Unlocking the Future of Automotive Manufacturing: A Deep Dive into Integrated Die Casting Technology

This technical summary is based on the academic paper "Status and Development of Integrated Die-casting Technology" by DAN Zhaoxue, LIN Yun, WAN Li, and YAN Feng, published in Special Casting & Nonferrous Alloys (2024).

Keywords

- Primary Keyword: Integrated Die Casting

- Secondary Keywords: Aluminum Alloy, New Energy Vehicles, Lightweighting, HPDC, Automotive Manufacturing

Executive Summary

- The Challenge: Traditional multi-part Body-in-White assembly is complex, costly, and heavy, hindering the progress of New Energy Vehicles.

- The Method: This paper analyzes the key technologies enabling large-scale integrated die casting, from heat-free alloys and mega-presses to advanced process control and machining.

- The Key Breakthrough: Integrated die casting successfully consolidates 50-100 stamped steel parts into a single aluminum casting, reducing weight by 16-30% and increasing torsional rigidity by ~10%.

- The Bottom Line: While integrated die casting offers revolutionary benefits in efficiency and performance, critical challenges in repairability, deformation control, and material recycling must be addressed for widespread, sustainable adoption.

The Challenge: Why This Research Matters for HPDC Professionals

The automotive industry is in the midst of a transformation driven by New Energy Vehicles (NEVs). A core objective in this shift is lightweighting to improve range and efficiency. The Body-in-White (BIW), which accounts for roughly 30% of a vehicle's total mass, has long been a prime target for weight reduction. However, traditional BIW manufacturing, which involves stamping and welding 300-500 individual sheet metal parts, presents a long and complex production chain.

In 2019, the introduction of integrated die casting marked a paradigm shift. This technology leverages ultra-large die casting machines to produce massive structural components—like an entire rear underbody—in a single piece. This approach promises to revolutionize automotive manufacturing by dramatically improving efficiency, reducing costs, and enhancing vehicle performance. However, scaling this technology from concept to mass production introduces a host of new engineering challenges across the entire value chain, from material science to final assembly. This paper provides a comprehensive overview of the current state of this technology and the critical problems that must be solved.

The Approach: Unpacking the Methodology

The successful implementation of integrated die casting relies on a synergistic combination of advancements in materials, equipment, and processing technologies. The paper analyzes the key technical pillars that make this manufacturing revolution possible.

Method 1: Advanced Materials: The Rise of Heat-Free Aluminum Alloys

Large, thin-walled structural parts are highly susceptible to distortion and blistering during conventional T6/T7 heat treatments (solutionizing and aging). To overcome this, the industry has developed specialized "heat-free" die-cast aluminum alloys. These materials are designed to achieve high strength and ductility in their as-cast or naturally aged condition. The paper details various Al-Si and Al-Mg based alloys (as shown in Table 1), which are micro-alloyed with elements like Mn, V, Zr, and Sr to optimize castability, mechanical properties, and mold release without the need for subsequent heat treatment.

Method 2: Mega-Casting Equipment & Process Control

Producing components the size of a vehicle's underbody requires a massive leap in equipment scale. The paper highlights that integrated die casting relies on machines with clamping forces of 60,000 kN and above, with leading manufacturers now deploying units as large as 160,000 kN. These "giga-presses" are part of sophisticated casting islands (Figure 2) that include robotics, high-vacuum systems (below 5 kPa), and advanced thermal management. Precise multi-zone temperature control of the hundred-ton molds (Figure 4) is critical to manage metal flow, ensure complete filling, and control solidification to minimize defects and internal stress.

