Unlocking the Potential of Secondary Aluminum Alloys: How Nickel Addition Mitigates Iron Impurities

This technical summary is based on the academic paper "Influence of Nickel Addition on Properties of Secondary AlSi7Mg0.3 Alloy" by L. Richtárech, D. Bolibruchová, M. Brůna, and J.Caiss, published in ARCHIVES of FOUNDRY ENGINEERING (2015).

Keywords

- Primary Keyword: Secondary AlSi7Mg0.3 Alloy

- Secondary Keywords: Iron correctors, Nickel addition, AlFeSi intermetallics, Mechanical properties, Aluminum casting, Fe-rich phases

Executive Summary

- The Challenge: High iron content in secondary aluminum alloys forms brittle, needle-like Al5FeSi phases, which severely degrade critical mechanical properties like ductility.

- The Method: Researchers intentionally increased the iron content in a secondary AlSi7Mg0.3 alloy and then added varying amounts of Nickel (0.5%, 1.0%, and 1.5% wt. of an AlNi20 master alloy) to study its effect on microstructure and mechanical performance.

- The Key Breakthrough: The addition of 1.5 wt.% of AlNi20 master alloy significantly improved both tensile strength and elongation, allowing the high-iron alloy to meet demanding industry standards without negatively impacting hardness.

- The Bottom Line: Nickel can serve as an effective "iron corrector" in secondary AlSi7Mg0.3 alloys, enabling the use of cost-effective recycled materials for high-performance castings, such as those in the automotive industry.

The Challenge: Why This Research Matters for HPDC Professionals

In the high-pressure world of automotive and industrial casting, there is constant pressure to reduce costs without sacrificing quality. Secondary aluminum alloys, derived from recycled scrap, offer a significant cost advantage over primary aluminum. However, this benefit comes with a major technical hurdle: impurities.

Iron (Fe) is the most common and detrimental impurity in secondary aluminum. It forms hard, brittle, needle-like intermetallic phases (specifically β-Al5FeSi) during solidification. These phases act as stress concentrators within the alloy matrix, drastically reducing ductility and making the final casting prone to premature failure. Because iron is practically impossible to remove from the melt using standard foundry operations, the industry has long sought effective ways to neutralize its harmful effects, allowing for wider use of secondary alloys in demanding applications.

The Approach: Unpacking the Methodology

To isolate and understand the effect of nickel, the researchers designed a controlled experiment.

Method 1: Base Material and Iron Contamination: The experiment began with a standard AlSi7Mg0.3 cast alloy. To simulate the conditions of a typical secondary alloy, a deliberate "contamination" was performed by adding 70,000 ppm of an AlFe10 master alloy, significantly increasing the iron content.

Method 2: Nickel as an Iron Corrector: The high-iron melt was then divided into batches. Different amounts of an AlNi20 master alloy were added to create three experimental groups: 0.5 wt.%, 1.0 wt.%, and 1.5 wt.% addition. Melts were prepared in an electrical resistance furnace and cast into a chill mold at a controlled temperature of 760 ± 5 °C.

Method 3: Comprehensive Analysis: The resulting samples were subjected to a rigorous analysis to evaluate the impact of the nickel addition. This included:

- Chemical Composition Analysis: To verify the exact elemental content of each melt.

- Microstructural Evaluation: Using light microscopy and scanning electron microscopy (SEM) with EDX analysis to identify the phases present and their morphology.

- Mechanical Testing: Measuring tensile strength, elongation, and Brinell hardness to quantify the changes in material performance.

The Breakthrough: Key Findings & Data

The study yielded clear, actionable data on the positive influence of nickel in high-iron secondary aluminum alloys.

Finding 1: Mechanical Properties Significantly Improved with Nickel Addition

The most critical finding was the direct improvement in mechanical properties. As shown in the figures from the paper, both tensile strength and elongation increased progressively with higher additions of the AlNi20 master alloy.

- Tensile Strength (Figure 5): The alloy with 1.5% AlNi20 addition showed the highest tensile strength, comfortably exceeding the minimum required value for AlSi7Mg0.3 according to the EN 1706 standard.

- Elongation (Figure 6): Ductility, a key challenge in high-iron alloys, saw a marked improvement. The sample with 1.5% AlNi20 addition again demonstrated the best performance, meeting the EN 1706 standard that the untreated high-iron alloy failed to meet.

