This technical summary is based on the academic paper "The Influence of Cr content on the Fe-rich phase Formation and Impact toughness of a Die-cast AlSi9Cu3(Fe) alloy" published by G. Timelli, S. Ferraro, A. Fabrizi, S. Capuzzi, F. Bonollo, L. Capra, and G.F. Capra in the proceedings of the World Foundry Congress (2014). It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: HPDC sludge formation

- Secondary Keywords: AlSi9Cu3(Fe) alloy, A380, Chromium in aluminum alloys, Impact toughness, Intermetallic compounds, Fe-rich phases, HPDC mechanical properties

Executive Summary

- The Challenge: Balancing the benefits of adding chromium (Cr) to AlSi9Cu3(Fe) alloys against the risk of forming detrimental "sludge" particles that degrade impact toughness in HPDC components.

- The Method: Researchers systematically varied the Cr content from 0.057% to 0.153% in a die-cast AlSi9Cu3(Fe) alloy and measured the resulting changes in microstructure and impact toughness.

- The Key Breakthrough: The study identified a clear performance threshold. Impact toughness remains stable up to 0.12 wt.% Cr. However, a further increase to 0.15 wt.% causes a sharp drop in toughness and maximum load by over 9%.

- The Bottom Line: For high-toughness applications using AlSi9Cu3(Fe) alloy (A380 equivalent), maintaining Cr content below the 0.12 wt.% threshold is critical to prevent a significant and sudden loss of mechanical performance.

The Challenge: Why This Research Matters for HPDC Professionals

For decades, engineers have added chromium (Cr) to Al-Si foundry alloys to enhance high-temperature strength and beneficially modify Fe-containing phases. However, Cr has a significant downside: it is the most potent element in the formation of primary intermetallic crystals known as "sludge." This is a well-known issue in the HPDC industry, where lower holding temperatures can often encourage sludge precipitation.

These hard sludge particles, enriched in Iron (Fe), Manganese (Mn), and Chromium (Cr), are denser than the molten aluminum and can segregate in furnaces or within the mold. Their presence not only alters the melt's chemical composition but can also increase the tendency for die-soldering and, most importantly, adversely affect the ductility and toughness of the final casting.

While the "Sludge Factor" formula (SF=(1·wt.%Fe)+(2·wt.%Mn)+(3·wt.%Cr)) has served as a guide, there has been a lack of specific data detailing the direct effect of varying Cr content on the fracture toughness of die-cast Al-Si alloys. This research fills that critical knowledge gap, providing a clear, data-driven understanding of the trade-offs involved.

The Approach: Unpacking the Methodology

To isolate the effect of chromium, the researchers conducted a controlled experiment:

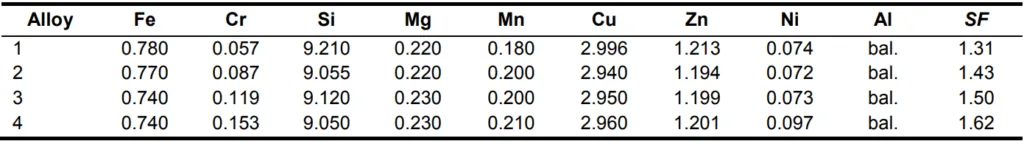

- Alloy Preparation: They started with a baseline secondary AlSi9Cu3(Fe) cast alloy (EN AB-46000, equivalent to A380). By adding a commercial Al-20Cr master alloy, they created four experimental alloys with Cr contents varying from 0.057 wt.% up to 0.153 wt.%.

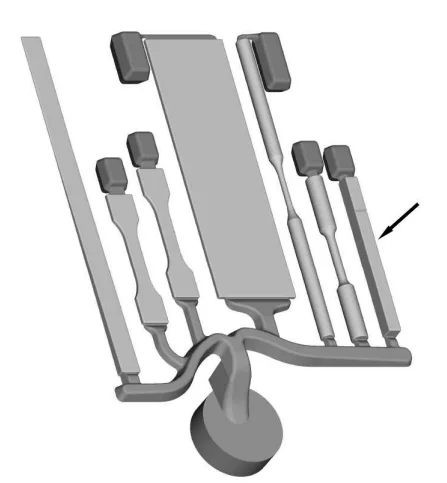

- Casting Process: The alloys were cast using a 2.9 MN locking force cold chamber HPDC machine to produce multicavity test specimens, ensuring the results were relevant to industrial production.

