Optimizing AA 5052-O Cold Rolling: How Rolling Speed Impacts Stress, Deformation, and Energy

This technical summary is based on the academic paper "Numerical Analysis of the Influence of the Rolling Speed on the Cold Rolling under Specific Thermal Condition of the AA 5052-0 Aluminum Alloy" by Sami Ali Nawi et al., published in Journal of Advanced Research in Fluid Mechanics and Thermal Sciences (2024).

Keywords

- Primary Keyword: AA 5052-O Cold Rolling

- Secondary Keywords: FEM analysis, Von Mises stress, strain energy, aluminum alloy processing, numerical modeling, rolling speed optimization, Ansys simulation

Executive Summary

- The Challenge: Predicting the complex effects of rolling speed on the mechanical behavior of AA 5052-O aluminum alloy during cold rolling is difficult, limiting process optimization and quality control.

- The Method: The study utilized a Finite Element Method (FEM) technique with a static structural tool in Ansys to simulate the cold rolling process at various speeds (50, 100, 150, and 200 RPM).

- The Key Breakthrough: The numerical analysis successfully established clear relationships between rolling speed and key outcomes, showing that as speed increases, deformation decreases, Von Mises stress drops, and strain energy rises.

- The Bottom Line: This research provides a predictive model that allows engineers to optimize rolling speed to achieve desired mechanical properties and stress levels in AA 5052-O aluminum plates, reducing trial-and-error and improving process efficiency.

The Challenge: Why This Research Matters for HPDC Professionals

Over the past few years, aluminum alloys like AA 5052-O have become highly desirable in the automotive, aerospace, and telecommunications industries due to their low density, high strength, and ease of recycling. However, fabricating wide sheets of this alloy is challenging and expensive. The cold rolling procedure is an essential component of this fabrication process.

For engineers, controlling the final microstructure and mechanical properties is paramount. Key process parameters like rolling reduction and speed have a significant influence, but their interplay is complex and non-linear. The formation of residual stress during rolling can reduce the material's strength, stability, and fatigue resistance. Accurately predicting how rolling speed impacts deformation, stress distribution, and energy absorption is critical for optimizing the process and ensuring the final product meets stringent quality standards. This study addresses the need for a reliable predictive tool to understand these dynamics without costly and time-consuming physical trials.

The Approach: Unpacking the Methodology

The researchers conducted a numerical analysis using a Finite Element Method (FEM) approach to predict the impact of rolling speed on the cold rolling of an AA 5052-O aluminum alloy plate. The simulation was designed to be a robust representation of the physical process.

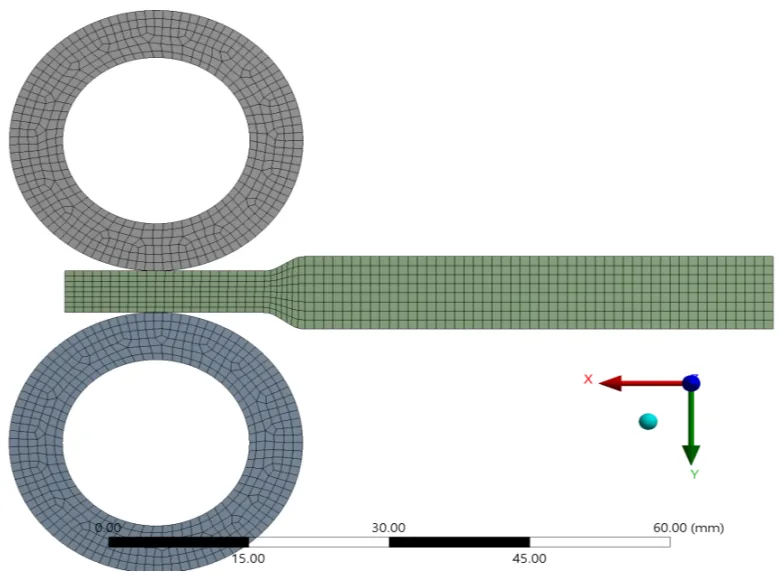

Method 1: Modeling and Meshing

A 3D model was created in AutoCAD, consisting of two rollers and a plate with a slightly pointed head to facilitate the rolling process. The model was meshed in Ansys, resulting in 11,900 elements. A non-linear swept mesh was used for the rollers to accurately simulate the large deflection that occurs under high load, ensuring the simulation reached the convergence stage.

