[WordPress Blog Post Template]

Eliminating Finishing Costs in HPDC: New Guidelines for Complex Aesthetic Parts

This technical summary is based on the academic paper "Establishing Guidelines to Improve the High-Pressure Die Casting Process of Complex Aesthetics Parts" by F.J.G. SILVA, Raul D.S.G. CAMPILHO, Luís Pinto FERREIRA and Maria Teresa PEREIRA, published in Transdisciplinary Engineering Methods for Social Innovation of Industry 4.0 (2018). It has been analyzed and summarized for technical experts by CASTMAN with the assistance of AI.

Keywords

- Primary Keyword: High-Pressure Die Casting

- Secondary Keywords: Aesthetic Parts, Zamak, Casting Defects, Process Optimization, Mould Design

Executive Summary

A 30-second overview for busy professionals.

- The Challenge: Producing defect-free Zamak alloy aesthetic parts in a single injection to eliminate costly and time-consuming secondary finishing operations.

- The Method: A hybrid approach combining empirical trials with advanced SolidCast™ simulations to optimize both process parameters and mould design.

- The Key Breakthrough: Inverting the mould orientation and implementing a central runner with risers—a change driven by simulation—dramatically improved material flow and surface quality when combined with optimized, low-pressure parameters.

- The Bottom Line: A structured, hybrid methodology can establish clear guidelines to reduce defects and finishing costs for complex aesthetic components produced via High-Pressure Die Casting.

The Challenge: Why This Research Matters for HPDC Professionals

In the world of High-Pressure Die Casting (HPDC), producing parts with a flawless aesthetic finish is a significant challenge, especially for components with complex geometries. While Zamak is an excellent light-weight alloy for such parts, achieving a perfect surface directly from the mould is difficult. Often, these components require extensive and costly finishing operations like polishing and smoothing to meet quality standards.

The core problem this research addresses is the need to obtain healthy, defect-free Zamak parts with a good aesthetic appearance in a single casting operation. The goal is to establish clear, actionable guidelines for the HPDC process that minimize or completely eliminate these secondary finishing tasks, thereby reducing production time and final cost.

The Approach: Unpacking the Methodology

To tackle this challenge, the researchers developed a hybrid methodology that integrated two powerful techniques:

- Empirical Approach: A comprehensive series of practical experiments were conducted to find the best combination of process parameters. The team explored a wide range of settings for pressure, injection time, and cooling time, conducting a total of 81 trials.

- Advanced Approach: Numerical simulations using SolidCast™ software were performed to visualize and analyze the molten metal flow within the mould. This allowed the team to understand the root causes of defects that couldn't be solved by parameter adjustments alone.

The study focused on a specific case: an aesthetic Zamak 5 alloy part used on a woman's wallet. This component's complex shape and high-quality surface requirements made it an ideal candidate for this investigation. An Ishikawa diagram (Figure 3) was used to map all potential factors influencing surface quality, from machine settings to material properties.

The Breakthrough: Key Findings & Data

The study yielded two critical findings that demonstrate the limitations of traditional process optimization and the power of a simulation-driven approach.

Finding 1: Parameter-Only Optimization is Insufficient

The initial round of 81 empirical trials revealed that simply adjusting injection pressure, time, and cooling time could not produce a defect-free part.