Method 3: Integrated Post-Processing and Assembly

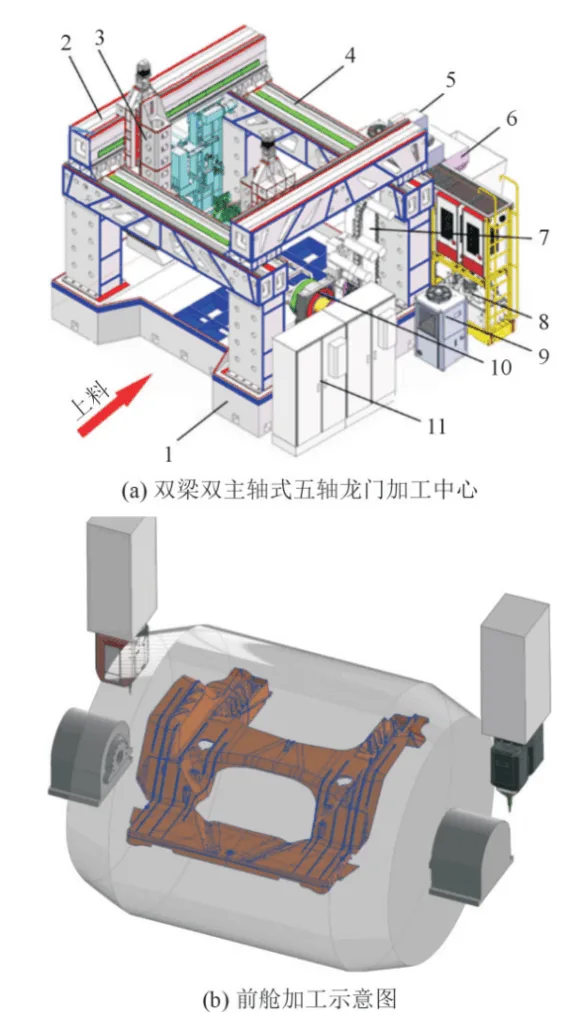

The complexity and size of integrated castings demand equally advanced post-processing solutions. To handle the numerous features on these large parts efficiently, the industry is moving towards large-travel, multi-axis machining centers. The paper identifies double-gantry, dual-spindle machining centers (Figure 6) as a highly effective solution that can significantly reduce cycle times. For assembly, particularly for joining the aluminum casting to dissimilar materials like steel, techniques such as Self-Pierce Riveting (SPR) and specialized stud welding are essential.

The Breakthrough: Key Findings & Data

The paper quantifies the significant impact of integrated die casting on vehicle manufacturing and performance, while also highlighting its rapid adoption across the industry.

Finding 1: Massive Part Consolidation and Performance Gains

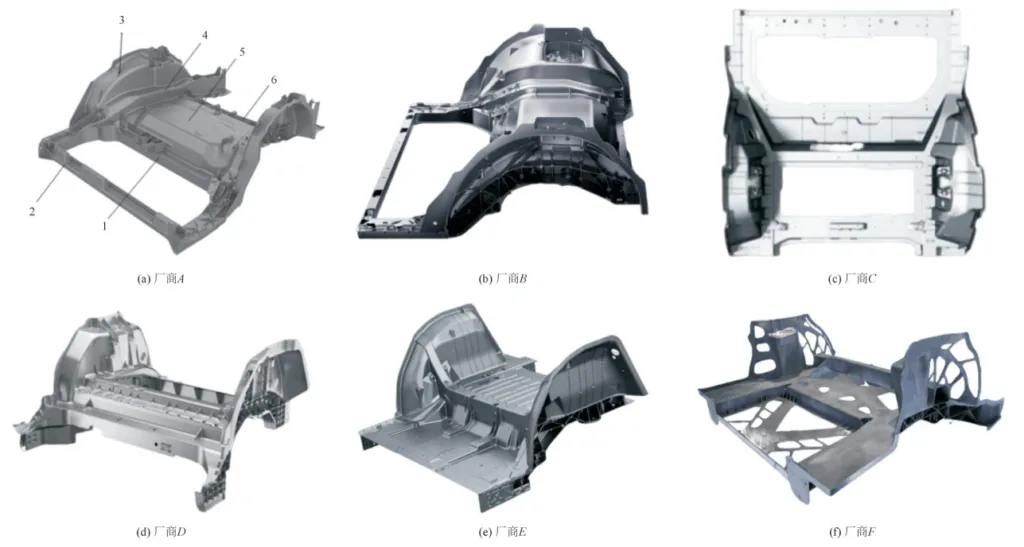

Integrated die casting delivers dramatic improvements by replacing complex assemblies with a single, optimized component. According to the paper, a single integrated rear floor casting can replace between 54 and 87 individual stamped and welded parts. This consolidation leads to a component weight reduction of 16% to 30% and an increase in the vehicle's overall torsional rigidity by approximately 10%. Figure 1 illustrates the different design approaches taken by various manufacturers, showing varying levels of integration, particularly concerning rear crumple zones, which impacts repairability.

