Solving Porosity in Complex EV Castings: A Guide to Die Casting Process Optimization

This technical summary is based on the academic paper "Numerical Simulation and Process Optimization of Die-casting Aluminum Alloy Connection Bracket" by HAN Wei, LU Jianneng, JIANG Lizhen, YANG An, and OU Junjie, published in Special Casting & Nonferrous Alloys (2025).

Keywords

- Primary Keyword: Die Casting Process Optimization

- Secondary Keywords: Aluminum Alloy, Connection Bracket, Numerical Simulation, Magma Software, Porosity Defects, HPDC, Gating System Design

Executive Summary

- The Challenge: Casting complex aluminum alloy connection brackets for new energy vehicle motors with uneven wall thicknesses leads to imbalanced metal flow, causing critical defects like porosity and cold shuts.

- The Method: The researchers used Magma® simulation software to analyze the filling and solidification process, redesigning the gating and overflow system based on P-Q² curve analysis.

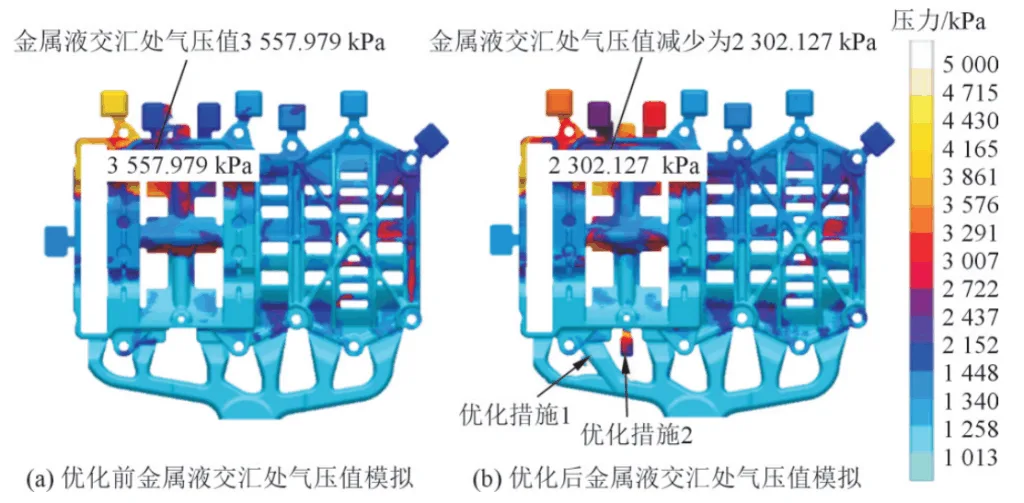

- The Key Breakthrough: Strategic modification of the ingate geometry and the addition of a targeted overflow channel dramatically balanced the filling flow, reducing simulated air pressure at critical weld lines by 35%.

- The Bottom Line: Simulation-driven Die Casting Process Optimization is essential for achieving the high density and product quality required for structurally complex, high-performance components.

The Challenge: Why This Research Matters for HPDC Professionals

In the fast-growing new energy vehicle (NEV) sector, components like the motor connection bracket are becoming increasingly complex. This specific A356.2 aluminum alloy bracket features a mix of thin-walled frames and robust mounting sections, a design necessity for connecting the motor to various powertrain components.

This geometric complexity presents a significant manufacturing challenge. The uneven wall thickness causes the molten aluminum to flow at different speeds and temperatures throughout the die cavity. This imbalanced flow is a primary cause of defects such as porosity, cold shuts, and shrinkage, particularly in areas that require subsequent machining for assembly. These defects compromise the dimensional accuracy and structural integrity of the final part, directly impacting its ability to perform its connection and mounting functions reliably. This research was initiated to find a systematic, data-driven solution to these common but critical production issues.

The Approach: Unpacking the Methodology

The research team employed a simulation-first approach to diagnose and solve the casting defects without costly and time-consuming physical trials.

