Optimizing Forging Temperatures for Cast Aluminium-Copper Alloys: A Guide to Improving Deformability

This technical summary is based on the academic paper "INVESTIGATION OF THE DEFORMABILITY OF ALUMINIUM-COPPER CASTING ALLOYS" by Grzegorz Winiarski, Anna Dziubińska, Krzysztof Majerski, Michał Szucki, and Krzysztof Drozdowski, published in Advances in Science and Technology Research Journal (2018). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Casting Alloy Deformability

- Secondary Keywords: Aluminium-Copper Alloys, Forging Temperature, Upsetting Test, Permanent Mould Casting, Sand Casting

Executive Summary

- The Challenge: Manufacturing complex, high-strength parts from casting alloys requires a combined casting and forging process, but the optimal parameters to ensure defect-free results are not well-defined.

- The Method: Researchers performed hot upsetting tests on EN AW-2017A and EN AW-2024 aluminium-copper alloys, cast using both sand and permanent moulds, across a temperature range of 420-500°C.

- The Key Breakthrough: The study revealed that the initial casting method (sand vs. permanent mould) has a critical impact on the alloy's deformability and determines the optimal forging temperature required to produce defect-free parts.

- The Bottom Line: Permanent mould castings exhibit superior deformability at lower temperatures compared to sand castings, offering a wider and more forgiving processing window for subsequent forging operations.

The Challenge: Why This Research Matters for HPDC Professionals

In modern manufacturing, combining casting with subsequent forging operations is a powerful technique for producing complex parts with superior mechanical properties. This hybrid approach leverages the shape-making freedom of casting with the strength enhancement and defect reduction of forging. However, the success of this process hinges on understanding the material's behavior, particularly the Casting Alloy Deformability.

Many high-strength aluminium alloys, while excellent in their final application, have limited deformability in their as-cast state. Incorrectly chosen process parameters, especially forging temperature, can lead to costly defects like underfill, overlap, or cracking, negating the benefits of the process. This research was undertaken to define the precise forging temperature ranges for two common aluminium-copper alloys—EN AW-2017A and EN AW-2024—and to determine how the initial casting method influences these critical parameters.

The Approach: Unpacking the Methodology

The research team conducted a rigorous investigation using both experimental tests and numerical analysis to assess the deformability of cast preforms.

- Materials: The study focused on two aluminium-copper alloys: EN AW-2017A and EN AW-2024.

- Casting Methods: Test specimens were produced using two distinct methods: sand casting and steel permanent mould casting.

- Pre-treatment: All castings were subjected to a homogenizing annealing process at 495°C for 24 hours to reduce segregation and create a more uniform microstructure.

- Deformation Test: Cylindrical specimens were subjected to a hot upsetting test on a Narges MX 700 hydraulic press. The test was conducted at various preform temperatures ranging from 420°C to 500°C, with the forging tools heated to 250°C.

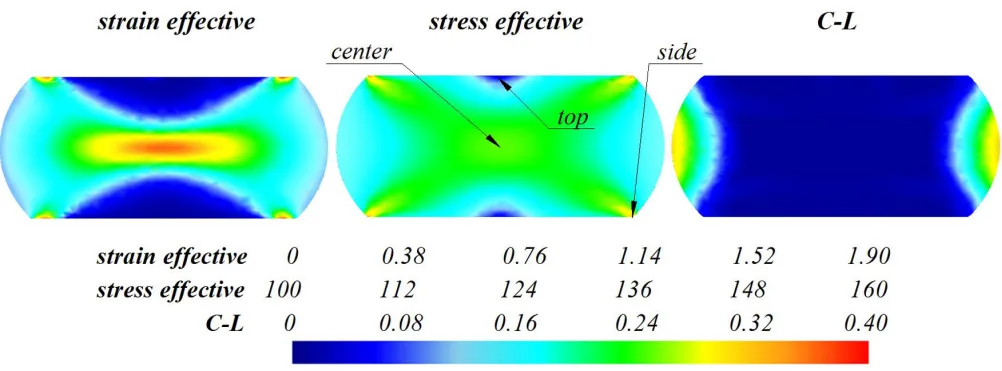

- Analysis: The deformed specimens underwent visual inspection for defects, microstructural examination to observe grain structure, and hardness testing to measure changes in mechanical properties. Numerical simulations using Deform-3D software were also performed to model effective stresses, strains, and predict fracture risk using the Cockcroft-Latham criterion.

