Slashing Defects and Boosting Efficiency: A Deep Dive into Modern Casting Processes

This technical summary is based on the academic paper "Recent Advancements and Critical Insights in Casting Processes" by Amarishkumar J Patel and Sunilkumar N Chaudhari, published in the International Journal of Scientific Research in Mechanical and Materials Engineering (2023).

![Figure 2: Defect Frequency in Casting Process [38-42]](https://castman.co.kr/wp-content/uploads/image-3592.webp)

Keywords

- Primary Keyword: Modern Casting Processes

- Secondary Keywords: Casting Defects, Process Optimization, Numerical Simulation, Investment Casting, Continuous Casting, Industry 4.0

Executive Summary

- The Challenge: Traditional casting methods often struggle with defects like porosity and cracking, leading to high scrap rates, wasted energy, and inconsistent quality in complex components.

- The Method: This review analyzes key technological developments across five critical areas: investment casting, numerical simulation, process optimization, defect analysis, and continuous casting.

- The Key Breakthrough: The integration of numerical simulation tools enables accurate prediction of flow dynamics and solidification, drastically reducing defects and improving efficiency before any metal is poured.

- The Bottom Line: Shifting from trial-and-error to a data-driven, simulation-first approach is essential for any foundry aiming to enhance quality, reduce costs, and meet the demands of modern manufacturing.

The Challenge: Why This Research Matters for HPDC Professionals

Casting is a foundational manufacturing process, but its success hinges on controlling a complex interplay of thermal, chemical, and physical variables. For engineers and managers in demanding fields like HPDC, common defects such as porosity, cracks, and inclusions are persistent pain points. These issues not only compromise the mechanical integrity of components but also lead to significant financial losses from scrapped parts, wasted energy, and production delays. As industries from aerospace to automotive demand components with increasingly complex geometries and higher performance standards, the limitations of traditional, experience-based casting methods become more apparent. This research was necessary to consolidate the latest technological advancements that directly address these challenges, providing a clear roadmap for improving process control, quality, and sustainability.

The Approach: Unpacking the Methodology

The authors conducted a comprehensive review of recent technological advancements and innovations across five critical domains of the casting process. The study's methodology was to synthesize and analyze current research and industrial practices in these key areas to provide a holistic overview of the state-of-the-art.

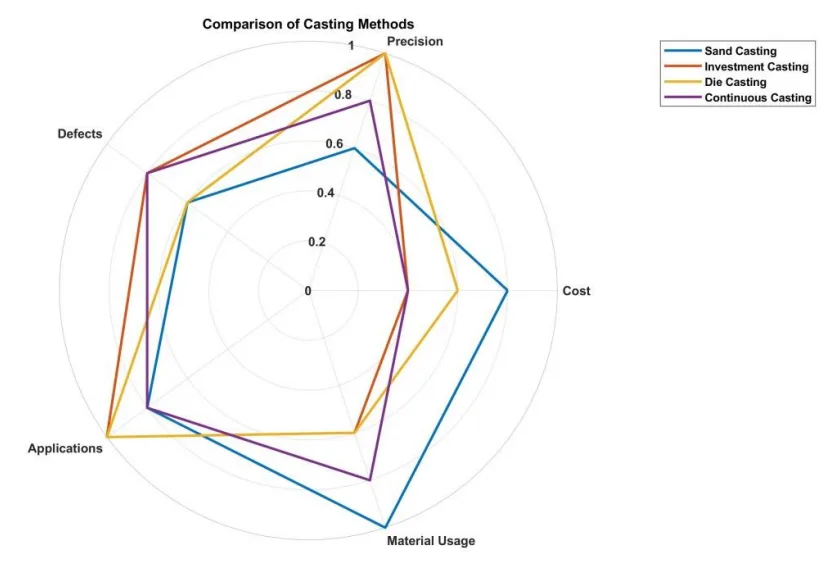

Method 1: Critical Review of Casting Types and Defects: The study began by analyzing the advantages, limitations, and common defects (e.g., porosity, cracks, inclusions) associated with major casting types, including sand, die, investment, continuous, and centrifugal casting. This established a baseline of common industry challenges.

