Beyond Trial and Error: A New Model for Aluminum Casting Process Optimization

This technical summary is based on the academic paper "Theoretical Analysis of Liquid Aluminum Flow in Aluminum Casting Processes" by Taiwo Alare and Feranmi J Adeloye, published in PriMera Scientific Engineering (2023).

Keywords

- Primary Keyword: Aluminum Casting Process Optimization

- Secondary Keywords: Liquid aluminum flow, aluminum cast strength, fluid mechanics in casting, Navier-Stokes casting model, shear stress prediction, mold flow analysis

Executive Summary

- The Challenge: Inaccurately predicting the final strength of an aluminum cast during the design phase can lead to unexpected component failure in critical applications.

- The Method: Researchers developed a theoretical model using the Navier-Stokes momentum equation to analyze the flow profile of liquid aluminum within the mold.

- The Key Breakthrough: The model establishes a direct mathematical link between the fluid dynamics of the casting process and the final mechanical properties, allowing for the predetermination of cast strength.

- The Bottom Line: This predictive model provides a powerful tool to optimize casting parameters at the design stage, ultimately reducing waste, cutting costs, and improving component reliability.

The Challenge: Why This Research Matters for HPDC Professionals

In high-stakes industries like aerospace and automotive, component failure is not an option. Every cast aluminum part, from an aircraft door to an engine block, must possess the exact required strength. However, traditional casting methods often rely on post-production testing to verify strength, a reactive approach that can lead to costly scrap and production delays.

The core problem has always been the inability to accurately predetermine a cast's final mechanical properties during the design phase. Factors like slag formation, dimensional inaccuracies, and the complex behavior of molten metal as it fills the mold cavity create uncertainty. This research tackles this challenge head-on by asking a fundamental question: Can we understand the flow of liquid aluminum so precisely that we can predict the final strength of the solidified part before we even pour the metal?

The Approach: Unpacking the Methodology

To build a predictive model, the researchers turned to the principles of fluid mechanics, treating the flow of liquid aluminum as a solvable engineering problem. The study is a theoretical analysis grounded in established physical laws.

Method 1: The foundation of the model is the Navier-Stokes momentum equation, a cornerstone of fluid dynamics. The researchers applied this equation to model the flow of liquid aluminum through the mold runner and into the cavity. To make the complex problem solvable, they established several key assumptions:

- The flow is unidirectional and laminar/viscous, representing a controlled injection process.

- The process is at a steady state.

- A no-slip wall boundary condition is applied, meaning the liquid aluminum's velocity at the mold surface is zero.

- The liquid aluminum is at its melting point temperature of 660°C.

Method 2: The model incorporates specific thermophysical properties of aluminum sourced from existing literature, including a density (ρ) of 2.7 x 10³ Kg/m³, viscosity (μ) of 1.3452 mPa.s, and surface tension (γ) of 875 mN m⁻¹. The pressure gradient, a critical driver of flow, was determined using LaPlace's law, which links surface tension to pressure. By integrating these real-world material properties, the theoretical model gains practical relevance.

The Breakthrough: Key Findings & Data

The study successfully translated complex fluid dynamics theory into tangible, predictive equations that link process variables to final material properties.

Finding 1: A Predictive Equation for Maximum Shear Stress

The most significant outcome is a model that predicts the shear stress of the casting, which is assumed to be the strength of the cast material after solidification. By analyzing the velocity profile of the liquid aluminum, the researchers determined that the maximum shear stress occurs at the mold wall (where δ = R/2 = r). This stress can be predetermined with the following equation:

τ = 304.32D N/m²

This provides a direct, quantifiable prediction of the cast's strength based on the geometry (D) of the mold cavity area.

Finding 2: Quantifying Mass and Volumetric Flowrate

The model also yielded equations to calculate the mass flowrate (ṁ) and volumetric flowrate (Q) of the liquid aluminum. These are critical for process control and ensuring complete mold filling. The relationships are given by:

- ṁ = 305336.7vD Kgs⁻¹

- Q = 0.32523v m³ s⁻¹

Where 'v' is the volume of the mold cavity and 'D' relates to the mold cavity area. These equations allow engineers to precisely calculate the required flow based on the part's design.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the pressure gradient and runner geometry (which influences the flow velocity, Uₓ) can be used to control the shear stress and, therefore, the final strength of the component.

- For Quality Control Teams: The data and equations in the paper provide a theoretical benchmark for cast strength. This can inform new quality inspection criteria, moving beyond simple dimensional checks to a more physics-based assessment.

- For Design Engineers: The findings indicate that the mold cavity's design (specifically its radius and area) directly influences the flow profile and resulting shear stress. This model provides a tool for optimizing part and mold design for strength in the earliest stages of development.

