This introduction paper is based on the paper "Mechanisms of Leaker Formation in Aluminium High Pressure Die Casting" published by "University of Queensland".

1. Overview:

- Title: Mechanisms of Leaker Formation in Aluminium High Pressure Die Casting

- Author: Stephen Thompson

- Year of publication: 1998

- Journal/academic society of publication: University of Queensland (Thesis for Masters of Engineering Science by Research)

- Keywords: Not specified in the paper.

2. Abstract:

Within this report an understanding of the mechanisms of leaker formation, both in general and in a specific aluminium high pressure die casting, is developed. This understanding is developed through several stages.

A review of previously published work determines casting defects that may contribute to the formation of leakers in high pressure die casting. Further review of the literature concentrates on understanding each of these defects and their effect on casting pressure tightness. The defects reviewed are, cold flakes, cold shuts, drag marks, gas porosity, oxide films, particulate inclusions, secondary operations that remove or damage the surface layer, shrinkage porosity, soldering, and surface cracks. This information is then compiled to form a “Fault Tree” that will assist in the determination of the “Root Causes” of leakers in a specific casting.

Observation of an automotive water inlet casting is then used to determine the likely root causes of leakers in a specific example. Defects found that may be root causes of leakers were cold shuts, gas porosity, shrinkage porosity, surface porosity due to volatilised fluids, drag marks, and surface cracks. The machining of critical areas of the casting also appeared to increase the likelihood of leaker formation.

Of these defects cold shuts appeared to be the most critical root cause of leakers. To analyse the effect process parameters on the occurrence of cold shuts and leakers a structured trial was carried out in which the die and metal temperatures were manipulated to increase the occurrence of leakers. The results show a strong link between the occurrence and extent of cold shuts and the occurrence of leakers. Furthermore, the results demonstrate a link between die temperatures and the occurrence of leakers.

Finally, a number of strategies to reduce the occurrence of leakers in the automotive water inlet casting are proposed and suggestions are made as to possible further investigation.

3. Introduction:

This document summarizes the key findings and methodologies presented in Stephen Thompson's 1998 thesis, "Mechanisms of Leaker Formation in Aluminium High Pressure Die Casting." The original work provides a comprehensive investigation into why "leaker" defects occur in aluminium high pressure die castings, focusing on an automotive water inlet casting as a specific case study. This summary aims to present the core concepts, research progression, and conclusions in a handbook-style format suitable for industry professionals and researchers in die casting technology.

4. Summary of the study:

Background of the research topic:

High pressure die casting is a common manufacturing process for complex components due to its low cost per casting and high production rates. It can produce parts with thin wall sections and high dimensional accuracy. However, castings, particularly those intended to contain or channel fluids, can suffer from "leakers," which are defects that allow fluid to pass through the casting wall under pressure. Such defects lead to rejection or the need for impregnation with sealing agents. This study focuses on an automotive water inlet casting made from aluminium alloy CA313, which is subject to leaker defects. The formation of leakers is often a result of combinations of other casting defects.

Status of previous research:

Chapter 2 of the thesis reviews previously published literature to identify casting defects that may contribute to leaker formation in high pressure die casting. The literature indicates that for leakage to occur, a path must exist through the surface layers and the center of the casting. Defects identified as potential causes include:

- Cold Flakes

- Cold Shuts

- Drag Marks

- Gas Porosity

- Oxide Films

- Particulate Inclusions

- Secondary Operations that Remove or Damage the Surface Layer

- Shrinkage Porosity

- Soldering

- Surface Cracks

The review compiled this information into a "Fault Tree" (Figure 2.18) to aid in determining the root causes of leakers. For each potential cause, the literature was examined for:

- Conditions under which it causes a leaker.

- Mechanisms governing its formation.

- Strategies for reducing its occurrence.

The paper notes that while some defects like gas porosity are often discounted as primary causes of leakers (as they tend to form separate bubbles), interactions with other defects or specific formation mechanisms (e.g., from volatilised die lubricants) can lead to leakage paths. Shrinkage porosity, particularly interdendritic porosity in long freezing range hypoeutectic alloys, is identified as a common feature that can create leakage paths, especially when surface layers are compromised.

