Solving Premature Nozzle Failure: A Breakthrough in Zamak HPDC Nozzle Design for the Automotive Industry

This technical summary is based on the academic paper "Improving the Design of Nozzles Used in Zamak High-Pressure Die-Casting Process" by V. F. C. Sousa, F. J. G. Silva, et al., published in FME Transactions (2021). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Zamak HPDC Nozzle Design

- Secondary Keywords: High-pressure die casting, nozzle wear, tool life, automotive die casting, design improvement, Bowden cables

Executive Summary

- The Challenge: Injection nozzles used in the Zamak HPDC process for automotive components were failing prematurely—some in less than one 8-hour shift—due to excessive wear and fracture, increasing costs and safety risks.

- The Method: An iterative "Action-Research" methodology was used to diagnose failures in existing nozzles, implement design changes, and evaluate their real-world performance over multiple cycles.

- The Key Breakthrough: A redesigned nozzle with a gradual inner channel transition, a straight and thinner outer profile for uniform heating, and a relocated choke point dramatically increased tool life from under 15 days to over 63 days.

- The Bottom Line: Strategic improvements in both the internal and external geometry of HPDC nozzles can solve chronic wear issues, significantly extending component lifespan and improving process stability and safety.

The Challenge: Why This Research Matters for HPDC Professionals

In the competitive automotive industry, every component's cost and reliability are under scrutiny. Bowden cables, though low-cost, are critical components, and their zamak-injected ends must be manufactured with high precision and repeatability. The high-pressure die casting (HPDC) process used for this is fast and efficient, but it's also harsh on tooling.

The core problem addressed in this study was the severe and premature failure of injection nozzles. These components are permanently subjected to high temperatures and pressures, and the abrasive nature of light alloys can cause rapid deterioration. In this specific industrial case, some nozzles failed in less than a single shift, leading to production stoppages, increased maintenance costs, and significant safety hazards from potential liquid metal leakage. The switch from a stable gas heating system to an electrical resistance one forced a complete rethink of the nozzle architecture, as existing commercial solutions had serious lifetime limitations. This research was born from the critical need to engineer a more robust and reliable Zamak HPDC Nozzle Design.

The Approach: Unpacking the Methodology

Instead of relying on pure theory, the researchers employed an "Action-Research" methodology—a practical, "learning by doing" approach. This iterative cycle allowed them to systematically solve a complex industrial problem where multiple factors (materials, thermal transfer, wear, geometry) were at play.

The process involved five key stages, repeated in cycles:

1. Diagnosis: Failed nozzles were collected from the sixty-two HPDC machines on the factory floor. They were sectioned using WEDM (Wire Electrical Discharge Machining) to analyze the internal wear channels and measure hardness.

2. Action Planning: Based on the diagnosis, specific design improvements for the nozzle's inner channel and outer geometry were formulated. Material and heat treatment protocols were also reviewed and corrected.

3. Implementation: New nozzles were manufactured according to the improved designs.

4. Evaluation: The performance of the new nozzles was tested under real production conditions, running at 400-600 injections per hour.

5. Monitoring/Outcomes: The results were analyzed, lessons were learned, and the knowledge was used to initiate a new cycle of improvements.

This hands-on approach ensured that each design change was validated by real-world performance data, leading to a highly optimized final product.

The Breakthrough: Key Findings & Data

The iterative research yielded two major breakthroughs that collectively solved the premature failure problem.

