Overcoming the 'Impossible': How Nanoparticles Unlock High-Strength Aluminum for Investment Casting

This technical brief is based on the academic paper "Rapid Investment Casting of Nano-treated Aluminum Alloy 2024" by Yitian Chi, Narayanan Murali, and Xiaochun Li. This is a preprint research paper and has not been peer reviewed. It is summarized and analyzed for manufacturing professionals by the experts at STI C&D.

Keywords

- Primary Keyword: Rapid Investment Casting AA2024

- Secondary Keywords: Nanoparticle-treated aluminum, TiC nanoparticles, hot cracking, grain refinement, investment casting defects, additive manufacturing patterns

Executive Summary

- The Challenge: High-strength aluminum alloys like AA2024 are highly desirable but traditionally considered "uncastable" via investment casting due to severe hot cracking and shrinkage defects that occur during slow solidification.

- The Method: Researchers employed a rapid investment casting (RIC) process, using additively manufactured patterns, and introduced approximately 1 vol.% of Titanium Carbide (TiC) nanoparticles into the AA2024 melt.

- The Key Breakthrough: The addition of nanoparticles completely eliminated hot cracking and solidification defects, enabling the successful casting of complex AA2024 parts. The resulting material exhibited a dramatically refined grain structure and extraordinary mechanical properties, rivaling those of commercially wrought AA2024.

- The Bottom Line: This nanotechnology-enabled approach makes it possible to produce complex, high-performance AA2024 components with the design freedom and cost-effectiveness of rapid investment casting, a feat previously thought impossible.

The Challenge: Why This Research Matters for HPDC Professionals

For decades, engineers have sought to use high-performance alloys like AA2024, known for its high strength and fatigue resistance, in components with complex geometries. Investment casting (IC) is an ideal process for producing such parts, especially when combined with additive manufacturing for rapid pattern production (Rapid Investment Casting, or RIC). However, a significant roadblock has always been the material itself.

AA2024 and similar high-strength Al-Cu-Mg alloys are notoriously susceptible to hot cracking and other shrinkage defects during the slow solidification inherent to the investment casting process (Shabestari and Ghoncheh 2015). This has largely prevented their use, forcing designers to compromise on material choice or opt for more expensive and time-consuming manufacturing methods. This study directly confronts this long-standing industry challenge.

The Approach: Unpacking the Methodology

To overcome the castability issues of AA2024, the researchers integrated nanotechnology into a modern RIC workflow. The core of their methodology was:

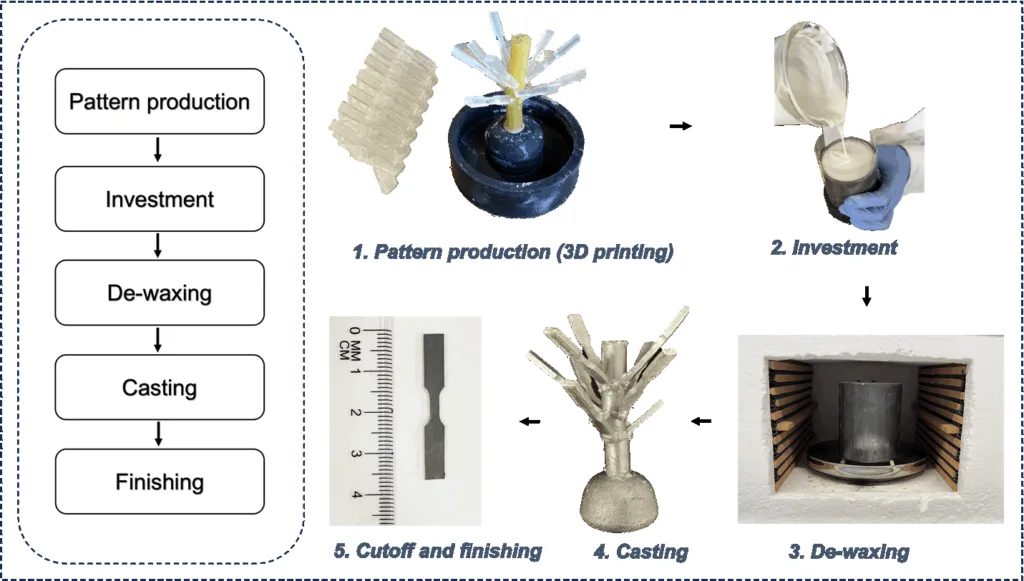

- Pattern Production: Tensile bar patterns were produced using a masked stereolithographic (MSLA) 3D printer and assembled onto a wax tree.