Purpose of the study:

The study had the following aims (as stated on page 6):

I. Compile existing published research to determine common mechanisms in the formation of leakers.

II. Use observations of the process and casting to determine likely mechanisms of leaker formation in the water inlet casting.

III. Propose parameters, based upon the published literature, that are likely to have an important effect on the formation of leakers in the water inlet casting.

IV. Confirm the importance of the mechanisms determine in Step II and the important parameters proposed in Step III using a controlled experiment.

V. Using published knowledge and experience gathered propose strategies that may be used to reduce the occurrence of leakers in the water inlet casting.

Core study:

The core of the study involved several stages:

- Literature Review (Chapter 2): Identification of potential causes of leakers and their formation mechanisms from existing research, culminating in a fault tree.

- Observational Study (Chapter 3): Examination of an automotive water inlet casting to identify common leaker locations and associated defects. This involved visual inspection and sectioning of leaking and sound castings. Defects like cold shuts, exposed gas/shrinkage porosity (especially after machining), surface porosity from volatilised fluids, drag marks, and small cracks were observed. A strong correlation between cold shuts and leakers was noted.

- Experimental Investigation (Chapter 4): A structured trial was conducted to analyze the effect of specific process parameters (die temperature and metal temperature) on the occurrence of cold shuts and leakers in the water inlet casting. Die cooling levels (using oil and uncooled cavities) and metal temperatures were systematically varied. Data on shot end parameters, die temperatures, and leaker rates were collected and analyzed.

- Development of Predictive Relationships: Statistical methods, including chi-squared tests and linear/multiple linear regressions, were used to establish relationships between control variables (oil cooling level, set metal temperature), measured variables (die cavity temperatures, plunger displacement), and casting output (leaker occurrence).

- Proposal of Strategies (Chapter 5): Based on the findings, strategies to reduce leaker occurrence in the specific water inlet casting were proposed, along with suggestions for future research.

5. Research Methodology

Research Design:

The research was designed in a multi-stage approach:

- Literature Review: A comprehensive review of published work on casting defects relevant to leaker formation in high pressure die casting.

- Observational Study: Detailed examination of a specific industrial casting (automotive water inlet) to identify common leaker sites and associated defects. This involved analyzing both leaking and sound castings.

- Controlled Experiment: A structured trial was designed to investigate the impact of key process parameters (die temperature and metal temperature) on leaker formation. This involved manipulating these parameters and observing the effect on casting quality. The experiment used a two-cavity die, allowing for different cooling conditions to be applied simultaneously.

- Statistical Analysis: Data collected from the experiment were analyzed using statistical methods to identify correlations and develop predictive models for leaker occurrence.

Data Collection and Analysis Methods:

Data Collection:

- Literature: Sourced from academic papers, conference proceedings, and industry reports.

- Casting Inspection (Chapter 3): Visual examination of leaking and sound water inlet castings. Sectioning and microscopy were used to study internal defects and microstructures. Cold shuts were quantified on a scale of 0 to 4.

- Process Parameters (Chapter 4 Trial):

- Machine Shot End Parameters: Measured using transducers for plunger displacement and hydraulic system pressure. Parameters included cycle time, plunger speeds and displacements at different stages, hydraulic pressures, and delay times (Table 4.1).

- Die Cavity Temperatures: Measured at four representative locations in each cavity using a hand-held surface probe immediately after die opening (Figure 4.3). Temperatures were interpolated for every shot.

- Molten Metal Temperature: Measured every 10 shots and interpolated for each casting.

- Leaker Testing: Castings were pressure tested at 300 Kpa by submerging them in water and observing for bubbles. This was a pass/fail test (Appendix A.4).

- Alloy Composition: Analyzed for samples taken during the trial (Appendix A.1, Appendix F.2).

Analysis Methods:

- Fault Tree Analysis: Used to summarize potential causes of leakers from the literature (Figure 2.18).

- Correlation Analysis (Chapter 3): A χ² (chi-squared) test was used to confirm the significance of the correlation between the level of cold shutting and the occurrence of leakers (Table 3.1, Appendix E).

- Statistical Analysis of Trial Data (Chapter 4):

- χ² (chi-squared) test: Used to determine the significance of the impact of oil cooling level and metal temperature on leaker probability (Tables 4.5, 4.7).