Finding 1: Eliminating Abrupt Internal Geometry Changes Drastically Reduced Wear

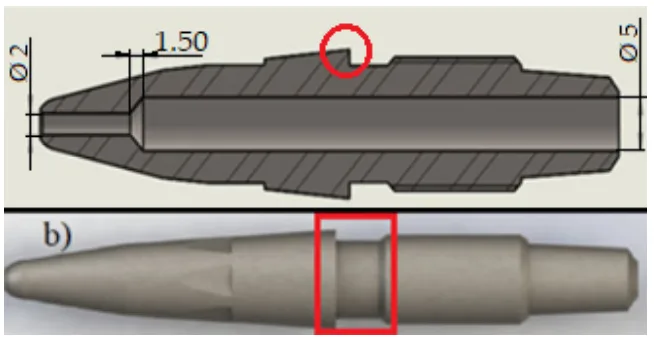

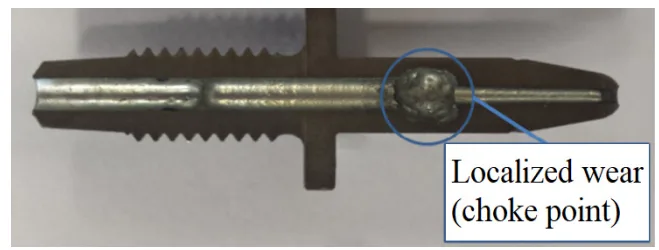

The initial diagnosis revealed that the original nozzle design featured an abrupt change in the inner channel's diameter, from 5 mm down to 2 mm (Figure 3). This sharp transition caused turbulence and "pooling" of the molten zamak, leading to severe, localized wear just before the choke point. As shown in Figures 4 and 5, nozzles with this original design showed catastrophic wear after just 11 to 17 days of use.

The first design iteration addressed this by creating a much more gradual transition, from 3 mm to 1.80 mm (Figure 7). This change, combined with a proper nitriding heat treatment, resulted in a massive improvement. As seen in Figures 8 and 9, nozzles from this first iteration showed only minimal wear after 47 and 59 days of use, respectively—more than tripling the component's lifespan.

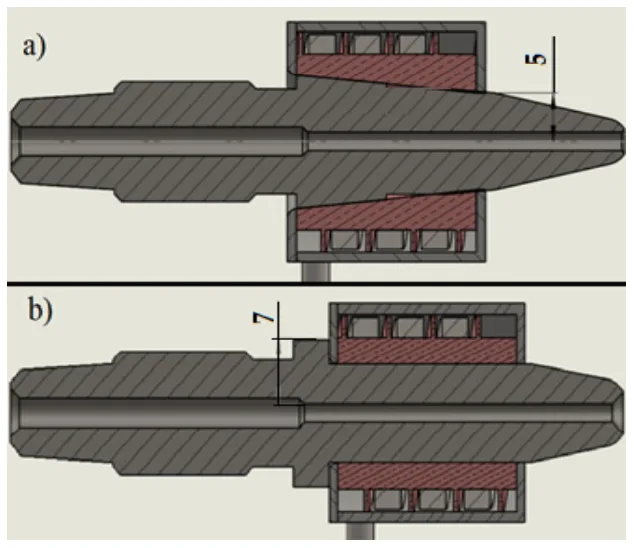

Finding 2: Optimizing External Geometry and Choke Point Location Solved Heating and Reflux Issues

While the first iteration solved the primary wear problem, it introduced secondary issues: slow, uneven heating and material reflux in the nozzle's cold zone. The second iteration tackled this by redesigning the nozzle's external shape and relocating the choke point.

The outer profile was changed from a conical shape (Figure 11) to a uniform, straight design (Figure 12). This reduced the wall thickness, bringing the electrical heating resistance closer to the inner channel (from 8.25 mm to 7 mm) and promoting faster, more homogeneous heating. Simultaneously, the choke point (the 3 mm to 1.80 mm transition) was moved from the hot zone to the cold zone of the nozzle (Figure 10). This change successfully corrected the material reflux problem without negatively impacting the nozzle's excellent wear resistance. The final design, shown in Figure 14, exhibited very little wear even after 63 days of continuous operation.

Practical Implications for R&D and Operations

This study provides highly valuable, transferable knowledge for improving the reliability of HPDC tooling.

- For Process Engineers: This study suggests that maintaining process temperatures at least 60°C below the nitriding treatment temperature is critical to preserving the nozzle's hardness and anti-adhesion properties. Overriding temperature controls to improve fluidity can catastrophically shorten tool life.

- For Quality Control Teams: The data in Figures 4, 5, 8, 9, and 14 of the paper illustrates the effect of geometric design on wear patterns. This knowledge can inform new visual inspection criteria for tooling, allowing for proactive maintenance before failure occurs.

- For Design Engineers: The findings indicate that abrupt section changes, both internal (flow channel) and external (stress concentration points, as seen in Figure 6), are primary drivers of premature failure. Implementing gradual transitions and fillets is a crucial consideration in the early design phase of any Zamak HPDC Nozzle Design.