Paper Details

Theoretical Analysis of Liquid Aluminum Flow in Aluminum Casting Processes

1. Overview:

- Title: Theoretical Analysis of Liquid Aluminum Flow in Aluminum Casting Processes

- Author: Taiwo Alare and Feranmi J Adeloye

- Year of publication: 2023

- Journal/academic society of publication: PriMera Scientific Engineering, Volume 3 Issue 2

- Keywords: Strength of cast; Aluminum casting; Fluid mechanics; Flow properties

2. Abstract:

Aluminum casting is a manufacturing process that has been around for some time. This method has been used in making many aluminum products used as parts of aircraft, automobiles, turbines, and structures like bridges. Every cast product is expected to be of the desired and required strength so it will not fail on application. It is good to predetermine the strength of aluminum cast accurately at the design stage before casting. Therefore, we developed a model that can predict the aluminum cast's strength and other mechanical properties by studying the flow profile of liquid aluminum flowing through the mold.

3. Introduction:

Metal casting is a manufacturing process where liquid metal is poured into a mold containing a hollow cavity of the desired shape and then allowed to solidify. The technology has been applied in manufacturing and artwork for approximately 7000 years. The process involves mold cavity making, metal liquefaction, injection, solidification, and product finishing. Casting is suitable for manufacturing products with complex geometries or from materials with low ductility. However, limitations exist, including dimensional inaccuracy and rough surface finish in processes like sand casting, as well as wastage due to slag formation. The study of the molten metal flow in the mold cavity can help solve these limitations. This paper focuses on aluminum, the second most abundant metallic element, which is widely used in aircraft and gas turbine manufacturing. The research aims to study the flow characteristics of liquid aluminum to determine its effect on the strength of the cast part by using Navier-Stokes equations to model the velocity profile.

4. Summary of the study:

Background of the research topic:

Metal casting is a fundamental and long-standing manufacturing technique used for producing complex metal parts. Aluminum casting is particularly significant due to the metal's widespread use in critical industries like aerospace and automotive. A primary challenge in casting is ensuring the final product meets required strength specifications to prevent failure in application.

Status of previous research:

The study builds upon foundational concepts in manufacturing and fluid mechanics. It references existing literature for general metal casting processes [1-4], the physical and chemical properties of aluminum [5-7], principles of viscous fluid flow modeling [8], and specific thermophysical data for liquid aluminum, such as viscosity and surface tension at its melting point [9-11]. The novelty lies in the specific application of these principles to create a predictive model for aluminum cast strength.

Purpose of the study:

The primary purpose is to develop a theoretical model capable of predicting the strength and other mechanical properties of an aluminum cast. This is achieved by analyzing the flow profile of liquid aluminum as it moves through the mold. The ultimate goal is to enable the accurate predetermination of cast strength during the design stage, before the physical casting process begins.

Core study:

The core of the study is the theoretical analysis of liquid aluminum flow within a casting mold. The researchers modeled the flow as unidirectional, laminar, and at a steady state. Using the Navier-Stokes momentum equation and applying a no-slip boundary condition at the mold walls, they derived a second-degree polynomial velocity profile. This profile was then used to derive equations for shear stress (assumed to be indicative of final cast strength), mass flowrate, and volumetric flowrate, incorporating known physical properties of liquid aluminum.

5. Research Methodology

Research Design:

The research employs a theoretical and analytical design. It is based on the mathematical modeling of a physical process rather than empirical experimentation.

Data Collection and Analysis Methods:

The study utilizes data for the physical properties of liquid aluminum (density, viscosity, surface tension) from previously published scientific literature [9, 10, 11]. The analysis method involves the application of fundamental fluid dynamics equations, specifically the Navier-Stokes momentum equation and LaPlace's law for pressure gradient. The process involves mathematical derivation to establish relationships between flow parameters and material properties.

Research Topics and Scope:

The research topic is the fluid mechanics of liquid aluminum within a casting mold. The scope is confined to a theoretical model under several key assumptions: the flow is unidirectional, laminar, and steady-state; the mold cavity is geometrically simplified (flat, uniform radius); and the temperature of the liquid aluminum is constant at its melting point (660°C).

6. Key Results:

Key Results:

The study produced a set of predictive equations based on the theoretical model:

- An equation for the mass flowrate of liquid aluminum: ṁ = 305336.7vD Kgs⁻¹

- An equation for the volumetric flowrate: Q = 0.32523v m³ s⁻¹

- An equation for the maximum shear stress at the mold wall, which is correlated with the final cast strength: τ = 304.32D N/m²

Figure Name List:

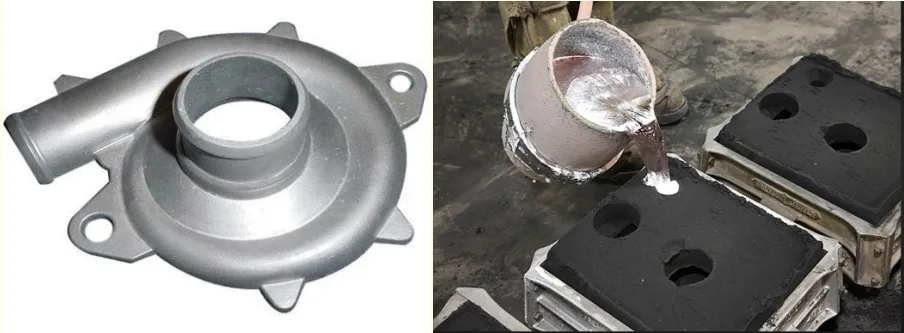

- Figure 1.0: Aluminum cast centrifugal pump casing.