The Breakthrough: Key Findings & Data

The study yielded clear, actionable data on how casting method and temperature interact to define the processing window for these alloys.

Finding 1: Mould Type Dictates the Forging Temperature Window

The initial casting method proved to be a critical factor in determining whether a part could be forged without defects. The results from visual inspection, shown in Tables 1 and 2 of the paper, reveal a stark contrast:

- EN AW-2017A: Sand-mould castings exhibited cracks on their lateral surface when upset at temperatures between 420-480°C and were only defect-free at 500°C. In contrast, permanent-mould castings were defect-free across the 420-480°C range but showed cracking at 500°C.

- EN AW-2024: Sand-mould castings showed defects when upset at 420-460°C, requiring a higher temperature of 480-500°C for a successful outcome. Remarkably, the steel permanent-mould castings of this alloy showed no defects across the entire tested temperature range of 420-500°C.

This demonstrates that permanent mould casting produces preforms with significantly better deformability, allowing for successful forging at lower temperatures and across a wider process window.

Finding 2: Forging Significantly Increases Hardness, Especially in Sand Castings

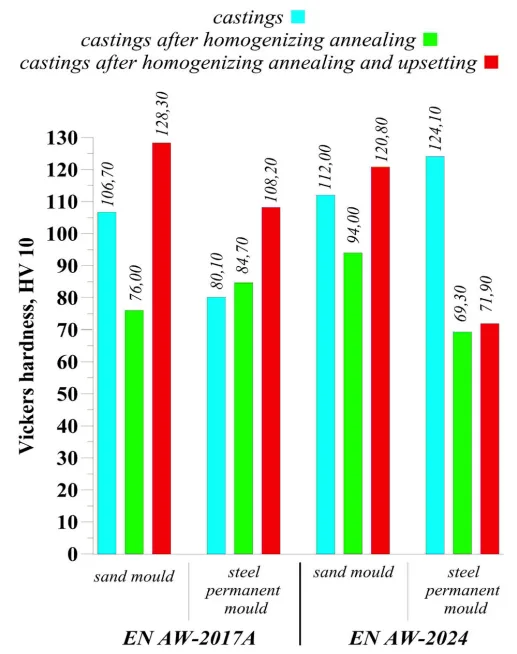

The forging process not only shapes the part but also improves its mechanical properties through work hardening. As shown in Figure 3, the hardness of all specimens increased after forging compared to their post-annealed state. The magnitude of this increase was heavily dependent on the casting method.

- For the EN AW-2017A alloy, the sand-mould casting saw a massive 68.8% increase in hardness (from 76 to 128.3 HV10). The permanent-mould casting increased by a more moderate 27.7%.

- For the EN AW-2024 alloy, the sand-mould casting's hardness increased by 28.5%, while the permanent-mould casting saw only a minimal 3.7% increase.

This suggests that while sand castings are less deformable, they experience a greater work-hardening effect when successfully forged.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that for EN AW-2024, using permanent mould preforms may allow for a broader and lower forging temperature window (420-500°C) compared to sand cast preforms (480-500°C), potentially reducing energy costs and cycle times. For both alloys, the forging temperature for sand mould castings must be higher than for permanent mould castings.

- For Quality Control Teams: The data in Tables 1 and 2 of the paper illustrates that cracks on the lateral surface are the primary defect. This indicates that visual inspection of this area is critical, especially when forging sand castings or operating at the boundaries of the acceptable temperature range.

