This introduction paper is based on the paper "Microstructure and Properties of A356 Alloy Wheels Fabricated by Low-Pressure Die Casting with Local Squeeze" published by "ASM International".

1. Overview:

- Title: Microstructure and Properties of A356 Alloy Wheels Fabricated by Low-Pressure Die Casting with Local Squeeze

- Author: Jia-Min Huang, Hai-Dong Zhao, and Zhen-Ming Chen

- Year of publication: 2019 (Published online: 29 March 2019)

- Journal/academic society of publication: Journal of Materials Engineering and Performance (JMEPEG), ASM International

- Keywords: A356, low-pressure die casting, local squeeze, wheel

2. Abstract:

The low-pressure die-casting process (LPDC) is widely utilized for manufacturing aluminum alloy automotive wheels, with A356 being a common material choice due to its favorable castability and mechanical properties. A significant challenge in practical casting is the formation of defects, particularly porosity, in the thick-walled sections like spokes, arising from inadequate interdendritic feeding. This porosity detrimentally affects mechanical properties. This investigation addresses this issue by incorporating local squeeze (LS) into the conventional LPDC process to enhance interdendritic feeding. Practical A356 alloy wheel castings were produced using varying LS velocities and times. The study involved a comparative analysis of microstructural features (α-Al cells, Si particles, porosities) with and without LS, employing optical microscopy, scanning electron microscopy, and 3D x-ray computed tomography. The impact of these microstructural variations on tensile and impact properties was assessed. The findings indicate that LS application increases the cooling rate and improves shrinkage feeding in spoke parts. This leads to finer grains and a denser microstructure, ultimately resulting in enhanced mechanical properties of the spoke sections.