- Linear Regression: Used to fit relationships between casting output (leaker occurrence, y) and control input variables (oil cooling level x1, set metal temperature x2) (Equations 4.2, 4.3, 4.4).

- Coefficient of Determination (R²): Used to assess the proportion of variation in leaker occurrence explained by regressions with measured input parameters (e.g., die temperatures, shot end parameters) (Equation 4.5, Table 4.10).

- Multiple Linear Regression: Used to predict leaker occurrence based on a combination of measured input parameters (e.g., four in-cavity temperatures and plunger displacement) (Figure 4.9, Figure 4.10).

- t-test: Used to assess the significance of the effect of metal temperature on average die temperature (Equation 4.6, 4.7).

Research Topics and Scope:

- Primary Research Topic: Mechanisms of leaker formation in aluminium high pressure die casting.

- Specific Focus: An automotive water inlet casting made from CA313 aluminium alloy.

- Key Defects Investigated: Cold shuts, gas porosity, shrinkage porosity, and their relationship to process parameters.

- Process Parameters Investigated:

- Die temperature (controlled via oil cooling channels).

- Molten metal temperature.

- Other shot end parameters (plunger velocity, displacement, pressures).

- Scope: The study included a literature review, observational analysis of an industrial casting, and a controlled experiment on an industrial die casting machine. The findings are primarily applicable to the specific casting studied but offer insights into general principles of leaker formation. The study also explored the potential for predicting leaker occurrence based on measurable process parameters.

6. Key Results:

Key Results:

- Literature Compilation: A comprehensive list of potential defects causing leakers in HPDC was compiled, including cold flakes, cold shuts, drag marks, gas porosity, oxide films, particulate inclusions, effects of secondary operations, shrinkage porosity, soldering, and surface cracks. A fault tree (Figure 2.18) was developed to trace leakers to their root causes.

- Observations on Water Inlet Casting (Chapter 3):

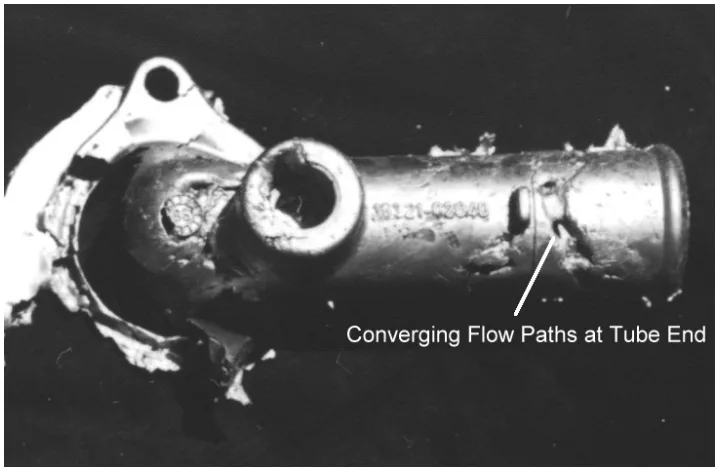

- Leakers predominantly occurred on or near the machined end of the tube, often near the parting line. Some leakers were found near the base of lugs.

- Machining was identified as a key factor exposing internal porosity.

- Cold shuts on the internal face of the tube were strongly correlated with leaker occurrence (Table 3.1). These cold shuts provide a path from the internal surface to the porous casting center.

- Exposed gas/shrinkage porosity on machined surfaces was common, but its direct link to leakers was less clear than cold shuts. Gas entrapment was attributed to early shot change-over and diverging runner design (Figures 3.9, 3.10, 3.11).

- Surface porosity on the internal cylinder surface, likely from volatilised die lubricant, was sometimes observed with leakers, usually in conjunction with cold shuts.

- Small cracks around lugs, associated with solidification stresses and other defects, were occasionally linked to leakers.

- Experimental Findings (Chapter 4):

- Effect of Die/Metal Temperature: Die temperature (controlled by oil cooling level) had a significant impact on leaker formation. Higher die cooling (lower die temperatures) led to a higher probability of leakers (Table 4.4, Table 4.5). Lower metal temperature showed a trend towards more leakers, but this was not statistically significant within this trial (Table 4.6, Table 4.7).

- Prediction of Leaker Rate:

- A non-linear relationship was found between the oil cooling level and leaker rates, which could be modeled using regression (Equations 4.3, 4.4; Figures 4.4, 4.5).