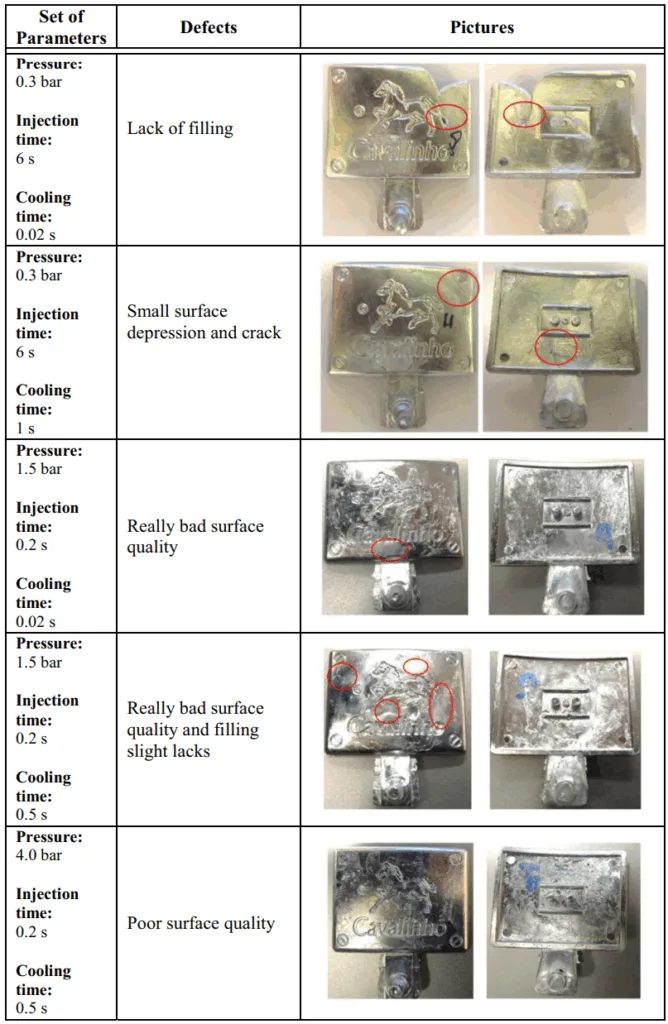

- Low Pressure (0.3 bar) with a long injection time (6 s) resulted in a "Lack of filling" (Table 2).

- High Pressure (4.0 bar) with a short injection time (0.2 s) led to "Poor surface quality," likely due to high turbulence during mould filling (Table 2).

- Medium Pressure (1.5 bar) with a short injection time (0.2 s) produced "Really bad surface quality and filling slight lacks" (Table 2).

The only clear conclusion from this phase was that pressure should be kept low to avoid turbulence. However, this created a conflict with the need to ensure the mould filled completely. It became evident that the root of the problem lay not just in the process parameters, but in the mould design itself.

Finding 2: Simulation-Driven Mould Redesign Unlocks Quality

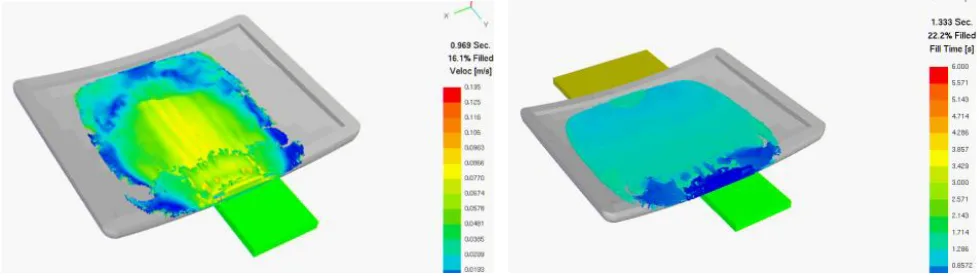

Turning to the advanced simulation approach, the researchers modeled the material flow and discovered that the original mould positioning was unfavorable, causing excessive turbulence. The key breakthrough came from two simulation-driven changes:

- Inverting the Mould Position: By flipping the orientation of the mould, the simulation showed that the molten Zamak would fill the central, concave part of the component first, leading to a more stable and evenly distributed flow to the outer areas.

- Optimizing the Runner System: A thin central runner and a posterior riser were added to the design. This further improved the flow dynamics and helped manage solidification.

After implementing these mould modifications, a new set of iterative trials was conducted. The best results were achieved with a completely new set of parameters, as shown in Table 3:

- Pressure: 2 bar

- Injection time: 0.5 s

- Cooling time: 1 s

The resulting part, shown in Figure 6, had a quality level high enough to "avoid intermediate steps before coating," successfully achieving the project's primary goal.

Practical Implications for R&D and Operations

Based on the study's conclusions, here are actionable guidelines for HPDC professionals working with complex aesthetic parts:

- For Process Engineers: This study suggests that adjusting pressure to a low level (e.g., 2 bar) is critical to avoiding turbulence. A short filling time (approx. 0.5 seconds for a 25-gram part) and a medium cooling time (approx. 1 second) provide the best balance for part consolidation and surface quality.

- For Quality Control Teams: The data and images in Table 2 provide a clear visual reference linking specific defects (lack of filling, surface cracks, poor quality) to process parameter imbalances. This can be used as a diagnostic tool for root cause analysis in production.

- For Design Engineers: The findings indicate that for parts with curvature, the mould should be oriented so the central, deeper area fills first. A single central runner is preferable to multiple runners to avoid turbulence at the confluence of streams. For thin-walled parts prone to turbulence, the use of risers should be a primary design consideration.