Paper Details

Improving the Design of Nozzles Used in Zamak High-Pressure Die-Casting Process

1. Overview:

- Title: Improving the Design of Nozzles Used in Zamak High-Pressure Die-Casting Process

- Author: V. F. C. Sousa, F. J. G. Silva, L. P. Ferreira, R. D. S. G. Campilho, T. Pereira, E. Braga

- Year of publication: 2021

- Journal/academic society of publication: FME Transactions

- Keywords: High-pressure die casting, Low-cost products; Competitiveness; Design improvement, Nozzles, Wear, Automotive industry.

2. Abstract:

The injection of light alloys is an activity that requires a high effort on the part of Engineering to maintain its competitiveness. Due to the temperatures used, the wear of the components connected to this manufacturing process is quite intense, requiring a constant updating effort. This work was developed with a view to solving problems related to the excessive wear of injection nozzles used in the die casting process, and corresponding electrical resistances, with a view to increase its lifetime and improve the competitiveness of the process in the injection of low-cost parts in zamak for the automotive industry. To study and solve the problems of premature wear of the injection nozzles, the action-research method was used, which, through several iterations, allowed to arrive at an improved design of the nozzle, as well as the corresponding electrical resistance, thus increasing the life span of these components, also improving safety around the process and generating knowledge that can be transferable to other similar situations.

3. Introduction:

Since 2018, the automotive industry has experienced some stagnation in production and sales, driven by undefined propulsion systems and the pandemic. Competitiveness is a main pillar, requiring constant improvements like vibration reduction and the use of new materials. To maintain market share, innovation is key, focusing on eliminating waste and maximizing process efficiency. Bowden cables are low-cost, high-value components in cars, used for mechanical commands like opening doors. Their production involves injecting zamak ends onto a braided metallic cable using high-pressure die casting. This process is fast and precise but presents severe maintenance challenges due to high temperatures and pressures, especially for components like injection nozzles. This study was initiated to solve serious reliability problems with injection nozzles in an industrial setting, which were failing prematurely after a switch to an electrical heating system.

4. Summary of the study:

Background of the research topic:

The study focuses on the high-pressure die casting (HPDC) of zamak alloy to produce ends for Bowden cables used in the automotive industry. This process, while efficient, subjects tooling like injection nozzles to intense wear due to high temperatures, high pressures, and abrasive elements in the alloy.

Status of previous research:

The paper notes that while extensive research exists for HPDC molds, parameters, and simulation, there is a "complete gap regarding the study and development of nozzles used in the high-pressure die-casting process." This work aims to fill that gap.

Purpose of the study:

The primary purpose was to solve an industrial problem of excessive, premature wear of injection nozzles. The goals were to increase the lifetime of the nozzles, improve the competitiveness of the manufacturing process, enhance safety, and generate transferable knowledge for similar situations.

Core study:

The study used an iterative action-research method to diagnose the causes of failure in the original nozzle design. Through two major redesign iterations, it systematically improved the nozzle's internal and external geometry. The first iteration focused on reducing wear by creating a smoother internal flow path. The second iteration refined the design further to optimize heating efficiency and solve material reflux issues, resulting in a final, highly durable design.

5. Research Methodology

Research Design:

The study employed the Action-Research methodology, based on the principle of "learning by doing." This involved a five-stage iterative cycle: Diagnosis, Action Planning, Implementation, Evaluation, and Monitoring/Outcomes. This approach was chosen because no pre-conceived theories could fully address the complex, multi-faceted industrial problem.

Data Collection and Analysis Methods:

Data was collected by physically retrieving failed nozzles from the production line. These nozzles were cut using WEDM for cross-sectional analysis. Hardness measurements were taken, and the internal wear channels were visually inspected and documented with photographs. The performance of redesigned nozzles was evaluated based on their service life (in days) under standard production conditions (400-600 injections/hour).

Research Topics and Scope:

The research was scoped to the injection nozzles used in the Zamak HPDC process for manufacturing Bowden cable ends. The key topics investigated were: wear mechanisms in the inner channel, the influence of internal and external geometry on performance and tool life, the effect of heat treatment and process temperature, and the efficiency of the electrical heating system.

6. Key Results:

Key Results:

- The original nozzle design, with an abrupt 5mm to 2mm inner diameter change, failed in under 17 days due to severe localized wear.