Method 2: Boundary Conditions and Material Properties

The simulation was run in Ansys using four cores. The key variable, rolling speed, was investigated at four levels: 50, 100, 150, and 200 revolutions per minute (RPM). The friction factor between the rollers and the plate was set to 0.3. The mechanical and thermal properties for AA 5052-O were defined, including a density of 2.68 g/cm³, a modulus of elasticity of 72.3 GPa, and a Poisson's Ratio of 0.33.

The Breakthrough: Key Findings & Data

The simulation yielded precise data on how rolling speed affects deformation, stress, and strain energy in the AA 5052-O plate.

Finding 1: Rolling Speed Inversely Affects Deformation

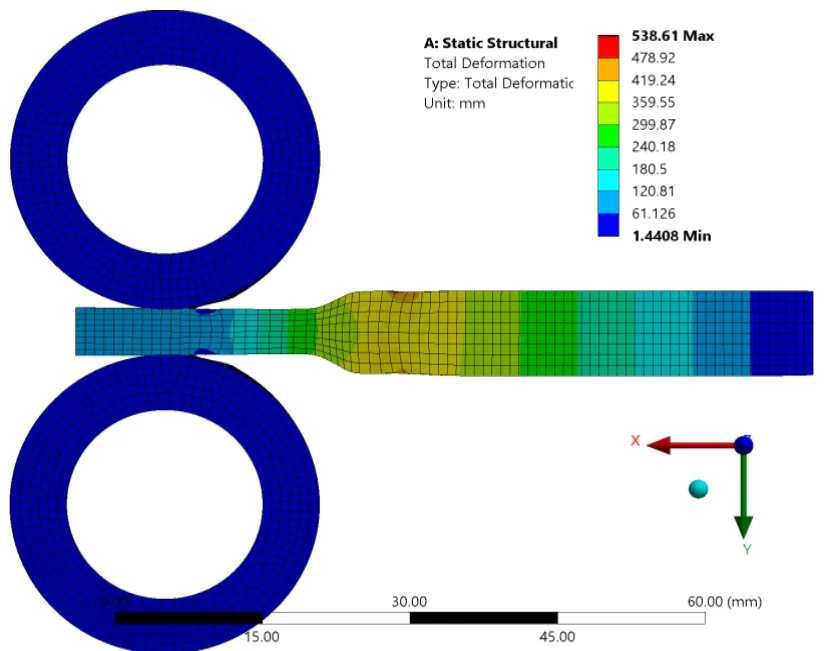

The study found a clear inverse relationship between rolling speed and material deformation. The highest deformation occurred at the lowest speed. As shown in Figure 3, at 50 RPM, the axial deformation reached a maximum of 550 mm and the radial deformation reached 140 mm. As the angular velocity increased to 200 RPM, both axial and radial deformation steadily decreased. This suggests that slower rolling speeds allow for more significant material elongation.

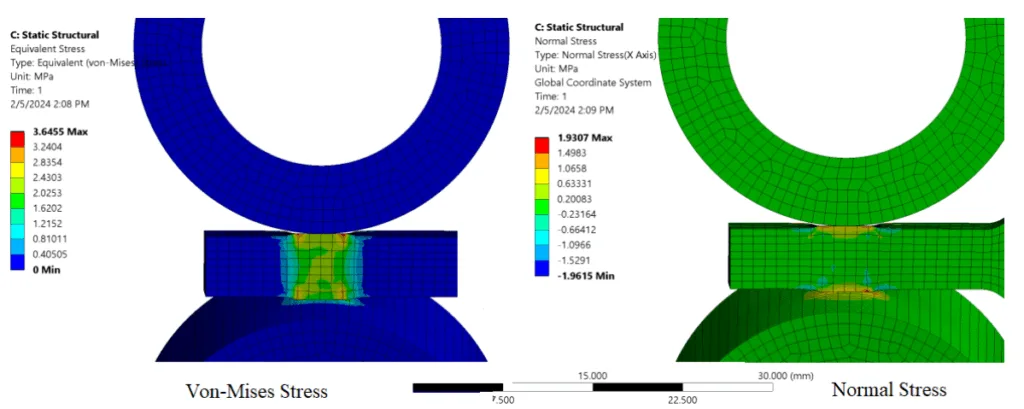

Finding 2: Stress Levels Decrease with Increased Rolling Speed

The analysis of Von Mises and normal stresses revealed that higher speeds lead to lower stress levels. According to the data presented in Figure 5, the maximum Von Mises stress was 3.6 MPa at 50 RPM, which dropped to approximately 3.1 MPa at 200 RPM. Similarly, the normal stress decreased from a peak of 1.9 MPa at 50 RPM to 1.01 MPa at 200 RPM. The graphical results in Figure 6 show that the maximum Von Mises stress is concentrated at the initial point of contact where the plate enters the rollers.