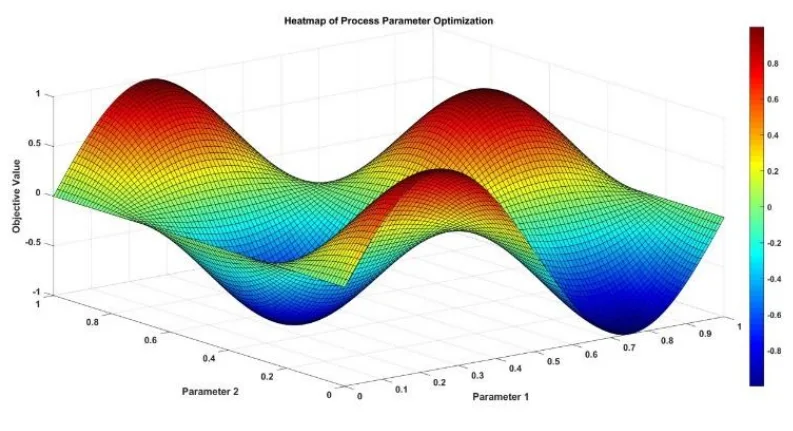

Method 2: Analysis of Simulation and Optimization Techniques: The authors examined the role of advanced computational tools, including numerical simulation (CFD, FEA) and optimization methods (DOE, Genetic Algorithms, ANNs). This part of the review focused on how these data-driven technologies are used to predict and mitigate defects, improve energy efficiency, and enhance overall process control.

Method 3: Exploration of Material and Process Innovations: The paper specifically investigated developments in investment casting and continuous casting, highlighting innovations in materials (e.g., ceramic slurries, wax patterns), automation (robotics, IoT), and sustainability practices that are pushing the boundaries of precision and efficiency.

The Breakthrough: Key Findings & Data

The paper consolidates extensive research to highlight how modern, data-driven approaches yield quantifiable improvements in casting quality and efficiency.

Finding 1: Drastic Defect Reduction Through Numerical Simulation

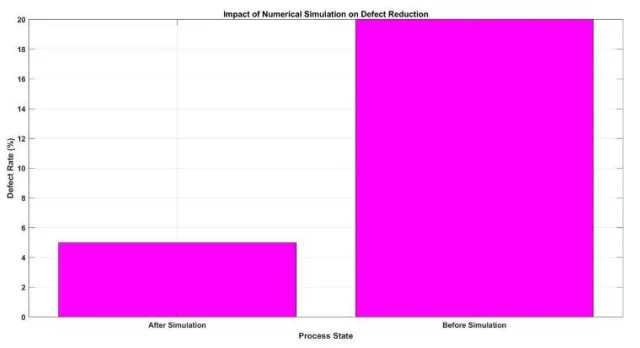

One of the most significant findings is the profound impact of numerical simulation on quality control. By modeling fluid flow, solidification, and thermal stresses, engineers can identify and correct potential issues before production begins. As shown in Figure 3, implementing numerical simulation resulted in a dramatic drop in defect rates.

The data shows defect rates falling from 20% before simulation to just 5% after simulation, representing a 75% reduction in defects. This shift from reactive to predictive quality control is a game-changer for reducing scrap and improving component reliability.

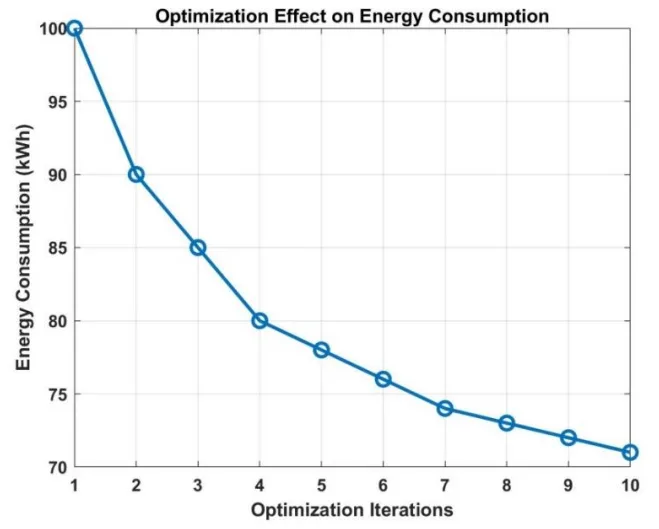

Finding 2: Significant Energy Savings via Process Optimization

Process optimization is not just about quality; it's also about sustainability and cost reduction. The review highlights how optimization techniques, when applied systematically, can lead to substantial energy savings. As illustrated in Figure 4, an iterative optimization process yields progressive reductions in energy consumption.