3. Introduction:

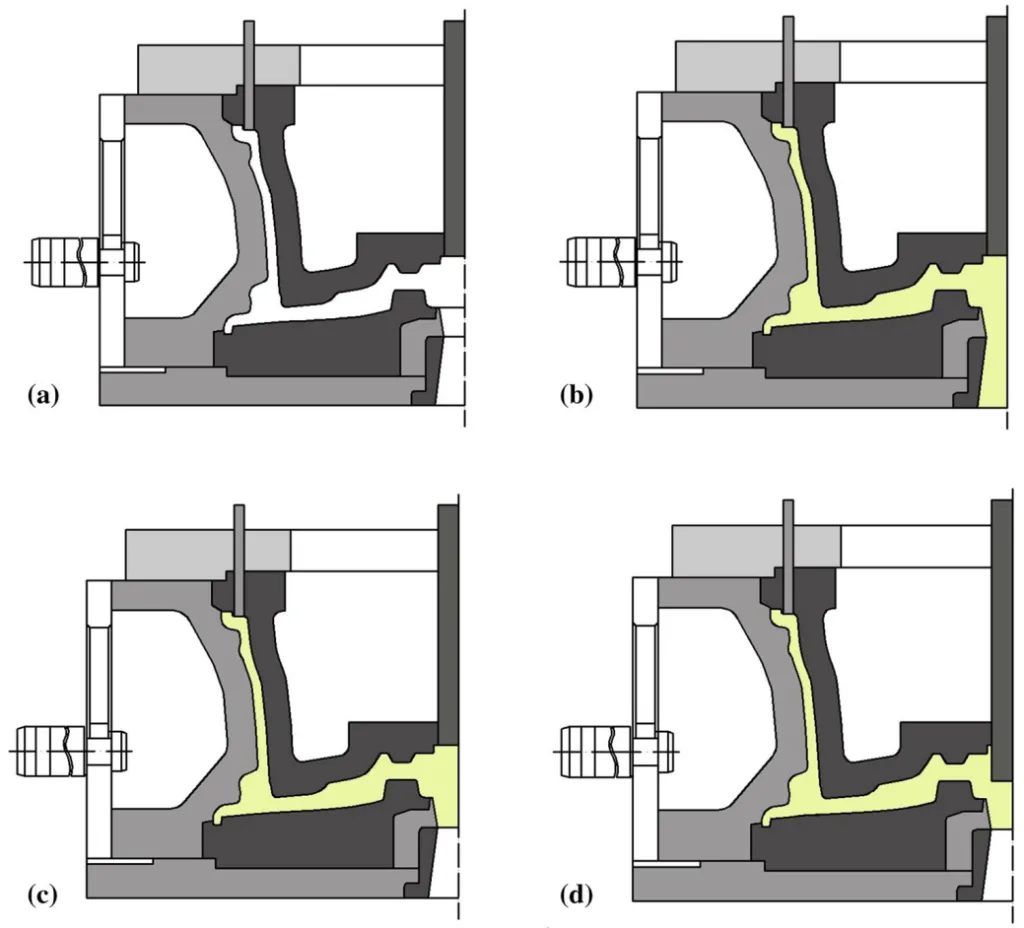

Low-pressure die casting (LPDC) dominates the production of aluminum alloy wheels (approx. 80%), favored for its suitability for complex structures, cost-effectiveness, and automation. A356 alloy is the predominant material for LPDC wheels owing to its excellent castability, corrosion resistance, and mechanical characteristics. The alloy's microstructure, comprising α-Al cells and eutectics, significantly influences its mechanical behavior. However, casting defects, especially porosity in thick sections like spokes and spoke-rim joints, are a common issue in LPDC A356 wheels (Ref 9). These defects, stemming from challenges in feeding during solidification, severely compromise the wheel's mechanical integrity, particularly fatigue life (Ref 5, 6). Consequently, enhancing the properties of these critical sections is highly desirable. Local squeeze (LS) technology, involving the application of high pressure to specific thick sections during solidification, offers a potential solution by reducing or eliminating porosity and increasing density, thereby improving mechanical properties (Ref 10, 11, 12).

4. Summary of the study:

Background of the research topic:

LPDC is the standard process for A356 automotive wheels, but porosity formation in thick sections like spokes remains a critical limitation affecting performance.

Status of previous research:

Prior studies have established the influence of cooling rate on A356 microstructure and properties (Ref 1, 2, 3, 4) and the detrimental effect of casting defects (porosity) on fatigue life and strength (Ref 5, 6, 7, 8). Porosity is known to concentrate in the thicker spoke/joint regions in LPDC wheels (Ref 9). LS technology has been explored to mitigate porosity and enhance properties in various casting processes (Ref 10, 11, 12), including high-pressure die casting (Ref 13). The authors previously proposed combining LPDC with LS for automotive wheels (Ref 14, 15).

Purpose of the study:

This investigation aimed to systematically evaluate the effectiveness of adding a local squeeze (LS) step to the conventional LPDC process for fabricating A356 automotive wheels. The primary goal was to enhance interdendritic feeding, particularly in the thick spoke sections, to reduce porosity and consequently improve the mechanical properties of the wheels.

Core study:

The core of the study involved fabricating A356 alloy wheels using both conventional LPDC and LPDC combined with LS under varying squeeze parameters (velocity and time). A detailed comparison was made between the resulting microstructures (α-Al cells, Si particles, porosity distribution and characteristics) and mechanical properties (tensile strength, elongation, impact energy) of samples taken from the hub, spoke, and rim sections of wheels produced with and without LS.

5. Research Methodology

Research Design:

An experimental comparative study was conducted. A specific A356 alloy automotive wheel design (Fig 2) was fabricated using two main process variations:

- Conventional LPDC (Control group, 7#).

- LPDC with Local Squeeze (LS) applied to the hub center (Experimental groups, 1#-6#).

Different LS parameters (squeeze speed V1/V2, time T1/T2, resulting in different total strokes) were investigated as detailed in Table 1. All castings underwent a standard T6 heat treatment (540 °C/6h quench + 140 °C/5h age).

Data Collection and Analysis Methods:

- Simulation: AnyCasting software (Ref 17) was used to simulate the LPDC process to determine the optimal start time for LS application (90 s post-filling).

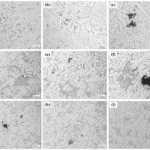

- Microstructural Analysis: Samples were extracted from hub, spoke, and rim sections. Optical microscopy (Leica DMI 5000 M) was used to observe α-Al cells and Al-Si eutectic phases (Fig 4) and measure secondary dendrite arm spacing (SDAS).

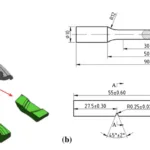

- Porosity Characterization: 3D x-ray computed tomography (YXLON micro-focus CT, 5 µm resolution) was used to inspect microporosity in spoke samples (Fig 3a). Volume Graphics 2.0 software analyzed the CT data to quantify pore characteristics (volume fraction, number, max volume, average volume, sphericity, number density) (Fig 5, Table 2).

