling time, solidification time, and porosity levels to identify the most effective optimization strategy.

5. Research Methodology

Research Design:

The study employed an analytical, simulation-based research design. A benchmark case for casting a Globe Valve (JIS 10K-50) was established. This benchmark was then compared against seven distinct optimization scenarios where key manufacturing parameters were systematically altered. The outcomes were quantitatively assessed to determine the optimal process configuration for defect reduction.

Data Collection and Analysis Methods:

Data was generated and collected through computer-aided engineering tools. The valve model was created and modified using CATIA V5. The casting simulation for analyzing material flow and solidification was conducted using Click2Cast software. Performance analyses, including modal and pressure loading tests, were performed using Hypermesh for pre-processing, OptiStruct and AcuSolve as solvers, and Hyperview for post-processing. The primary data points collected were melt fill time, melt solidification time, and porosity size and percentage.

Research Topics and Scope:

The research is focused on the reduction of thermal-induced defects in a casting process. The scope is confined to the simulation of a sand casting process for a single product, a Globe Valve, using Cast Iron GGG-50 as the primary material. The investigation is limited to the effects of varying seven specific process parameters on filling, solidification, and porosity.

6. Key Results:

Key Results:

- The study demonstrated that modifying process parameters yields varied outcomes. Some changes improved one metric (e.g., time) while worsening another (e.g., defects).

- Analysis of the seven optimization cases, summarized in Table I, identified Case06 (material change) and Case07 (change in the number of ingates) as the most optimal configurations, providing good quality casting products.

- Case07, specifically, resulted in the lowest porosity percentage (1.63%) and significantly reduced both melt fill time (0.2118 s) and solidification time (61.97 s) compared to the benchmark (1.87%, 0.3855 s, and 82.07 s, respectively).

- The results suggest that combining optimal strategies, such as adding another gating system, could lead to further improvements in production time and defect reduction.

Figure Name List:

- Figure 1. Example of defect by porosity

- Figure 2. Example of defect by shrinkage

- Figure 3. Globe Valve 20 JIS 10K-50

- Figure 4. Modified CAD data of Valve for Manufacturing Analysis

- Figure 5. DOF's for normal mode and pressure loading

- Figure 6. Total Time for Mold Filling

- Figure 7. Final Temperature of Melt Solidification

- Figure 8. Porosity Volume at Final Time of Solidification

7. Conclusion:

It can be observed that casting products are still being applied in all major industries worldwide. Thus, it is essential to get along with the latest adaptation of technology for best and optimum product manufacturing. By this method, material flow in casting can be optimized in terms of filling, solidification time and defect detection. This optimization can be done by modifying and adjusting process parameters and dimensional configuration (such as gate sizing). Thus, the best and most efficient process can be utilized to reduce defects to an acceptable margin. The findings from this research showed that Casting Case06 and Casting Case07 were considered having optimum parameters with good quality product. The benefits obtained can be helpful in reducing material, cost, lead time and defect detection/reduction.

8. References:

- [1] S. S. Shipp, B. Lal, J. A. Scott, C. L. Weber, M. S. Finin, M. Blake, S. Newsome, and S. Thomas, Emerging Global Trends in Advanced Manufacturing. Virginia: Institute for Defense Analyses, 2012.

- [2] C. J. Davey, "the early history of lost wax casting. metallurgy and civilization," J. Mei and Th. Rehren eds. Archetype, London, 2009: pp. 147-154, 2009.

- [3] A. P. More, R. N. Baxi, and S. B. Jaju, "Review of casting defect analysis to initiate the improvement process," Mechanical Engineering Department, G. H. Raisoni College of Engineering, Nagpur, 2011.

- [4] H. C. Pandit and S. M. Ingale, "Casting optimization aided by simulation," International Conference on Sunrise Technologies, 13th-15th Jan 2011, pp. 4-7, 2011.

- [5] S. D. Lockhart and C. Johnson, Engineering Design Communication: Reading, MA: Addison-Wesley, 1996.

- [6] C. Merrill, R. Custer, J. Daugherty, M. Westrick, and Y. Zeng, "Delivering core engineering concepts to secondary level students," Presented at The American Society for Engineering Education, Honolulu, HI, 2007.

- [7] U. A. Dabade and R. C. Bhedasgaonkar, "Casting defect analysis using Design of Experiments (DoE) and computer aided casting simulation technique,” Procedia CIRP 7, 616-621, 2013.

Expert Q&A: Your Top Questions Answered

Q1: Why was a Globe Valve chosen as the sample product for this study?

A1: The paper states that a standard geometrical model of a Globe Valve, obtained from JIS Standard data of 10K-50, was used. It was selected to serve as a benchmark model, allowing the researchers to check its design integrity and provide a consistent basis for comparing the various optimization scenarios.

Q2: What specific simulation software was used for the analysis?

A2: The study utilized a suite of computer-aided tools. The CAD model was developed in CATIA V5. For the core casting simulation, the paper specifies that the model was exported for pre-processing activity in Click2Cast casting simulation software. For subsequent performance analysis, Hypermesh v14.0 was used for pre-processing, OptiStruct v14.0 and AcuSolve 14.0 were used as solvers, and Hyperview v14.0 was used for post-processing.

Q3: The study tested seven different optimization cases. Which one yielded the most significant improvement?

A3: According to the results in Table I and the paper's conclusion, Case07, which involved changing the number of ingates, was one of the two "optimum sample" cases. It delivered the lowest porosity percentage (1.63%) while also significantly reducing both the melt fill time and solidification time, making it a highly effective and well-rounded improvement over the benchmark.

Q4: Did every parameter change result in a better product?

A4: No, the research explicitly states that the results were varied. Some proposed cases did not yield the best output. For example, the paper mentions that adjusting melt temperature (Case01) could lead to an improvement in one area (like time) but a worsening in another (like defect percentage), and vice versa. This highlights the complexity of the process and the value of simulation in navigating these trade-offs.

Q5: What were the baseline process parameters for the benchmark analysis?

A5: The baseline, or initial, process parameters were clearly defined. The simulation used Cast Iron GGG-50 as the melt material at a temperature of 1580°C. The mold was defined as Green Sand with a temperature of 20°C. The gating system consisted of two 20x20 gates, with gravity set in the Y-direction and an ingate velocity of 5.0 m/s.

Q6: What is the significance of shrinkage in the casting process as described in the paper?

A6: The paper defines shrinkage as a change in the volume of material that occurs when molten metal solidifies. This is a significant issue because most metals, including aluminum, copper, and steel, shrink during this phase change. This phenomenon can lead to the formation of voids and cavities within the cast part if there is not enough molten metal available to "feed" the shrinkage as it occurs, compromising the part's structural integrity.

Conclusion: Paving the Way for Higher Quality and Productivity

Thermal-induced defects like porosity and shrinkage remain a critical challenge in the casting industry. This research demonstrates that a systematic, simulation-driven approach to Casting Process Optimization can effectively identify the root causes of these flaws and provide clear, data-backed solutions. By analyzing variables like gating design and material selection, manufacturers can move beyond trial-and-error and implement the most efficient processes to reduce defects to an acceptable margin.

The key takeaway is that technology is a powerful ally in achieving higher quality. The findings show that targeted adjustments, validated through simulation, can lead to significant reductions in material waste, cost, and lead time, paving the way for more robust and reliable components.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Thermal-Induced Defects and Optimization of Casting Process" by "S. Sulaiman, M. Aljermi, M. I. S. Ismail and M.F. Fadzil".

Source: https://doi.org/10.18178/ijmerr.8.6.900-904

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.