- Measured die cavity temperatures (gate, fixed cavity, moving cavity, sliding core) showed a correlation with leaker occurrence, with coefficients of determination (R²) ranging from ~0.04 to ~0.09 (Table 4.10).

- A multiple linear regression model using four in-cavity temperatures and plunger displacement at the end of injection provided a reasonable prediction of leaker occurrence rates (Figures 4.9, 4.10).

- Thermal Condition of the Die: The study highlighted that die temperature measurements can provide sufficient information about the thermal condition of the die to be used as a predictor of leakers. The sliding core temperature was strongly influenced by the oil cooling level (Figure 4.11). Average die temperature was measurably affected by metal temperature (Figure 4.12).

- Other Parameters: Total plunger displacement during injection (indicating amount of metal ladled) also showed a noticeable relationship with leaker formation. Longer-than-usual displacements (less metal) correlated with more leakers.

Figure Name List:

![Figure 2.10 Short Shots in Zinc and Aluminium Alloys Showing How Gas

Entrapment Can Occur in the Cavity. Shots A, B, and C Differ in the Amount of

Metal Ladled. [12]](https://castman.co.kr/wp-content/uploads/image-2366.webp)

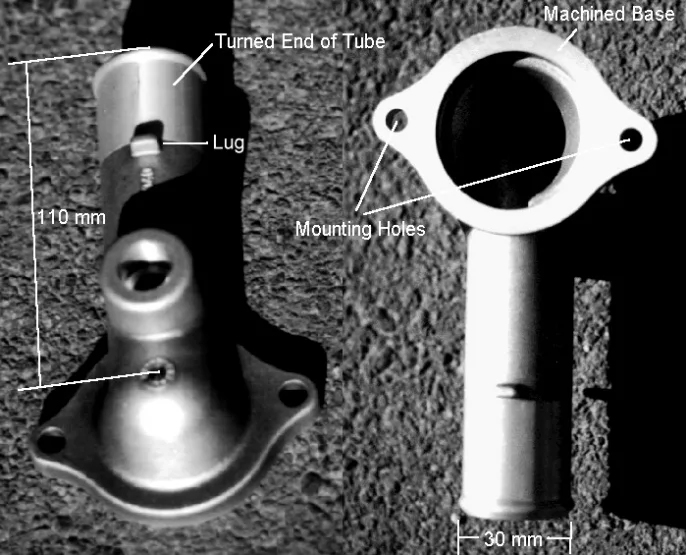

- Figure 1.1 Automotive Water Inlet Casting.

- Figure 1.2 Flow Chart of Part Manufacture.

- Figure 2.1 Fracture Along the Face of a Cold Flake.

- Figure 2.2 Mechanism of Cold Flake Formation.

- Figure 2.3 Heat Losses From Alloy During Casting Cycle.

- Figure 2.4 Flow Lines on Flat Plate Castings Showing Difference Between Casting Filled by Full Width of Fan Gate (a) and Casting Filled by Partially Blocked Gate (b).

- Figure 2.5 "Large Gate Pores … Exposed by Machining to Create a Leaker."

- Figure 2.6 Air Entrapment at too Low and too High a First Stage Velocity.

- Figure 2.7 Wave Formed at Critical First Stage Plunger Speed.

- Figure 2.8 Optimum Acceleration Profiles For Different Shot Fill Ratios.

- Figure 2.9 Air Entrapment in a Poorly Designed Runner.

- Figure 2.10 Short Shots Showing How Gas Entrapment Can Occur in the Cavity.

- Figure 2.11 Typical Inclusions in Die Cast Aluminium Alloys.

- Figure 2.12 Tendency for Sludge Formation as a Function of Temperature and Sludge Factor.

- Figure 2.13 Interdendritic Shrinkage in Sand Cast Gun Metal Casting.

- Figure 2.14 Solidification Shrinkage in Aluminium Silicon Alloys.

- Figure 2.15 Shrinkage Porosity Distributions at Different Alloy Compositions.

- Figure 2.16 Shrinkage Feeding Using Directional Solidification.

- Figure 2.17 Surface Cracking in a Zinc Casting.

- Figure 2.18 Fault Tree Summarising the Major Causes of Leakers.

- Figure 3.1 Photograph of Water Inlet Casting Showing Common Sites of Leakers.