- Figure 1.1: Aluminum casting process.

7. Conclusion:

The paper shows that the shear stress and strength of aluminum cast can be predetermined before casting.

8. References:

- Dewi Suriyani Che Halin. Metal Processing. Presentation. (13) (PDF) Lecture 2- Metal Processing (2018).

- Guides to Industrial Art. Metal Casting 101: Learn to Cast Metal [Types & Processes].

- Manufacturing Technology-1 Note by R. Ganesh Narayanan. Metal casting processes.

- E Abbilash, B Ravi and SS joshi. "Opportunities in Aerospace Casting Manufacte". 26th Indian Engineering Congress (2011).

- Sayed M Amer. Aluminum and Its Alloy (2022).

- M Thiugnanam. "Modern High Pressure Die-Casting Processes for Aluminum Casting". 61st Indian Foundry Congress (2013).

- Aluminium - Wikipedia.

- Frank M White. Viscous Fluid Flow. Mc Graw Hill Companies. 3rd ed (2006).

- MJ Assael., et al. J. Phys. Chem. Ref. Data 35.1 (2006): 285-300.

- Matthias Leitner., et al. "Thermophysical Properties of Liquid Aluminum". Metallurgical and Materials Transactions. Cross Mark 48A (2017): 3036-3045.

- Ron Cobden Alcan and Banbury. Aluminum: Physical Properties, Characteristics and Alloys. TALAT Lecture 1501. EAA (1994).

Expert Q&A: Your Top Questions Answered

Q1: Why was a unidirectional laminar flow assumed for this model, when real-world mold filling can be turbulent?

A1: The assumption of unidirectional laminar/viscous flow is a standard approach in initial fluid dynamics modeling to make the highly complex Navier-Stokes equations solvable. This creates a foundational model for an idealized, controlled casting process. While real-world filling can have turbulent phases, this model provides a crucial baseline for understanding the fundamental relationship between flow and strength, upon which more complex turbulent models can be built.

Q2: What is the significance of the "no-slip wall boundary condition" in this context?

A2: The no-slip condition is a fundamental principle in fluid mechanics stating that the velocity of a fluid at a solid boundary (the mold wall) is zero. This is critical for the model because it anchors the velocity profile. The velocity is zero at the walls and maximum at the center of the flow, creating a gradient that directly determines the shear stress, which the paper links to the final cast strength.

Q3: How does the model specifically incorporate the properties of liquid aluminum?

A3: The model is tailored to aluminum by using specific, experimentally determined thermophysical property values from existing literature. Key values include the viscosity of liquid aluminum at its melting point (μ = 1.3452 mPa.s), its density (ρ = 2.7 × 10³ Kg/m³), and its surface tension (γ = 875 mN m⁻¹). Using these specific values allows the general fluid dynamics equations to yield results that are predictive for aluminum casting.

Q4: The paper uses LaPlace's law to determine the pressure gradient. What role does this play?

A4: In the model, the pressure gradient (dp/dx) is the driving force that pushes the liquid aluminum into the mold. LaPlace's law provides a way to calculate this pressure based on the surface tension of the liquid metal and the geometry of the runner/ingate (rin). It effectively connects a material property (surface tension) to a critical process variable (pressure), making the flow model more physically accurate.

Q5: What is the practical meaning of the final shear stress equation, τ = 304.32D N/m²?

A5: This equation is the key practical output of the model. It provides a direct, quantifiable prediction of the maximum stress the material will experience at the mold wall during filling. The paper posits that this shear stress is directly related to the final strength of the solidified cast. Therefore, a design engineer can use the mold's geometry (represented by D) to calculate a predicted strength value before any metal is poured, enabling design optimization for mechanical performance.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of ensuring component strength in aluminum casting has long been a barrier to achieving perfect first-time quality. This research demonstrates a powerful theoretical framework for overcoming that barrier. By modeling liquid aluminum flow, the study provides a method for predicting final cast strength during the design phase, marking a significant step forward in Aluminum Casting Process Optimization. This shift from a reactive, test-based approach to a predictive, physics-based one empowers engineers to design better parts and more efficient processes from the outset.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Theoretical Analysis of Liquid Aluminum Flow in Aluminum Casting Processes" by "Taiwo Alare and Feranmi J Adeloye".

Source: https://primerascientific.com/psen (Based on the footer of the document)

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.