The data demonstrates a reduction in energy use from 100 kWh down to 71 kWh over 10 optimization iterations. This 29% decrease in energy consumption showcases the power of optimization algorithms in making casting processes more environmentally friendly and cost-effective.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that leveraging numerical simulation tools to model mold filling and solidification is a highly effective strategy for reducing common defects like porosity and cold shuts. The findings on optimization techniques (Section 5) indicate that systematically adjusting parameters like pouring temperature and cooling rates can lead to significant gains in both quality and energy efficiency.

- For Quality Control Teams: The data in Figure 2, which highlights porosity as the most frequent defect, reinforces the need for robust mitigation strategies like degassing and proper mold venting. The paper’s discussion on advanced non-destructive testing (NDT) techniques (Section 2.3) suggests that integrating X-ray and ultrasonic imaging can enable earlier detection of internal defects, preventing faulty components from moving down the production line.

- For Design Engineers: The findings on the causes of defects like thermal stress-induced cracks (Section 2.2) indicate that material selection and component geometry are critical considerations in the early design phase. Using simulation to evaluate designs for castability can prevent costly downstream issues related to solidification and residual stress.

Paper Details

Recent Advancements and Critical Insights in Casting Processes

1. Overview:

- Title: Recent Advancements and Critical Insights in Casting Processes

- Author: Amarishkumar J Patel, Sunilkumar N Chaudhari

- Year of publication: 2023

- Journal/academic society of publication: International Journal of Scientific Research in Mechanical and Materials Engineering

- Keywords: Casting Processes, Investment Casting, Numerical Simulation, Process Optimization, Continuous Casting

2. Abstract:

Casting is a foundational manufacturing process that has evolved significantly over the years due to advancements in material science, simulation technologies, and optimization techniques. This review explores key developments and innovations across five critical areas of the casting process. Investment casting, known for its precision and versatility, has seen significant strides in material improvements, automation, and sustainable practices. Numerical simulation tools have transformed the casting landscape, enabling accurate predictions of flow dynamics, solidification, and thermal stresses, thus reducing errors and improving efficiency. Optimization methods, including Design of Experiments, machine learning, and Industry 4.0 integration, have enhanced the quality and energy efficiency of casting processes. A critical review of various casting types highlights their advantages, limitations, and associated defects such as porosity, cracks, and inclusions, emphasizing the importance of defect mitigation strategies. Finally, the modeling and simulation of continuous casting processes are examined, showcasing advancements in thermal modeling, fluid dynamics, and real-time monitoring. This paper aims to consolidate recent advancements and provide a comprehensive overview to guide future research and practical applications in the field of casting.

3. Introduction:

Casting is one of the oldest and most widely used manufacturing processes, enabling the production of complex geometries and high-strength components across diverse industries. Its versatility accommodates a wide range of materials, including metals, alloys, and polymers, making it indispensable in sectors like automotive, aerospace, and construction. Over the years, advancements in materials and methods have enabled products with superior mechanical properties. The rise of computational tools and simulation has significantly enhanced the understanding and control of casting processes, allowing engineers to predict defects and optimize parameters with high accuracy, reducing reliance on trial-and-error methods. Simultaneously, sustainability concerns have driven the adoption of optimization strategies and advanced techniques like machine learning and IoT to minimize waste and improve energy efficiency.

4. Summary of the study:

Background of the research topic:

The study is situated within the field of manufacturing, specifically focusing on casting processes. It acknowledges casting as a fundamental but evolving technology facing increasing demands for quality, precision, efficiency, and sustainability from modern industries.

Status of previous research:

The paper builds upon a body of research that has documented the evolution of casting. It recognizes previous work on individual casting types, defect analysis, and the initial applications of computational tools. However, it identifies a need for a consolidated review that bridges recent, distinct advancements in materials, simulation, and optimization to present a comprehensive, modern overview.

Purpose of the study:

The purpose of this paper is to provide an in-depth exploration of advancements in casting by focusing on five critical areas: investment casting developments, progress in numerical simulations, optimization techniques, a critical evaluation of casting types and defects, and modeling in continuous casting. The aim is to consolidate these recent advancements to highlight the current state of the art, guide future research, and inform practical applications in the casting industry.

