Cracking the Code: How Iron Contamination Creates Catastrophic Failure in Al-Si Alloy Castings

This technical summary is based on the academic paper "Influence of Al5FeSi Phases on the Cracking of Castings at Al-Si Alloys" by I. Hren, J. Svobodova, and Š. Michna, published in ARCHIVES of FOUNDRY ENGINEERING (2018). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Iron Contamination in Aluminum Alloys

- Secondary Keywords: Al5FeSi intermetallic phases, casting cracks, Al-Si alloys, fractographic analysis, low pressure casting, aluminum alloy microstructure

Executive Summary

- The Challenge: High-performance aluminum-silicon alloy castings were cracking across their entire cross-section during production, leading to total component failure.

- The Method: Researchers performed a detailed fractographic analysis, including microscopic structure assessment and EDS chemical analysis, on the fracture surfaces of a failed AlSi9NiCuMg0.5 casting.

- The Key Breakthrough: The cracking was initiated by large, brittle needle-like Al5FeSi intermetallic phases that formed due to severe iron contamination, measured at 2.32 wt.%—more than three times the maximum specified limit.

- The Bottom Line: Uncontrolled iron contamination is a direct cause of catastrophic casting failure, as it promotes the growth of crack-initiating intermetallic phases that destroy the material's mechanical integrity.

The Challenge: Why This Research Matters for HPDC Professionals

In high-performance casting operations, unexpected component failure is a critical issue that impacts yield, cost, and product reliability. This research addresses a common but often misdiagnosed problem: the cracking of Al-Si alloy castings in operating conditions. While Al-Si alloys like AA 4032 are chosen for their high specific strength, low density, and good castability, they are highly sensitive to impurities.

Iron (Fe) is the most common impurity in aluminum alloys, often introduced from melting tools, steel parts of equipment, or recycled charge materials. While small amounts can improve hardness, excessive iron content leads to the formation of brittle intermetallic phases. This study investigates a real-world case of casting failure, providing a clear and direct link between a specific contaminant (iron), the resulting microstructure (Al5FeSi phases), and the final catastrophic outcome (cracking). For any engineer striving for zero-defect production, understanding this failure mechanism is essential.

The Approach: Unpacking the Methodology

The researchers investigated a newly developed and patented eutectic silumin alloy, AlSi9NiCuMg0.5 (AA 4032), intended for low-pressure casting applications requiring high heat resistance.

- Materials: The batch was prepared from 60% purchased material and 40% "porter waste" which already had an elevated iron content. The melt was treated with refining salt and modified with strontium.

- Casting Process: Castings were produced using a low-pressure die-casting process at 745°C with a pressure of 0.3 MPa. Critically, the melt was fed into the mold via a cast iron filler pipe.

- Analysis Equipment:

- Chemical Analysis: An optical emission spectrometer (Q4 TASMAN) was used to determine the exact chemical composition of the failed casting near the fracture.

- Microstructure Analysis: A confocal laser microscope (Olympus LEXT OLS 3100) was used to evaluate the overall structure and identify the different phases present.

- Fractographic Analysis: A scanning electron microscope (SEM) equipped with Energy-Dispersive X-ray Spectroscopy (EDS) was used to analyze the fracture surface, identify the chemical composition of specific features, and pinpoint the crack initiation sites.

The Breakthrough: Key Findings & Data

The investigation revealed a clear chain of events leading from chemical contamination to structural failure, supported by compelling data.

Finding 1: Severe and Unacceptable Iron Contamination

The primary issue was an extremely high iron content in the final casting. Spectral analysis confirmed the iron level was far beyond the material's specification.

- As shown in Table 1, the patented AA 4032 alloy specifies a maximum iron content of 0.7 wt.%.

- However, the chemical analysis of the failed casting, presented in Table 2, revealed an actual iron content of 2.32 wt.%. This is nearly 3.5 times the maximum allowable limit, fundamentally altering the alloy's properties. The paper concludes this was caused by the dissolution of the cast iron ascension tube during the low-pressure casting process, compounded by the use of high-iron recycled material.

Finding 2: Formation of Large, Brittle Intermetallic Phases

This excessive iron content did not remain in the solid solution; instead, it precipitated as large, brittle intermetallic phases within the microstructure, acting as internal stress concentrators.

