International Journal of Metalcasting (2022)Cite this article

Abstract

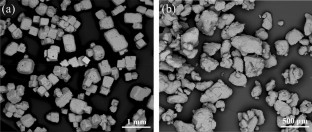

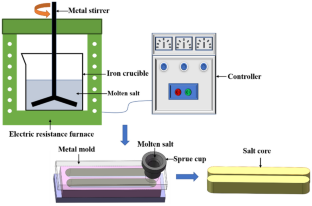

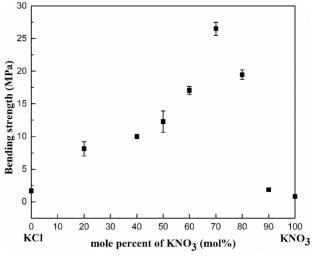

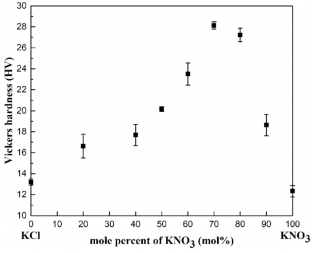

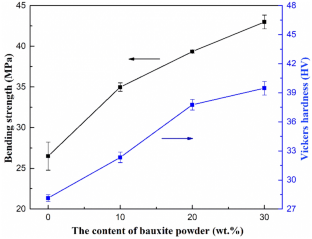

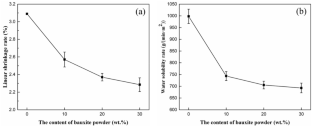

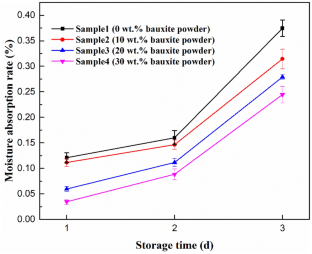

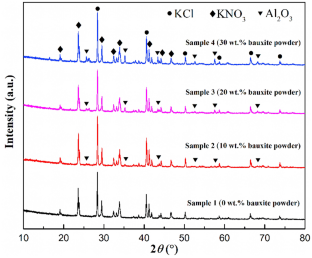

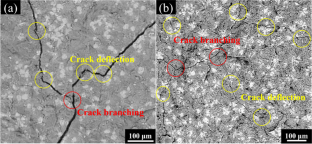

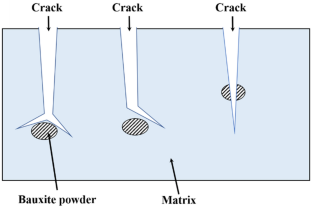

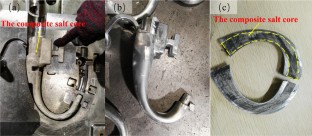

A composite inorganic salt core with good water solubility and formability was proposed using potassium nitrate (KNO3) and potassium chloride (KCl) as base materials. The KNO3–KCl molar ratio has been optimized for the KNO3–KCl composite salt core, and then a low-cost bauxite powder acting as a reinforcing material was added to strengthen the optimized KNO3-KCl composite salt core for the application of hollow zinc alloy die castings. The results show that 70 mol% KNO3-30 mol%KCl composite salt core (CSC) possesses a good comprehensive performance, which has the maximum bending strength of 26.5 MPa and the excellent water solubility rate of 998 g/(min·m2). With increasing the bauxite powder content, the bending strength and vickers hardness of the CSC increase, but the water solubility rate of the CSC decreases gradually. When the bauxite powder content is 30 wt.%, the CSC has a bending strength of 42.99 MPa and vickers hardness of 39.2 HV, which respectively increased by 62.2% and 39.5%, and the water solubility rate is still higher than 692.9 g/(min·m2). The microanalysis reveals that the bauxite powder is stable and evenly distributed among the CSC matrix, which significantly refines the KCl primary phase, resulting in improving the properties of the CSC. Additionally, the crack deflection and branching caused by bauxite powder also enhance the properties of the CSC.

Korea Abstract

질산칼륨(KNO3)과 염화칼륨(KCl)을 모재로 하여 수용성 및 성형성이 우수한 복합 무기염 코어를 제안하였다.