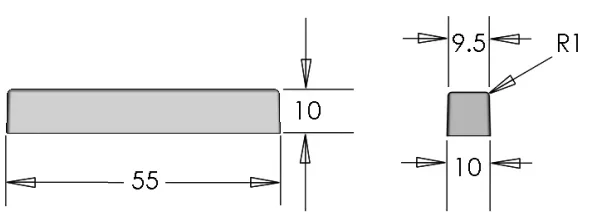

- Microstructural Analysis: The team used optical microscopy (OM) and a field emission gun scanning electron microscope (FEG-SEM) with energy-dispersive X-ray spectroscopy (EDX) to investigate and quantify the size, area fraction, and morphology of the Fe-bearing compounds.

- Mechanical Testing: Impact toughness was evaluated at room temperature using an instrumented gravity drop tower on un-notched specimens, according to the ASTM E2298-13a standard. This allowed for precise measurement of absorbed energy (Wt) and maximum load (Fm) during fracture.

The Breakthrough: Key Findings & Data

The investigation yielded several crucial insights into how chromium concentration directly impacts the alloy's microstructure and performance.

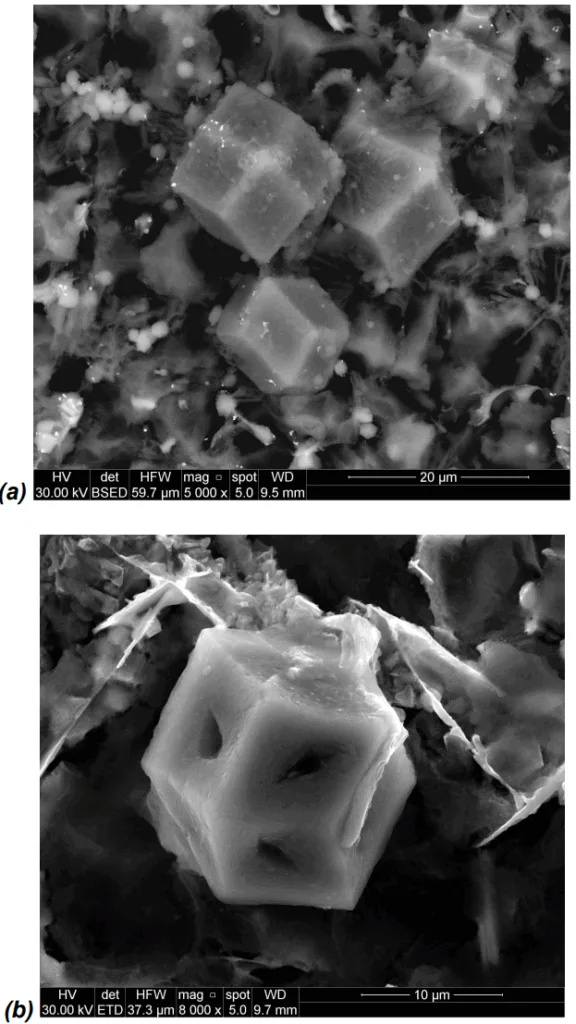

- Finding 1: Sludge Volume and Morphology Worsen with More Cr: As Cr content increases, the area fraction of primary α-Alx(Fe,Mn,Cr)ySiz intermetallic sludge particles increases. Critically, their shape degenerates from a relatively compact polyhedral form to more detrimental branched or star-like structures (Figure 6).

- Finding 2: Sludge Becomes the Dominant Defect: The research quantified this change. The proportion of Fe-rich particles classified as sludge (the f'/f ratio) more than doubled, increasing from 0.18 at 0.057% Cr to 0.38 at 0.153% Cr (Table 2). This shows that higher Cr levels make sludge the prevailing type of intermetallic.

- Finding 3: The Impact Toughness "Safe Zone": Up to a Cr content of 0.119 wt.%, the alloy's impact toughness (Wt) and maximum absorbed load (Fm) remained almost constant, averaging a robust 15.7 J and 9.3 kN, respectively. This range represents a stable operating window (Table 3, Figure 8).