Finding 2: Rapid Industry Adoption and a Converging Architecture

This technology is no longer a niche concept but a mainstream trend. As of the end of 2023, 28 major global automotive OEMs had publicly announced their adoption of integrated die casting technology (Figure 9). The primary applications are rear underbodies, front shock towers/cabins, and battery trays. The analysis suggests the industry is converging on a "three-piece" underbody architecture, where the front section, middle battery tray, and rear section are produced as separate large castings. This approach balances the benefits of integration with manufacturing feasibility and serviceability.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that overcoming the limitation of maximum filling distance is critical for part quality. Adjusting mold temperature gradients to be progressively hotter along the flow path and exploring advanced solutions like dual injection systems may contribute to improving the mechanical properties of end-of-fill regions.

- For Quality Control Teams: The data in Figure 8, which shows the distribution of elongation across a rear floor casting, illustrates that mechanical properties are not uniform. This highlights the need for strategic placement of test coupons for destructive testing and suggests that non-destructive inspection criteria should be more stringent in historically weaker, end-of-fill locations.

- For Design Engineers: The findings indicate that the decision of whether to integrate features like crumple zones directly influences repairability and insurance costs. The analysis of different OEM strategies in Figure 1 suggests that keeping these zones as separate, bolt-on components is a valuable consideration in the early design phase to balance manufacturing efficiency with total cost of ownership.

Paper Details

Status and Development of Integrated Die-casting Technology

1. Overview:

- Title: Status and Development of Integrated Die-casting Technology

- Author: DAN Zhaoxue, LIN Yun, WAN Li, YAN Feng

- Year of publication: 2024

- Journal/academic society of publication: SPECIAL CASTING & NONFERROUS ALLOYS

- Keywords: Integrated Die Casting, Aluminum Alloy, New Energy Vehicles, Lightweighting

2. Abstract:

Integrated die casting has been successfully applied in the manufacturing of new energy vehicles, leading the manufacturing revolution in the automotive industry in terms of component performance, production efficiency and manufacturing cost. The key aspects of integrated die casting were analyzed, including integrated design, heat-free aluminum alloy, casting technology, machining technology, assembly technology, and testing technology. The current application status of integrated die casting in the automotive field was introduced, and the relevant technical problems were reviewed.

3. Introduction:

Die casting, due to its ability to form complex, thin-walled structures in a single step with extremely short cycle times and near-net-shape characteristics, has become a primary manufacturing process for large-scale automotive production. In the trend towards vehicle lightweighting through the substitution of aluminum for steel, this process is widely used for manufacturing body structural parts, electric drive system housings, engine blocks, and various brackets. In 2019, Tesla introduced integrated die casting technology, which highly integrates multiple individual components into a single part formed by an ultra-large tonnage die casting machine. This has led a manufacturing revolution in the automotive industry in terms of component performance, production efficiency, and manufacturing cost, providing a new direction for automotive manufacturing.

4. Summary of the study:

Background of the research topic:

The study is set against the backdrop of the automotive industry's shift towards new energy vehicles (NEVs), where lightweighting is a critical objective for enhancing efficiency and range. Integrated die casting has emerged as a disruptive manufacturing technology to achieve these goals.

Status of previous research:

Traditional automotive manufacturing relies on stamping and welding hundreds of steel components to create the Body-in-White (BIW). While die casting has long been used for smaller aluminum components, the application of large-scale, integrated die casting for major structural parts is a recent development, pioneered by Tesla. This has spurred widespread research and development into enabling technologies such as new alloys, mega-presses, and advanced process controls.

Purpose of the study:

The purpose of this paper is to provide a comprehensive review of the current status and development of integrated die casting technology. It aims to analyze the key technical aspects of the entire process chain, document its application status in the automotive industry, and identify the primary technical challenges and potential solutions.

Core study:

The core of the study is a systematic analysis of the key technologies that enable integrated die casting. This includes:

1. Product Integration Design: Examining different strategies for part consolidation in underbody structures.

2. Heat-Free Aluminum Alloys: Reviewing the composition and properties of specialized alloys designed for large castings.

3. Die Casting Process Technology: Covering equipment (mega-presses), tooling (large, thermally managed molds), and process simulation/control.

4. Post-Processing: Analyzing the requirements for machining, assembly (e.g., SPR), and testing (e.g., machine vision).

The study also assesses the current adoption rate among OEMs and concludes by discussing five major unresolved challenges: repairability, deformation control, material recycling, filling distance limitations, and machining bottlenecks.