KNO3-KCl 복합염 코어에 대해 KNO3-KCl 몰비를 최적화한 후 보강재 역할을 하는 저가의 보크사이트 분말을 첨가하여 중공아연합금 적용에 최적화된 KNO3-KCl 복합염 코어 강화 다이 캐스팅.

결과는 70 mol% KNO3-30 mol% KCl 복합염 코어(CSC)가 26.5 MPa의 최대 굽힘 강도와 998 g/(min·m2)의 우수한 수용해도를 갖는 우수한 종합 성능을 가지고 있음을 보여줍니다.

보크사이트 분말 함량이 증가함에 따라 CSC의 굽힘 강도 및 비커스 경도는 증가하지만 CSC의 수용해도율은 점차 감소한다.

보크사이트 분말 함량이 30중량%일 때 CSC의 굽힘 강도는 42.99MPa, 비커스 경도는 39.2HV로 각각 62.2% 및 39.5% 증가했으며 수용해도율은 여전히 692.9g/( 분·m2).

미세 분석 결과 보크사이트 분말이 안정적이고 CSC 매트릭스 사이에 고르게 분포되어 KCl 1차상을 크게 정제하여 CSC의 특성을 향상시키는 것으로 나타났습니다. 또한 보크사이트 분말로 인한 균열 변형 및 분기도 CSC의 특성을 향상시킵니다.

Keywords

- composite salt core

- potassium nitrate

- potassium chloride

- properties optimization

- bauxite powder

- strengthening mechanism

- Figure 1

View in article

View in article - Figure 2

View in article

View in article - Figure 3

View in article

View in article - Figure 4

View in article

View in article - Figure 5

View in article

View in article - Figure 6

View in article

View in article - Figure 7

View in article

View in article - Figure 8

View in article

View in article - Figure 9

View in article

View in article - Figure 10

View in article

View in article - Figure 11

View in article

View in article - Figure 12

View in article

View in article

References

- V. Reveko, F. Lampert, G. Winther, P. Moller, Change of the decorative properties of zinc-plated zinc die castings over time. Inter. Metalcast. 13, 130–136 (2019). https://doi.org/10.1007/s40962-018-0237-0CAS Article Google Scholar

- A. Pola, M. Tocci, F.E. Goodwin, Review of microstructures and properties of zinc alloys. Metals 10, 253–289 (2020)CAS Article Google Scholar

- M. Page, B. Weidenfeller, S. Hartmann, Influence of temperature and aging on the thermal diffusivity, thermal conductivity and heat capacity of a zinc die casting alloy. J. Alloy Compd. 786, 1060–1067 (2019)Article Google Scholar

- T. Xue, W.Q. Gu, Y.F. Yu, J. Wu, Research and application development in die casting zinc alloy. Special Casting & Nonferrous Alloys 36, 260–264 (2016). ((in Chinese))Google Scholar

- M.A. Page, S. Hartmann, Experimental characterization, material modeling, identification and finite element simulation of the thermo-mechanical behavior of a zinc die-casting alloy. Int. J. Plasticity 101, 74–85 (2018)Article Google Scholar

- R. Huang, B. Zhang, Study on the composition and properties of salt cores for zinc alloy die casting. Inter. Metalcast. 11, 440–447 (2017). https://doi.org/10.1007/s40962-016-0086-7Article Google Scholar

- A. Fortini, M. Merlin, G. Raminella, A comparative analysis on organic and inorganic core binders for a gravity diecasting Al alloy component. Inter. Metalcast. (2021). https://doi.org/10.1007/s40962-021-00628-1Article Google Scholar

- S. Tu, F.C. Liu, G.J. Li, W.M. Jiang, X.W. Liu, Z.T. Fan, Fabrication and characterization of high-strength water-soluble composite salt core for zinc alloy die castings. Int. J. Adv. Manuf. Tech. 95, 505–512 (2018)Article Google Scholar

- B. Fuchs, H. Eibisch, C. Körner, Core viability simulation for salt core technology in high-pressure die casting. Inter. Metalcast. 7(3), 39–45 (2013). https://doi.org/10.1007/BF03355557CAS Article Google Scholar

