This introduction paper is based on the paper "Integrated Structural Casting Development with Digital Twin Technology" published by "The 75th World Foundry Congress".

1. Overview:

- Title: Integrated Structural Casting Development with Digital Twin Technology

- Author: Shouxun Ji, Zhichao Niu, Xixi Dong, Xiangzhen Zhu

- Year of publication: 2024

- Journal/academic society of publication: The 75th World Foundry Congress

- Keywords: aluminium alloys; casting; microstructures; mechanical properties; digital twin

2. Abstract:

In the present paper, we introduced the development of integrated structural castings with digital twin technology for the rear structure of high-end E-sports cars. The topological optimisation, casting structural design, materials verification, melt flow and solidification, mechanical property prediction and the final verification using low pressure die casting (LPDC) for the component manufacturing are described in details for digital twin. The microstructures and mechanical properties of the casting with satisfied quality are described under heat-treated condition.

3. Introduction:

Aluminium alloys are increasingly utilized as lightweight materials in transport to improve energy consumption and reduce CO₂ emissions. Castings of aluminium alloys are crucial for geometrically complex parts. Due to the high temperature and complex casting process, understanding and leveraging potentials for property improvement of lean structures before production is highly significant. Digital twin technology, a new development technique, offers a reliable approach for smart manufacturing process development, from component conception to dispatch. However, its application in casting manufacturing is still rare. This study introduces the digital twin assisted development of integrated structural castings for the rear structures of high-end E-sports cars.

4. Summary of the study:

Background of the research topic:

The increasing demand for lightweight materials in the transport sector to enhance energy efficiency and reduce emissions drives the use of aluminium alloys. Aluminium alloy castings are particularly important for producing geometrically complex components. Improving the properties of these structures, especially before actual production, is critical due to the complexities of the casting process.

Status of previous research:

Digital twin technology is emerging as a reliable method for smart development in manufacturing, covering all process steps. However, its application within the casting manufacturing industry is not yet widespread.

Purpose of the study:

The study aims to introduce and detail the development of integrated structural castings for the rear structure of high-end E-sports cars, assisted by digital twin technology. This includes demonstrating the process from topological optimisation to final component verification.

Core study:

The core of the study involves the application of digital twin technology to the development of integrated structural castings. This encompasses topological optimisation, casting structural design, materials verification, simulation of melt flow and solidification, prediction of mechanical properties, and final verification through Low Pressure Die Casting (LPDC) manufacturing of the component. The study also examines the microstructures and mechanical properties of the heat-treated castings.

5. Research Methodology

Research Design:

The research was designed to demonstrate a holistic approach to developing integrated structural castings using digital twin technology. This involved:

- Topological optimisation of the rear chassis structure.

- Materials modelling and verification using a standard A356.2 alloy casting.

- Digital twin simulation for melt flow, solidification, defect formation, and mechanical property prediction.

- Manufacturing of a verification casting using LPDC.

- Comparison of predicted data with experimental results from the physical casting.

Data Collection and Analysis Methods:

- Material: A356.2 alloy.

- Casting: Low pressure die casting (LPDC) machine by LPM (Italy) with a locking force of 24 tonne, plate size 1.9 m×1.6 m. Casting pressure was 0.8 bar.

- Tensile Testing: Conducted following ASTM E08/E08M using an Instron 5500 Universal Electromechanical Testing System with Bluehill software. Gauge length of extensometer was 25 mm, ramp rate for extension was 2 mm/min.

- Microstructure Analysis: Zeiss optical microscope with quantitative metallography.

- Digital Twin Simulation: Magmasoft with specially developed modules for melt flow, solidification, and mechanical properties prediction.

- Heat Treatment: T6 heat treatment (540 °C/8 h for solution and 180 °C/6 h for ageing) was applied to some samples.

Research Topics and Scope:

The research covered the following topics:

- Topological optimisation for integrated casting structure of rear chassis.

- Materials verification of A356.2 alloy.

- Digital twin simulation of melt flow, solidification, and prediction of casting defects.

- Prediction of mechanical properties (yield strength, UTS, elongation) under as-cast and T6 heat-treated conditions.

- Final verification of the component manufactured by LPDC, including geometry tolerance and mechanical properties.

- Microstructural characterization of the cast A356.2 alloy.