- Figure 3.2 Likely Porosity Distribution at Tube End, Showing Effect of Overflows and Machining.

- Figure 3.3 Water Inlet Die Cavity Showing Location of Overflows.

- Figure 3.4 Short Shot Showing Last Areas to Fill.

- Figure 3.5 Restrained Sections Near Tube End.

- Figure 3.6 Cold Shut at Surface of Leaking Casting Leading to Porous Inner Region.

- Figure 3.7 Large Cold Shut Leaving Void Through Casting Centre.

- Figure 3.8 Extensive Gas Porosity Found Through Section of Tube End.

- Figure 3.9 Diverging Runner Section of Water Inlet Casting.

- Figure 3.10 Shot Timing for Water Inlet Casting.

- Figure 3.11 Short Shot Showing Flow Through Runner.

- Figure 3.12 Surface Porosity on Internal Face of Tube.

- Figure 3.13 Section Through Surface Porosity on Internal Face of Tube Leading to Interconnected Pores Within the Casting.

- Figure 3.14 Section Through Surface Porosity on Internal Face of Tube that Appears to be Isolated from Porosity Within the Casting.

- Figure 3.15 Drag Marks on Internal Wall of Tube.

- Figure 3.16 Small Crack Running Through Casting Near Base of Lug.

- Figure 3.17 Cracks Associated With Large Gas Pores Near Base of Lug.

- Figure 4.1 Diagram of Cooling Line Set-up During Trial.

- Figure 4.2 Summary of Experimental Design and Expected Effects.

- Figure 4.3 Locations of Temperature Measurements in Cavity.

- Figure 4.4 Plot of Predicted Leaker Rate, Using Equation 4.3, Versus Shot Number.

- Figure 4.5 Plot of Predicted Leaker Rate, Using Equation 4.4, Versus Shot Number.

- Figure 4.6 Plot of the Value of Linear Regression Based on Measured Metal Temperature Versus Trial Shot Number.

- Figure 4.7 Plot of the Value of Linear Regression Based on Sliding Core Temperature Versus Trial Shot Number

- Figure 4.8 Plot of the Value of Linear Regression Based on Moving Cavity Temperature Versus Trial Shot Number

- Figure 4.9 Prediction of Leakers Using Multiple Linear Regression.

- Figure 4.10 Average Values of Multiple Linear Regression.

- Figure 4.11 Relationship Between Casting Cavity Core Temperature and Oil Cooling Level.

- Figure 4.12 Effect of Metal Temperature on Average Die Temperature.

- Figure 5.1 Cross Section Through Tube Wall Showing Cold Shuts, Internal Porosity, and Material Removal Combining to Provide a Path for Leakage.

- Figure A.1 Full Shot Trace for Water Inlet Casting.

- Figure A.2 Close Ups of Cavity Filling Period of Three Shot Traces.

- Figure A.3 Water Inlet Casting With Runners and Overflows.

- Figure A.4 Area of Casting Obscured by Support During Pressure Testing.

- Figure B.1 Enlarged Shot Trace for Water Inlet Casting.

- Figure C.1 Optimum Shot Profile for Water Inlet Casting.

- Figure C.2 Actual Shot Profile for Water Inlet Casting.

- Figure D.1 Level 0 (No Cold Shuts)

- Figure D.2 Level 1 (Small Cold Shuts)

- Figure D.3 Level 2 (Moderate Cold Shuts)

- Figure D.4 Level 3 (Extensive Cold Shuts)

- Figure D.5 Level 4 (Severe Cold Shuts)

7. Conclusion:

From the information presented in this study a number of important conclusions can be drawn.

- When analysing the occurrence of leakers, the casting can be divided into the surface regions and the casting centre. All of these must contain a leakage path for a leaker to occur. A logical procedure then exists for the diagnosis and reduction in the occurrence of leakage defects.

- The rate of heat transfer from the casting alloy to the die will have a critical effect on the occurrence of cold shuts in the water inlet casting.

- Cold shuts on the casting surface have a strong link with the occurrence of leakers in the water inlet casting.

- An ability to predict a critical casting output by analysis of the state of important casting inputs has been demonstrated. This indicates that through monitoring of the high pressure die casting process the occurrence of such critical casting outputs can be predicted and controlled in production.