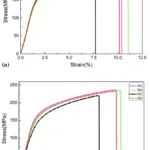

- Mechanical Testing: Tensile and impact test samples (dimensions in Fig 3b) were machined from spoke and rim sections (5 per part type). Tensile tests were performed using a SHIMADZ AG-X 100 KN machine at 1 mm/min (Table 3, Fig 6). Impact tests were conducted using a JBN-300 machine (Fig 9).

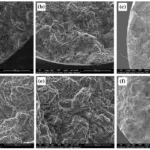

- Fractography: Scanning electron microscopy (SEM) was employed to observe the fracture surfaces of tensile (Fig 7, Fig 8) and impact (Fig 10) samples to identify failure mechanisms and defect types (pores, oxide films, intermetallics). Energy-dispersive spectroscopy (EDS) was used for phase identification (Fig 8c, Fig 10g).

Research Topics and Scope:

The research focused on the influence of adding LS (with varying speeds and times) to the LPDC process for A356 wheels. The scope included:

- Characterizing the effect of LS on the microstructure (grain refinement via SDAS, porosity reduction) in different wheel locations (hub, spoke, rim).

- Evaluating the impact of LS on mechanical properties (tensile strength, elongation, impact energy) of spoke and rim sections.

- Analyzing the role of defects (porosity, oxide films) on fracture behavior and mechanical performance.

- Comparing the results of LPDC+LS with conventional LPDC.

6. Key Results:

Key Results:

- Microstructure Modification: LS application significantly refined the microstructure in the hub and spoke parts, characterized by smaller α-Al grains (reduced SDAS) and less Al-Si eutectic phase compared to conventional LPDC (Fig 4a, b, d, e vs Fig 4c, f). Spoke SDAS was reduced from 51.6 µm (without LS) to an average of 48.95 µm (with LS). LS had minimal effect on the rim microstructure due to its distance from the squeeze application and earlier solidification (Fig 4g, h, i).

- Porosity Reduction: LS effectively reduced the amount and size of porosity in the spoke parts (Fig 5). Quantitative CT analysis (Table 2) showed a dramatic decrease in total pore number (e.g., S7: 3731 vs S1: 694) and maximum pore volume (S7: 55.5 mm³ vs S1: 0.76 mm³) with LS application. Higher squeeze velocity (S4 vs S1) improved feeding further from the ingate (Fig 5d vs 5b).

- Tensile Property Improvement: Spoke sections produced with LS exhibited improved tensile strength and elongation compared to those without LS (Table 3, Fig 6a). This improvement is attributed to the reduced porosity (Fig 7a, b vs 7c) and finer grain structure achieved with LS. Rim tensile properties showed slight improvement with LS but were also significantly affected by oxide film defects (Fig 8b, c).

- Impact Property Behavior: Rim parts generally showed higher impact energy than spoke parts due to their finer microstructure (smaller SDAS) (Fig 9). The impact properties of both spoke and rim parts demonstrated an inverse linear relationship with the total area fraction of defects (pores and oxide films) observed on the fracture surfaces (Fig 11). Appropriate, longer LS application times were found to be beneficial for impact properties compared to shorter times (#1-#4 vs #5, #6 in Fig 9). Impact fracture surfaces revealed pores and/or oxide films contributing to failure (Fig 10).

- Fig. 2 Three-dimensional geometry of the wheel casting

- Fig. 3 (a) Samples obtained from spoke parts for x-ray CT inspection; (b) shape and dimensions of tensile and impact samples (mm)

- Fig. 4 Microstructure of hub, spokes, and rim parts after T6-treated; (a)-(c) are from H1, H4, and H7, respectively; (d)-(f) are from S1, S4, and S7, respectively; (g)-(i) are from R1, R4, and R7, respectively

- Fig. 5 Microporosities in spoke parts inspected by 3D x-ray tomography: samples near to the ingate (a) and far from the ingate (b) in S1; samples near the ingate (c) and far from the ingate (d) in S4; samples near to the ingate (e) and far from (f) the ingate in S7

- Fig. 6 (a) Tensile properties of T6-treated samples from spoke parts; (b) tensile properties of T6-treated samples from rim parts