6. Key Results:

Key Results:

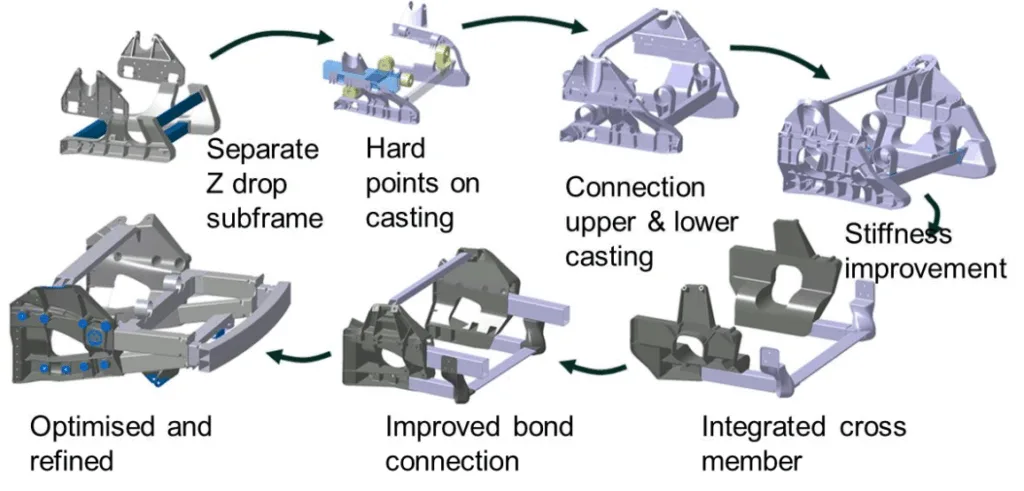

- A full design procedure for topological optimisation of integrated rear chassis structures was established, incorporating aspects like subframe separation, hardpoint integration, improved bond connections, and casting manufacturability feedback (Figure 1).

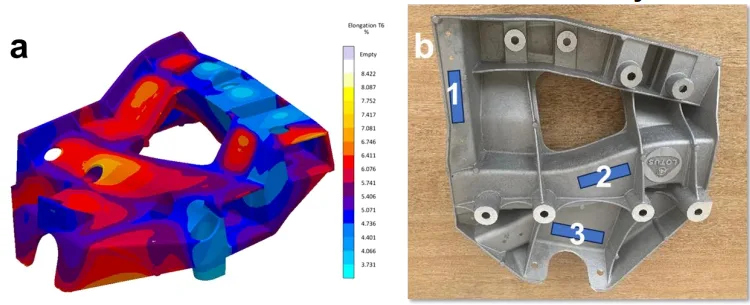

- Materials verification using A356.2 alloy showed that digital analysis predicted yield strength from 243 to 246 MPa, UTS from 320 to 330 MPa, and elongation from 8.2 to 8.7% for the middle section of top flanges. Physical castings after T6 heat treatment exhibited yield strength of 250±7 MPa, UTS of 330±13 MPa, and elongation of 7±1.5% (Table 1, Figure 2), with elongation being slightly lower than predicted.

- Digital analysis of the optimised gating system showed superior design, with no obvious defects in key areas and only tiny defects at rib cross-sections (Figure 3).

- Predicted elongation for the final casting under T6 condition varied from 4.5% to 7.5% (Figure 4a). Measured tensile properties from the verified LPDC casting (Figure 4b) showed that the elongation of tested samples was better than the prediction (Figure 5).

- The microstructure of the as-cast A356.2 alloy showed dendrites with a size of 300-400 µm. After T6 heat treatment, dendrite tips were blunted, and the eutectic Si phase was spheroidized (Figure 6).

- The casting verification of A356.2 tensile samples yielded a strength of 250 MPa, a UTS of 330 MPa, and an elongation of 7%, closely matching digital results.

Figure Name List:

- Figure 1 Topological design and optimisation of the integrated casting structure for rear chassis.

- Figure 2 Materials verification of A356.2 alloy using a standard casting structure at auto OEMs.

- Figure 3 Simulation of casting defects after melt filling and solidification simulation of A356.2 alloy

- Figure 4 Digital twin of casting made by A356.2 alloy for (a) virtual simulation of elongation under T6, (b) physical casting made by LPDC with sampling for tensile test

- Figure 5 Tensile properties measured from verified casting and the data obtained from prediction (P) of A356.2 alloy

- Figure 6 Microstructures in cast A356.2 alloy: (a) as-cast grain size; (b) morphology of primary α-Al phase after T6

7. Conclusion:

The digital twin technique is capable of developing casting manufacturing from structural optimisation design to final mechanical properties. The gating system optimisation, melt filling, modification and defect formation, and the mapping of mechanical properties can be obtained from digital analysis with relatively accurate data. The casting verification of A356.2 tensile samples have a yield strength of 250 MPa, a UTS of 330 MPa and an elongation of 7%, which is close to the digital results.

8. References:

- [1] Dong X, Zhang Y, Ji S. Enhancement of mechanical properties in high silicon gravity cast AlSi9Mg alloy refined by Al3Ti3B master alloy. Mat. Sci. Eng. A, 2017, 700: 291-300.

- [2] Amirkhanlou S, Ji S. Casting lightweight stiff aluminium alloys: A review. Critical Reviews in Solid State and Materials Sciences, 2020, 45(3): 171-186.

9. Copyright:

- This material is a paper by "Shouxun Ji, Zhichao Niu, Xixi Dong, Xiangzhen Zhu". Based on "Integrated Structural Casting Development with Digital Twin Technology".

- Source of the paper: The 75th World Foundry Congress (DOI not provided in the paper).

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.