Method 1: Process Simulation and Zonal Analysis

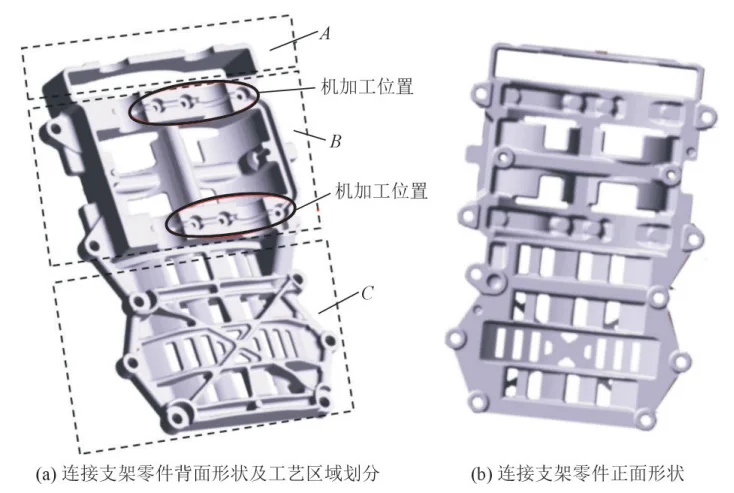

Using Magma® software, the team simulated the entire die-casting process, from filling to solidification. To systematically analyze the complex part, they divided its geometry into three distinct process areas based on structural characteristics and machining requirements:

- Area A: Thin-walled connecting ribs, prone to premature cooling and incomplete filling.

- Area B: Thicker mounting sections requiring post-cast machining, where internal porosity is unacceptable.

- Area C: A relatively uniform frame section.

This zonal analysis allowed for a targeted investigation of how molten metal behaved in each functionally critical area.

Method 2: Gating System Optimization via P-Q² Analysis

The initial design featured six ingates with identical cross-sections, which the simulation revealed was the source of the imbalanced flow. The team used P-Q² (Pressure vs. Flow Rate Squared) curve analysis to redesign the gating system. This engineering tool helps validate whether the size and shape of the ingates are optimized for the specific die-casting machine's capabilities, ensuring the molten metal enters the cavity with the ideal pressure and velocity to achieve a sound casting. The optimization focused on modifying ingate shapes and sizes to balance flow rates across all three process areas.

The Breakthrough: Key Findings & Data

The simulation-driven optimization yielded significant, quantifiable improvements in the casting process, directly addressing the root causes of the predicted defects.

Finding 1: Initial Gate Design Caused Severe Flow Imbalance and Air Entrapment

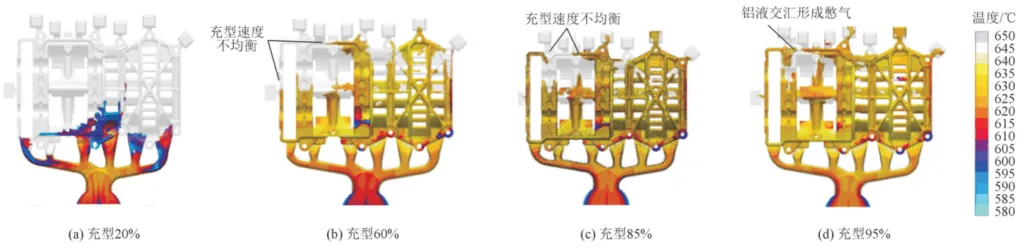

The initial simulation confirmed that the six identical ingates failed to deliver a uniform fill. As shown in the temperature simulations (Figure 3), when the uniform Area C was nearly full, Areas A and B still had approximately 20% of their volume unfilled. This lag caused the molten metal fronts to meet chaotically, trapping air. The air pressure simulation (Figure 4a) clearly predicted high-pressure pockets—a direct indicator of porosity—at the junction points, especially in the critical machined sections of Area B.

Finding 2: Optimized Gating System Reduced Air Entrapment Risk by 35%

The optimized design involved several key changes, including converting a sharp-angled ingate to a smooth radius, increasing its cross-sectional area from 2.35 cm² to 3.35 cm², and adding a new, dedicated overflow channel between two ingates to improve venting. The results were dramatic. As shown in Figure 7, the simulation of the optimized process showed that the maximum air pressure at the critical melt front junction was reduced from 3557.979 kPa in the initial design to 2302.127 kPa—a 35% reduction. This substantial drop in trapped air pressure directly correlates to a lower probability of porosity defects in the final casting.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that for parts with non-uniform wall thickness, a "one-size-fits-all" gating strategy is ineffective. Adjusting individual ingate geometries and strategically placing overflow channels are critical levers for balancing flow and reducing scrap.

- For Quality Control Teams: The data in Figure 4 and Figure 7 of the paper illustrates how simulation can predict the exact location of potential porosity. This information can be used to develop more targeted inspection plans, focusing on high-risk areas identified in the simulation phase.

- For Design Engineers: The findings indicate that the interaction between thin ribs and thick sections directly influences defect formation during solidification. This reinforces the importance of Design for Manufacturing (DFM) principles, where early collaboration between design and process engineers can mitigate casting issues before a single tool is cut.

