This introduction paper is based on the paper "Temperature Conditions Change in the High Pressure Die Casting mold Volume Depending on the Gating System Volume" published by "Archives of Foundry Engineering".

![Fig. 1 Gating system of casting and experimental tempering system [17]](https://castman.co.kr/wp-content/uploads/image-1928-png.webp)

1. Overview:

- Title: Temperature Conditions Change in the High Pressure Die Casting mold Volume Depending on the Gating System Volume

- Author: J. Majerník, M. Podaril, M. Majernikova, K. Sramhauser

- Year of publication: 2025

- Journal/academic society of publication: Archives of Foundry Engineering (Published quarterly as the organ of the Foundry Commission of the Polish Academy of Sciences)

- Keywords: Product development, Application of information technology to the foundry industry, Thermal stress, Mould material, tempering

2. Abstract:

The high pressure die casting technology is characterized by high efficiency, which is given by pressing the liquid metal into the die cavity and the subsequent solidification of the cast in a short period of time. The short casting cycle duration and the rapid temperature conditions alternation at the interface cast – die cavity, as well as in the die volume itself, cause cyclic thermal stress of the die material. The submitted article investigates the influence of gating system volume on the temperature conditions change in the high pressure die casting mold volume. Five gating system variants with different runners volume for specific type of low-weight silumin based cast were used to assess the temperature changes in the high pressure die casting mold volume. The temperature was monitored in two selected places of the gating system, with a distribution of 1mm, 2mm, 5mm, 10mm and 20mm in the direction from the working die cavity face to the volume of the fixed and movable part of the die. As a comparison parameter, the melt temperature in the runner center above the measured point and the melt temperature close to the die face were monitored. Monitoring of the temperature change was performed using the Magmasoft simulation program. It has been proven that the gating system volume affects the thermal stress of the die, the temperature drop in the die volume and the casting cycle duration. In conclussions, proposals for measures to reduce the high thermal stress of the die resulting from the gating system volume and design are presented. These proposals will subsequently be verified in the following research activities and compared with the resulting casts quality.

3. Introduction:

High pressure die casting (HPDC) is a pivotal manufacturing process, particularly for large series production of complex components in industries such as automotive and aerospace, valued for its cost-effectiveness, shape variability, repeatability, and productivity [1, 2]. The process involves injecting molten metal into a die cavity under high speed and pressure. The cyclical nature of HPDC—encompassing filling, solidification, die opening/closing, cast removal, and die treatment (spraying/blowing)—subjects the die to significant, periodic temperature fluctuations. This thermal cycling induces thermal imbalance and considerable thermal stress within the die material, impacting die lifespan and potentially cast quality [7-10]. Heat transfer dynamics at the cast-die interface and within the solidifying alloy are critical, influencing microstructure, mechanical properties, and defects like shrinkage porosity [3, 4, 5, 6]. Factors governing thermal drop include the die material's thermal conductivity, the ratio of die mass to cast mass, and the initial die temperature [10-13]. Efficient heat dissipation is crucial for maintaining optimal die temperature and preventing issues like cast sticking or deterioration of solidification conditions. This study builds upon prior research concerning die thermal characteristics [10, 16, 17] to specifically investigate how the volume of the gating system influences the temperature conditions and associated thermal stress within the HPDC mold volume.

4. Summary of the study:

Background of the research topic:

HPDC processes inherently involve rapid thermal cycling at the cast-die interface and within the die volume. This leads to cyclic thermal stress, which is a primary factor affecting die longevity and the consistency of cast quality. Managing heat transfer and thermal balance within the die is crucial for optimizing the process and mitigating defects.

Status of previous research:

Previous contributions by the authors' team addressed the overall die heat balance [16], mechanisms of heat removal, and the thermal characteristics of die materials. It was demonstrated that dies accumulate heat, with layers further from the cavity face experiencing less temperature change [10]. The influence of tempering channel distribution and distance from the die face on die volume temperature was investigated, establishing that a zone approximately 5mm from the die face exhibits complete heat transfer without accumulation, and that tempering channel distance impacts solidification/cooling time and cycle duration [17], consistent with findings in [3, 5, 12, 13].

Purpose of the study:

The primary objective was to assess the impact of gating system volume on the temperature condition changes (interpreted as thermal stress) within the high pressure die casting mold volume. A secondary aim was to verify the hypothesis, derived from prior knowledge, that increased gating system volume leads to higher thermal stress within the die material, and to corroborate findings from previous related studies [10, 17].