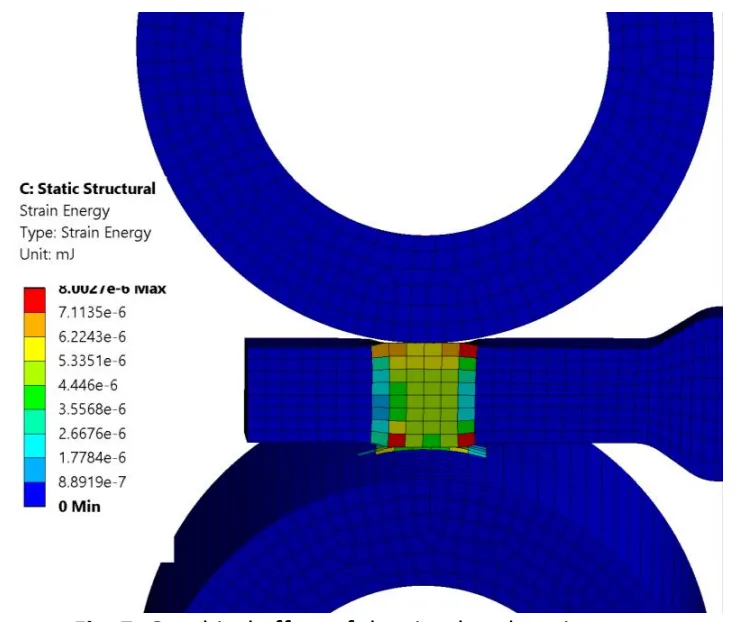

Finding 3: Strain Energy Increases Directly with Rolling Speed

In contrast to deformation and stress, the strain energy generated in the system increased with the rolling speed. The numerical data in Figure 8 shows that the strain energy was 3.8 kilojoules (kJ) at 50 RPM and rose significantly to a maximum of 8.1 kJ at 200 RPM. This indicates that more energy is absorbed by the material at higher processing speeds.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting rolling speed is a powerful tool for controlling final product characteristics. To maximize elongation (deformation), a lower speed like 50 RPM is preferable. To minimize residual stress, a higher speed of 200 RPM should be considered, though this comes with higher energy consumption.

- For Quality Control Teams: The data in Figure 5 and Figure 6 of the paper illustrates the effect of rolling speed on both Von Mises and normal stress. This information can be used to establish new quality inspection criteria, allowing teams to predict stress distribution based on process parameters and focus inspections on high-stress regions, such as the initial contact area of the plate.

- For Design Engineers: The findings indicate that the initial geometry of the workpiece (the "slightly pointed" head) is a factor in how stress is initiated. While not the primary focus, the simulation confirms that stress concentration begins at the neck of the plate, providing a valuable consideration for designing pre-formed blanks to manage stress during rolling.

Paper Details

Numerical Analysis of the Influence of the Rolling Speed on the Cold Rolling under Specific Thermal Condition of the AA 5052-0 Aluminum Alloy

1. Overview:

- Title: Numerical Analysis of the Influence of the Rolling Speed on the Cold Rolling under Specific Thermal Condition of the AA 5052-0 Aluminum Alloy

- Author: Sami Ali Nawi, Ahmed Abed Ali Ghaidan Al-Rubaiy, Ayad Naseef Jasim, Hussein Kadhim Sharaf, Muzher Taha Muhammad

- Year of publication: 2024

- Journal/academic society of publication: Journal of Advanced Research in Fluid Mechanics and Thermal Sciences

- Keywords: Cold rolling; FEM; Ansys; Von mises stress; strain energy

2. Abstract:

In this study, the behavior of the rolling process of the AA 5052 aluminum alloy plate has been investigated using numerical data. An FEM technique was utilized in order to make a prediction regarding the impact that the rolling speed has on the cold rolling of the AA 5052-0 aluminum alloy. In order to carry out the simulation procedure, the static structure tool was considered. The geometry of the situation. The total deformation, stresses, including von and normal stresses, and energy have all been the subject of investigation for the simulation that is now being performed. In both the axial and radial directions, the deformation has been investigated using numerical methods. It is possible to get a maximum result of 550 and 140 mm, respectively. at a speed of 200 revolutions per minute, the energy reached 8 kilojoules. It has been established that both normal and von mises stresses have been established. A total of 3.6 and 1.9 MPa are the numerical results that the stress has produced.