- Mold Creation: A ceramic shell was created around the pattern tree using a standard investment slurry, which was then de-waxed and preheated.

- Nano-treatment: The key innovation was the preparation of the AA2024 melt. Researchers added an Al master nanocomposite containing TiC nanoparticles to achieve a final concentration of approximately 1 vol.% TiC in the alloy. A control sample without nanoparticles was also prepared.

- Casting & Testing: The molten alloys were poured into the pre-heated molds under a vacuum. The resulting castings were then subjected to comprehensive microstructural analysis (SEM, XRD, DSC) and mechanical testing (microhardness, tensile tests) to evaluate the effect of the nanoparticles.

The Breakthrough: Key Findings & Data

The results demonstrated a dramatic and unequivocal success for the nano-treated alloy. While the standard AA2024 casting failed, the nano-treated version excelled.

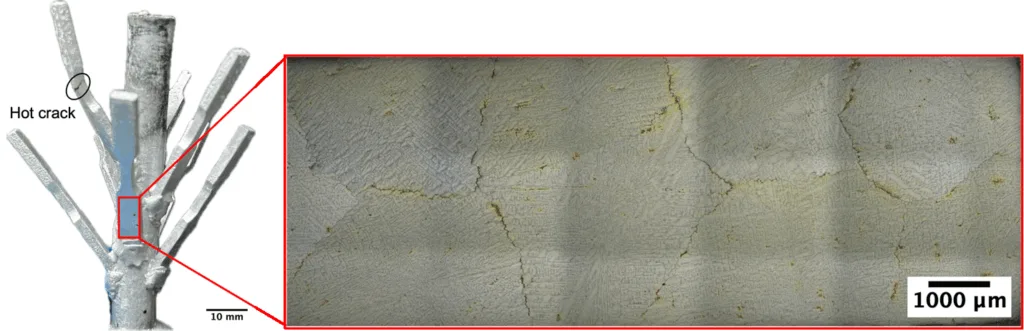

- Elimination of Casting Defects: The control sample of pure AA2024 exhibited poor casting quality with large, visible cracks. In stark contrast, the nano-treated IC2024-NT was successfully cast without any solidification defects, as shown by the comparison in Figure 2.

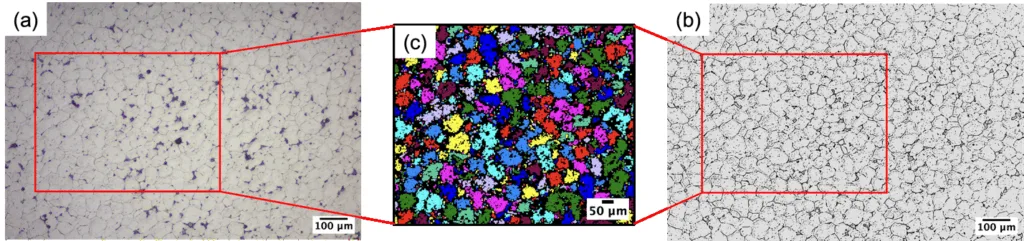

- Massive Grain Refinement: The nanoparticles acted as potent nucleation sites, preventing grain coarsening. The average grain size in the pure AA2024 was a massive 2431.3 µm. The nano-treated sample, however, had an average grain size of just 49.6 µm—a reduction of over 98% (Figure 3). This fine, globular grain structure is critical for preventing hot cracking.