Core study:

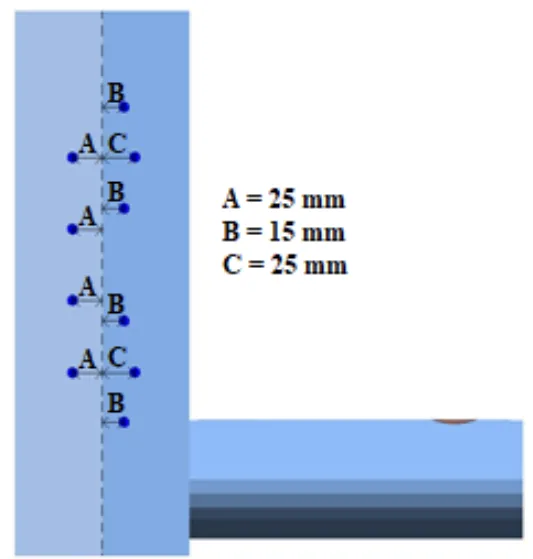

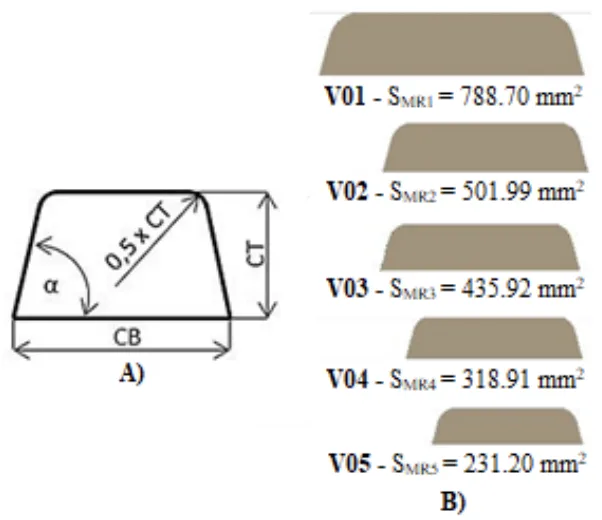

The research involved designing five distinct gating system variants (V01 to V05) for the HPDC production of a specific low-weight silumin based cast (electric motor flange, alloy EN AC 47 100). These variants featured systematically different runner volumes, achieved by varying runner cross-sections (Table 3, Fig 3), while maintaining consistent ingate geometry principles (Table 2). The die material selected was X38CrMoV5_1 steel. Using the Magmasoft simulation program, temperature changes (ΔT) were monitored at specific depths (0mm, 1mm, 2mm, 5mm, 10mm, 20mm) from the working die cavity face into the volume of both the fixed (cover) and movable (ejector) die parts, specifically at locations corresponding to the main runner (MR_CD, MR_ED) and secondary runner (SR_CD, SR_ED) (Fig 1). Simulations were run under defined industrial process parameters (Table 5), including pre-heating cycles, with data collected during the sixth production cycle. The study compared the ΔT values across the five variants and correlated these with simulated filling times and solidification/cooling times (Table 7).

5. Research Methodology

Research Design:

A comparative numerical simulation approach was employed. Five gating system designs with varying runner volumes (V01-V05) were created for a constant cast geometry and die configuration. The study systematically evaluated the effect of this variation on the thermal response of the die using the Magmasoft simulation software under standardized HPDC process parameters.

Data Collection and Analysis Methods:

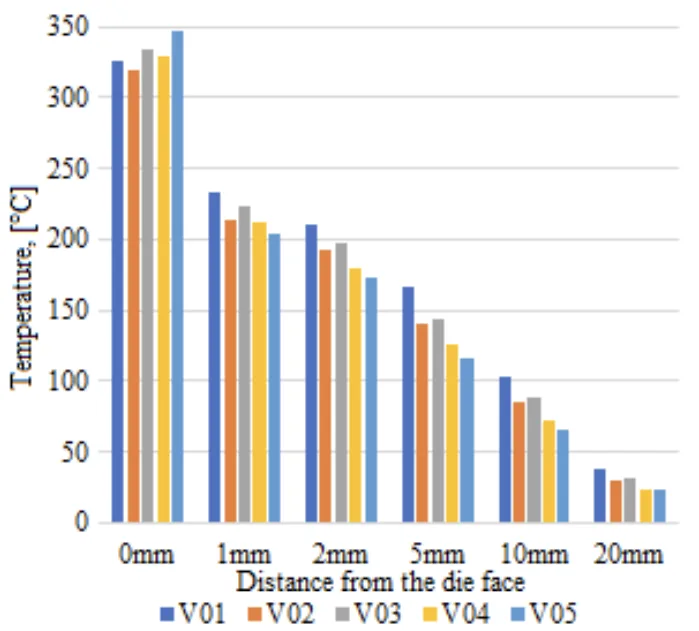

Temperature data was collected from the Magmasoft simulation results at predefined measurement points. These points were located at depths of 0, 1, 2, 5, 10, and 20 mm perpendicular to the die cavity face within the cover die and ejector die sections, specifically under the main and secondary runners (Fig 1). Temperature change (ΔT) was calculated for the sixth simulated casting cycle. Additionally, simulation outputs for die cavity filling time and total solidification and cooling time were recorded for each variant (Table 7). Analysis involved comparing ΔT values across variants and depths (Table 6, Fig 4) and examining correlations between gating system volume, ΔT, filling time, and solidification/cooling time.

Research Topics and Scope:

The research focused specifically on quantifying the relationship between the gating system volume and the resultant temperature changes (thermal stress) within the volume of an HPDC die (material: X38CrMoV5_1). The scope encompassed temperature monitoring up to a depth of 20mm from the cavity face for an aluminum alloy casting (EN AC 47 100). The study also investigated the consequential effects on die cavity filling time and the duration of the solidification and cooling phase.

6. Key Results:

Key Results:

- The volume of the gating system was proven to significantly affect the temperature change (ΔT), and thus thermal stress, within the high pressure die volume.

- Contrary to the initial hypothesis for the die face, the highest temperature change (ΔT) at the die cavity surface (0mm depth) was observed with the smallest gating system volume (V05). This was attributed to longer die cavity filling times (Table 7) associated with smaller runner cross-sections, leading to prolonged exposure of the die face to flowing molten metal.

- Within the die material (depths > 0mm), the thermal stress (ΔT) generally increased with increasing gating system volume, supporting the hypothesis for the die bulk (Table 6, Fig 4).

- Larger gating system volumes resulted in significantly longer solidification and cooling times (Table 7), reflecting the increased thermal capacity of the larger melt batch and extended heat conduction into the die volume.

- Temperature fluctuation (ΔT) was consistently highest at the die face (0mm) and decreased progressively with increasing depth into the die material for all variants (Table 6, Fig 4).

Figure Name List:

- Fig. 1 Gating system of casting and experimental tempering system [17]

- Fig. 2 Distribution of tempering channels in die

- Fig. 3 Comparison of main runners cross-sections

- Fig. 4 Average temperature change in die material

7. Conclusion:

This study successfully demonstrated that the gating system volume directly influences the thermal stress experienced by the die material during HPDC. A key finding is that the thermal stress at the die face is inversely proportional to the gating system volume, primarily due to variations in die cavity filling time. Conversely, within the bulk of the die, thermal stress tends to increase with larger gating system volumes. Furthermore, it was confirmed that the gating system volume, dictating the melt batch size and its heat capacity, proportionally affects the duration of the solidification and cooling phase, thereby influencing the overall casting cycle time. While minimizing internal die thermal stress (achieved with smaller gating volumes) might seem beneficial for die lifespan, it is crucial to recognize that thermal stress is not the sole determinant of production quality and sustainability. Future research should delve deeper into the interplay between melt flow velocity, filling time, gating system volume, and potential deviations between simulated and actual melt velocities. Additionally, investigating the impact of gating system volume variations on critical process indicators (e.g., metal batch usability, required closing force) and qualitative aspects (e.g., cast homogeneity, gas entrapment) is warranted.

8. References:

- [1] Takeda, S., Shinmura, N. & Sannakanishi, Sh. (2017). Stress analysis of thin wall core pin in aluminum alloy high pressure die casting. Materials Transactions. 58(1), 85-90. DOI: 10.2320/matertrans.F-M2016836.

- [2] Ebrahimi, A., Fritsching, U., Heuser, M., Lehmhus, D., Struß, A., Toenjes, A. & von Hehl, A. (2020). A digital twin approach to predict and compensate distortion in a High Pressure Die Casting (HPDC) process chain. Procedia Manufacturing. 52, 144-149. https://doi.org/10.1016/j.promfg.2020.11.026.

- [3] Yu, W. B., Liang, S., Cao, Y. Y., Li, X. B., Guo, Z. P. & Xiong, S. M. (2017). Interfacial heat transfer behavior at metal/die in finger-plated casting during high pressure die casting process. China Foundry. 14(4), 258-264. DOI: 10.1007/s41230-017-6066-6.