- Finding 4: The Performance Cliff: A small increase in Cr content to 0.153 wt.% pushed the alloy past a tipping point. This resulted in a dramatic drop in performance, with impact toughness falling by 14.6% and maximum load decreasing by 9.5%. This demonstrates a clear and critical upper limit for chromium in toughness-critical applications.

Practical Implications for HPDC Products

This research provides actionable intelligence for improving product quality and process control in any HPDC operation working with A380-type alloys.

- For Process Engineers: The findings establish a clear, data-backed upper control limit for chromium. To ensure consistent impact performance and part reliability, Cr levels in the melt must be strictly monitored and maintained below 0.12 wt.%. This is especially important when using recycled aluminum, where tramp element concentrations like Cr can fluctuate.

- For Quality Control: The strong correlation between Cr content above 0.12 wt.% and a sharp drop in toughness (Table 3) makes chemical analysis a powerful predictive tool. A high chromium reading on a spectrometer can serve as a reliable early warning for potential part brittleness, preventing the casting and shipment of components that don't meet mechanical specifications.

- For Die Design and Alloy Specification: When specifying materials for components where toughness is a key requirement, engineers should explicitly define a maximum Cr content of ~0.12%. This study validates that Cr is the most influential element in the Sludge Factor equation and that controlling it is the most effective strategy for mitigating sludge-related failures.

Paper Details

The Influence of Cr content on the Fe-rich phase Formation and Impact toughness of a Die-cast AlSi9Cu3(Fe) alloy

1. Overview:

- Title: The Influence of Cr content on the Fe-rich phase Formation and Impact toughness of a Die-cast AlSi9Cu3(Fe) alloy

- Author: G. Timelli, S. Ferraro, A. Fabrizi, S. Capuzzi, F. Bonollo, L. Capra, G.F. Capra

- Year of publication: 2014

- Journal/academic society of publication: World Foundry Congress

- Keywords: Aluminium alloys; Chromium; Microstructure; Impact properties; High-pressure diecasting; Intermetallic compounds; Sludge.

2. Abstract:

The influence of chromium on the microstructure and impact toughness of high-pressure die-cast AlSi9Cu3(Fe) alloy was investigated systematically as the content of Cr was varied. The results indicate that, with the increase of Cr content, the area fraction of primary (sludge) and secondary (proeutectic) α-Alx(Fe,Mn,Cr)ySiz intermetallic compounds increase. Moreover, the sludge morphology evolves from polyhedral to branched or star-like shapes while the secondary Fe-rich particles seem to not be morphologically affected. The polyhedral sludge particles are associated to a regular rhombic dodecahedron, while the star-like and branched morphologies originate from hollowed rhombic dodecahedron. From the load-deflection curves, the impact toughness (Wt) and maximum load absorbed by the specimens (Fm) during impact testing were measured. The mechanical tests reveal that Wt and Fm values are almost constant up to 0.12wt.% Cr content achieving about 15.7 J and 9.3 kN, respectively, while a further addition of Cr ( 0.15 wt.%) leads a overall performance decrease higher than 9%.

3. Introduction:

It is well known that chromium can be added to Al-Si foundry alloys to enhance the high temperature strength of the materials by formation of intermetallic compounds with high thermal stability, such as a-AlCrSi, a-Al(Cr,Fe)Si, a-Al(Fe,Mn,Cr)Si phases 1,2. Moreover, small Cr addition can beneficially influence the morphology of the Fe-containing phases or enhance the precipitation of compounds less harmful than ß-Al5FeSi phase, i.e. with a Chinese script or polyhedral morphology 3,4. Generally, a Fe:Cr ratio of 3 is required in order to promote the formation of a Chinese script a-Al13(Fe,Cr)4Si4 phase 5. Anyway, the addition of Cr for the modification of Fe-bearing intermetallics must be however limited otherwise large primary intermetallic crystals precipitate from the melt by peritectic reaction as sludge 6-8. These complex intermetallic compounds enriched in Fe, Mn and Cr form at temperatures above the liquidus temperature of the alloy, and due to higher density than the molten metal, they segregate into the melt. Segregation may occur either in the mould at slow cooling rates or in the bulk liquid within the furnaces or ladles. Therefore, sludge formation changes the chemical composition of the molten metal 8. The sludge precipitation occurs most often in high-pressure die-casting (HPDC) foundry where, in order to preserve the die and tools, the holding temperature is typical lower than the other foundry processes. The sludge formation not only changes the chemical composition of the molten metal, but may also increase the die-soldering tendency of the alloy. Furthermore, the sludge compounds are hard particles that can adversely affect the ductility and toughness properties of castings 10,11. A sludge factor (SF) has been suggested by Jorstad 10 and Gobrecht 12 for Al-Si-Cu alloys to act as a guide for avoiding sludge. This factor is calculated from the formula: SF=(1·wt.%Fe)+(2·wt.%Mn)+(3·wt.%Cr) Equation 1 where Cr is the most deleterious element for the formation of sludge.