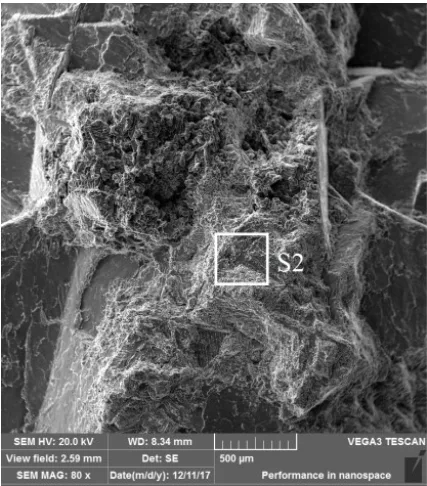

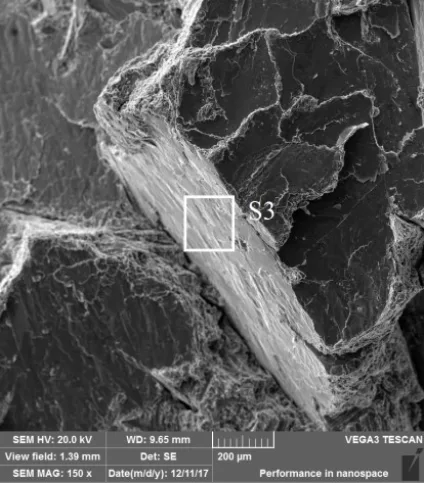

- Microstructure analysis (Figure 2 and Figure 4) identified rough, needle-like intermetallic phases of the Al5FeSi type, with sizes ranging from 160-400 µm.

- Additionally, branched intermetallic phases of the AlFe(Si)Mn "Chinese script" type were observed, with sizes of 100-300 µm (Figure 3). The Al5FeSi phases, due to their sharp, needle-like morphology, are particularly detrimental to mechanical properties.

Finding 3: Direct Evidence of Intermetallic Phases on the Fracture Surface

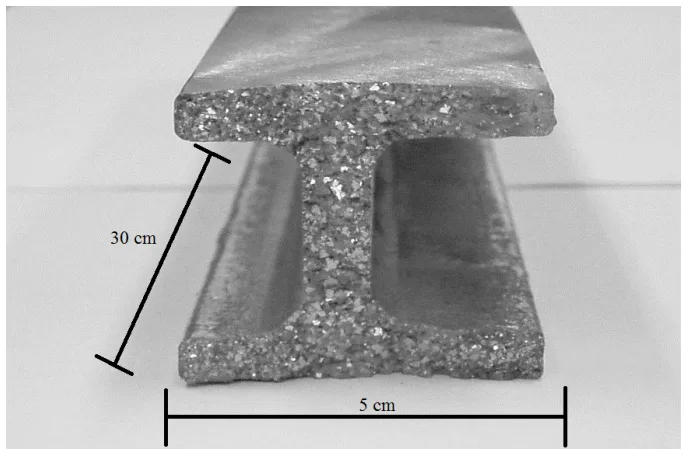

Fractographic analysis provided the "smoking gun," proving that these brittle phases were the direct cause of the cracking. The glossy surfaces observed on the fracture area (Figure 1) were confirmed to be these intermetallic phases.

- Figure 5 shows a cross-section of the fracture, where the crack path clearly follows the brittle intermetallic phases.

- EDS analysis of these glossy areas (Figure 10 and Table 5) confirmed the presence of Al, Fe, and Si in stoichiometric ratios consistent with fragile Al5FeSi phases. The paper states, "A large number of these brittle intermetallic phases at the fracture area initiate their fission breakdown and cause total cracking and crack propagation across the entire cross section of the casting."

Practical Implications for R&D and Operations

- For Process Engineers: This study is a critical reminder that all contact materials matter. The dissolution of the cast iron filler pipe was a primary source of contamination. This suggests that tooling materials must be carefully selected, monitored for wear, and potentially coated to prevent melt contamination. Furthermore, the use of high-impurity recycled materials ("porter waste") must be carefully managed with rigorous chemical analysis of every batch.

- For Quality Control Teams: The data in Table 2 and the images in Figure 2 and Figure 4 highlight that relying solely on standard alloy certification may be insufficient if the process itself introduces contamination. Microstructural analysis should be a key quality check, with specific rejection criteria for the size, density, and morphology (e.g., needle-like vs. "Chinese script") of iron intermetallic phases.