- Superior Mechanical Properties: The pure AA2024 casting was so brittle it failed before reaching its yield point. The nano-treated IC2024-NT, however, showed remarkable performance. After a T6 heat treatment, it achieved a yield strength of 377.4 MPa and an ultimate tensile strength of 429.5 MPa, values that are competitive with commercial wrought AA2024 (Table 3). Furthermore, it demonstrated excellent ductility, reaching 16.9% elongation in the T4 condition (Figure 10).

Practical Implications for Your HPDC Operations

This research is not just an academic exercise; it presents a tangible pathway for expanding the capabilities of investment casting.

- For Design Engineers: The barrier to using high-strength, lightweight AA2024 for complex, net-shape components is now significantly lowered. This study proves that designers can specify this high-performance alloy for parts that previously required multi-piece assemblies or extensive machining from billet, unlocking new possibilities in aerospace, automotive, and other high-performance applications.

- For Process Engineers: The paper provides a clear methodology for success. The introduction of TiC nanoparticles is a viable process step that transforms an "uncastable" alloy into a reliable one. This nanotechnology-enabled RIC process can reduce production costs by up to 60% and shorten lead times by 89% compared to traditional tooling methods (Wang et al. 2019).

- For Quality Control: The research highlights critical quality indicators. The presence of a fine, equiaxed grain structure (as seen in Figure 3) and a uniform distribution of secondary phases are hallmarks of a successful nano-treated casting. This provides a clear microstructural fingerprint for ensuring part quality and performance.

Paper Details

Rapid Investment Casting of Nano-treated Aluminum Alloy 2024

1. Overview:

- Title: Rapid Investment Casting of Nano-treated Aluminum Alloy 2024

- Author: Yitian Chi, Narayanan Murali, Xiaochun Li

- Year of publication: 2023 (Preprint)

- Journal/academic society of publication: SSRN Electronic Journal

- Keywords: Investment casting, AA2024, Additive manufacturing, Nano-treating

2. Abstract:

Rapid investment casting (RIC) based on additive manufacturing has been widely applied in the casting industry owing to its rapid production of patterns and components of free-form and complex geometries without tooling, which is highly desirable for multiple industries. However, high-performance Al-Cu-Mg alloys with high strength and good fatigue resistance, such as AA2024, are traditionally considered very difficult, if not impossible, for investment casting, as they are susceptible to hot cracking and other shrinkage defects during the slow solidification process. In this study, nanoparticles are used to enable the rapid investment casting of AA2024 without any cracks or shrinkage defects. Nanotechnology-enabled RIC of AA2024 is successfully demonstrated to offer good casting quality and extraordinary mechanical performance. This work shows great potential for nanotechnology-enabled RIC of other high-strength aluminum alloys for widespread applications.

3. Introduction:

Investment casting (IC) is a widely used process for mass-producing complex metal parts. However, traditional IC suffers from high tooling costs and long lead times. By using additive manufacturing for pattern production, rapid investment casting (RIC) significantly reduces costs and lead times, while allowing for greater design freedom. Despite these advantages, high-strength aluminum alloys like AA2024, which are valued for their strength and fatigue resistance, have been incompatible with RIC. Their susceptibility to hot cracking during the slow solidification phase of IC has made them nearly impossible to cast successfully. This study aims to solve this long-standing problem by introducing nanoparticles into the process.

4. Summary of the study:

Background of the research topic:

The research addresses the challenge of casting high-strength aluminum alloys, specifically AA2024, using the rapid investment casting (RIC) process. AA2024 is desirable for its mechanical properties but is prone to severe defects like hot cracking when cast, especially with the slow cooling rates typical of IC.

Status of previous research:

Previous research has shown that nanotechnology can successfully improve the weldability and printability of AA2024 in processes like additive manufacturing. By adding nanoparticles, the solidification behavior can be dramatically altered, leading to crack-free, fine-grained structures. However, little success had been reported for applying this concept to the investment casting of AA2024.