Paper Details

Establishing Guidelines to Improve the High-Pressure Die Casting Process of Complex Aesthetics Parts

1. Overview:

- Title: Establishing Guidelines to Improve the High-Pressure Die Casting Process of Complex Aesthetics Parts

- Author: F.J.G. SILVA, Raul D.S.G. CAMPILHO, Luís Pinto FERREIRA and Maria Teresa PEREIRA

- Year of publication: 2018

- Journal/academic society of publication: Transdisciplinary Engineering Methods for Social Innovation of Industry 4.0

- Keywords: Die casting, Casting, Casting defects, Zamak, Aesthetic parts.

2. Abstract:

Zamak is a light-weight alloy presenting very good properties for parts not requiring high mechanical strength. Due to its low melting temperature, this alloy is perfectly suitable for complex shape parts because it is easily moulded by high-pressure die casting process. Industrial parts usually do not require perfect look but this alloy can be also suitable for aesthetic parts, requiring complex finishing processes.The challenge embraced by this work aims to optimize the injection parameters and mould configuration of a Zamak alloy aesthetic part, to be obtained through a single injected casting operation, minimizing finishing operations. In order to obtain healthy, defect-free Zamak parts with a good aesthetic appearance, it was necessary to study the problem and then try to find the best possible solution. Thus, a study was carried out about the high-pressure die casting process and corresponding parameters. Throughout the work, and in order to solve the problem, numerical simulations were carried out using the SolidCast™™ software, studying the material flow into the mould and corresponding fusion lines, and empirical tests were carried out in order to correlate the results with the parameters. Changes in the mould were also performed. After the experiences, it was possible to draw some guidelines in order to achieve better results in the Zamak high-pressure die casting process of complex aesthetic parts, allowing for save time in next approaches.

3. Introduction:

The use of complex parts in light-weight materials is very often. The need to obtain them in a quick manner in order to lower their cost uses frequently the high-pressure die casting process. Zamak is a light-weight alloy commonly used in mechanical parts subjected to polishing processes, smoothing the surface and becoming the products with a better look. The main goal of this work is to establish the main guidelines to use high-pressure die casting in aesthetic parts, avoiding or decreasing the finishing operations, reducing tasks and cutting in their final cost.The structure of this paper is divided into five sections: the first of these presents the introduction; section 1 consisted of a literature review, where the main topics regarding the subject of this paper are referred; section 2 deals with the methodology used in this study; section 3 describes the experiments taking into account the part used as case study and the practical work developed; section 4 presents the results and discussion, and section 5 deals with the conclusions and suggestions for future works.

4. Summary of the study:

Background of the research topic:

High-pressure die casting is a common manufacturing technique for producing geometrically complex metal parts, particularly for the automotive industry. Light-weight alloys like Zamak are frequently used for parts that require good mechanical properties and a shape close to the final desired form, reducing machining time. However, when these parts are aesthetic and require a high-quality surface finish, the process becomes challenging, often necessitating costly secondary finishing operations.

Status of previous research:

Previous studies have focused on optimizing die casting process parameters such as temperature, pressure, and injection time. Research has also been conducted on mould design elements like gates, runners, and cooling systems. Software applications based on Finite Element Methods (FEM) have become more reliable for predicting defects by analyzing the mould filling process. However, a comprehensive, hybrid approach combining empirical testing with advanced simulation to specifically address aesthetic quality in complex Zamak parts has been less explored.

Purpose of the study:

The main goal of this work is to establish the main guidelines for using high-pressure die casting to produce aesthetic parts, with the aim of avoiding or decreasing finishing operations, thereby reducing tasks and final cost. The study seeks to optimize both the injection parameters and the mould configuration to obtain defect-free Zamak parts with a good aesthetic appearance in a single operation.

Core study:

The core of the study involved a hybrid methodology applied to a case study of a complex aesthetic part made of Zamak 5 alloy. This methodology included:

1. An initial empirical investigation with 81 trials to test various combinations of pressure, injection time, and cooling time.

2. An advanced investigation using SolidCast™ simulation software to analyze material flow, identify root causes of defects, and test virtual modifications to the mould design (such as inverting the mould and changing the runner system).

3. A final set of iterative empirical trials based on the simulation findings to validate the new mould design and determine the final optimized process parameters.