3. Introduction:

Aluminum alloys are highly desirable materials in industries like automotive, aerospace, and telecommunications due to their low density, high strength, and recyclability. However, the fabrication of wide aluminum alloy sheets is restricted by high costs and difficult processing. Cold rolling is an essential procedure in this fabrication process. The rolling reduction and subsequent annealing temperature significantly influence the material's microstructure and mechanical properties. This study focuses on the impact of rolling speed on the cold rolling of AA 5052-0 aluminum alloy under specific temperature conditions, aiming to provide a numerical analysis of this process to overcome the challenges associated with high nonlinearity and the formation of residual stress, which can degrade the material's performance.

4. Summary of the study:

Background of the research topic:

The research is grounded in the industrial need to better control the cold rolling process for aluminum alloys. The process is characterized by high nonlinearity in both material behavior and boundary conditions (temperature and stress), making analytical prediction difficult. Residual stress formed during rolling is a major concern as it negatively affects the strength, stability, and fatigue resistance of the final product.

Status of previous research:

Previous research has utilized finite element methods to study various aspects of rolling and casting processes. Studies have investigated ring rolling, twin-roll casting defects, and thermo-mechanical models for casting alloys. Researchers have identified contact pressure between the strip and rolls as a critical variable influencing heat transfer and stress development. However, a specific numerical analysis focusing on the influence of a range of rolling speeds on the deformation, stress, and strain energy during the cold rolling of AA 5052-0 alloy was an area requiring further investigation.

Purpose of the study:

The purpose of this study is to conduct a numerical analysis of the impact that the rolling speed has on the cold rolling of the AA 5052-0 aluminum alloy under certain temperature conditions. The study aims to use an FEM technique to predict the behavior of the alloy plate in terms of total deformation, Von Mises and normal stresses, and strain energy at different rotational speeds.

Core study:

The core of the study is a numerical simulation of the cold rolling process of an AA 5052-0 aluminum plate. A 3D model was developed and analyzed using Ansys software. The simulation was performed at four different rolling speeds (50, 100, 150, and 200 RPM) to investigate their effect on the plate's mechanical response. The analysis focused on quantifying total deformation (axial and radial), Von Mises stress, normal stress, and strain energy.

5. Research Methodology

Research Design:

The study employed a quantitative, simulation-based research design. A finite element model was created to simulate the cold rolling process. The independent variable was the angular velocity (rolling speed) of the rollers, and the dependent variables were total deformation, Von Mises stress, normal stress, and strain energy.

Data Collection and Analysis Methods:

Data was generated through numerical simulation using the Ansys software package. The model was created in AutoCAD. A swept mesh was used for the simulation. The static structural tool in Ansys was used to perform the analysis. The results (deformation, stress, energy) were extracted from the simulation output and plotted on graphs to analyze the relationships between rolling speed and the measured outcomes.

Research Topics and Scope:

The research is focused on the cold rolling of AA 5052-0 aluminum alloy. The scope is limited to a numerical investigation using FEM. The study specifically examines the influence of four distinct rolling speeds (50, 100, 150, 200 RPM) on the mechanical behavior of the alloy plate. The investigation covers total deformation, Von Mises stress, normal stress, and strain energy.

6. Key Results:

Key Results:

- Deformation: An inverse relationship was found between rolling speed and deformation. The maximum axial deformation was 550 mm and the maximum radial deformation was 140 mm, both occurring at the lowest speed of 50 RPM. Deformation decreased as speed increased.

- Stress: Both Von Mises and normal stresses decreased as rolling speed increased. The maximum Von Mises stress was 3.6 MPa at 50 RPM, dropping to 3.1 MPa at 200 RPM. The maximum normal stress was 1.9 MPa at 50 RPM, decreasing to 1.01 MPa at 200 RPM.