Purpose of the study:

The study's purpose was to demonstrate that by introducing TiC nanoparticles, it is possible to successfully fabricate AA2024 components using the RIC process, achieving defect-free castings with excellent mechanical properties.

Core study:

The core of the study involved a direct comparison between two sets of AA2024 castings made via RIC. One set was a standard AA2024 alloy (IC2024), and the other was treated with approximately 1 vol.% of TiC nanoparticles (IC2024-NT). The study evaluated the casting quality, microstructure (grain size, phase distribution), and mechanical performance (hardness, tensile properties) of both samples to prove the effectiveness of the nano-treatment.

5. Research Methodology

Research Design:

The experiment was designed as a comparative study. Tensile bar patterns were 3D printed (MSLA), assembled into a tree, and used to create ceramic investment molds. Two batches of AA2024 melt were prepared: one standard and one with TiC nanoparticles. Both were cast under identical conditions (pre-heated mold, vacuum pressure). The resulting samples were then analyzed and compared. Post-process T4 and T6 heat treatments were also performed to evaluate the material's response.

Data Collection and Analysis Methods:

- Chemical Composition: Inductively coupled plasma-optical emission spectroscopy (ICP-OES) was used to verify the alloy compositions.

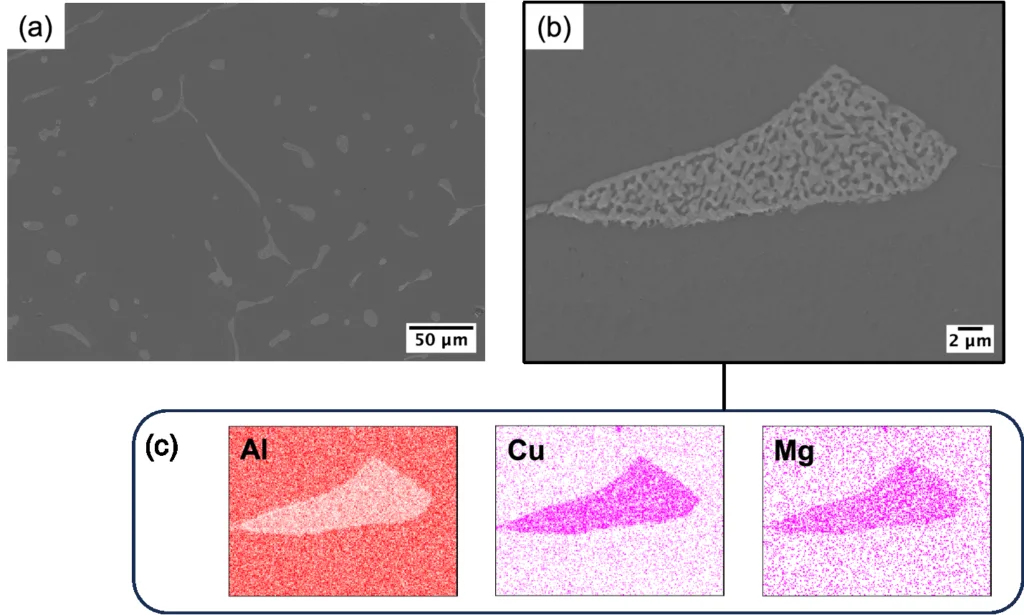

- Microstructural Analysis: Scanning electron microscopy (SEM) with energy-dispersive x-ray spectroscopy (EDX) was used to examine the microstructure and phase distribution. Grain size was measured using an optical microscope after chemical etching.

- Phase Identification: X-ray diffraction (XRD) was used to identify the phases present in the cast samples.

- Thermal Analysis: Differential scanning calorimetry (DSC) was used to study the solidification behavior.

- Mechanical Testing: Vickers microhardness and tensile tests (at a strain rate of 0.001 s⁻¹) were conducted to evaluate mechanical performance.

Research Topics and Scope:

The research focused on the feasibility of using nanotechnology to enable the RIC of AA2024. The scope included the fabrication of test samples, detailed characterization of the resulting microstructure, and a thorough evaluation of the mechanical properties in as-cast and heat-treated conditions.