4. Summary of the study:

Background of the research topic:

Chromium is a common alloying element in Al-Si alloys, but it is also the primary contributor to the formation of detrimental intermetallic sludge particles, which is a significant concern in HPDC processes.

Status of previous research:

While the negative effects of sludge were known, and formulas like the Sludge Factor existed, there was limited quantitative data on how systematically varying Cr content specifically affects the fracture toughness of die-cast Al-Si alloys.

Purpose of the study:

To systematically investigate the influence of Cr content on the microstructure (specifically Fe-rich phase formation and morphology) and the resulting impact toughness of a die-cast AlSi9Cu3(Fe) alloy.

Core study:

The research involved creating four batches of AlSi9Cu3(Fe) alloy with Cr contents ranging from 0.057% to 0.153%. These were die-cast and then subjected to detailed microstructural analysis and instrumented impact testing to correlate the Cr level with sludge characteristics and mechanical performance.

5. Research Methodology

Research Design:

The study was designed as a comparative analysis of four alloy compositions, identical except for the systematic variation of chromium content.

Data Collection and Analysis Methods:

Data was collected through chemical analysis of the alloys, microstructural investigation using OM and SEM/EDX for phase identification and quantification, and mechanical testing using an instrumented drop tower impact tester as per ASTM E2298-13a. Image analysis software was used to quantify particle size, area fraction, and distribution.

Research Topics and Scope:

The research focused on AlSi9Cu3(Fe) alloy (EN AB-46000) under HPDC conditions. The scope was limited to the influence of Cr on Fe-rich phase formation (primary sludge and secondary particles) and the resulting room-temperature impact toughness in the T1 (as-cast) condition.

6. Key Results:

Key Results:

- Increasing Cr content increases the area fraction of both primary (sludge) and secondary α-Alx(Fe,Mn,Cr)ySiz intermetallic compounds.

- The morphology of sludge particles degrades with increasing Cr, evolving from polyhedral to branched or star-like shapes.

- Impact toughness and maximum load (Fm) are nearly constant up to 0.12 wt.% Cr.

- A Cr content of 0.15 wt.% causes a significant drop in impact toughness (>9%) and maximum load.

- The dynamic yield strength of the material was found to be independent of the Cr level in the tested range.

Figure Name List:

0.057 and (b) 0.153 wt.% Cr after deep-etching.

- Fig. 1. Geometry of the diecasting where the investigated impact bar is indicated by the arrow.