8. References:

- [1] LaVelle, ‘Aluminium Die Casting and Factors Affecting Pressure Tightness’, Transactions of the American Foundrymen's Society, Volume 70, 1962.

- [2] Walkington, ‘Short Course on Analysis of Die Casting Defects’, Cooperative Research Centre for Alloy and Solidification Technology, 1995.

- [3] Holz, ‘Trouble-Shooting Aluminium Die Casting Quality Problems’, 7th International Die Casting Congress, 1972.

- [4] Murray, ‘Defects in Pressure Die Castings as Pertaining to Low Gas Pressure Applications’, CSIRO Consultation Report 90/M/101, Commonwealth Scientific and Industrial Research Organisation, 1990.

- [5] Harding, Bennet, and Robinson, ‘Production of Aluminium Die Castings Using a Fan Gate [3] Some Factors Affecting Conditions at the Orifice’, 8th SDCE International Die Casting Exposition and Congress, 1975.

- [6] Iwahori, Nakamura, Tozawa, and Yamamoto, ‘Metal Flowing Behavior in Die Castings and Defects in Aluminium Die Castings’, 13th SDCE International Die Casting Congress and Exposition, 1985.

- [7] Murray, Chadwick, and Ghomashchi, ‘Aluminium Alloy Solidification in High Pressure Die Castings’, Materials Australasia, June 1990.

- [8] Murray, ‘Shot Sleeves, a Quality Control’, Die Casting Bulletin, April 1996.

- [9] Herman, ‘Die Casting Technology - Calculations’, Die Casting Education Project RMIT University, 1995.

- [10] Davis and Robinson, ‘Production of Aluminium Die Castings Using a Fan Gate [2] The Effect of Casting Conditions at the Gate on Casting Quality’, 8th SDCE International Die Casting Exposition and Congress, 1975.

- [11] Editor of the Die Casting Engineer, ‘Eliminating Surface Defects on Zinc Die Castings’, Die Casting Engineer, January/February 1977.

- [12] Stuhrke and Wallace, ‘Gating of Die Castings’, Transactions of the American Foundrymen’s Society, Volume 73, 1966.

- [13] Neff, ‘Principles of Molten Metal Processing for Improving Die Cast Quality’, 16th NADCA Congress and Exposition, 1991.

- [14] Titone, ‘Important Considerations in the Trimming of Die Castings’, 5th SDCE National Die Casting Congress, 1968.

- [15] Johnson, Bishop, and Pellini, ‘Application of Chills to Improving Pressure Tightness of Gun Metal (88-8-4)’, Transactions of the American Foundrymen's Society, Volume 62, 1954.

- [16] Veinik, ‘Thermodynamic Factors in Metal Injection: Effect of Friction on Gas Content and Quality’, 4th SDCE National Die Casting Exposition and Congress, 1966.

- [17] Garber, ‘Theoretical Analysis and Experimental Observation of Air Entrapment during Cold Chamber Filling’, Die Casting Engineer, May/June 1982.

- [18] Thome and Brevick, ‘Optimal Slow Shot Velocity Profiles For Cold Chamber Die Casting’, 18th NADCA Congress, 1995.

- [19] Luis-Martin and Robla, ‘Evaluation of Gas Porosity in Zinc Die Castings’, 12th SDCE International Die Casting Congress and Exposition, 1983.

- [20] Miller, ‘Inclusion Control of Die Casting Alloys’, Die Casting Engineer, September/October 1984.

- [21] Shivkumar, Apelian, and Brucher, ‘Melt Cleanliness in Die Cast Aluminium Alloys’, 16th NADCA Congress and Exposition, 1991.

- [22] Anderson, ‘Shot Peening to Reduce Porosity in Die Castings’, Modern Metals, Volume 9 Number 1, 1953.

- [23] DePue and Pennington, ‘Influence of Silicon on Gun Metal Alloys’, Transactions of the American Foundrymen's Society, Volume 70, 1962.

- [24] Gordon, Meszaros, Naizer, and Mobley, ‘Equations for Predicting the Percent Porosity in Die Castings’, 17th NADCA Congress, 1993.

- [25] Garber and Draper, ‘Shrinkage in #380A Aluminium Alloy’, Die Casting Engineer, November/December 1979.