- Strain Energy: A direct relationship was observed between rolling speed and strain energy. The energy increased from 3.8 kJ at 50 RPM to a maximum of 8.1 kJ at 200 RPM.

Figure Name List:

- Fig. 1. Meshed model of the roller and plate of AA5052-0

- Fig. 2. Explanation of rotating joints in this mesh

- Fig. 3. Deformation due to angular velocity

- Fig. 4. Graphical effect of the simulated deformation

- Fig. 5. Stress analysis of the AA5052-0

- Fig. 6. Graphical effect of the simulated of stresses

- Fig. 7. Graphical effect of the simulated strain energy

- Fig. 8. Simulation results of strain energy due to various roll speeds

7. Conclusion:

The behavior of the rolling process of the AA 5052 aluminum alloy plate was successfully evaluated using numerical data. A finite element method (FEM) approach was utilized to forecast the impact of rolling speed on the cold rolling of the AA 5052-O alloy. The simulation considered total deformation, stresses (von and normal), and energy. It was determined that maximum deformation (550 mm axial, 140 mm radial) occurs at lower speeds. As speed increases, stress decreases, with maximum values of 3.6 MPa (von Mises) and 1.9 MPa (normal) being recorded. Conversely, total strain energy increased with speed, reaching 8 kilojoules at 200 RPM. The study successfully established the relationships between rolling speed and key mechanical outcomes.

8. References:

- [1] Zhao, Xingyu, Tao Jin, Lipeng Ding, Baowei Wan, Xiuchuan Lei, Chengzhi Xu, Cailong Zhang, Zhihong Jia, and Qing Liu. "The effect of combined cold rolling and homogenization on the microstructures and mechanical properties of twin-roll casted 8021 aluminum alloy." Journal of Alloys and Compounds 937 (2023): 168385. https://doi.org/10.1016/j.jallcom.2022.168385

- [2] Tychsen, Jörn, and Joachim Rösler. "Investigation of the Porosity Gradient in Thickness Direction Formed by Cold Rolling in Porous Aluminum." Metals 13, no. 4 (2023): 681. https://doi.org/10.3390/met13040681

- [3] Wang, Xiuliang, Weidong Zhang, and Yibo Ai. "Influence of edge thermal spraying on the temperature field and thermal crown of work roll during cold rolling of aluminum alloy strip." The International Journal of Advanced Manufacturing Technology 127, no. 9 (2023): 4331-4338. https://doi.org/10.1007/s00170-023-11830-2

- [4] Sharaf, Hussein Kadhim, M. R. Ishak, S. M. Sapuan, and N. Yidris. "Conceptual design of the cross-arm for the application in the transmission towers by using TRIZ-morphological chart-ANP methods." Journal of Materials Research and Technology 9, no. 4 (2020): 9182-9188. https://doi.org/10.1016/j.jmrt.2020.05.129

- [5] Sharaf, Hussein Kadhim, M. R. Ishak, S. M. Sapuan, N. Yidris, and Arash Fattahi. "Experimental and numerical investigation of the mechanical behavior of full-scale wooden cross arm in the transmission towers in terms of load-deflection test." Journal of Materials Research and Technology 9, no. 4 (2020): 7937-7946. https://doi.org/10.1016/j.jmrt.2020.04.069

- [6] Mouhmmd, Leqaa Taha, Mohammed Alwan Rahima, Abdulkareem Mahmood Mohammed, Hussein Falah Hasan, Ali Saad Alwan, and Hussein Kadhim Sharaf. "The effect of firm type on the relationship between accounting quality and trade credit in listed firms." Corporate and Business Strategy Review 4, no. 2 (2023): 175-183. https://doi.org/10.22495/cbsrv4i2art16

- [7] Sharaf, Hussein Kadhim, Sadeq Salman, Mohammad Hassan Dindarloo, Valery I. Kondrashchenko, Alla Andronikovna Davidyants, and Sergey V. Kuznetsov. "The effects of the viscosity and density on the natural frequency of the cylindrical nanoshells conveying viscous fluid." The European Physical Journal Plus 136 (2021): 1-19. https://doi.org/10.1140/epjp/s13360-020-01026-y

