This technical summary is based on the academic paper "ANALYZE OF THE POSSIBLE CAUSES OF POROSITY TYPE DEFECTS IN ALUMINIUM HIGH PRESSURE DIECAST PARTS" by Ference Peti and Lucian Grama, published by SC CIE Matronca SA, Romania. It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: Aluminum HPDC porosity defects

- Secondary Keywords: Shrinkage porosity, gas porosity, high pressure die casting, shot parameters, die design, metal temperature, solidification simulation

Executive Summary

- The Challenge: Porosity defects, such as shrinkage and gas porosity, compromise the quality and pressure tightness of aluminum high-pressure die-cast (HPDC) parts, leading to costly rejections.

- The Method: The study categorizes the main causes of porosity defects, focusing on process parameters, die design, and metal conditions, with visual analysis via microscopy and simulation.

- The Key Breakthrough: Identifying critical process parameters like shot velocity, intensification pressure, and die thermal control as primary drivers of porosity defects.

- The Bottom Line: Optimizing shot parameters, die design, and metal temperature can significantly reduce porosity, improving part quality and production efficiency.

The Challenge: Why This Research Matters for HPDC Professionals

Porosity defects, including shrinkage and gas porosity, are a persistent challenge in aluminum HPDC, particularly for components requiring high pressure tightness, such as automotive and aerospace parts. These defects lead to leaks (as shown in Figure 4) and reduced mechanical properties, causing costly scrap rates and quality issues. For engineers and managers, understanding the root causes of porosity is critical to achieving consistent, high-quality castings and maintaining competitive production.

The Approach: Unpacking the Methodology

The researchers conducted a detailed analysis of porosity defects in aluminum HPDC parts, focusing on both shrinkage and gas porosity. They used:

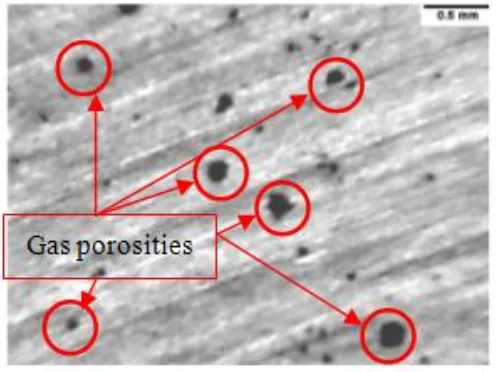

- Microscopic Analysis: To measure the dimensions of shrinkage porosities (Figure 3).

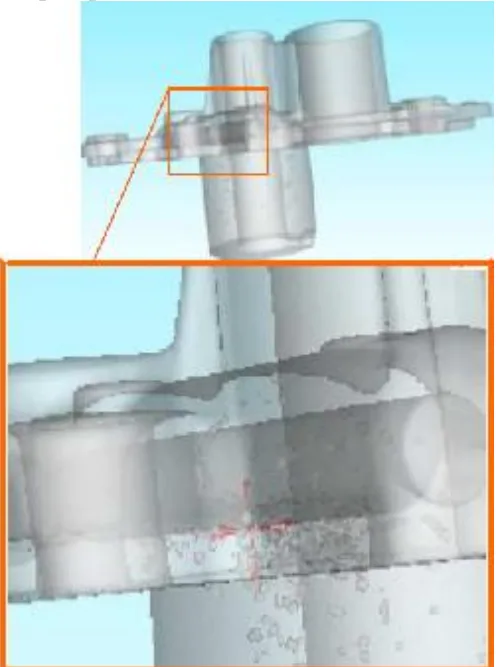

- Visual Inspection: To identify leakers in cross-sections of defective parts (Figure 4).