- Fig. 2. Dimensions (mm) of the impact testing bar

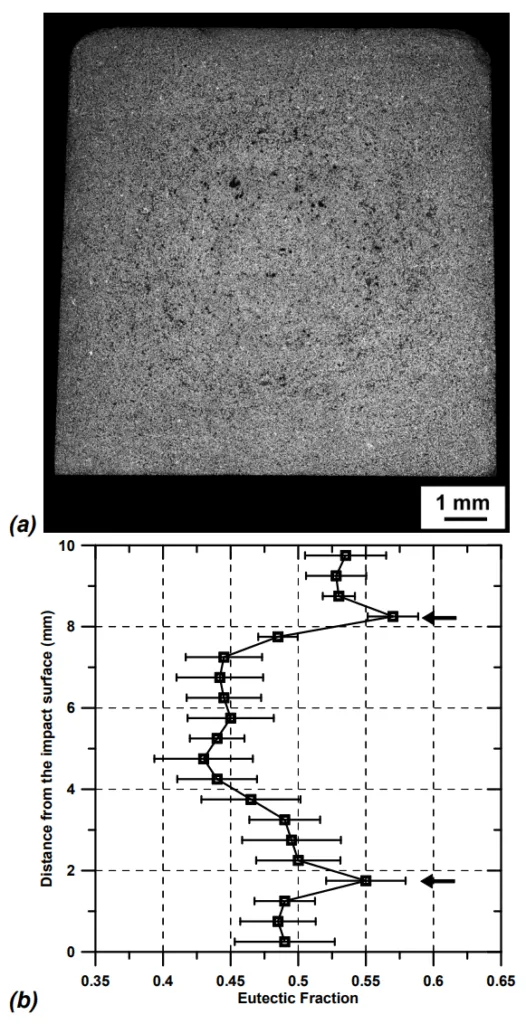

- Fig. 3. (a) Typical etched cross section of diecast AlSi9Cu3(Fe) (0.087wt.% Cr) impact specimen showing the presence of an internal segregation band. Darker material in the macrograph contains higher fraction of Al-Si eutectic and secondary intermetallics. (b) Mean eutectic profile over the cross section of the analysed alloys. Arrows indicate approximately the distance of the internal segregation band. The scattering of data is depicted by horizontal bars.

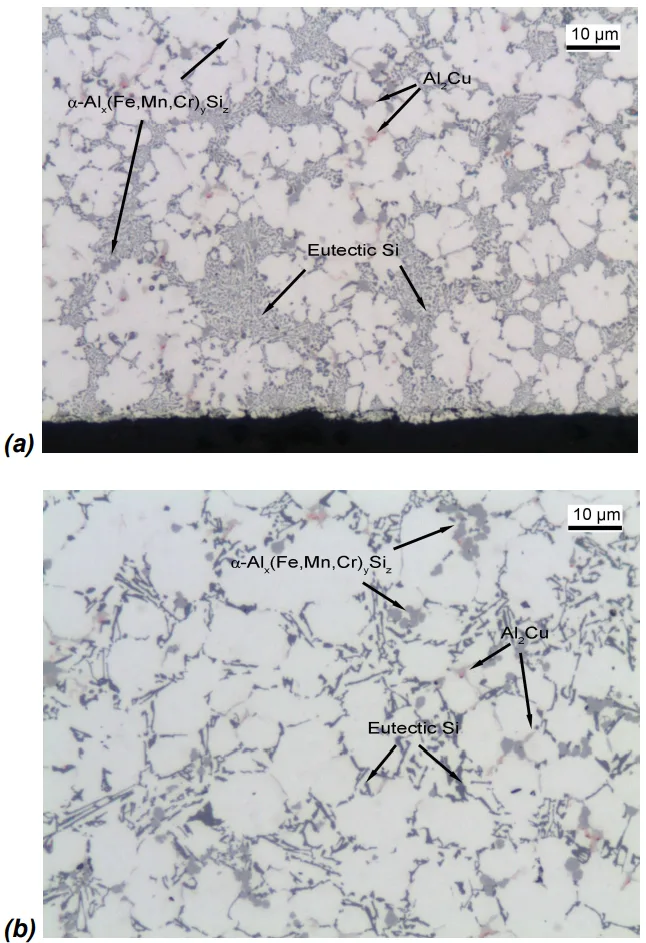

- Fig. 4. Eutectic Si particles in the analysed AlSi9Cu3(Fe) alloys. Micrographs refer to (a) the impact surface and (b) the centre of the diecast impact bars.

- Fig. 5. SEM micrograph of die-cast AlSi9Cu3(Fe) alloy. Arrows indicate a-Alx(Fe,Mn,Cr)ySiz compounds and Cu-rich particles, as revealed by EDS spectra (b and c, respectively).

- Fig. 6. Typical microstructures of Cr-added AlSi9Cu3(Fe) alloys: (a) 0.057, (b) 0.087, (c) 0.119 and (d) 0.153 wt.% Cr. Primary a-Alx(Fe,Mn,Cr)ySiz compounds (sludge) are indicated by arrows.

- Fig. 7. SEM micrographs of sludge particles in the diecast experimental AlSi9Cu3(Fe) alloys with (a) 0.057 and (b) 0.153 wt.% Cr after deep-etching.