- For Design Engineers: The findings indicate that the initial microstructure from the casting process directly influences subsequent deformability. This suggests that specifying the casting method (e.g., permanent mould for a more homogenous structure) is a critical design consideration for parts intended for a combined casting-forging manufacturing route.

Paper Details

INVESTIGATION OF THE DEFORMABILITY OF ALUMINIUM-COPPER CASTING ALLOYS

1. Overview:

- Title: INVESTIGATION OF THE DEFORMABILITY OF ALUMINIUM-COPPER CASTING ALLOYS

- Author: Grzegorz Winiarski, Anna Dziubińska, Krzysztof Majerski, Michał Szucki, Krzysztof Drozdowski

- Year of publication: 2018

- Journal/academic society of publication: Advances in Science and Technology Research Journal

- Keywords: aluminium alloy, metal forming, upsetting test, qualitative research.

2. Abstract:

The paper presents the results of a numerical analysis and experimental tests investigating the deformability of castings made of two aluminium alloys: EN AW-2017A and EN AW-2024. Test specimens were produced by two casting methods: sand casting and permanent mould casting. The castings were first subjected to homogenizing annealing; afterwards, they were shaped into cylindrical specimens for an upsetting test. This test was conducted on a hydraulic press in the temperature range of 420-500°C. Visual inspection of the specimens and examination of their microstructure were performed. Hardness of selected specimens was also measured. The study led to determination of the effect of the mould type on the deformability of the castings and the hardness of forgings obtained from these casting. Obtained results also became a basis for determining the forging temperature ranges for casting preforms made of the investigated aluminium alloys.

3. Introduction:

A wide variety of production technologies are used for producing parts for machines and devices. In many cases, manufacturing requires the use of different techniques, such as combining casting and forging. This production method consists in forging a preform produced by casting, making it possible to produce parts with complex shapes and/or made of materials with limited deformability. The use of metal working improves the mechanical properties of a preform produced by casting and reduces structural defects produced in the casting process. The casting/forging process depends on many factors. This paper presents the results of a study investigating the deformability of castings made of EN AW-2017A and EN AW-2024 alloys.

4. Summary of the study:

Background of the research topic:

The manufacturing of parts often requires combining different techniques to reduce production time and costs while achieving the desired shape, quality, and strength. A rapidly developing technique is the combination of casting and forging.

Status of previous research:

Previous studies have investigated integrated casting and forging for products like aluminium automobile wheels (Zhang et al.), die forgings from cast billets (Płonka et al.), tie-rod ends (Kim et al.), and large flanges (Wang et al.). These studies confirmed that process parameters like preform shape, forging temperature, and strain rate significantly impact the final product's microstructure and properties.

Purpose of the study:

The study aimed to investigate the deformability of castings made from two aluminium-copper alloys (EN AW-2017A and EN AW-2024). The key objectives were to determine the effect of the casting mould type (sand vs. permanent) on deformability, measure the hardness of the resulting forgings, and establish recommended forging temperature ranges for these cast preforms.

Core study:

The core of the study involved performing hot upsetting tests on cylindrical specimens made from sand-cast and permanent-mould-cast aluminium alloys. The tests were conducted across a temperature range of 420-500°C. The resulting specimens were analyzed through visual inspection, microstructure examination, and hardness measurement to evaluate the impact of casting method and temperature on deformability and final properties.

5. Research Methodology

Research Design:

The research employed an experimental design comparing two aluminium alloys (EN AW-2017A, EN AW-2024), two casting methods (sand casting, permanent mould casting), and five forging temperatures (420, 440, 460, 480, 500°C). The primary assessment method was the upsetting test, a standard procedure for evaluating material deformability.

Data Collection and Analysis Methods:

Data was collected through:

1. Visual Inspection: Naked-eye examination of upset specimens to identify surface cracks and material cohesion loss.

2. Microstructural Examination: Analysis of the microstructure of castings before and after annealing, and in different zones of the deformed specimens (top, center, side).