5. Research Methodology

Research Design:

The research is conducted as a comprehensive literature and industry review. It synthesizes information from academic papers, technical patents, public disclosures from automotive OEMs and suppliers, and industry reports to present a holistic overview of the technology.

Data Collection and Analysis Methods:

Data was collected from a wide range of public sources. The analysis involves comparing different technological approaches (e.g., alloy compositions, OEM integration strategies), identifying common trends, and systematically outlining the technical challenges and proposed solutions discussed within the industry and academia.

Research Topics and Scope:

The scope of the research covers the entire integrated die casting ecosystem. The topics include:

- Integrated product design for BIW components.

- Metallurgy of heat-free die-cast aluminum alloys.

- Advancements in large-tonnage die casting machines and molds.

- Process design, simulation, and control.

- Technologies for machining, assembly, and quality inspection.

- Current market application and adoption trends.

- Key technical problems and future research directions.

6. Key Results:

Key Results:

- Integrated die casting consolidates 54 to 87 individual components into a single casting, resulting in a weight reduction of 16-30% and an increase in vehicle torsional rigidity of approximately 10%.

- The technology's feasibility is dependent on the development of heat-free aluminum alloys, typically Al-Si or Al-Mg systems, which achieve required mechanical properties without distortion-inducing heat treatment.

- Massive die casting machines with clamping forces exceeding 60,000 kN are required, with the industry trending towards direct-acting clamping mechanisms.

- Effective thermal management of the large, complex molds and high-vacuum systems are critical for ensuring part quality and minimizing casting defects.

- As of late 2023, 28 major automotive OEMs have adopted the technology, with a common trend toward a three-piece underbody architecture (front, middle, rear).

- Five significant challenges remain prominent: repairability, deformation control, closed-loop material recycling, limitations on maximum metal flow distance, and machining cycle time acting as a production bottleneck.

Figure Name List:

![Fig.7 Surface defect inspection of die castings by machine

vision [36]](https://castman.co.kr/wp-content/uploads/image-3721.webp)

- 图1 各厂商一体化压铸后地板

- 图2 一体化压铸岛布局示意图

- 图3 广东鸿图160000kN超大型智能压铸单元

- 图4 一体化压铸模温分区控制方案

- 图5 压铸工艺设计流程

- 图6 一体化压铸前舱机加工方案示意图

- 图7 采用机器视觉进行压铸件表面缺陷检测[36]

- 图8 一体化压铸后地板伸长率分布

- 图9 各汽车厂商布局一体化压铸的进展及其应用

7. Conclusion:

In the current environment of rapid product iteration and intense price competition in the new energy vehicle industry, using integrated die casting for efficiency improvement and cost reduction has become a consensus. The technology has been successfully promoted within the automotive sector, with various OEMs achieving technical implementation through in-house R&D or collaboration with die casting suppliers. Analysis of the key technical links—including integrated design, heat-free alloys, equipment, molds, process, machining, assembly, and testing—reveals that integrated die casting presents greater challenges than traditional die casting. Attracted by the vast market prospects, all these technologies are showing a positive trend of rapid innovation. However, the application of integrated die casting technology also faces several challenges and problems. Among them, repairability, deformation control, same-grade material recycling, maximum filling distance limitation, and machining cycle time bottleneck are prominent issues in current practical applications.

8. References:

- [1] BASERTA, ELIF U, AKINCI V. New trends in aluminum die casting alloys for automotive applications [J]. The Eurasia Proceedings of Science Technology Engineering and Mathematics, 2022, 21: 79-87.

- [2] MARCUS P. Auto body warfare: Aluminum attack [R]. World Steel Dynamics Report, 2014.

- [3] 田崎,王高祥,屈汀等.基于高压压铸一体化成形的车身开发流程优化研究[J].汽车技术,2022(5):17-21.

- [4] PAI S A, SAWANT S M, WAGHERE V D, et al. Integrated energy absorbing castings: US, WO2022/031991A1[P]. 2021-08-05.

- [5] 张春江,潘治中,孙林富,等.乘用车身一体化铸铝后地板结构设计与研究[J].机械设计与制造工程,2023,52(4):17-21.

- [6] RHEINFELDEN. Primary aluminum alloys for high pressure die casting [Z]. Germany: Rheinfelden Alloys Gmbh & Co.KG, 2005.

- [7] ZOVI A, CARROZZA F, Silafont-36, the low iron ductile die casting alloy: development and applications [J]. La Metallurgia Italiana, 2008, 99(6): 33-38.