6. Key Results:

Key Results:

- The standard IC2024 sample failed during casting, exhibiting severe hot cracks. The nano-treated IC2024-NT sample was cast successfully without any defects.

- The addition of TiC nanoparticles caused dramatic grain refinement. The average grain size was reduced from 2431.3 µm in the pure sample to 49.6 µm in the nano-treated sample.

- The nanoparticles modified the morphology of secondary phases (like Al₂CuMg), breaking up the bulky, continuous networks into finer, fragmented, and more uniformly distributed particles.

- The mechanical properties of IC2024-NT were vastly superior. In the T6 condition, it achieved a yield strength of 377.4 MPa and an ultimate tensile strength of 429.5 MPa, which is competitive with wrought AA2024. The pure cast sample was too brittle to test properly.

- The ductility of IC2024-NT was excellent, reaching 16.9% in the T4 condition, demonstrating the effectiveness of nano-treating in mitigating solidification defects.

Figure Name List:

- Figure 1. Basic rapid investment casting process flowchart

- Figure 2. Investment casting tensile bar tree for IC2024 (left) and its optical microstructures (right)

- Figure 3. Optical microstructures of cross-sections for IC2024-NT (a); (b) shows threshold image of (a); (c) shows color-labeled grain structure of one segment of (a) &(b)

- Figure 4. XRD spectra of pure and nano-treated samples

- Figure 5. SEM images of as-cast IC2024 (a, b); (c) shows EDS maps of Al, Cu, and Mg in (b)

- Figure 6. SEM images of as-cast IC2024-NT (a, b) conditions; (c) shows EDS maps of Al, Cu, Mg, and Ti in (b)

- Figure 7. SEM images of IC2024-NT after T6 heat treatment (a,b); (c) shows EDS mapping of Al, Cu, Mg, and Ti in (b)

- Figure 8. DSC heating curves for investment cast AA2024

- Figure 9. Microhardness of cast samples under different processing conditions

- Figure 10. Representative stress-strain curves for cast samples in different conditions

7. Conclusion:

This work successfully demonstrates that nanotechnology can enable the rapid investment casting of AA2024, an alloy conventionally considered impossible to cast this way due to hot cracking. The inclusion of TiC nanoparticles improves castability by eliminating defects, promotes significant grain refinement, and modifies secondary phases. The resulting nano-treated AA2024 exhibits extraordinary mechanical properties, including high strength and ductility, that are competitive with wrought counterparts. This research shows great potential for applying this method to other high-strength aluminum alloys, opening up new avenues for producing complex, high-performance components for widespread applications.

8. References:

- [The full list of 19 references from pages 17-19 of the paper is included here.]

- Cáceres, C.H., J.R. Griffiths, A.R. Pakdel, and C.J. Davidson. 2005. "Microhardness Mapping and the Hardness-Yield Strength Relationship in High-Pressure Diecast Magnesium Alloy AZ91.” Materials Science and Engineering: A 402 (1–2): 258–68.

- Cheah, C. M., L. H. Tan, C. Feng, C. W. Lee, and C. K. Chua. 2004. “Rapid Investment Casting: Direct and Indirect Approaches via Fused Deposition Modelling.” The International Journal of Advanced Manufacturing Technology 23 (1–2): 93–101.

- Chen, Guan-Cheng, and Xiaochun Li. 2023. “Effect of TiC Nano-Treating on the Fluidity and Solidification Behavior of Aluminum Alloy 6063.” Journal of Materials Processing Technology, November, 118241.

- Chi, Yitian, Narayanan Murali, Jingke Liu, Maximilian Liese, and Xiaochun Li. 2022. “Wire Arc Additive Manufacturing (WAAM) of Nanotreated Aluminum Alloy 6061.” Rapid Prototyping Journal 29 (7): 1341–49.