3. Hardness Measurement: Vickers hardness tests (HV10) were performed on castings and final forgings.

4. Numerical Simulation: The finite element method (FEM) using Deform-3D software was used to model the process and calculate parameters like effective stress, strain, and the normalized Cockcroft-Latham ductile fracture criterion.

Research Topics and Scope:

The research focused on the hot deformability of cast aluminium-copper alloys. The scope included preparing castings via sand and permanent moulds, pre-treating them with homogenizing annealing, conducting upsetting tests at elevated temperatures (420-500°C), and analyzing the resulting deformability, microstructure, and hardness.

6. Key Results:

Key Results:

- The mould type and forging temperature have a key impact on the deformability of the aluminium alloy castings.

- Permanent-mould castings of both alloys showed better deformability at lower temperatures than sand-mould castings.

- For EN AW-2017A, the recommended forging temperature for defect-free products is 500°C for sand castings and 420-480°C for permanent mould castings.

- For EN AW-2024, the recommended forging temperature for defect-free products is 480-500°C for sand castings and 420-500°C for permanent mould castings.

- The primary defect observed was cracking on the lateral surface of the specimens.

- Forging increases the hardness of the castings compared to their hardness after homogenizing annealing. The increase in hardness is greater for sand-mould castings than for permanent-mould castings.

Figure Name List:

- Fig. 1. Examples of: a) sand castings made of EN AW-2017A and b) cylindrical specimens made of these castings

- Fig. 2. Distribution of effective strains, effective stresses and the normalized Cockcroft-Latham ductile fracture criterion, obtained for EN AW-2017A specimens deformed at 500°C.

- Fig. 3. Vicker hardness of EN AW-2017A and EN AW-2024 specimens after casting and upsetting

7. Conclusion:

- The upsetting test is an effective method for assessing the deformability of cast aluminium alloys.

- Selection of the mould type (sand or steel permanent moulds) has a crucial effect on casting deformability.

- Visual assessment and microstructure examination demonstrated that the recommended forging temperatures for EN AW-2017A and EN AW-2024 alloys are 500°C and 460°C for sand mould castings and steel permanent mould castings, respectively; for both tested alloys, the forging temperature of sand mould castings is higher than that of steel permanent mould castings.

- The upsetting test revealed that cracking may occur along the grain boundary on the lateral surface of the specimens when deforming EN AW-2017A and EN AW-2024 alloy castings.

- As a result of deformation, the hardness of the castings increases (when compared to their hardness after homogenization); the increase in hardness after the forging process is higher for the sand-mould castings than for permanent-mould castings.

8. References:

- Zhang Q., Miao C., Dawei Z., Shuai Z. and Jue S. Research on integrated casting and forging process of aluminum automobile wheel. Advances in Mechanical Engineering, 6, 2015, 1-12.

- Płonka B., Kłyszewski A., Senderski J. and Lech-Grega M. Application of Al alloys, in the form of cast billet, as stock material for the die forging in automotive industry. Archives of Civil and Mechanical Engineering, 8(2), 2008, 149-156.

- Kim H.R., Seo M.G. and Bae W.B. A study of the manufacturing of tie-rod ends with casting/forging process. Journal of Materials Processing Technology, 125-126, 2002, 471-476.

- Wang S.I., Seo M.K., Cho J.R. and Bae W.B. A study on the development of large aluminum flange using the casting/forging process. Journal of Materials Processing Technology, 130–131, 2002, 294-298.

- Zhou H.T., Xu S.X., Li W.D., Wang S.C. and Peng Y. A study of automobile brake bracket formed by casting-forging integrated forming technology. Materials and Design 67, 2015, 285-292.

- Standard PN-H-04411.

- Malas J.C., Venugopal S. and Seshacharyulu T. Effect of microstructural complexity on the hot deformation behavior of aluminum alloy 2024. Materials Science and Engineering: A, 368(1-2), 2004, 41-47.

- Segal V.M. New hot thermo-mechanical processing of heat treatable aluminum alloys. Journal of Materials Processing Technology, 231, 2016, 50-57.