- [8] Wang, Yunlei, Fangzhou Yang, Liping Ren, Qi Liu, Yu Cao, and Guangjie Huang. "Microstructure and texture of an aluminum plate produced by multipass cold rolling and graded annealing process." Metals 12, no. 2 (2022): 260. https://doi.org/10.3390/met12020260

- [9] Wang, Tao, Yufeng Huang, Yunzhu Ma, Lei Wu, Huanyuan Yan, Chao Liu, Yang Liu, Bing Liu, and Wensheng Liu. "Microstructure and mechanical properties of powder metallurgy 2024 aluminum alloy during cold rolling." Journal of Materials Research and Technology 15 (2021): 3337-3348. https://doi.org/10.1016/j.jmrt.2021.09.120

- [10] Jeng, Yeau-Ren, Jian-Ting Lee, Yhu-Jen Hwu, Lee-Cheng Liu, and Chun-Yi Lu. "Effects of operation parameters of cold rolling on surface finish of aluminum." Tribology International 148 (2020): 106321. https://doi.org/10.1016/j.triboint.2020.106321

Expert Q&A: Your Top Questions Answered

Q1: Why was a swept mesh chosen for the simulation model?

A1: According to Section 2.2 of the paper, a swept mesh was constructed to accurately simulate the large deflection that takes place as a result of the high load during the rolling process. This method was chosen to ensure that the simulation procedure was carried out successfully and could reach a convergence stage, providing reliable results for the complex, non-linear deformation.

Q2: What specific mechanical and thermal properties of AA 5052-O were used as inputs for the simulation?

A2: The paper specifies the properties in Section 2.3. The key values used were a density of 2.68 g/cm³, a modulus of elasticity of 72.3 GPa, a Poisson's Ratio of 0.33, a Specific Heat Capacity of 0.88 J/g-°C, and a Thermal Conductivity of 138 W/m-K. These properties are essential for the FEM model to accurately predict the alloy's behavior.

Q3: How exactly did increasing the rolling speed from 50 RPM to 200 RPM affect the maximum Von Mises stress?

A3: The results in Section 3.2 and Figure 5 show a clear inverse relationship. At 50 RPM, the maximum Von Mises stress was 3.6 MPa. As the speed increased to 200 RPM, this stress value dropped to approximately 3.1 MPa. This indicates that higher rolling speeds can help reduce the overall stress induced in the material during the process.

Q4: What was the relationship observed between the angular velocity of the rollers and the total strain energy in the system?

A4: The study found a direct and positive correlation between angular velocity and strain energy, as detailed in Section 3.3 and Figure 8. At the lowest speed of 50 RPM, the strain energy was 3.8 kJ. This value increased steadily with speed, reaching a maximum of 8.1 kJ at 200 RPM. This suggests that more energy is transferred into the workpiece at higher processing speeds.

Q5: The paper mentions both axial and radial deformation. What were the maximum values for each, and under what condition did they occur?

A5: Section 3.1 states that the maximum deformations were observed at the lowest speed of 50 RPM. The maximum axial deformation reached 550 millimeters, while the maximum radial deformation reached 140 millimeters. Both types of deformation decreased as the rolling speed was increased.

Q6: What was the friction factor used between the rollers and the plate, and how was it determined?

A6: As stated in Section 2.2, the friction factor between the roller and the plate was set to 0.3. The paper notes that "This number has been determined throughout time," suggesting it is an established and accepted value for this type of simulation based on prior work or empirical data.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear and actionable framework for understanding the complex dynamics of AA 5052-O Cold Rolling. By using FEM simulation, the study successfully demystifies the relationship between rolling speed and critical outcomes like deformation, stress, and energy absorption. The key breakthrough is the quantitative evidence that engineers can strategically manipulate rolling speed to either maximize elongation or minimize residual stress, depending on the application's requirements. These predictive insights empower R&D and operations teams to move beyond trial-and-error, leading to more efficient process development, higher product quality, and reduced manufacturing costs.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Numerical Analysis of the Influence of the Rolling Speed on the Cold Rolling under Specific Thermal Condition of the AA 5052-0 Aluminum Alloy" by "Sami Ali Nawi, Ahmed Abed Ali Ghaidan Al-Rubaiy, Ayad Naseef Jasim, Hussein Kadhim Sharaf, Muzher Taha Muhammad".

Source: https://doi.org/10.37934/arfmts.122.1.6979

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.