- [8] 段宏强,韩志勇,王斌.汽车结构件用非热处理铝压铸合金研究进展[J].汽车工艺与材料,2022,13(4):1-6.

- [9] 卢畅畅,吴国华,胡晓军,等.新能源汽车用一体化压铸铝合金研究现状与发展趋势[J].特种铸造及有色合金,2023,43(11): 1 472-1 478.

- [10] AKYOL A. Effect of silicon content on machinability of Al-Si alloys [J]. Advances in Science and Technology Research Journal, 2016, 10(31): 51-57.

- [11] HE Z Q, WANG L, WANG S, et al. Microstructure and mechanical properties of high strength die-cast Al-Mg-Si-Mn alloy [J]. Materials and Design, 2013, 46: 451-456.

- [12] 刘勇,陈超,张震富,等.不同Mg-Si质量比对压铸铝合金组织与性能的影响[J].特种铸造及有色合金,2017,37(11):1 179-1 182.

- [13] 陈超.高强韧压铸Al-Si-(Mg)合金组织与性能研究[D].上海:上海交通大学,2020.

- [14] SHIBUATH G K, DONAHUE R J. The metallurgy of aluminum alloys for structural high-pressure die casting [J]. International Journal of Metal Casting, 2021, 15(3): 1 031-1 046.

- [15] LIN J, FANG D Q, SINDEL M, et al. Al-Si-Mg alloy for forming automotive structural parts by casting and T5 heat treatment: US, WO2016/167652A1[P]. 2005-09-04.

- [16] KOCH H. Casting alloy: US6824737B2[P]. 2004-11-30.

- [17] STUCKI J, PATTISSON G, HAMILL Q, et al. Die cast aluminum alloy for structural components: US2020035131A1 [P]. 2020-11-12.

- [18] 郭军辉,叶起平,赵玉龙,等.一种铝合金结构件及其制备方法:CN111359811A[P]. 2020-06-30.

- [19] 朱双杰,高坤,刘红伟,等.一种免热处理高强韧铝合金及其制备方法:CN114717455A[P]. 2022-07-11.

- [20] 黄华,朱宇,等.免热处理高强韧压铸铝合金及其制备方法:CN111501183B[P]. 2023-01-31.

- [21] 彭立明,郑凯,张海涛,等.一种高强高韧压铸AlSiMg合金及其制备方法:CN114438380B[P]. 2023-07-21.

- [22] 彭立明,董文斌,杨森,等.一种非热处理强化压铸铝硅镁合金及其应用方法:CN114438381B[P]. 2023-10-14.

- [23] 傅高升,符涛涛,熊开祥,等.一种压铸铝合金结构件的制备方法和应用:CN1119079712B[P]. 2020-11-10.

- [24] 佟国栋,熊守美,熊开祥,等.高强韧压铸铝合金及压铸工艺制备方法:CN113122129A[P]. 2021-07-13.

- [25] 杨毛吉,闫国庆,曹畅,等.一种新能源汽车电池用免热处理铝合金及其制备方法:CN116374944A[P]. 2023-08-11.

- [26] 邱磊,邱泽亮,江水兵,等.一种新能源车用高强压铸铝合金及其制备方法:CN11613871B[P]. 2023-07-04.

- [27] 吴新颖,胡天亮,郭兴家,等.一种免热处理铸铝合金及其制备方法和应用:CN11528701B[P]. 2023-08-08.

- [28] 郭灿,但昭学,陈晓彤,等.一体化压铸技术的发展加快了大型压铸机的研制[J].铸造设备与工艺,2023(3):1-5.

- [29] 叶能.大型一体化压铸模具制造工艺[J].模具制造,2023(10):159-162.

- [30] 赵堂伟,但学青,朱敬敬,等.我国压铸模具钢研究新进展[J].特殊钢,2022,43(5):1-6.

- [31] 杨永强,陈杰,宋长辉,等.金属零件激光选区熔化技术的现状及进展[J].激光与光电子学进展,2018,55(1):1-26.

- [32] 王永.一体化压铸后地板与钢板的自冲铆接性能影响因素分析及研究[J].汽车工艺与材料,2022(10):1-6.

- [33] WALKINGTGN W G. Die Casting Defects [M]. USA: Arlington Heights, 2018.

- [34] SAVEEN S, MOHAN G, MANJUNATHA H R, et al. Analysis of casting surface using machine vision and digital image processing techniques [J]. International Journal of Innovative Research in Science, Engineering and Technology, 2017, 6(10): 10 119-10 124.