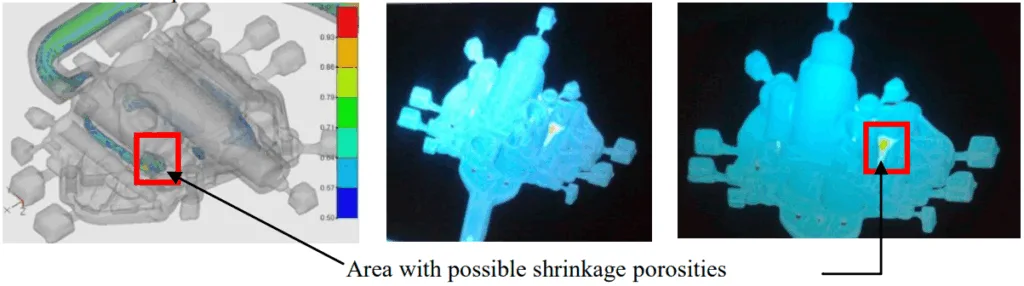

- Solidification Simulation: To study metal flow and cavity filling in an aluminum housing, using fluid flow equations (Figure 7 and Figure 8).

- Process Parameter Review: To categorize causes of porosity, including shot parameters, die surface conditions, and metal quality.

This multi-faceted approach allowed the researchers to pinpoint the factors contributing to porosity defects in real-world HPDC settings.

The Breakthrough: Key Findings & Data

The study identifies several critical causes of porosity defects, categorized into gas and shrinkage porosity, with actionable insights for HPDC operations:

- Gas Porosity Causes:

- First Stage Velocity Issues: High velocity or incorrect change-over points (too early or too late) trap air, leading to gas porosity.

- Second Stage Issues: Low velocity or insufficient intensification pressure exacerbates gas entrapment (Figure 5).

- Shrinkage Porosity Causes:

- Shot End Parameters: Low metal pressure, incorrect shot weight, or late intensification cause incomplete filling and shrinkage (Figure 5).

- Die Surface Conditions: Insufficient die spray or excessive die temperature leads to hot spots and uneven cooling.

- Die Design: Poor gating, runner design, or thermal control creates hot and cold spots, contributing to shrinkage in thick-walled sections (Figure 2).

- Metal Conditions: Overheated, undercooled, or contaminated metal increases porosity risk.

- Simulation Insights: Solidification simulations (Figure 7) show that shrinkage porosity concentrates in areas with high aluminum mass and thick walls, while fluid flow equations (Figure 8) highlight the importance of controlled cavity filling to minimize defects.

Practical Implications for HPDC Products

The findings from this study offer actionable strategies for HPDC manufacturers to reduce porosity and enhance part quality:

- For Process Engineers: Adjusting shot parameters, such as first and second stage velocities and intensification timing, can reduce gas and shrinkage porosity, as highlighted in Figure 5. For example, optimizing change-over points could minimize air entrapment.

- For Quality Control: Microscopic analysis (Figure 3) and computerized tomography (used by companies like VW Group) provide precise methods to detect porosity early, ensuring pressure-tight components.

- For Die Design: Improving gating and runner design, along with better thermal management (Figure 7), can prevent hot spots and reduce shrinkage in thick-walled sections, as seen in Figure 2.

- For Production Managers: Maintaining consistent metal temperature and quality (avoiding contamination) is critical to minimizing porosity risks, as noted in the study’s analysis of metal conditions.

Paper Details

ANALYZE OF THE POSSIBLE CAUSES OF POROSITY TYPE DEFECTS IN ALUMINIUM HIGH PRESSURE DIECAST PARTS

1. Overview:

- Title: ANALYZE OF THE POSSIBLE CAUSES OF POROSITY TYPE DEFECTS IN ALUMINIUM HIGH PRESSURE DIECAST PARTS

- Authors: Ference Peti, Lucian Grama

- Year of Publication: Not specified in the provided document

- Journal/Academic Society: SC CIE Matronca SA, Romania

- Keywords: Aluminum HPDC, porosity defects, shrinkage porosity, gas porosity, shot parameters, die design, solidification simulation

2. Abstract:

The paper does not provide a formal abstract, but it focuses on identifying and categorizing the causes of porosity defects in aluminum HPDC parts, including gas and shrinkage porosity, and their impact on pressure tightness and part quality.

3. Introduction:

Porosity defects, such as gas and shrinkage porosity, are critical issues in aluminum HPDC, leading to leaks and reduced mechanical performance. The study aims to analyze these defects’ causes, focusing on process parameters, die conditions, and metal quality.

4. Summary of the Study:

- Background of the Research Topic: Porosity defects compromise the integrity of HPDC parts, especially in applications requiring pressure tightness (e.g., automotive housings).

- Status of Previous Research: The paper references the use of computerized tomography by companies like VW Group for porosity analysis but does not cite specific prior studies.