- Chi, Yitian, Narayanan Murali, Tianqi Zheng, Jingke Liu, and Xiaochun Li. 2022. “Wire-Arc Additive Manufacturing of Nano-Treated Aluminum Alloy 2024.” 3D Printing and Additive Manufacturing, August.

- Chi, Yitian, Shauihang Pan, Maximillian Liese, Jingke Liu, Narayanan Murali, Ebryanto Soemardy, and Xiaochun Li. 2022. “Wire-Arc Directed Energy Deposition of Aluminum Alloy 7075 With Dispersed Nanoparticles.” Journal of Manufacturing Science and Engineering 145 (031010).

- Davis, Joseph R. 1998. Metals Handbook Desk Edition. 1st ed. American Society of Mechanical Engineers.

- Dotchev, K., and S. Soe. 2006. “Rapid Manufacturing of Patterns for Investment Casting: Improvement of Quality and Success Rate.” Rapid Prototyping Journal 12 (3): 156–64.

- Eskin, D.G., Suyitno, and L. Katgerman. 2004. “Mechanical Properties in the Semi-Solid State and Hot Tearing of Aluminium Alloys.” Progress in Materials Science 49 (5): 629–711.

- García-Hernández, J.L., et al. 2019. “Influence of Plastic Deformation and Cu/Mg Ratio on the Strengthening Mechanisms and Precipitation Behavior of AA2024 Aluminum Alloys.” Journal of Materials Research and Technology 8 (6): 5471–75.

- Greer, A.L, et al. 2000. “Modelling of Inoculation of Metallic Melts: Application to Grain Refinement of Aluminium by Al-Ti-B." Acta Materialia 48 (11): 2823–35.

- Grote, Karl-Heinrich, and Hamid Hefazi, eds. 2021. Springer Handbook of Mechanical Engineering. Springer Handbooks. Cham: Springer International Publishing.

- Guo, Enyu, et al. 2018. “The Influence of Nanoparticles on Dendritic Grain Growth in Mg Alloys.” Acta Materialia 152 (June): 127–37.

- Hamilton, R.W, et al. 2003. “Multiscale Modeling for the Prediction of Casting Defects in Investment Cast Aluminum Alloys.” Materials Science and Engineering: A 343 (1–2): 290–300.

- Humphreys, F.J., and M.G. Ardakani. 1996. “Grain Boundary Migration and Zener Pinning in Particle-Containing Copper Crystals.” Acta Materialia 44 (7): 2717–27.

- Jia, Yiwang, Shuncheng Wang, and Da Shu. 2020. “Grain Size Prediction and Investigation of 7055 Aluminum Alloy Inoculated by Al–5Ti–1B Master Alloy.” Journal of Alloys and Compounds 821 (April): 153504.

- Kaiser, R., et al. 2013. “The Influence of Cooling Conditions on Grain Size, Secondary Phase Precipitates and Mechanical Properties of Biomedical Alloy Specimens Produced by Investment Casting.” Journal of the Mechanical Behavior of Biomedical Materials 24 (August): 53–63.

- Li, Jiehua, et al. 2021. “The Nucleation Sequence of a-Al on TiB2 Particles in Al-Cu Alloys.” Acta Materialia 206 (March): 116652.

- Li, Siyu, et al. 2014. “Influence of Mg Contents on Aging Precipitation Behavior of Al-3.5Cu-xMg Alloy.” Acta Metallurgica Sinica (English Letters) 27 (1): 107–14.

- Lin, Y.C., et al. 2012. "Precipitation in Al-Cu-Mg Alloy during Creep Exposure.” Materials Science and Engineering: A 556 (October): 796–800.

- Martin, John H., et al. 2017. "3D Printing of High-Strength Aluminium Alloys.” Nature 549 (7672): 365–69.

- Moon, Joonoh, et al. 2008. “Orowan Strengthening Effect on the Nanoindentation Hardness of the Ferrite Matrix in Microalloyed Steels.” Materials Science and Engineering: A 487 (1–2): 552–57.

- Pattnaik, Sarojrani, D. Benny Karunakar, and P.K. Jha. 2012. “Developments in Investment Casting Process—A Review.” Journal of Materials Processing Technology 212 (11): 2332–48.