- Hardness (Figure 7): Importantly, these improvements in strength and ductility were achieved without a detrimental increase in hardness, which remained stable across all samples.

Finding 2: Microstructure Reveals the Persistence of Needle-Like Phases

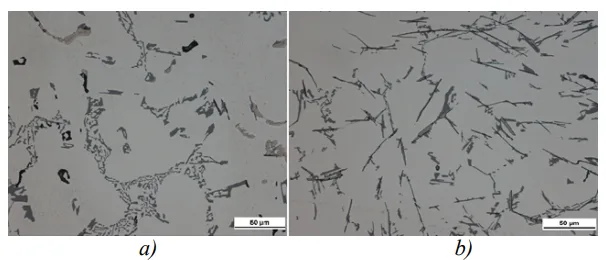

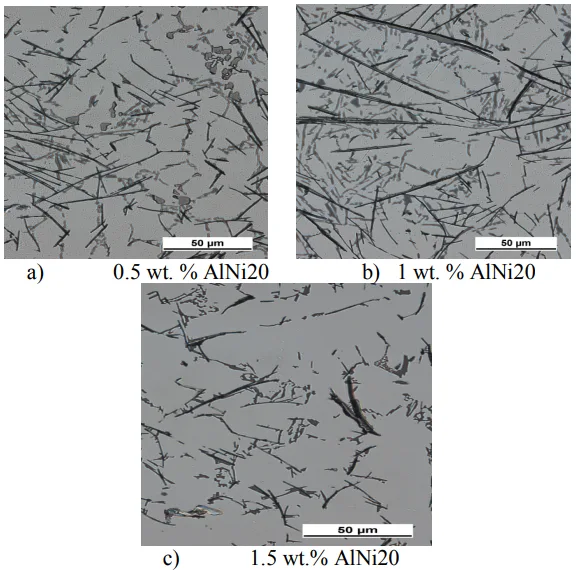

Interestingly, the microstructural analysis showed that nickel addition did not significantly alter the morphology or length of the iron-based intermetallic particles.

- As seen in Figure 2, the needle-like phases persisted even after the addition of 1.5% AlNi20.