- The first iteration, featuring a gradual 3mm to 1.80mm transition and an external fillet, extended nozzle life to approximately 50 days but caused slow heating and material reflux.

- The second and final iteration moved the choke point to the nozzle's cold zone and changed the external profile from conical to a thinner, straight design. This solved the reflux and heating issues while maintaining excellent wear resistance, achieving a service life of over 63 days.

- It was established that the process temperature must be kept significantly below the material's nitriding temperature (a limit of 60°C below was set) to maintain hardness.

- Key influential factors for nozzle design were identified as: inner channel section variation, exterior design influence on heating performance, electrical resistance positioning, and choke point position.

Figure Name List:

- Figure 1. Different steps of the Action-Research cycle used in this work [31].

- Figure 2. External aspect of some nozzles removed from the high-pressure die-casting equipment after severe damage: (a) exhibiting a hole; (b) or even being broken

- Figure 3. Original zamak injection nozzle inner channel design.

- Figure 4. Sample 1 - Wear sustained by injection nozzles (original design) after 11 days of use, at an injection rate of 500 injections per hour.

- Figure 5. Sample 2 - Wear sustained by an injection nozzle (original design) after 17 days of use, at an injection rate of 500 injections per hour.

- Figure 6. Cross-sectional view (a) and 3D model (b) of the original nozzle, with the abrupt external change in section highlighted in red

- Figure 7. Cross-sectional view of the improved nozzle's inner channel, with the choke point (CP) identified (a) and 3D model of the filleted area, highlighting this area with a red square(b)

- Figure 8. Sample 1 - Wear sustained by injection nozzle (first iteration) after 59 days of use, at an injection rate of 500 injections per hour.

- Figure 9. Sample 2 - Wear sustained by injection nozzle (first iteration) after 47 days of use, at an injection rate of 500 injections per hour.

- Figure 10. Position of the injection nozzle CP (choke point) at two different locations, first iteration nozzle (hot zone) (a) and second iteration nozzle (cold zone) (b)

- Figure 11. First iteration design of the injection nozzle (outer design)

- Figure 12. Second iteration design of the injection nozzle (outer design)

- Figure 13. First iteration nozzle with assembled electrical resistance (a) Second iteration nozzle with assembled electrical resistance (b)

- Figure 14. Sample 1 – Wear sustained by injection nozzle (first iteration) after 63 days of use, at an injection rate of 500 injections per hour.

- Figure 15. Wear sustained at the choke point by a second iteration injection nozzle (after intense use)

- Figure 16. Chosen design for the injection nozzle (second iteration).

7. Conclusion:

The action-research methodology proved highly effective for the continuous improvement of the injection nozzle design. Two iterations successfully addressed the initial problems of severe wear and stress concentration. The first iteration reduced the abruptness of the inner channel's section change, significantly increasing tool life. The second iteration solved remaining issues of material reflux and slow heating by relocating the choke point to the cold area and changing the nozzle's outer shape to a straight, thinner profile. The final design demonstrated a significant improvement over the original in all aspects: less wear, faster and more homogeneous heating, and improved overall process safety.

8. References:

- [List the references exactly as cited in the paper, Do not translate, Do not omit parts of sentences.]

[1] Araújo, W.F.S., Silva, F.J.G. and Campilho R.: Manufacturing cushions and suspension mats for vehicle seats: a novel cell concept. Springer - Int. J. Adv. Manuf. Tech., Vol. 90, No. (5-8), pp. 1539- 1545, 2017. doi: 10.1007/s00170-016-9475-6.

[2] Rosa, C., Silva, F.J.G., Ferreira, L.P., Pereira, T. Gouveia R.: Establishing Standard Methodologies to Improve the Production Rate of Assembly Lines Used for Low Added-Value Products; Elsevier Procedia Manuf., Vol. 17, pp. 555–562, 2018. doi: 10.1016/j.promfg.2018.10.096.

[3] Dengiz, B., Tansel, Y. and Belgin, O.: A meta- model based simulation optimization using hybrid simulation-analytical modeling to increase the productivity in automotive industry; Elsevier Math. Comput. Simul., Vol. 120, pp. 120-128, 2016. doi:10.1016/j.matcom.2015.07.005

[4] Grodzicki, M.J. Skrzypek, J.: Cost-competitiveness and structural change in value chains - vertically- integrated analysis of the European automotive sector; Elsevier – Struct. Change Econ. Dyn., Vol. 55, pp. 276-287. doi: 10.1016/j.strueco.2020.08.009

[5] Matijevic, D.V. and Popovic, V.M.: Overview of the Modern Contributions in Vehicle Noise and Vibration Refinement with Special Emphasis on Diagnostics; FME Trans., Vol. 45, pp. 448-458, 2017. doi:10.5937/FMET1703448M.