- Sato, Yutaka S., et al. 2003. “Hall-Petch Relationship in Friction Stir Welds of Equal Channel Angular-Pressed Aluminium Alloys." Materials Science and Engineering: A 354 (1–2): 298–305.

- Shabestari, S. G., and M. H. Ghoncheh. 2015. “Investigation on the Effect of Cooling Rate on Hot Tearing Susceptibility of Al2024 Alloy Using Thermal Analysis.” Metallurgical and Materials Transactions B 46 (6): 2438–48.

- Singh, Daljinder, Rupinder Singh, and Kamaljit Singh Boparai. 2018. “Development and Surface Improvement of FDM Pattern Based Investment Casting of Biomedical Implants: A State of Art Review." Journal of Manufacturing Processes 31 (January): 80–95.

- Sokoluk, Maximilian, et al. 2019. “Nanoparticle-Enabled Phase Control for Arc Welding of Unweldable Aluminum Alloy 7075.” Nature Communications 10 (1): 98.

- Wang, Jiayi, et al. 2019. "Design and Topology Optimization of 3D-Printed Wax Patterns for Rapid Investment Casting." Procedia Manufacturing 34: 683–94.

- Yang, Hanry, et al. 2017. "Reinforcement Size Dependence of Load Bearing Capacity in Ultrafine-Grained Metal Matrix Composites.” Metallurgical and Materials Transactions A 48 (9): 4385–92.

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing the investment casting of high-strength aluminum. The findings offer a clear, data-driven path toward improving quality, reducing defects, and expanding the portfolio of alloys available for complex, net-shape manufacturing.

STI C&D is committed to applying cutting-edge industry research to solve our customers’ most challenging technical problems. If the problem discussed in this white paper aligns with your research goals, please contact our engineering team to discuss how we can help you apply these advanced principles to your research.

Expert Q&A:

- Q1: Why is it normally so difficult to make parts from AA2024 using investment casting?

- A: According to the paper, AA2024 is traditionally considered very difficult, if not impossible, for investment casting because it is "susceptible to hot cracking and other shrinkage defects during the slow solidification process." The slow cooling allows large, dendritic grains to form, which contributes to these defects.

- Q2: What was the key innovation in this study that allowed for successful casting of AA2024?

- A: The key innovation was the use of nanotechnology. Specifically, researchers added "approximately 1 vol.% of TiC nanoparticles" to the AA2024 melt. This nano-treatment was the critical factor that enabled the casting of AA2024 "without any cracks or shrinkage defects."

- Q3: How exactly did the nanoparticles improve the castability and quality of the AA2024 alloy?

- A: The paper identifies two primary mechanisms. First, the nanoparticles acted as powerful grain refiners, promoting continuous nucleation and inhibiting grain growth. This is supported by data showing the grain size was reduced from 2431.3 µm to just 49.6 µm. Second, the nanoparticles were "dispersed in pseudo-clusters near or within the secondary phases to break them into discontinuous fragments," leading to a more uniform and refined microstructure, as shown in Figure 6.

- Q4: How do the mechanical properties of this new nano-treated cast AA2024 compare to the standard material?

- A: The properties are exceptionally better. The standard cast AA2024 was brittle and failed prematurely. In contrast, the nano-treated version (IC2024-NT) showed remarkable performance that "can compete with even commercial wrought AA2024." For example, after T6 heat treatment, it achieved a yield strength of 377.4 MPa and an ultimate tensile strength of 429.5 MPa, as detailed in Table 3. It also showed excellent ductility of 16.9% after T4 treatment.

Copyright

- This material is an analysis of the paper "Rapid Investment Casting of Nano-treated Aluminum Alloy 2024" by Yitian Chi, et al.

- Source of the paper: https://ssrn.com/abstract=4670054

- This material is for informational purposes only. Unauthorized commercial use is prohibited.

- Copyright © 2025 CASTMAN. All rights reserved.