- For Design Engineers: While this study focuses on a material failure, it underscores the importance of material specification. The findings confirm that exceeding the 0.6-0.7 wt.% iron threshold in Al-Si alloys directly leads to the formation of brittle Al5FeSi phases. This reinforces the need to strictly adhere to material standards and understand the metallurgical consequences of impurities during the design and material selection phase.

Paper Details

Influence of Al5FeSi Phases on the Cracking of Castings at Al-Si Alloys

1. Overview:

- Title: Influence of Al5FeSi Phases on the Cracking of Castings at Al-Si Alloys

- Author: I. Hren, J. Svobodova, Š. Michna

- Year of publication: 2018

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING, Volume 18, Issue 4/2018

- Keywords: Aluminium alloy, Intermetallic phase, Low pressure casting, Structure, Iron contamination

2. Abstract:

The research described in this contribution is focused on fractographic analysis of the fracture area of newly developed eutectic silumin type AlSi9NiCuMg0.5 (AA 4032), which was developed and patented by a team of staff of the Faculty of Mechanical Engineering. The paper presents determination of the cause of casting cracks in operating conditions. Fractographic analysis of the fracture area, identification of the structure of the casting, identification of structural components on the surface of the fracture surface and chemical analysis of the material in the area of refraction were performed within the experiment. Al-Si alloys with high specific strength, low density, and good castability are widely used in pressure-molded components for the automotive and aerospace industries. The results shown that the inter-media phases Fe-Al and Fe-Si in aluminium alloys lead to breakage across the entire casting section and a crack that crossed the entire cross section, which was confirmed by EDS analysis.

3. Introduction:

Iron is an element we always find in aluminium and its alloys. The melt is obtained in a variety of ways, for example, by foul the batch of melting iron, steel tools used in the melting and casting process, dissolving the steel or cast iron parts of the apparatus, etc. Iron is therefore most commonly found in aluminium alloys as impurities. In some cases, Fe is added to aluminium alloys as an alloying element. If the iron is an alloying element, its content in aluminium alloys typically does not exceed 1.0 weight percent. Iron in the form of an alloying element improves the strength properties at higher alloy strengths and increases its hardness at the expense of a considerable reduction in elongation. Iron mainly causes corrosion resistance (point corrosion), reduces thermal and electrical conductivity [1, 2]. Iron has low solubility in aluminium alloys and is eliminated as intermetallic phases. The intermetallic phases are for example FeAl6, FeAl3, Fe2SiAl8, AlFeMnSi and Al5FeSi. At an iron content above 0.6 wt.% of Al5FeSi brittle phases begin to prevail, which are eliminated in the sub-eutectic siluminates in the interventricular spaces. These phases significantly reduce the plastic properties of the material [3, 4, 5].

4. Summary of the study:

Background of the research topic:

Iron is a ubiquitous element in aluminum and its alloys, often present as an impurity introduced from melting tools, equipment, or the charge itself. While sometimes used as an alloying element to increase strength, its content is typically kept below 1.0 wt.%. Above 0.6 wt.%, brittle Al5FeSi intermetallic phases begin to form, which significantly reduce the ductility and plastic properties of the material.

Status of previous research:

Previous research and literary sources have established that iron contents above 0.6-0.7 wt.% lead to the formation of brittle intermetallic phases like Al5FeSi in Al-Si alloys, which are known to negatively impact mechanical properties.

Purpose of the study:

The purpose of this study was to determine the root cause of cracking in castings made from a newly developed and patented eutectic silumin alloy, AlSi9NiCuMg0.5 (AA 4032), under operating conditions. The research focused on fractographic analysis to identify the failure mechanism.

Core study:

The core of the study involved a comprehensive analysis of a failed casting. This included:

1. Spectral chemical analysis to determine the exact composition of the alloy near the fracture.

2. Confocal laser microscopy to assess the microstructure and identify the structural components, particularly intermetallic phases.

3. Scanning electron microscopy (SEM) with EDS to analyze the fracture surface, identify the chemical makeup of features on the surface, and confirm the role of intermetallic phases in the crack initiation and propagation.

5. Research Methodology

Research Design:

The study employed a failure analysis methodology. A cracked casting from a production run was selected as the subject. The research was designed to systematically investigate the material from its bulk chemical composition down to the micro-scale features on the fracture surface to identify the root cause of failure.

Data Collection and Analysis Methods:

- Chemical Composition: An optical emission spectrometer was used to perform 5 measurements near the fracture, with the average value reported.

- Microstructure Examination: Samples were prepared for metallographic analysis and observed with a confocal laser microscope.