5. Research Methodology

Research Design:

The study employed a hybrid research design that combined an Empirical Approach with an Advanced (Simulation) Approach. An Ishikawa diagram was first created to identify all potential factors influencing surface quality. The research was structured in phases: an initial broad empirical study, a focused simulation study to diagnose and solve problems identified in the first phase, and a final empirical validation study.

Data Collection and Analysis Methods:

Data was collected through physical casting trials and numerical simulations.

- Empirical Data: Cast parts were visually inspected to evaluate surface quality, checking for defects like incomplete filling, cracks, and surface depressions.

- Simulation Data: The SolidCast™ software provided data on material flow velocity, fill time, and temperature distribution during the casting process.

- Material Analysis: The Zamak 5 alloy's chemical composition was assessed by mass spectroscopy, and its mechanical properties (tensile strength, hardness) were determined by standard tests.

Research Topics and Scope:

The research focused on the high-pressure die casting of a complex, thin-walled aesthetic part made from Zamak 5 alloy. The scope included the optimization of process parameters (pressure, injection time, cooling time) and mould-related factors (mould positioning, runner design, use of risers). The goal was to develop general guidelines applicable to similar aesthetic parts.

6. Key Results:

Key Results:

- Initial empirical trials showed that no combination of pressure, injection time, and cooling time alone could produce a defect-free part. Low pressure (0.3 bar) caused incomplete filling, while higher pressures (1.5-4.0 bar) caused turbulence and poor surface quality.

- Simulation analysis revealed that the original mould orientation was unfavorable. Inverting the mould to allow the central, concave area to fill first resulted in a significantly less turbulent material flow.

- The addition of a thin central runner and a posterior riser, guided by simulation, further improved the casting process.

- The combination of the redesigned mould and a new set of optimized parameters (Pressure: 2 bar, Injection time: 0.5 s, Cooling time: 1 s) produced parts with a surface quality sufficient to proceed directly to electroplating without intermediate finishing operations.

Figure Name List:

- Figure 1. Flow diagram of the hybrid methodology used in this work.

- Figure 2. (a) Part used as case study in this work. (b) Contextualization of the part in the final product.

- Figure 3. Ishikawa diagram corresponding to problem root-causes analysis.

- Figure 4. Parameters used in the simulations process and some tests carried out with different runner positioning.

- Figure 5. (Right hand) Simulation after the mould has been inverted and using a central runner; (Left hand) Simulation after the mould has been inverted and using a central runner and a posterior riser.

- Figure 6. Parts obtained with the inverse positioning of the mould, central runner and three risers in the other sides of the part. The part is not perfect, but the quality is enough to avoid intermediate steps before coating.

7. Conclusion:

The study successfully developed and validated a hybrid approach to solve high-pressure die casting problems for aesthetic parts. The model allowed for the establishment of key guidelines to improve surface quality and reduce finishing steps. The main guidelines are:

- Pressure should be low to avoid turbulence.

- Filling time should be low (e.g., ~0.5 s for a 25g part).

- Cooling time should be medium to allow for part consolidation.

- For curved parts, the central area should be the lower part of the mould to receive the initial material flow.

- A central runner is generally preferable to multiple runners.

- Risers should be considered for parts subject to turbulence.

8. References:

- [1] V. Nunes, F.J.G. Silva, M.F. Andrade, R. Alexandre and A.P.M. Baptista Increasing the lifespan of high-pressure die cast molds subjected to severe wear, Surface and Coatings Technology, Vol. 332, 2017, pp. 319-331.

- [2] J. Santos, R.M. Gouveia and F.J.G. Silva, Designing a new sustainable approach to the change for lightweight materials in structural components used in truck industry, Journal of Cleaner Production, Vol. 64, 2017, pp. 115-123.

- [3] F.J.G. Silva, J. Santos and R. Gouveia Dissolution of Grain Boundary Carbides by the Effect of Solution Annealing Heat Treatment and Aging Treatment on Heat-Resistant Cast Steel HK30, Metals, Vol. 7, 2017, pp. 251-263.

- [4] F. Casarotto, A.J. Franke and R. Franke High-pressure die-cast (HPDC) aluminium alloys for automotive applications, Advanced Materials in Automotive Engineering, Vol. 6, 2012, pp. 109-149.

