I.Rajkumara N.Rajinia A.Alavudeena T.Ram Prabhub S.O.Ismailc FaruqMohammadd Hamad A.Al-Lohedand

a Department of Mechanical Engineering, International Research Centre, Kalasalingam Academy of Research and Education, Krishnankoil 626126, Tamilnadu, India

b CEMILAC, Defence R&D Organization, Bangalore, 37, India

c Centre for Engineering Research, Department of Engineering, School of Physics, Engineering and Computer Science, University of Hertfordshire, AL10 9AB, England, UK

d Surfactants Research Chair, Department of Chemistry, College of Science, King Saud University, P.O. Box 2455, Riyadh, Kingdom of Saudi Arabia 11451

Received 12 April 2020, Revised 5 December 2020, Accepted 6 December 2020, Available online 25 December 2020.

Abstract

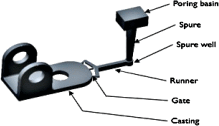

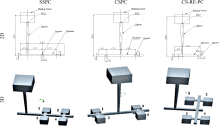

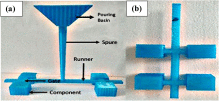

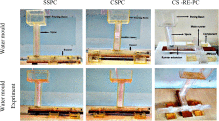

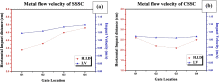

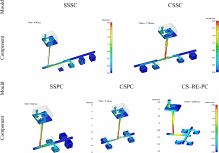

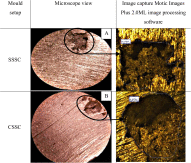

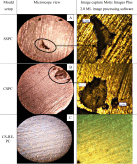

The present work proposes an improved multi-gate designs (MGDs) in sand casting process, using both experimental and simulation (FLOW 3D) approaches, aiming to produce defect-free component. In this regard, the variant MGDs were developed and compared with the existing designs reported in the previous studies. Accordingly, the following new MGDs: side sprue serial connection (SSSC), centre sprue serial connection (CSSC), side sprue parallel connection (SSPC), centre sprue parallel connection (CSPC) and centre sprue runner extension parallel connection (CS-RE-PC) were modelled for both techniques. The experimental set-ups were developed for the aforementioned designs to study the flow behaviour of aluminium alloy and water. The validity of aluminium alloy flow characteristics in closed mould condition was checked with the water mould experimentation. The quality of the casting was examined by visual inspection, optical microscopy, ultrasonic and X-ray tests. From the results obtained, it was evident that CS-RE-PC mould set-up or design was most suitable with a runner system for four-cavity application. This design exhibited best flow rate, as a nearly defect-free casting component was produced. Comparison of the FLOW 3D simulation results with similar experimental findings provided potential opportunity to reduce both cast product rejection rate and rework, and consequently it aids enhancement of the productivity and profitability in a manufacturing/casting industry.

Korea Abstract

현재 작업은 결함 없는 부품을 생산하기 위해 실험 및 시뮬레이션 (FLOW 3D) 접근법을 모두 사용하여 모래 주조 공정에서 개선 된 다중 게이트 설계 (MGD)를 제안합니다. 이와 관련하여 변형 MGD가 개발되어 이전 연구에서보고 된 기존 설계와 비교되었습니다.

따라서 다음과 같은 새로운 MGD : 사이드 스프 루 직렬 연결 (SSSC), 센터 스프 루 직렬 연결 (CSSC), 사이드 스프 루 병렬 연결 (SSPC), 센터 스프 루 병렬 연결 (CSPC) 및 센터 스프 루 러너 확장 병렬 연결 (CS-RE- PC)는 두 기술 모두에 대해 모델링 되었습니다.

실험 설정은 알루미늄 합금과 물의 유동 거동을 연구하기 위해 앞서 언급 한 설계를 위해 개발되었습니다. 밀폐형 상태에서 알루미늄 합금 유동 특성의 타당성은 수형 실험을 통해 확인되었습니다. 주물의 품질은 육안 검사, 광학 현미경, 초음파 및 X-ray 테스트로 검사되었습니다.

얻은 결과로부터 CS-RE-PC 금형 설정 또는 설계가 4- 캐비티 적용을위한 러너 시스템에 가장 적합하다는 것이 분명해졌습니다. 이 설계는 거의 결함이없는 주조 부품이 생산 되었기 때문에 최고의 유속을 나타 냈습니다.

FLOW-3D 시뮬레이션 결과와 유사한 실험 결과를 비교하면 주조 제품 거부율과 재 작업을 모두 줄일 수 있는 잠재적 기회가 주어졌고, 그 결과 제조 / 주조 산업에서 생산성과 수익성 향상에 도움이 됩니다.

Keywords

Casting, Liquid aluminium alloy/metal, Water, Multi-gate system, Experimental and simulation, Defects