Core study:

The core of the study is a comprehensive review structured around five key themes. First, it provides a critical review of major casting types (sand, die, investment, etc.), outlining their respective advantages, limitations, and common defects. Second, it details recent developments in investment casting, focusing on material innovations, automation, and sustainability. Third, it examines the transformative role of numerical simulation in predicting flow dynamics, solidification, and thermal behavior to mitigate defects. Fourth, it reviews various optimization techniques (DOE, machine learning, Industry 4.0) used to enhance process efficiency, quality, and energy usage. Finally, it discusses the modeling and simulation of continuous casting processes.

5. Research Methodology

Research Design:

The research design is a comprehensive literature review. It synthesizes and analyzes existing academic papers, technical reports, and industry publications to present a consolidated overview of advancements in the field of casting.

Data Collection and Analysis Methods:

The study collects data from a wide range of scholarly sources and presents it thematically. The analysis involves critically evaluating the findings from these sources to identify key trends, innovations, challenges, and future directions across the five selected areas of casting. The paper uses tables and charts to comparatively analyze casting methods and visualize the impact of new technologies.

Research Topics and Scope:

The scope of the research covers five specific topics within the broader field of casting:

1. A comparative analysis of major casting types and their associated defects.

2. Developments in investment casting, including materials, automation, and sustainability.

3. Progress in the numerical simulation of casting processes.

4. A review of optimization aspects and techniques for casting.

5. Modeling and simulation of continuous casting processes.

6. Key Results:

Key Results:

- A comparative analysis (Table 1) shows that while sand casting is low-cost, it suffers from moderate precision and porosity defects, whereas investment and die casting offer high precision at a higher cost.

- Porosity is identified as the most prevalent defect in casting processes, followed by inclusions, cracks, and cold shuts (Figure 2).

- Numerical simulation is demonstrated to be highly effective in quality improvement, with data showing a reduction in defect rates from 20% to 5% after implementation (Figure 3).

- Optimization techniques are shown to significantly improve energy efficiency, with a progressive reduction in energy consumption from 100 kWh to 71 kWh over 10 optimization iterations (Figure 4).

- The integration of Industry 4.0 technologies, such as IoT sensors and machine learning, is transforming casting into a dynamic, data-driven process, enabling real-time monitoring and proactive adjustments.

Figure Name List:

- Figure 1: Casting Methods Comparison [38-42]

- Figure 2: Defect Frequency in Casting Process [38-42]

- Figure 3. Effect of Numerical Simulation on Defect Reduction

- Figure 4. Optimization impact in Energy Consumption

- Figure 5. Process Parameter Optimization

7. Conclusion:

Casting processes remain a cornerstone of modern manufacturing. The review concludes that recent advancements in material innovations, numerical simulation, and optimization techniques have significantly transformed the field, enhancing efficiency, precision, and product quality. Investment casting has particularly benefited from these innovations. While these technologies offer powerful tools for predictive analysis and defect mitigation, significant challenges remain, including high costs, workforce skill gaps, and limitations in computational resources. Future efforts should focus on integrating smart technologies like IoT and AI, developing eco-friendly materials, and pursuing sustainability goals to ensure the continued evolution and relevance of the casting industry.

8. References:

- [1]. Lynch, Paul, et al. "Challenges and opportunities to integrate the oldest and newest manufacturing processes: metal casting and additive manufacturing." Rapid Prototyping Journal 26.6 (2020): 1145-1154.

- [2]. Gao, Mengdi, et al. "Integration of additive manufacturing in casting: advances, challenges, and prospects." International Journal of Precision Engineering and Manufacturing-Green Technology (2022): 1-18.

- [3]. Campbell Jr, Flake C. Manufacturing technology for aerospace structural materials. Elsevier, 2011.

- [4]. Chakrabarti, A. K. Casting technology and cast alloys. PHI Learning Pvt. Ltd., 2022.

- [5]. Li, Neng, et al. "Progress in additive manufacturing on new materials: A review." Journal of Materials Science & Technology 35.2 (2019): 242-269.

- [6]. Luo, Alan A., Anil K. Sachdev, and Diran Apelian. "Alloy development and process innovations for light metals casting." Journal of Materials Processing Technology 306 (2022): 117606.

- [7]. Regli, William, et al. "The new frontiers in computational modeling of material structures." Computer-Aided Design 77 (2016): 73-85.

- [8]. Suthar, Janak, Jinil Persis, and Ruchita Gupta. "Critical parameters influencing the quality of metal castings: a systematic literature review." International Journal of Quality & Reliability Management 40.1 (2023): 53-82.

- [9]. Javaid, Mohd, et al. "Understanding the adoption of Industry 4.0 technologies in improving environmental sustainability." Sustainable Operations and Computers 3 (2022): 203-217.