- Fig. 7 Typical SEM view of the fractured surface of samples from spoke part and rim part; (a)-(c) are from S1, S4, and S7, respectively; (d)- (f) are from R1, R4, and R7, respectively

- Fig. 8 Typical SEM view of the fractured surface of S2 (best elongation) and R5 (poorest elongation); (a) is from S2 and (b) is from R5; (c) EDS result of oxide film

- Fig. 9 Impact energy of T6-treated samples from spoke and rim parts (J/cm2 ) Fig. 11 Influence of area fraction of fractographic defects on impact roughness

- Fig. 10 Fracture morphologies of T6-treated impact samples from spoke and rim parts; (a)-(c) are from S1, S4, and S7, respectively; (d)-(f) are from R1, R4, and R7, respectively; (g) EDS result of Fe-based intermetallics (pointed out by an arrow in (f))

Figure Name List:

- Fig. 1 Schematic of low-pressure die cast with LS for A356 alloy wheels

- Fig. 2 Three-dimensional geometry of the wheel casting

- Fig. 3 (a) Samples obtained from spoke parts for x-ray CT inspection; (b) shape and dimensions of tensile and impact samples (mm)

- Fig. 4 Microstructure of hub, spokes, and rim parts after T6-treated; (a)-(c) are from H1, H4, and H7, respectively; (d)-(f) are from S1, S4, and S7, respectively; (g)-(i) are from R1, R4, and R7, respectively

- Fig. 5 Microporosities in spoke parts inspected by 3D x-ray tomography: samples near to the ingate (a) and far from the ingate (b) in S1; samples near the ingate (c) and far from the ingate (d) in S4; samples near to the ingate (e) and far from (f) the ingate in S7

- Fig. 6 (a) Tensile properties of T6-treated samples from spoke parts; (b) tensile properties of T6-treated samples from rim parts

- Fig. 7 Typical SEM view of the fractured surface of samples from spoke part and rim part; (a)-(c) are from S1, S4, and S7, respectively; (d)-(f) are from R1, R4, and R7, respectively

- Fig. 8 Typical SEM view of the fractured surface of S2 (best elongation) and R5 (poorest elongation); (a) is from S2 and (b) is from R5; (c) EDS result of oxide film

- Fig. 9 Impact energy of T6-treated samples from spoke and rim parts (J/cm²)

- Fig. 10 Fracture morphologies of T6-treated impact samples from spoke and rim parts; (a)-(c) are from S1, S4, and S7, respectively; (d)-(f) are from R1, R4, and R7, respectively; (g) EDS result of Fe-based intermetallics (pointed out by an arrow in (f))

- Fig. 11 Influence of area fraction of fractographic defects on impact roughness

7. Conclusion:

- The application of Local Squeeze (LS) during the Low-Pressure Die Casting (LPDC) of A356 wheels effectively refines α-Al grains and significantly reduces internal porosity within the hub and spoke sections. However, due to limited pressure transmission over distance, LS has minimal effect on the microstructure of the rim part, which is far from the squeeze location.

- Compared to conventional LPDC, the tensile properties of spoke parts fabricated with LS are improved. Fractographic analysis indicates that porosity is the primary factor governing the tensile properties of the spoke parts, whereas the properties of the rim parts are influenced by both porosity and oxide films.

- The impact energies exhibited greater variation in the spoke parts compared to the rim parts. Rims generally displayed superior impact resistance due to their finer grain structure. Critically, the impact properties of both spoke and rim sections show an inverse linear relationship with the measured fraction of defects (pores and oxide films) on the fracture surface.

8. References:

- [1.] A. Mazahery and M.O. Shabani, Experimental Investigation on the Aging Response, Hardness and Total Impact Energy Absorption of Sr-Modified Heat-Treatable Cast Automotive Aluminum Alloys, Trans. Indian Inst. Met., 2014, 67(5), p 753-759

- [2.] M.O. Shabani and A. Mazahery, Microstructural Prediction of Cast A356 Alloy as a Function of Cooling Rate, JOM, 2011, 63(8), p 132-136

- [3.] M.O. Shabani and A. Mazahery, Automotive Copper and Magnesium Containing Cast Aluminium Alloys: Report on the Correlation Between Yttrium Modified Microstructure and Mechanical Properties, Russ. J. Nonferrous Met., 2014, 55(5), p 436-442