- [4] Liu, F., Zhao, H., Chen, B. & Zheng, H. (2022). Investigation on microstructure heterogeneity of the HPDC AlSiMgMnCu alloy through 3D electron microscopy. Materials and Design. 218, 110679, 1-11. DOI: 10.1016/j.matdes.2022.110679.

- [5] Hamasaiid, A., Dargusch, M.S. & Dour, G. (2019). The impact of the casting thickness on the interfacial heat transfer and solidification of the casting during permanent mold casting of an A356 alloy. Journal of Manufacturing Processes. 47, 229-237. DOI: 10.1016/j.jmapro.2019.09.039.

- [6] Navah, F., Lamarche-Garnon, M. & Ilinca, F. (2024). Thermofluid topology optimization for cooling channel design. Applied Thermal Engineering. 236, 121317, 1-17. DOI: 10.1016/j.applthermaleng.2023.121317.

- [7] Šeblt, J. (1962). Molds for High Pressure Die Casting (Formy pro lití kovů pod tlakem). Praha: SNTL.

- [8] Paško, J., Gašpár, Š. (2014). Technological Factors of Die Casting. Lüdenscheid: RAM-Verlag.

- [9] Kırmızıgöl, S.F., Özaydin, O. & Acarer, S. (2024). Improving heat transfer and compressed air consumption in low pressure die casting of aluminum wheels. Applied Thermal Engineering. 251, 123598, 1-23. DOI: 10.1016/j.applthermaleng.2024.123598.

- [10] Majernik, J. & Podaril, M. (2019). Evaluation of the temperature distribution of a die casting mold of X38CrMoV5_1 steel. Archives of Foundry Engineering. 19(2), 107-112. DOI: 10.24425/afe.2019.127125.

- [11] Ružbarský, J., Paško, J. & Gašpár, Š (2014). Techniques of Die Casting. Lüdenscheid: RAM-Verlag.

- [12] Choi, J., Choi, J., Lee, K., Hur, N. & Kim, N. (2022). Fatigue life prediction methodology of hot work tool steel dies for high-pressure die casting based on thermal stress analysis. Metals. 12(10), 1744, 1-18. DOI: 10.3390/met12101744.

- [13] Capela, P., Gomes, I. V., Lopes, V., Prior, F., Soares, D. & Teixeira, J. C. (2023). Experimental analysis of heat transfer at the interface between die casting molds and additively manufactured cooling inserts. Journal of Materials Engineering and Performance. 32(23), 10934-10942. DOI: 10.1007/s11665-023-08425-z.

- [14] Bohacek, J., Mraz, K., Krutis, V., Kana, V., Vakhrushev, A., Karimi-Sibaki, E. & Kharicha, A (2023). Experimental and numerical investigations into heat transfer using a jet cooler in high-pressure die casting. Journal of Manufacturing and Materials Processing. 7(6), 212. DOI: 10.3390/jmmp7060212.

- [15] Jiao, X., Liu, C., Wang, J., Guo, Z., Wang, J., Wang, Z., Gao, J. & Xiong, S. (2020). On the characterization of microstructure and fracture in a high-pressure die-casting Al-10 wt%Si alloy. Progress in Natural Science: Materials International. 30(2), 221-228. DOI: 10.1016/j.pnsc.2019.04.008.

- [16] Majerník, J., Gaspar, S., Podaril, M. & Coranic, T. (2020). Evaluation of thermal conditions at cast-die casting mold interface. MM Science Journal. 2020, 4112-4118. DOI: 10.17973/MMSJ.2020_11_2020041.

- [17] Majernik, J., Podaril, M. & Majernikova M. (2024). Evaluation of high pressure die casting mold temperature relations depending on the location of the tempering channels. Archives of Foundry Engineering. 24(1), 115-120. DOI: 10.24425/afe.2024.149258.

- [18] Construction of compression casting moulds: Instructions (Formy tlakové licí: Zásady pro navrhování). (1984). Praha: Český normalizační institute, 32.

- [19] Majernik, J. (2019) The issue of the gating system design for permanent dies (Problematika návrhu vtokových soustav permanentních forem pro lití kovů pod tlakem). Stalowa Wola: Wydawnictwo Sztafeta Sp. z.o.o.

- [20] Ruzbarský, J., Pasko, J., Gaspar, S. (2014). Techniques of Die casting. Lüdenscheid: RAM-Verlag.

9. Copyright:

- This material is a paper by "J. Majerník, M. Podaril, M. Majernikova, K. Sramhauser". Based on "Temperature Conditions Change in the High Pressure Die Casting mold Volume Depending on the Gating System Volume".

- Source of the paper: https://doi.org/10.24425/afe.2025.153774

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.