- Fractographic Analysis: The fracture surface was directly examined using an SEM. Specific areas, particularly the glossy surfaces, were targeted for detailed imaging and EDS analysis to determine their elemental composition.

Research Topics and Scope:

The research was scoped to the analysis of a specific failed casting of AA 4032 alloy produced by low-pressure casting. The investigation focused on the influence of iron content and the resulting intermetallic phases on the cracking phenomenon. It did not explore variations in other process parameters or alloying elements beyond what was measured in the failed part.

6. Key Results:

Key Results:

- The chemical composition of the failed casting showed an iron (Fe) content of 2.32 wt.%, which is more than three times the maximum specified value of 0.7 wt.%.

- The microstructure contained large, coarse needles of brittle Al5FeSi intermetallic phases, approximately 160-400 µm in size. Branched AlFe(Si)Mn "Chinese script" phases (100-300 µm) were also present.

- Fractographic analysis confirmed that the fracture path followed these brittle intermetallic phases.

- EDS analysis of the glossy areas on the fracture surface showed the presence of Al, Fe, and Si, confirming these were the Al5FeSi phases and that they were the initiators of the material breakdown and cracking.

- The high iron content was attributed to the dissolution of the cast iron ascension tube used in the casting process and the use of high-iron "porter waste" in the charge.

Figure Name List:

- Fig. 1. Total casting surface, mag. 3x

- Fig. 2. Microstructure of AA 4032 alloy with brittle intermetallic phases of the Al5FeSi

- Fig. 3. Area of microstructure of AA4032 alloy with intermetallic phases of AlFeSiMn type Chinese script

- Fig. 4. Morphology of Fe-rich intermetallic phases in as-cast structure of AA 4032 alloy

- Fig. 5. Cross section of fractured surfaces of AA 4032 alloy showing fracture mechanism of Al5FeSi intermetallic phase

- Fig. 6. Area analysis of the sample

- Fig. 7. Spectrum of analysed chemical elements

- Fig. 8 Area analysis of the sample

- Fig. 9 Spectrum of analysed chemical elements

- Fig. 10 Area analysis of the sample

- Fig. 11 Spectrum of analysed chemical elements

7. Conclusion:

Spectral chemical analysis of the casting revealed a high iron content of 2.32 wt.%, far exceeding the specified maximum of 0.7 wt.%. This high iron content led to the formation of coarse, brittle intermetallic phases of the Al5FeSi type (160-400 µm) and branched AlFe(Si)Mn phases (100-300 µm). Fractographic and EDS analysis of the fracture surface demonstrated that these brittle Al5FeSi phases were the direct initiators of the material breakdown, causing total cracking across the entire cross-section of the casting. The source of the contamination was identified as the dissolution of the cast iron ascension tube during the low-pressure casting process.

8. References:

- [1] Michna, Š. et al. (2005). Encyclopedia of Aluminum. (1st ed.). Prešov. SR: Adin s. r. o. ISBN 80-89041-88-4. (in Czech).

- [2] Oniszuk, A., Rzadkosz, S., Wójcik, A. & Cieślak, W. (2007). Iron presence in the technology of Mg-Al casting. Archives of Foundry Engineering. 7(2), 19-24.

- [3] Bolibruchová, D., Tillová, E. (2005). Foundry alloys Al-Si. ŽU v Žiline - EDIS. ISBN 80-8070-485-6.

- [4] Górny, Z., Kluska Nawarecka, S. & Saja, K. (2013). The Effect of Toughening Combined with Microjet Cooling During Quenching (Solution Heat Treatment) of Calcium Carbide-modified CuAl10Fe4Ni4 Alloy on its Mechanical Properties. Archives of Foundry Engineering. 13(1), 29-32.

- [5] Mondolfo, L.F. (1979). Aluminium Alloys, Structure and Properties. Butterworths, London.

- [6] Romankiewicz, F. & Romankiewicz, R. (2006). The influence of modification for structure and morphology fractures of alloy AlSi132. Archives of Foundry. 6(22), 436-440. (in Polish).

- [7] Lipiński, T. (2011). Microstructure and Mechanical Properties of the AlSi13Mg1CuNi Alloy With Ecological Modifier. Manufacturing Technology. 11(11), 40-44. ISBN 1213-2489.

- [8] Lipiński, T. (2008). Improvement of mechanical properties of AlSi7Mg alloy with fast cooling homogenous modifier. Archives of Foundry Engineering. 8(1), 85-88.