- Purpose of the Study: To categorize and analyze the main causes of porosity defects and provide insights for improving HPDC processes.

- Core Study: The study examines gas and shrinkage porosity through visual inspection, microscopy, and solidification simulation, linking defects to specific process and design factors.

5. Research Methodology

- Research Design: Observational and analytical study of porosity defects in aluminum HPDC parts.

- Data Collection and Analysis Methods:

- Microscopic analysis of shrinkage porosity dimensions (Figure 3).

- Visual inspection of leakers in part cross-sections (Figure 4).

- Solidification simulation to study metal flow and cavity filling (Figures 7 and 8).

- Research Topics and Scope: Focuses on gas and shrinkage porosity, covering shot parameters, die design, die surface conditions, and metal quality.

6. Key Results:

Key Results:

- Gas porosity is driven by improper shot velocities, change-over timing, and low intensification pressure (Figure 5).

- Shrinkage porosity occurs in thick-walled sections due to low metal pressure, poor thermal control, and inadequate die design (Figure 2).

- Solidification simulations show defect concentration in high-mass areas (Figure 7).

- Fluid flow equations highlight the importance of controlled cavity filling to reduce porosity (Figure 8).

Figure Name List:

- Figure 2. Shrinkage porosity in the section of an aluminium diecast part

- Figure 3. Analyze of the dimensions of shrinkage porosities with microscope

- Figure 4. Leaker in the section of an aluminium diecast part

- Figure 5. Main causes for porosity type of defects in high pressure diecast aluminium parts

- Figure 7. Solidification simulation in the case of an aluminium housing

- Figure 8. Filling of cavity is done with molten aluminium

7. Conclusion:

The study concludes that porosity defects in aluminum HPDC parts are caused by a combination of improper shot parameters, poor die design, inadequate die surface conditions, and suboptimal metal quality. Optimizing these factors can significantly reduce defects and improve part quality.

8. References:

The provided document does not include a formal reference list.

Expert Q&A: Your Top Questions Answered

Q1: What was the single most critical factor identified in this study for improving part quality?

A1: The study highlights improper shot parameters (e.g., first and second stage velocities, intensification pressure) as critical drivers of porosity defects, as detailed in Figure 5.

Q2: How does this research compare to traditional methods for addressing porosity?

A2: While traditional methods focus on trial-and-error adjustments, this study systematically categorizes causes (e.g., shot parameters, die design) and uses simulations (Figure 7) to provide data-driven solutions, offering a more precise approach.

Q3: Is this finding applicable to all types of alloys, or a specific one?

A3: The study does not specify a particular alloy, focusing generally on aluminum HPDC. Applicability to specific alloys would require further testing, as noted in the methodology.

Q4: What specific measurement or simulation technique did the researchers use to arrive at this conclusion?

A4: The researchers used microscopic analysis (Figure 3) for porosity measurement, visual inspection for leakers (Figure 4), and solidification simulation (Figures 7 and 8) to analyze metal flow and defect formation.

Q5: According to the paper, what is the main limitation or area for future research?

A5: The paper does not explicitly state limitations but implies that further research is needed to validate findings across different alloys and to refine simulation models for broader applications.

Q6: What is the direct, practical takeaway from this paper for a die casting facility?

A6: By optimizing shot parameters, improving die thermal control, and ensuring consistent metal quality, facilities can reduce porosity defects and enhance pressure tightness, as supported by the findings in Figure 5 and Figure 7.

Conclusion & Next Steps

This research provides a clear roadmap for tackling porosity defects in aluminum HPDC, offering data-driven insights into shot parameters, die design, and metal quality. By addressing these factors, manufacturers can achieve higher-quality castings with fewer defects, improving efficiency and customer satisfaction.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers’ most challenging die casting problems. If reducing porosity in your HPDC components is a priority, contact our engineering team to discuss how we can implement these advanced principles in your production process.

Copyright

- This material is a paper by Ference Peti and Lucian Grama. Based on "ANALYZE OF THE POSSIBLE CAUSES OF POROSITY TYPE DEFECTS IN ALUMINIUM HIGH PRESSURE DIECAST PARTS."

- Source of the paper: Not provided in the document.

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.