Paper Details

Numerical Simulation and Process Optimization of Die-casting Aluminum Alloy Connection Bracket

1. Overview:

- Title: Numerical Simulation and Process Optimization of Die-casting Aluminum Alloy Connection Bracket

- Author: HAN Wei, LU Jianneng, JIANG Lizhen, YANG An, OU Junjie

- Year of publication: 2025

- Journal/academic society of publication: Special Casting & Nonferrous Alloys

- Keywords: Connecting Brackets, Numerical Simulation, Aluminum Alloy, Processing Optimization, Die Casting

2. Abstract:

Aiming at the problems of uneven filling flow and porosity caused by uneven wall thickness of aluminum alloy connecting bracket for new energy automobile motors, the structural characteristics and forming quality requirements of bracket were analyzed. The filling and solidification process was simulated by Magma software, and process area was divided according to the structural characteristics of parts and subsequent machining parts. The causes of local flow imbalance in liquid aluminum filling was investigated and occurrence trend of defects such as pores, cold shut and shrinkage porosity was predicted to optimize exhausting-overflow system of the connection bracket. According to the P-Q² curves of relationship between pressure and flow during die casting process, the shape and size of the ingate were modified to adjust the filling flow rate and filling pressure of each area, thus improving the internal density and production quality of casting.

3. Introduction:

High-pressure die casting is employed to produce aluminum alloy connection brackets for new energy vehicle motors. To facilitate connection with various power components, the bracket is designed with non-uniform frames and thin-walled connecting ribs. This complex geometry leads to imbalanced filling speeds and flow rates during casting, resulting in defects such as porosity, cold shuts, and insufficient filling, particularly in areas requiring subsequent machining. These defects compromise dimensional accuracy and the functional requirements of connection and assembly. This study utilizes Magma® software to simulate and analyze the die-casting filling and solidification process. By identifying defects like shrinkage and porosity in the initial process design and considering the functional quality requirements of different regions of the casting, the study aims to optimize the process to improve the internal density and production quality of the casting.

4. Summary of the study:

Background of the research topic:

The study addresses the manufacturing challenges associated with producing complex-shaped aluminum alloy connection brackets for the new energy vehicle industry. The inherent structural features of these components, such as non-uniform wall thickness, create difficulties in achieving sound castings using conventional high-pressure die-casting methods.

Status of previous research:

The study leverages the established methodology of using numerical simulation software (Magma®) as a tool for diagnosing and resolving die-casting defects. This approach allows for the analysis of metal flow, thermal profiles, and defect prediction without the need for physical tooling and trials.

Purpose of the study:

The primary purpose is to systematically analyze and resolve the issues of uneven filling flow and porosity in an aluminum alloy connection bracket. The objective is to optimize the die-casting process parameters, specifically the gating and overflow system, to enhance the internal structural density and overall product quality.

Core study:

The core of the study involved a multi-step simulation and optimization process. First, the initial die-casting process was simulated to identify the location and cause of defects like air entrapment and shrinkage porosity. Second, based on the analysis and engineering principles such as P-Q² curve validation, the gating and overflow system was redesigned. Finally, a new simulation was conducted on the optimized process to verify that the proposed changes effectively mitigated the identified defects and improved the overall casting quality.

5. Research Methodology

Research Design:

The research employed a comparative simulation study. An initial, baseline die-casting process design was established and simulated. The results were analyzed to identify predicted defects. An optimized process design was then developed, and a second simulation was performed. The results of the two simulations were compared to quantify the improvements.

Data Collection and Analysis Methods:

Data was generated and collected using Magma® die-casting simulation software. The analysis focused on key output parameters, including:

- Temperature distribution during filling and solidification.

- Velocity and flow patterns of the molten metal.

- Air pressure distribution to predict air entrapment and porosity.

- P-Q² curves to ensure the gating design was compatible with the die-casting machine's operational window.

Research Topics and Scope:

The research was focused on a single component: an A356.2 aluminum alloy connection bracket for a new energy vehicle motor. The scope was limited to the optimization of the gating and overflow system design to improve filling dynamics and reduce porosity and shrinkage defects. The material used was A356.2 aluminum alloy, and the die material was SKA61 tool steel.

6. Key Results:

Key Results:

- The initial design with six uniform ingates caused significant flow imbalance, leading to predicted air entrapment where melt fronts converged, particularly in machined areas (Area B).

- Simulation of the initial design predicted a high air pressure of 3557.979 kPa at the melt front junction, indicating a high risk of gas porosity.