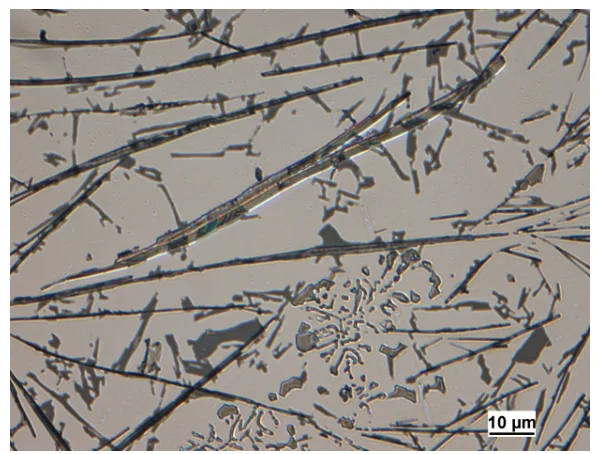

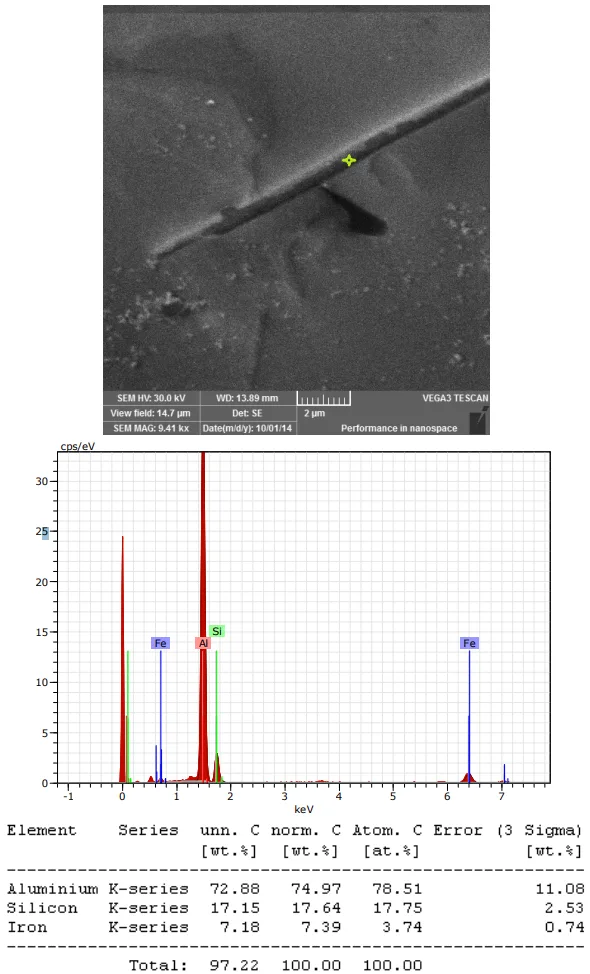

- EDX analysis (Figure 4) confirmed these particles were the undesirable β-Al5FeSi phase.

- Measurements in Table 4 showed no significant reduction in the length of these particles.

This suggests that nickel's corrective mechanism is more complex than simply refining the shape of the brittle phases. Despite the persistence of the needle-like morphology, the overall mechanical integrity of the alloy was enhanced.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adding up to 1.5 wt.% of an AlNi20 master alloy is a viable process step to upgrade the properties of high-iron secondary AlSi7Mg0.3 melts. This could help reduce scrap rates and improve the consistency of castings made from recycled materials.

- For Quality Control Teams: The data in Figure 5 and Figure 6 of the paper demonstrates that alloys treated with 1.5% AlNi20 can meet the EN 1706 standard, even with high initial iron content. This provides a clear criterion for accepting and treating secondary alloy batches that might otherwise be rejected.

- For Procurement Specialists: The findings indicate that lower-cost secondary aluminum with higher iron content can be successfully utilized for high-demand castings if treated with nickel. This opens the door to significant material cost savings without compromising the performance of the final product.

Paper Details

Influence of Nickel Addition on Properties of Secondary AlSi7Mg0.3 Alloy

1. Overview:

- Title: Influence of Nickel Addition on Properties of Secondary AlSi7Mg0.3 Alloy

- Author: L. Richtárech, D. Bolibruchová, M. Brůna, J.Caiss

- Year of publication: 2015

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING (Volume 15, Issue 2/2015)

- Keywords: Secondary AlSi7Mg0.3 based alloys, Iron phases, Thermal analysis, Iron correctors

2. Abstract:

This paper deals with influence on segregation of iron based phases on the secondary alloy AlSi7Mg0.3 microstructure by nickel. Iron is the most common and harmful impurity in aluminum casting alloys and has long been associated with an increase of casting defects. In generally, iron is associated with the formation of Fe-rich intermetallic phases. It is impossible to remove iron from melt by standard operations. Some elements eliminates iron by changing iron intermetallic phase morphology, decreasing its extent and by improving alloy properties. Realization of experiments and results of analysis show new view on solubility of iron based phases during melt preparation with higher iron content and influence of nickel as iron corrector of iron based phases.

3. Introduction:

Due to increased requirements on casting quality and final properties, coupled with price pressure, it is necessary to find compromises in production using secondary alloys with various impurities. Secondary aluminum alloys, made from recycled scrap, generally exhibit inferior ductility compared to primary alloys due to a higher level of impurities forming brittle intermetallic phases. Iron (Fe) is a particularly detrimental impurity. Various elements, including Mn, Cr, Be, Co, and Ni, have been investigated to neutralize the ill effects of Fe. Nickel is a strongly partitioning, slow-diffusing element that is often associated with iron, forming AlFeSi intermetallics at grain boundaries. This work was initiated to address the lack of theoretical knowledge regarding the use of secondary Al-Si-Mg alloys with high iron content and the effective elimination of its negative effects.

4. Summary of the study:

Background of the research topic:

The use of secondary aluminum alloys in demanding applications, such as in the automotive industry, is limited by the presence of impurities, particularly iron, which forms brittle intermetallic phases and degrades mechanical properties.