- M. Merchán, M.G. de Cortazar, H. Galarraga, Research on coatings and infiltration to strengthen ceramic lost cores used in high-pressure die casting processes. Inter. Metalcast. 13(3), 597–603 (2019). https://doi.org/10.1007/s40962-018-00301-0CAS Article Google Scholar

- J. Beňo, E. Adámková, F. Mikšovský, Development of composite salt cores for foundry applications. Mater. Tech. 49, 619–623 (2015)Google Scholar

- P. Jiang, F.C. Liu, Z.T. Fan, W.M. Jiang, X.W. Liu, Performance of water-soluble composite sulfate sand core for magnesium alloy castings. Arch. Civ. Mech. Eng. 16, 494–502 (2016)Article Google Scholar

- X.L. Gong, W.M. Jiang, F.C. Liu, Z.Y. Yang, Z.T. Fan, Effects of glass fiber size and content on microstructures and properties of KNO3-based water-soluble salt core for high pressure die casting. Inter. Metalcast. 15, 520–529 (2021). https://doi.org/10.1007/s40962-020-00480-9CAS Article Google Scholar

- P. Jelínek, F. Mikšovský, J. Beňo, E. Adámková, Development of foundry cores based on inorganic salts. Mater. tech. 6, 689–693 (2013)Google Scholar

- J. Yaokawa, D. Miura, K. Anzai, Y. Yamada, Strength of salt core composed of alkali carbonate and alkali chloride mixtures made by casting technique. Mater. Trans. 48, 1034–1041 (2007)CAS Article Google Scholar

- Z. Xiao, L.T. Harper, A.R. Kennedy, N.A. Warrior, A water-soluble core material for manufacturing hollow composite sections. Compos. Struct. 182, 380–390 (2017)Article Google Scholar

- R.J. Donahue, M.T. Degler, Congruent melting salt alloys for use as salt cores in high pressure die casting. U.S. Patent 9878367, 2018-1-30

- X.Y. Liu, W.H. Liu, X.T. Wang, Composition optimization and strengthening mechanism of high-strength composite water-soluble salt core for foundry. Inter. Metalcast. (2021). https://doi.org/10.1007/s40962-021-00725-1Article Google Scholar

- C. Cantas, B. Baksan, Effects of composition on the physical properties of water-soluble salt cores. Inter. Metalcast. 15, 839–851 (2021). https://doi.org/10.1007/s40962-020-00511-5CAS Article Google Scholar

- F.C. Liu, P. Jiang, Y. Huang, W.M. Jiang, Z.T. Fan, A water-soluble magnesium sulfate bonded sand core material for manufacturing hollow composite castings. Compos. Struct. 201, 553–560 (2018)Article Google Scholar

- Youji Y. Method of manufacturing expendable salt core for casting. U.S. Patent 8574476B (2013)

- L. Zhang, Effect of kaolin on tensile strength and humidity resistance of a water-soluble potassium carbonate sand core. Chin. Foundry 13, 15–21 (2016)Article Google Scholar

- W. Jiang, J. Dong, L. Lou, M. Liu, Z. Hu, Preparation and properties of a novel water soluble core material. J. Mater. Sci. Tech. 26, 270–275 (2010)CAS Article Google Scholar

- X.L. Gong, X.W. Liu, Z. Chen, Z.Y. Yang, W.M. Jiang, Z.T. Fan, 3D Printing of high-strength water-soluble salt cores via layered extrusion forming. Int. J. Adv. Manuf. Tech. 118, 2993–3003 (2022)Article Google Scholar

- F.C. Liu, S. Tu, X.L. Gong, Z.T. Fan, Comparative study on performance and microstructure of composite water-soluble salt core material for manufacturing hollow zinc alloy castings. Mater. Chem. Phys. 252, 123257 (2020)CAS Article Google Scholar

- Salt Phase Diagrams. https://www.crct.polymtl.ca/fact/phase_diagram.php?file=KCl-KNO3.Jpg&dir=FTsalt. Accessed July 6, 2020

- W. Yuan, S.K. Panigrahi, J. Su, R.S. Mishra, Influence of grain size and texture on Hall-Petch relationship for a magnesium alloy. Scripta Mater. 65, 994–997 (2011)