- [35] LIN J, WEN K, LIU Y Y, et al. Recognition and classification of surface defects of aluminum castings based on machine vision [A]. Proceedings of the 2021 International Conference on Machine Learning and Intelligent Systems Engineering [C]. Sanya, 2021.

- [36] NGUYEN T P, CHOI S, PARK S J, et al. Inspecting method for defective casting products with convolutional neural network (CNN) [J]. International Journal of Precision Engineering and Manufacturing-Green Technology, 2022, 9(2): 511-521.

- [37] DU W Z, SHEN H Y, FU J Z, et al. Approaches for improvement of the x-ray image defect detection of automobile casting aluminum parts based on deep learning [J]. Independent Nondestructive Testing and Evaluation, 2019, 6(1): 1-12.

- [38] LIN J H, YAO Y, MA L, et al. Detection of a casting defect tracked by deep convolution neural network [J]. The International Journal of Advanced Manufacturing Technology, 2018, 97: 573-581.

Expert Q&A: Your Top Questions Answered

Q1: Why are "heat-free" aluminum alloys so essential for integrated die casting?

A1: Conventional high-strength aluminum alloys require a solution heat treatment and artificial aging (e.g., T6 or T7 temper) to achieve their final properties. This process involves heating the casting to high temperatures, which would cause large, thin-walled parts like an underbody to warp significantly. Heat-free alloys are specifically designed with micro-alloying elements that promote the formation of strengthening phases in the as-cast state, eliminating the need for a distortion-inducing heat treatment process and making the production of large structural castings feasible.

Q2: What are the main differences in integration strategy among automotive OEMs, as shown in Figure 1?

A2: The paper shows that OEMs take different approaches, primarily concerning the rear crumple zones. For example, Manufacturer A integrates a portion of the crumple zone directly into the casting, which maximizes part consolidation. In contrast, Manufacturer B terminates the casting before the crumple zone and uses a separate, bolt-on component. This latter approach improves repairability, as a low-speed rear collision would only require replacing the smaller crumple zone part rather than the entire expensive rear underbody casting.

Q3: The paper mentions a 160,000 kN press. What is the significance of such a large machine?

A3: The size of the die casting machine, defined by its clamping force (in kilonewtons, kN), directly limits the maximum projected area of the part that can be cast. To produce extremely large components like a full battery tray or underbody section, a massive clamping force is needed to counteract the immense pressure of the injected molten aluminum. The 160,000 kN press represents the current frontier in equipment scale, enabling the casting of even larger and more complex integrated components for future vehicle architectures.

Q4: What is the biggest bottleneck in the integrated die casting production line?

A4: According to the paper, the primary bottleneck is machining. The die casting process itself has a very short cycle time, often just a few minutes. However, the subsequent machining of the large, complex casting—which requires milling, drilling, and tapping numerous features—takes significantly longer. This disparity in cycle times means that the machining center's throughput dictates the overall production rate of the entire line.

Q5: How does the paper address the critical issue of repairability for these large castings?

A5: The paper identifies repairability as a major challenge. Unlike steel, which can be easily pulled and repaired, cast aluminum is prone to fracture. A damaged integrated casting often requires complete replacement, leading to high repair costs. The paper suggests a multi-faceted solution: developing more weldable aluminum alloys, optimizing advanced welding techniques like laser welding to minimize heat input, and, critically, adjusting the product design to reduce the scope of integration by making high-risk areas like crumple zones separate, replaceable parts.

Conclusion: Paving the Way for Higher Quality and Productivity

The shift to Integrated Die Casting represents one of the most significant manufacturing innovations in the modern automotive industry. By replacing hundreds of parts with a single, highly engineered aluminum casting, automakers can achieve unprecedented levels of lightweighting, structural performance, and production efficiency. However, as this comprehensive review highlights, this breakthrough is not without its challenges. Overcoming hurdles in repairability, deformation control, and post-processing bottlenecks is essential for the technology's long-term success. The ongoing advancements in materials, equipment, and process control are rapidly closing these gaps, paving the way for a new era of vehicle manufacturing.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Status and Development of Integrated Die-casting Technology" by "DAN Zhaoxue, LIN Yun, WAN Li, YAN Feng".

Source: https://doi.org/10.15980/j.tzzz.2024.08.002

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.