- Fig. 8. Impact load-deflection curves of different Cr-added alloys.

7. Conclusion:

The effect of Cr content on the microstructural evolution of Fe-rich compounds in a high-pressure die-cast AlSi9Cu3(Fe) alloy has been investigated and then addressed to the impact toughness of the alloy. The following conclusions can be drawn.

The initial Cr content in the molten metal does not influence microstructural features such as positive eutectic segregation bands and ESCs, which are here ascribed to the HPDC process.

- The presence of Cr, joined with a high cooling rate, promotes the formation of primary sludge particles and proeutectic α-Alx(Fe,Mn,Cr)ySiz intermetallic compounds.

- The volume fraction of both Fe-rich intermetallic compounds increases as the Cr content increases. Any increase in the amount of the particles is coupled with an increase in their size.

- The progressive Cr addition promotes the modification of sludge morphology from more or less well-formed hexagon to branched or star-like shapes.

- The polyhedral sludge particles are associated to a regular rhombic dodecahedron, while the star-like and branched morphologies originate from hollowed rhombic dodecahedron.

- With the present casting conditions, the morphology of secondary Fe-rich particles is not influenced by Cr addition.

- The impact toughness and the maximum load of the diecast AlSi9Cu3(Fe) alloy decrease as the Cr level exceeds 0.12 wt.%. On the other hand, the strain hardening of the material is not influenced by Cr addition.

8. References:

- Cho, Y.-H., Joo, D.-H., Kim, C.-H., Lee, H.-C., Materials Science Forum, 519-521, pp. 461-466. (2006).

- Lodgaard, L., Ryum, N.,Materials Science and Engineering A, 283, pp.144-152 (2000).

- Kim, H.Y., Han, S.W., Lee, H.M., Materials Letters, 60, pp. 1880-1883 (2006).

- Eidhed, W., Journal of Materials Science&Technology, 24, pp. 45-47, (2008).

- Mahta, M., Emamy, M., Daman, A., Keyvani, A., Campbell, J., International Journal of Cast Metals Research, 18, pp.73-79 (2005).

- http://metalcasting.govtools.us/reports/casting_characteristics_of_aluminum.pdf (5 February, 2002).

- Shabestari, S.G., Materials Science and Engineering A, 383, pp. 289-298 (2004).

- Shabestari, S.G., Gruzleski, J.E., Metallurgical and Materials Transactions A, 26, pp. 999-1006 (1995).

- Wallace, J., “A guide to correcting soldering”, North American Die Casting Association, Des Plaines, IL (2006).

- Jorstad, J.L., Die Casting Engineer, 11-12, pp. 30-36 (1986).

- Cao, X., Campbell, J., International Journal of Cast Metals Research, 17, pp. 1-11 (2004).

- Gobrecht, J., Giesserei, 61, pp. 263-265 (1975).

- Makhlouf, M.M., Apelian, D., Wang, L., “Microstructure and Properties of Aluminium Die Casting Alloys”, North American Die Casting Association, Rosemont, IL (1998).

- EN 1706, “Aluminium and aluminium alloys - Castings - Chemical composition and mechanical properties” (2010).

- Timelli, G., Bonollo, F., Materials Science and Engineering A, 528, pp. 273-282 (2010).

- ASTM E2298-13a, “Standard Test Method for Instrumented Impact Testing of Metallic Materials”, ASTM International, West Conshohocken, Philadelphia, PA (2013).

- Gourlay, C.M., Laukl,i H.I., Dahle, A.K., Metallurgical and Materials Transactions A, 38, pp. 1833-1844 (2007).

- Otarawanna, S., Gourlay, C.M., Laukli, H.I., Dahle, A.K., Metallurgical and Materials Transactions A, 40 pp.1645-1659 (2009).

- Gourlay, C.M., Dahle, A.K., Nature, 445, pp.70-73 (2007).

- Meylan, B., Terzi, S., Gourlay, C.M., Suéry, M., Dahle, A.K., Scripta Materialia, 63, pp. 1185-1188 (2010).

- Laukli, H.I., Gourlay, C.M., Dahle, A.K., Lohne, O., Materials Science and Engineering A, 413-414, pp. 92-97 (2005).