- [10]. Nižetić, Sandro, et al. "Smart technologies for promotion of energy efficiency, utilization of sustainable resources and waste management." Journal of cleaner production 231 (2019): 565-591.

- [11]. Ripetskiy, A. V., G. K. Khotina, and O. V. Arkhipova. "The role of additive manufacturing in the investment casting process." E3S Web of Conferences. Vol. 413. EDP Sciences, 2023.

... [and so on for all 62 references]

Expert Q&A: Your Top Questions Answered

Q1: The paper identifies porosity as the most frequent defect. What are the primary causes and mitigation strategies discussed?

A1: According to the paper (Section 2.2), porosity is caused by the entrapment of gases or by shrinkage during solidification. The most effective mitigation strategies highlighted are degassing the molten metal before pouring, ensuring proper mold venting to allow gases to escape, and optimizing cooling rates to manage shrinkage.

Q2: How exactly does numerical simulation help reduce defects? What specific techniques are mentioned?

A2: Numerical simulation provides a virtual environment to predict and analyze the complex physics of casting before production. The paper notes (Section 4) that techniques like Computational Fluid Dynamics (CFD) are used to model the flow of molten metal to ensure uniform filling and minimize turbulence, while Finite Element Analysis (FEA) and other thermal simulations help optimize cooling rates to reduce residual stresses and prevent cracking. This predictive capability allows engineers to refine the process parameters and mold design virtually, avoiding costly physical trials.

Q3: The review mentions Industry 4.0. What specific technologies are enabling a more data-driven casting process?

A3: The paper emphasizes the integration of Industry 4.0 technologies to transform casting into a dynamic, data-driven process (Sections 5.4 and 6.1). Key technologies mentioned include IoT-enabled sensors for real-time process monitoring, machine learning algorithms trained on simulation and production data to predict outcomes and suggest adjustments, and data analytics to provide continuous feedback for dynamic process control.

Q4: What are the main barriers preventing wider adoption of these advanced simulation and optimization tools in the industry?

A4: The paper identifies several key challenges (Sections 4.5 and 5.5). The primary barriers include high computational costs associated with complex simulations, the need for accurate and comprehensive material property data to ensure model accuracy, and the complexity of multi-physics modeling. Additionally, high initial costs for software and hardware, along with a skills gap in the workforce for advanced data analytics and simulation, can hinder adoption.

Q5: For investment casting specifically, what are the most significant recent innovations?

A5: The review highlights three major areas of innovation in investment casting (Section 3). First are material innovations, such as advanced ceramic slurries that improve mold durability and thermal shock resistance, and new wax formulations that enhance pattern stability. Second is the increased use of automation and robotics for wax injection and shell building, which reduces human error and increases throughput. Third is a growing focus on sustainability, including the recycling of ceramic slurries and wax, and exploring biodegradable materials.

Q6: The paper discusses various optimization techniques. Which ones are most relevant for solving complex, multi-objective problems in casting?

A6: For complex problems with multiple competing objectives (e.g., minimizing defects while also reducing cycle time), the paper points to Genetic Algorithms (GA) as particularly useful (Section 5.2). GAs are inspired by evolutionary principles and can effectively search for optimal solutions in complex scenarios involving factors like selection, crossover, and mutation, making them well-suited for multi-objective optimization in casting.

Q7: What does the paper suggest for future research in enhancing simulation capabilities?

A7: The paper's future work section (6.2) suggests that efforts should focus on overcoming the current limitations of simulation. This includes developing faster algorithms to reduce high computational costs and creating more comprehensive material property databases. A key priority is the development of multi-physics models that can integrate fluid dynamics, thermal behavior, and solid mechanics for a more complete understanding of casting phenomena.

Conclusion: Paving the Way for Higher Quality and Productivity

The core challenge in manufacturing has always been to balance quality, cost, and speed. This comprehensive review demonstrates that for Modern Casting Processes, the key breakthrough lies in the systematic integration of simulation and data-driven optimization. By moving beyond traditional, experience-based methods, foundries can now predict and prevent defects, slash energy consumption, and produce highly complex components with greater consistency. The practical insights from this research provide a clear path for R&D and operations teams to enhance process control and achieve new levels of performance.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Recent Advancements and Critical Insights in Casting Processes" by "Amarishkumar J Patel and Sunilkumar N Chaudhari".

Source: https://doi.org/10.32628/IJSRMME

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.