[6] Concilio, A., De Simone, M.C., Rivera, Z.B. and Guida, D.: A New Semi-Active Suspension System for Racing Vehicles; FME Trans., Vol. 45, pp. 578- 584, 2017. doi:10.5937/fmet1704578C.

[7] Sathickbasha, K., Selvakumar, A.S., Sai, B.M.A. and Surya, R.B.: Effect of Steel Famility Fibers on Friction and Stiction Behavior of Brake Pads; FME Trans., Vol. 47, pp. 856-864, 2019. Doi: doi:10.5937/fmet1904856S.

[8] Costa, M.J.R., Gouveia, R.M., Silva, F.J.G. and Campilho, R.D.S.G.: How to solve quality prob-

[... The full list of 39 references continues as in the original paper.]

Expert Q&A: Your Top Questions Answered

Q1: Why was the Action-Research method chosen over a purely simulation-based approach for this problem?

A1: The paper suggests this approach was chosen because there were no "previously conceived theories that would allow a purely scientific approach to the proposed problem." The issue involved a complex interplay of wear, thermal dynamics, material properties, and operator behavior. The Action-Research method, a form of "learning by doing," was ideal for iteratively developing and validating solutions in a real-world industrial environment where many variables were present.

Q2: The paper mentions operators increased temperature, compromising the nitriding treatment. How critical was controlling this parameter to the final success?

A2: It was extremely critical. The analysis found that the original nozzles were nitrided at 580°C, but operators would increase process temperatures above 550°C to improve metal fluidity. This removed the hardness conferred by the heat treatment, accelerating wear. The study established a strict process limit of 60°C below the nitriding temperature to ensure the hardening effect was not compromised, which was a key factor in the extended lifespan of the redesigned nozzles.

Q3: What was the specific reason for moving the choke point from the "hot zone" in the first iteration to the "cold zone" in the second?

A3: After implementing the first successful redesign, the team noted "some problems regarding zamak refluxes in the nozzle's cold zone." By moving the section variation (the choke point) into this colder area, as depicted in Figure 10, the second iteration was able to directly address and mitigate this material reflux issue, leading to a more stable injection process.

Q4: Figure 6 shows an abrupt external change causing stress concentration and fracture. How did the final design address this?

A4: The problem was addressed in two stages. The first iteration introduced a fillet in this area (Figure 7) to better distribute the stresses. The second and final iteration went further by completely changing the outer design from a conical shape to a uniform, straight profile (Figure 12). This new linear shape entirely eliminated the abrupt section change, solving the stress concentration problem while also making the assembly of the heating element easier and improving heating uniformity.

Q5: The paper states the final linear design made assembly/disassembly of the electrical resistance easier. Can you elaborate on this benefit?

A5: The paper notes, "The external linear design of the nozzle will make easier the assembly/disassembly of the electrical resistance when one of the needs to be replaced, but the other can continue in service in the posterior part of the nozzle." This implies that the simpler, straight geometry (as seen in Figure 13b) allows for a smoother setup of the spiral resistance heater compared to the previous conical design. This simplifies maintenance, reduces downtime when a heating element fails, and potentially allows for partial replacement, which adds to the overall efficiency and cost-effectiveness of the solution.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear roadmap for solving one of the most persistent challenges in high-pressure die casting: premature tool wear. By moving from a design with abrupt geometric changes to a highly optimized and streamlined form, the team was able to extend nozzle lifespan from a matter of days to over two months. The key takeaway is that a holistic approach to Zamak HPDC Nozzle Design, considering both internal flow dynamics and external thermal efficiency, is essential for achieving robust, reliable, and cost-effective production.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Improving the Design of Nozzles Used in Zamak High-Pressure Die-Casting Process" by "V. F. C. Sousa, F. J. G. Silva, et al.".

- Source: https://doi.org/10.5937/fme2104005S

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.