- Otarawanna, S., Gourlay, C.M., Laukli, H.I., Dahle, A.K., Materials Characterization, 60, pp. 1432-1441 (2009)

- Murali, S., Raman, K.S., Murthy, K.S.S., Materials Characterization, 33, pp. 99-112 (1994).

- Fabrizi, A., Ferraro, S., Timelli, G., Shape Casting 5: International Symposium, TMS (2014).

- Kim, B., Lee, S., Yasuda, H., Materials Science Forum, 654-656, pp. 974-977 (2010).

- Server, W.L., J Eng Mater Technol Trans, 100, pp. 183-187 (1978).

- Stepanov, G.V., Kharchenko, V.V., Strength of Materials, 17, pp. 1102-1107 (1985).

- Klepaczko, J.R, Journal of the mechanics and physics of solids, 46, pp. 2139-2153 (1998).

- Seifeddine, S., Johansson, S., Svensson, I.L., Materials Science and Engineering A, 49, 385-390 (2008).

- Kobayashi, T., Engineering fracture mechanics, 19, pp. 67-79 (1984).

Expert Q&A: Your Top Questions Answered

Q1: What is the single most critical takeaway from this research for an engineer working with A380 (AlSi9Cu3(Fe)) alloy?

A1: The most critical takeaway is that there is a performance "cliff" for chromium content. The alloy can tolerate Cr up to about 0.12 wt.% without a significant loss in impact toughness. However, exceeding this level (e.g., to 0.15 wt.%) causes a sharp reduction in mechanical performance. As shown in Table 3, impact toughness dropped by 14.6% with this small increase. Therefore, strict control of Cr content is paramount for ensuring part reliability.

Q2: What exactly is "sludge" and how does chromium affect it?

A2: Sludge refers to primary α-Alx(Fe,Mn,Cr)ySiz intermetallic compounds that form in the molten alloy before the main solidification event. This research shows that increasing chromium has two negative effects: 1) it increases the total amount of these sludge particles, and 2) it changes their shape from compact polyhedrons to more harmful branched or star-like morphologies, as shown in Figure 6 and Figure 7. These larger, irregular particles act as weak regions, facilitating crack propagation and making the final casting more brittle.

Q3: The paper mentions a "Sludge Factor" (SF). How can I use this in practice?

A3: The Sludge Factor, SF=(1·wt.%Fe)+(2·wt.%Mn)+(3·wt.%Cr), is a guideline for predicting the risk of sludge formation. The formula, cited from Jorstad [10] and Gobrecht [12], highlights that chromium is three times more potent than iron in promoting sludge. This study experimentally validates the critical role of Cr. You can use the SF calculation to quickly assess the risk level of a given melt chemistry, knowing from this paper's results that keeping the contribution from Cr under control is the most effective strategy.

Q4: Does chromium only affect the primary sludge particles?

A4: No. The study found that as chromium content increases, the area fraction of both primary (sludge) and secondary (proeutectic) Fe-rich intermetallic compounds increases (Abstract). However, a key distinction is that the morphology of the secondary Fe-rich particles was not significantly affected by the Cr addition. The main detrimental effect on toughness comes from the negative changes to the size and shape of the primary sludge particles (Conclusions section).

Q5: Why was impact toughness the focus here, and not just tensile strength?

A5: Impact toughness measures a material's ability to absorb energy under a sudden load, which is critical for components in automotive and structural applications that might experience collisions or shocks. As the paper notes, hard, brittle particles like sludge are known to severely compromise this property (Introduction). The impact test is a highly effective method for evaluating how microstructural features like sludge influence the dynamic fracture resistance of die castings, providing a clear picture of the material's durability.

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing the reliability of AlSi9Cu3(Fe) components in HPDC. The findings offer a clear, data-driven threshold for chromium content, creating a direct path toward improving quality, reducing the risk of brittle fracture, and optimizing production by avoiding the detrimental effects of sludge.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues of sludge formation and mechanical toughness discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "G. Timelli, S. Ferraro, A. Fabrizi, S. Capuzzi, F. Bonollo, L. Capra, G.F. Capra". Based on "The Influence of Cr content on the Fe-rich phase Formation and Impact toughness of a Die-cast AlSi9Cu3(Fe) alloy".

- Source of the paper: [DOI URL Not Available in Document]

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.