- [9] Pastircak, R., Sladek, A. & Kucharcikova, E. (2015). The production of plaster molds with patternless process technology. Archives of Foundry Engineering. 15(2), 91-94.

- [10] Roskosz, S., Adamiec, J. & Blotnicki, M. (2007). Influence of delivery state quality on microstructure and mechanical properties of as cast AZ91 Mg alloy. Archives of Foundry Engineering. 7(1), 143-146.

- [11] Turzyński, J., Pytel, A., Pysz, S. & Żuczek, R. (2006). Improving casting quality through application of modern tools for designing and testing. Archives of Foundry Engineering. 6(18), 224-230.

- [12] Cais, J., Svobodova, J. & Stancekova, D. (2017). Modification of the AlSi7Mg0.3 alloy using antimony. Manufacturing Technology. 17(5), 685-690.

- [13] Dinnis, C., Taylor, J.A. & Dahle, A.K. (2005). As-cast morphology of iron-intermetalics in Al-Si foundry alloys. Scripta Materialia. 53(8), 955-958.

Expert Q&A: Your Top Questions Answered

Q1: What were the specific sources of the high iron contamination mentioned in the paper?

A1: The paper identifies two primary sources. First, the batch material itself was problematic, as it consisted of 60% new material and 40% "porter waste which already carries an increased iron content." Second, and most critically, the paper concludes that the high iron content was due to the "dissolution of the cast iron ascension tube by low-pressure casting," indicating that the process equipment directly contaminated the aluminum melt.

Q2: How did the researchers definitively link the Al5FeSi phases to the crack initiation?

A2: They used a multi-step approach. First, visual inspection showed glossy areas on the fracture surface (Figure 1). Second, microscopic analysis of a cross-section (Figure 5) showed the crack propagating directly through these phases. The final confirmation came from SEM with EDS analysis (Figure 10 and Table 5) performed directly on these glossy fracture surfaces, which confirmed their chemical composition as being rich in Al, Fe, and Si, consistent with the Al5FeSi intermetallic phase.

Q3: The paper mentions the alloy was modified with strontium. Why wasn't this effective in preventing the failure?

A3: Strontium modification is used to change the morphology of eutectic silicon from coarse plates into a fine, fibrous structure, which improves ductility and toughness. However, strontium has no effect on the precipitation of iron-based intermetallic phases. The negative impact of the massive, 160-400 µm needle-like Al5FeSi phases was so severe that it completely negated any potential benefits from the silicon modification, leading to a brittle failure.

Q4: What is the difference between the Al5FeSi "needle" phase and the AlFe(Si)Mn "Chinese script" phase, and why was the former blamed for the failure?

A4: Both are iron-based intermetallic phases, but their morphology and impact differ. The Al5FeSi phase typically forms as sharp, plate-like needles (appearing as needles in a 2D cross-section) which act as powerful stress risers, making them extremely detrimental to ductility. The "Chinese script" AlFe(Si)Mn phase has a more complex, branched morphology that is generally considered less harmful than the sharp needles. The paper concludes the Al5FeSi phase was the primary cause of failure because it was this phase that was clearly identified on the fracture surfaces as the crack initiator.

Q5: Could this problem have been avoided simply by using 100% new batch material?

A5: While using 100% new, high-purity ingot would have certainly helped by providing a lower starting iron content, it may not have completely prevented the problem. The paper strongly suggests that the dissolution of the cast iron filler pipe was a major contributor. Therefore, even with a clean charge, the iron content could have risen above the acceptable 0.7 wt.% limit due to contamination from the process equipment itself. A comprehensive solution requires control over both the input material and the process environment.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a definitive and practical case study on the devastating effects of Iron Contamination in Aluminum Alloys. The core problem—catastrophic casting failure—was traced directly to excessive iron content, which led to the formation of large, brittle Al5FeSi phases that initiated cracks. The key breakthrough was the use of fractographic analysis to prove, without a doubt, that these intermetallic phases were the root cause of the failure.

For R&D and operations teams, the message is clear: rigorous control over both raw material purity and process contamination is not optional, it is essential for producing reliable, high-performance castings. Monitoring iron levels and understanding the resulting microstructure are critical steps to preventing costly failures and improving overall productivity.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "Influence of Al5FeSi Phases on the Cracking of Castings at Al-Si Alloys" by "I. Hren, J. Svobodova, Š. Michna".

- Source: https://doi.org/10.24425/afe.2018.125180

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.