- [26] Otte, ‘Castability of Aluminium Alloy 380’, Report for the Cooperative Research Centre for Alloy and Solidification Technology, 1997.

- [27] Taylor, ‘The Role of Iron and Other Elements in the Formation of Porosity in Al-Si-Cu Alloy Castings’, Department of Mining, Minerals, and Materials Engineering, University of Queensland, 1997.

- [28] Kalghatgi, ‘Effect of Silicon Content on Porosity in Aluminium Die Castings with More than 1/4-in. Wall Thickness’, 14th SDCE International Die Casting Congress and Exposition, 1987.

- [29] Herman, ‘Die Casting Technology - Die Casting Process and Die Design Level II’, Die Casting Education Project RMIT University, 1997.

- [30] Kulunk, Shabestari, Gruzleski, and Zuliani, ‘Beneficial Effects of Strontium on A380 Alloy’, Transactions of the American Foundrymen's Society, 1996.

- [31] Sugiyama, Yonekura, and Ookouchi, ‘Transferred Pressure and Casting Qualities of Aluminium Diecasting’, Diecasting World, September 1996.

- [32] Arnberg, Dahle, Paradies, and Syvertsen, ‘Factors Affecting the Castability of Aluminium Foundry Alloys’, International Conference on Casting and Solidification of Light Alloys, August 1995.

- [33] Garber and Draper, ‘The Effects of Process Variables on the Internal Quality of Aluminium Die Castings’, 10th SDCE International Die Casting Exposition and Congress, 1979.

- [34] Micks and Zabek, ‘Identifying Some Common Problems With Aluminium Castings’, Transactions of the American Foundrymen’s Society, Volume 81, 1973.

- [35] Chu, Cheng, and Shivpuri, ‘Soldering Phenomenon in Aluminum Die Casting: Possible Causes and Cures’, 17th NADCA Congress, 1993.

- [36] ‘Engineering Design, (12.7 Fault Tree Analysis)’, Text, GET DETAILS FROM NICK

- [37] ASM International, ‘Metals Handbook - Volume 2, Properties and Selection: Nonferrous Alloys and Special-Purpose Materials’, 10th Edition, ASM International, 1990.

- [38] ASM International, ‘Metals Handbook - Volume 9, Metallography and Microstructure’, 9th Edition, ASM International, 1985.

- [39] Walpole and Myers, ‘Probability and Statistics for Engineers and Scientists’, Fifth Edition, Macmillan Publishing Company, 1993.

- [40] Ball and Buckwell, ‘Work out Statistics “A” Level’, Macmillan Education Ltd., 1986.

- [41] Moroney, ‘Facts from Figures’, Second Edition, Penguin Books Ltd., 1957.

- [A1] Buhler, ‘Operating Manual for Buhler H250B-P Horizontal Cold Chamber Die Casting Machine’, Buhler. (Referenced in Appendix A)

- [B1] Herman, ‘Die Casting Technology - Calculations’, Die Casting Education Project RMIT University, 1995. (Referenced in Appendix B)

- [B2] Iwahori, Nakamura, Tozawa, Yamamoto, ‘Metal Flowing Behavior in Die Castings and Defects in Aluminium Die Castings’, 13th SDCE International Die Casting Congress and Exposition, 1985. (Referenced in Appendix B)

- [B3] ASM International, ‘Metals Handbook - Volume 2, Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, 10th Edition’, ASM International, 1990. (Referenced in Appendix B)

- [C1] ASM International, ‘Metals Handbook - Volume 2, Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, 10th Edition’, ASM International, 1990. (Referenced in Appendix C)

- [C2] Herman, ‘Die Casting Technology - Calculations’, Die Casting Education Project RMIT University, 1995. (Referenced in Appendix C)

- [E1] Walpole and Myers, ‘Probability and Statistics for Engineers and Scientists’, Fifth Edition, Macmillan Publishing Company, 1993. (Referenced in Appendix E)

- [E2] Moroney, ‘Facts from Figures’, Second Edition, Penguin Books Ltd., 1957. (Referenced in Appendix E)

9. Copyright:

- This material is a paper by "Stephen Thompson". Based on "Mechanisms of Leaker Formation in Aluminium High Pressure Die Casting".

- Source of the paper: 10.13140/RG.2.2.25896.08963

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.