Status of previous research:

Prior research has identified several elements (Mn, Cr, Be, Co, Mo, Cd, Ni, S, V, etc.) that can act as "iron correctors" by modifying the morphology of Fe-rich phases. Each element has its own advantages and limitations. Nickel, specifically, is known to associate with iron to form AlFeSi intermetallics.

Purpose of the study:

The study aims to investigate the influence of nickel addition on the segregation of iron-based phases and the resulting microstructure and mechanical properties of a secondary AlSi7Mg0.3 alloy with an intentionally elevated iron content.

Core study:

The core of the study involved an experimental process where a base AlSi7Mg0.3 alloy was first contaminated with an AlFe10 master alloy to increase the iron content. Subsequently, varying amounts (0.5%, 1.0%, and 1.5%) of an AlNi20 master alloy were added to the melt. The resulting cast samples were then analyzed for chemical composition, microstructure (using light and electron microscopy), and mechanical properties (tensile strength, elongation, Brinell hardness, and gas content).

5. Research Methodology

Research Design:

The study was an experimental investigation conducted in a foundry laboratory setting. It compared the properties of a high-iron AlSi7Mg0.3 alloy with those of the same alloy treated with three different levels of nickel addition.

Data Collection and Analysis Methods:

- Melting and Casting: Melts were prepared in an electrical resistance furnace (T15) in a graphite crucible. Samples were poured at 760 ± 5 °C into a chill mold preheated to a minimum of 100 °C.

- Material Modification: The base AlSi7Mg0.3 alloy was modified with AlFe10 master alloy to increase Fe content, followed by additions of AlNi20 master alloy.

- Microstructural Analysis: Samples were prepared using standard metallographic techniques and etched with 20 ml of H2SO4 + 100 ml of H2O. Microstructures were observed using a NEOPHOT 32 light microscope. Further analysis of particle composition was performed using an electron microscope with EDX.

- Mechanical Testing: Tensile tests were performed on a WDW – 20 tensile machine at 22 °C to determine tensile strength and elongation. Brinell hardness was also measured.

Research Topics and Scope:

The research focused on the AlSi7Mg0.3 alloy system. It investigated the effect of nickel additions (via AlNi20 master alloy) on microstructure, iron-based particle length, tensile properties, hardness, and gas content in alloys with high iron concentrations (up to 1.716 wt.%).

6. Key Results:

Key Results:

- The addition of AlNi20 master alloy resulted in an unexpected decrease in the measured iron content in the final chemical analysis, from 1.716 wt.% down to 0.878 wt.% in the 1.5% AlNi20 melt.

- Microstructural analysis confirmed the presence of needle-like iron-based particles, identified by EDX as the β-phase (Al5FeSi), in all samples, including those treated with nickel.

- The length of these iron-based particles was not significantly affected by the addition of nickel (Table 4).

- Tensile strength and elongation showed a clear positive trend with increasing nickel addition. The best results were achieved with a 1.5% addition of AlNi20, with values meeting the EN 1706 standard for the alloy (Fig. 5 and Fig. 6).

- Brinell hardness was not negatively impacted by the nickel additions and remained relatively stable (Fig. 7).

- The addition of the AlNi20 master alloy had a less negative effect on the gas content of the melt compared to the untreated high-iron sample (Fig. 8).

Figure Name List:

- Fig. 1. Microstructures of alloys a) AlSi7Mg0.3 alloy b) with 70 000 ppm of AlFe10 and without addition of AlNi20

- Fig. 2. Microstructures with different amount of iron correctors

- Fig. 3. Detail of large iron particle

- Fig. 4. EDX analysis of large iron particle

- Fig. 5. Results of measurements of tensile strength

- Fig. 6. Results of measurements of elongation

- Fig. 7. Results of measurements of Brinell Hardness

- Fig. 8. Results of measurements of gas content

7. Conclusion:

The addition of nickel to a secondary AlSi7Mg0.3 alloy does not have a detrimental effect on the shape of the β(Al5FeSi) particles. However, it leads to improved tensile strength and elongation. The best results were observed after an addition of 1.5 wt.% of AlNi20 to the secondary alloy. The addition of AlNi20 does not negatively affect hardness and has a less negative effect on gas content. Based on these results, AlNi20 can be used as an effective iron corrector in secondary aluminum alloys. It is concluded that alloys with higher iron content, after treatment with an iron corrector like nickel, could be used in the production of castings with higher demands, such as for the automotive industry.