- The optimized design, which involved modifying the shape of ingate #2 to a filleted transition, increasing its cross-sectional area, and adding a dedicated overflow channel, resulted in a more balanced filling pattern.

- The optimized process simulation showed a reduction in peak air pressure at the critical junction to 2302.127 kPa, a significant improvement.

- Analysis using P-Q² curves confirmed that increasing the ingate area from a theoretical 2.35 cm² to an optimized 3.35 cm² placed the process within the ideal operating window for the die-casting machine.

- The thermal simulation of the optimized process showed a more gradual and uniform temperature drop during solidification, reducing the potential for shrinkage porosity.

Figure Name List:

- 图1 连接支架零件工艺区域划分及3D图

- 图2 连接支架压铸浇注系统和排溢系统初始设计

- 图3 连接支架压铸充型过程温度模拟

- 图4 压铸充型时裹气及缩松缺陷预测模拟

- 图5 改变内浇口形状后的优化方案图

- 图6 通过P-Q²关系曲线检查内浇口设计的合理性

- 图7 充型过程气压优化对比模拟图

- 图8 充型过程金属液和模具温度变化模拟图

7. Conclusion:

(1) The differential wall thickness of the aluminum alloy connection bracket impedes balanced flow velocity and volume during filling. An initial design with six equal ingates leads to significant variations in solidification speed across different sections, causing air entrapment and cold shut defects where melt fronts meet.

(2) By designing a differentiated ingate system tailored to the varying wall thicknesses and structures of the casting's different regions, and by adding an overflow channel at the ingate, it is possible to improve venting efficiency and enhance the filling and solidification quality.

8. References:

- HAN W, LUJN, JIANG LZ, et al. Numerical simulation and process optimization of die-casting aluminum alloy connection bracket[J]. Special Casting & Nonferrous Alloys, 2025, 45(5):718-722.

Expert Q&A: Your Top Questions Answered

Q1: Why was the connection bracket divided into three distinct process areas (A, B, and C) for the analysis?

A1: The division was based on the part's structural characteristics and functional requirements. Area A consisted of thin-walled ribs prone to filling issues; Area B included thicker sections that required post-cast machining and thus demanded high internal density; Area C was a more uniform frame section. This zonal approach allowed for a targeted analysis and optimization strategy for each functionally distinct part of the casting.

Q2: What was identified as the primary cause of the predicted porosity in the initial design?

A2: The primary cause was the imbalanced filling created by the six identical ingates. The simulation showed that different areas of the die filled at different rates. This caused the molten metal fronts to meet late and turbulently, trapping air at their junctions, which was predicted as high-pressure zones (porosity) in the simulation, especially in the critical Area B.

Q3: How was the P-Q² curve used to validate the optimized gate design?

A3: The P-Q² curve plots the relationship between filling pressure (P) and the square of the flow rate (Q²), defining the optimal operating window for a specific die-casting machine. By simulating the process with the modified ingate area (increased from 2.35 cm² to 3.35 cm²), the researchers confirmed that the resulting process point on the P-Q² graph fell within the "optimal process window," ensuring the new design was both effective and compatible with the machine's capabilities.

Q4: What specific geometric changes were made to the gating system in the optimized design shown in Figure 5?

A4: The optimization involved several key modifications. For ingate #2, the cross-sectional area was increased, and the entry into the cavity was changed from perpendicular to slanted to reduce turbulence. Furthermore, a new, dedicated overflow channel was added between ingates #2 and #3 specifically to improve venting and exhaust in that region.

Q5: What is the dual function of the overflow system in this application?

A5: The overflow system serves two critical functions. First, it acts as a vent, allowing air trapped in the die cavity to escape as the molten metal fills it, which is crucial for preventing gas porosity. Second, it helps to stabilize the flow of the molten metal and serves as a trap for the initial, colder, or potentially contaminated metal at the leading edge of the flow front, ensuring only hot, clean metal forms the final part.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of casting complex components with high-quality requirements is a constant in the HPDC industry. This research demonstrates that a systematic approach to Die Casting Process Optimization, driven by powerful simulation tools, can effectively solve critical defects like porosity. By moving beyond a generic gating strategy and tailoring the design to the unique geometry of the part, the researchers achieved a more balanced fill, reduced the risk of defects, and improved the overall quality of the final casting.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Numerical Simulation and Process Optimization of Die-casting Aluminum Alloy Connection Bracket" by "HAN Wei, LU Jianneng, JIANG Lizhen, YANG An, OU Junjie".

Source: DOI: 10.15980/j.tzzz.T20240099

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.