- [4.] A. Mazahery and M.O. Shabani, Modification Mechanism and Microstructural Characteristics of Eutectic Si in Casting Al-Si Alloys: A Review on Experimental and Numerical Studies, JOM, 2014, 66(5), p 726-738

- [5.] Q.G. Wang, D. Apelian, and D.A. Lados, Fatigue Behavior of A356-T6 Aluminum Cast Alloys: Part I. Effect of Casting Defects, J. Light Met., 2001, 1(1), p 73-84

- [6.] J.Z. Yi, Y.X. Gao, P.D. Lee et al., Scatter in Fatigue Life Due to Effects of Porosity in Cast A356-T6 Aluminum-Silicon Alloys, Metall. Mater. Trans. A, 2003, 34(9), p 1879-1890

- [7.] A. Bahmani, N. Varahram et al., A Mathematical Model for Prediction of Microporosity in Aluminum Alloy; A356, Int. J. Adv. Manuf. Technol., 2013, 64(9-12), p 1313-1321

- [8.] A. Bahmani, G.B. Eisaabadi, P. Davami et al., Effects of Hydrogen Level and Cooling Rate on Ultimate Tensile Strength of Al A319 Alloy, Russ. J. Nonferrous Met., 2014, 55(4), p 365-370

- [9.] D.M. Maijer, W.S. Owen, and R.A. Vetter, An Investigation of Predictive Control for Aluminum Wheel Casting via a Virtual Process Model, J. Mater. Process. Technol., 2009, 209(4), p 1965-1979

- [10.] M.S. Dargusch, G. Dour, N. Schauer et al., The Influence of Pressure During Solidification of High Pressure Die Cast Aluminum Telecommunications Components, J. Mater. Process. Technol., 2006, 180(1-3), p 37-43

- [11.] Z. Brodarac, P. Mrvar, J. Medved et al., Local Squeezing Casting Influence on the Compactness of AlSi10 Mg Alloy Castings, Metalurgija, 2007, 46(1), p 29-35

- [12.] I. Ohnaka, J.D. Zhu, and A. Sugiyama, et al. A Method to Set Process Parameters of Local Squeeze in HPDC. In: 13th International Conference on Modeling of Casting, Welding and Advanced Solidification Processes (MCWASP), Schladming, Austria, vol. 33, p 012001, 2012

- [13.] Y. Bai and H. Zhao, Tensile Properties and Fracture Behavior of Partial Squeeze Added Slow Shot Die-Cast A356 Aluminum Alloy, Mater. Des., 2010, 31(9), p 4237-4243

- [14.] W. Zhuang, H.D. Zhao, Y.Y. Li et al. Chinese Patent, 201310369926.3[P]

- [15.] W. Zhuang, H.D. Zhao, Y.Y. Li et al. Japanese Patent, 51302708294[P]

- [16.] C. Reilly, D. Jiang, Y. Lu et al., Process Modeling of Low-Pressure Die Casting of Aluminum Alloy Automotive Wheels, JOM, 2013, 65(9), p 1111-1121

- [17.] J.M. Huang, H.D. Zhao, and Z.M. Chen. Simulation and Experiment Study on Low Pressure Die-Cast A356 Wheels with Local Squeeze. In: The 10th Pacific Rim International Conference on Modeling of Casting and Solidification Process, Beijing, China, 2017

- [18.] S.J. Luo, B.G. Chen, and P.X. Qi, Liquid Die Forging and Extrusion Casting Technology, Chemical Industry Press, Beijing, 2007

- [19.] Y.F. Bai, H.D. Zhao, L.I. Yuan-Yuan et al., Microstructure and Impact Properties of Slow Injection A356 Die Castings with Partial Squeeze, Chin. J. Nonferrous Met., 2010, 20(3), p 442-450

- [20.] H.D. Zhao, I. Ohanaka, Y. Sako, et al. Estimation of Porosity Defects with Consideration of Oxide Entrapment. In: The 65th World Foundry Congress, Gyeongju, Korea, 2002

9. Copyright:

- This material is a paper by "Jia-Min Huang, Hai-Dong Zhao, and Zhen-Ming Chen". Based on "Microstructure and Properties of A356 Alloy Wheels Fabricated by Low-Pressure Die Casting with Local Squeeze".

- Source of the paper: https://doi.org/10.1007/s11665-019-03993-5

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.