8. References:

- [1] Hurtalová, L. & Tillová, E. (2013). Elimination of the negative effect of Fe-rich intermetallicphases in secondary (recycled) aluminium cast alloy. Manufacturing Technology. 13(1), 44-50. ISSN 1213-2489.

- [2] Pastirčák, R. & Krivoš, E. (2013). Effect of opening material granularity on the mould properties and the quality of casting made by patternless process technology. Manufacturing technology. 13(1), 92-97. ISSN 1213-2489.

- [3] Bolibruchová, D. & Richtarech, L. (2013). Effect of adding iron to the AlSi7Mg0.3 (EN AC 42 100, A356) alloy. Manufacturing Technology.13(3), 276-281. ISSN 1213-2489.

- [4] Brůna, M. & Kucharčík, L. (2013). Prediction of the porosity of Al alloys. Manufacturing technology. 13(3), 296-302, ISSN 1213-2489.

Expert Q&A: Your Top Questions Answered

Q1: Why was Nickel chosen as the iron corrector for this study instead of a more common element like Manganese?

A1: The paper lists Nickel among several known elements used to neutralize the ill effects of iron. While elements like Manganese are widely used to transform the needle-like β-phase into a more compact α-phase, this study was specifically designed to investigate the effects of Nickel. The goal was to fill a gap in theoretical knowledge regarding its specific influence on high-iron secondary Al-Si-Mg alloys.

Q2: If the length of the brittle Al5FeSi needles didn't change (Table 4), what is the proposed mechanism for the significant improvement in mechanical properties?

A2: The paper does not propose a specific mechanism, but the results are compelling. While the needle-like morphology of the β-phase persisted (Figure 2), the additions of nickel still led to substantial improvements in tensile strength and elongation (Figures 5 & 6). This suggests that nickel's corrective effect may not be purely morphological; it could be influencing the properties of the matrix, the interface between the matrix and the intermetallic phase, or other subtle microstructural features not captured by particle length measurement alone.

Q3: Table 3 shows a large drop in measured iron content after adding AlNi20. Is Nickel removing iron from the melt?

A3: The paper explicitly notes that "it is impossible to remove iron from melt by standard operations." The authors highlight the measured decrease in iron from 1.716 wt.% to 0.878 wt.% as an interesting observation. This is likely not due to iron removal but could be related to factors like increased segregation of heavy, iron-rich phases that settle out of the melt before sampling, or analytical variations. The key takeaway remains that the properties improved in a melt that was initially high in iron.

Q4: What is the optimal addition level of the AlNi20 master alloy according to this research?

A4: Based on the data presented, the optimal level among those tested is 1.5 wt.%. The graphs for both tensile strength (Figure 5) and elongation (Figure 6) show a clear positive trend, with the highest values achieved at the 1.5% addition level. This amount was sufficient to bring the alloy's properties in line with the EN 1706 standard.

Q5: The study confirms the β-Al5FeSi phase is still present. Does this pose a risk for the fatigue life of components made from this alloy?

A5: This is an excellent question. The study focused on static mechanical properties: tensile strength, elongation, and hardness. While the results are positive for these metrics, the continued presence of brittle, needle-like β-phases is a known concern for dynamic properties like fatigue resistance. The paper's findings are a crucial first step, but for components subjected to cyclical loading, further investigation into the fatigue life of nickel-treated secondary alloys would be essential.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of managing iron impurities has long been a barrier to the widespread use of cost-effective recycled materials in high-performance castings. This research demonstrates a practical and effective path forward. By using Nickel as an iron corrector, it is possible to significantly improve the mechanical properties of a Secondary AlSi7Mg0.3 Alloy, even with high initial iron content. The key breakthrough is that this treatment allows the alloy to meet demanding industry standards, opening the door for greater use of secondary aluminum in critical applications and delivering both economic and environmental benefits.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Influence of Nickel Addition on Properties of Secondary AlSi7Mg0.3 Alloy" by "L. Richtárech, D. Bolibruchová, M. Brůna, J.Caiss".

Source: Published in ARCHIVES of FOUNDRY ENGINEERING, Volume 15, Issue 2/2015, pp. 95-98.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.