- Winiarski G., Gontarz A. and Dziubińska A. The influence of tool geometry on the course of flanges radial extrusion in hollow parts. Archives of Civil and Mechanical Engineering, 17(4), 2017, 986-996.

- Winiarski G. and Gontarz A. Numerical and experimental study of producing two-step flanges by extrusion with a movable sleeve. Archives of Metallurgy and Materials, 62(2), 2017, 495-499.

- Różyło P. and Wójcik Ł. Fem and experimental based analysis of the stamping process of aluminum alloy. Advances in Science and Technology Research Journal, 11(3), 2017, 94-101.

- Gontarz A., Dziubińska A. and Okoń Ł. Determination of friction coefficients at elevated temperatures for some Al, Mg and Ti alloys. Archives of Metallurgy and Materials, 56(2), 2011, 379-384.

- Bulzak T., Tomczak J. and Pater Z. Forming a lever preform made of aluminium alloy. Metalurgija, 53(4), 2014, 505-508.

Expert Q&A: Your Top Questions Answered

Q1: Why was homogenizing annealing performed on the castings before the upsetting test?

A1: The homogenizing annealing step, conducted at 495°C for 24 hours, was crucial for preparing the material for deformation. According to the paper, this process helps dissolve some precipitates on the grain boundaries and reduces segregation within the alloy. This creates a more uniform and homogenous microstructure, which is essential for accurately assessing the inherent deformability of the material itself, rather than being influenced by casting inconsistencies.

Q2: The paper states that permanent-mould EN AW-2024 castings were defect-free from 420-500°C, yet the conclusion recommends a forging temperature of 460°C. Why this specific temperature?

A2: While the visual inspection (Table 2) showed a wide success window, the final recommendations in the conclusion are based on both visual assessment and the detailed examination of the microstructure. The specific recommendation of 460°C likely represents the temperature that provided the optimal balance of defect-free formability and a desirable final microstructure (e.g., grain size, degree of recrystallization). Forging at unnecessarily high temperatures can sometimes lead to undesirable grain growth or other microstructural issues.

Q3: What was the primary failure mode observed during the tests, and where did it occur?

A3: The paper consistently identifies a single primary defect: cracks occurring on the lateral (cylindrical) surface of the upset specimens. The microstructural analysis further reveals that these cracks form along the grain boundaries of the alloy. This indicates that failure is initiated by decohesion between grains in the area of highest tensile stress during upsetting.

Q4: Did the numerical simulation in Deform-3D predict the location of these cracks?

A4: Yes, it did. As shown in Figure 2, the numerical simulation calculated the normalized Cockcroft-Latham ductile fracture criterion. The results showed the highest values for this criterion (around 0.4) on the lateral surface of the specimen model. This area corresponds exactly to where cracking was observed in the physical experiments, validating the simulation's ability to predict the most failure-prone zones.

Q5: Why did sand-mould castings generally require higher forging temperatures than permanent-mould castings?

A5: The paper's microstructural analysis provides the answer. In permanent-mould castings, the faster cooling rate leads to a more homogenous material where eutectic precipitates dissolve more completely during annealing, and other intermetallic phases are more evenly distributed. This results in a preform with better inherent deformability. Sand casting's slower cooling likely produces a coarser, more segregated initial structure that is less forgiving during deformation and thus requires higher temperatures to achieve the necessary plasticity.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear and valuable roadmap for engineers working with combined casting and forging processes for aluminium-copper alloys. The core takeaway is that the initial casting method is not just a preliminary step but a critical decision that dictates the entire downstream forging process. By demonstrating the superior Casting Alloy Deformability of permanent mould castings, the study highlights a pathway to wider processing windows, lower energy consumption, and more reliable, defect-free production.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "INVESTIGATION OF THE DEFORMABILITY OF ALUMINIUM-COPPER CASTING ALLOYS" by "Grzegorz Winiarski, Anna Dziubińska, Krzysztof Majerski, Michał Szucki, Krzysztof Drozdowski".

- Source: https://doi.org/10.12913/22998624/95056

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.