- [5] B. Zabala, A. Igartua, V. Scarpis, G. Timelli, F. Girot and R. Nevshupa Multiparametric study of Leidenfrost point and wettability of lubricants on high-pressure die-casting dies, International Journal of Thermal Sciences, 125, (2015). 66-73.

- [6] C. Favi, M. Germani and M. Mandolini, Analytical cost estimation model in High Pressure Die Casting, Procedia Manufacturing, Vol. 11, 2017, pp. 526-535.

- [7] W., Z. Yuan, Z. Guo and S. Xiong Characterization of A390 aluminum alloy produced at different slow shot speeds using vacuum assisted high pressure die casting, Transactions of Nonferrous Metals Society of China, Vol. 27(12), 2017, pp. 2529-2538.

- [8] H. Pinto and F. J. G. Silva, Optimisation of die casting process in Zamak alloys, Procedia Manufacturing, Vol. 11, 2017, pp. 517-525.

- [9] X. Li, Z. Guo and S. Xiong Influence of melt flow on the formation of defect band in high pressure die casting of AZ91D magnesium alloy, Materials Characterization, Vol. 129, 2017, 344-352.

- [10] K.Ch. Apparao, A.K Birru, QFD-Taguchi based hybrid approach in die casting process optimization, Transactions of Nonferrous Metals Society of China, Vol. 27(11), 2017, pp. 2345-2356.

- [11] L.X. Kong, F.H. She, W.M. Gao, S. Nahavandi and P.D. Hodgson Integrated optimization system for high pressure die casting processes, Journal of Materials Processing Technology, Vol. 201, 2008, pp. 629-634.

- [12] M.S. Dargusch, G. Dour, N. Schauer, C.M. Dinnis and G. Savage The influence of pressure during solidification of high pressure die cast aluminium telecommunications components, Journal of Materials Processing Technology, 180(1-3), 2006, pp. 37-43.

- [13] R.V. Rao, D.P.Rai, Optimization of Selected Casting Processes Using Jaya algorithm, Materials Today Proceedings, Vol. 4(10), 2017, pp. 11056-11067.

- [14] A. Hamasaiid, G. Dour, T. Loulou and M.S. Dargusch A predictive model for the evolution of the thermal conductance at the casting-die interfaces in high pressure die casting, International Journal of Thermal Sciences, Vol. 49(2), 2010, pp. 365-372.

- [15] S.H. Wu, J.Y.H. Fuh and K.S.Lee Semi-automated parametric design of gating systems for die-casting die, Computers & Industrial Engineering, Vol. 53(2), 2008, pp. 222-232.

- [16] R. Helenius, O. Lohne, L. Arnberg and H.I. Laukli The heat transfer during filling of a high-pressure die-casting shot sleeve, Materials Science and Engineering A, Vol. 413-414, 2005, pp. 52–55.

- [17] M.T. Alonso Rasgado and K. Davey Thermal models for copper-alloyed dies in pressure die casting, Applied Mathematical Modelling, Vol. 33, 2009, pp. 61–80.

- [18] P. Terek, L. Kovačević, A. Miletić, P. Panjan, S. Baloš, B. Škorić and D. Kakaš Effects of die core treatments and surface finishes on the sticking and galling tendency of Al-Si alloy casting during ejection, Wear, Vol. 356-357, 2016, pp. 122-134.

- [19] R.V. Rao, V.D. Kalyankar and G. Waghmare Parameters optimization of selected casting processes using teaching-learningbased optimization algorithm, Appl. Math. Modelling, 2014, doi: http://dx.doi.org/10.1016/j.apm.2014.04.036.

- [20] P.W. Cleary, J. Ha, M. Prakash and T. Nguyen Short shots and industrial case studies: Understanding fluid flow and solidification in high pressure die casting, Applied Mathematical Modelling, Vol. 34, 2010, pp. 2018-2033.

- [21] G.O. Verran, R.P.K. Mendes and L.V.O. DallaValentina DOE applied to optimization of aluminum alloy die castings, Journal of Materials Processing Technology, 200(1-3), 2008, pp. 120-125.

- [22] M.A. Martinez Page and S. Hartmann, Experimental characterization, material modeling, identification and finite element simulation of the thermo-mechanical behavior of a zinc die-casting alloy, Internacional Journal of Plasticity, 2017, doi: 10.1016/j.ijplas.2017.10.010.

- [23] K.-D. Bouzakis, G. Maliaris and A. Tsouknidas FEM supported semi-solid high pressure die casting process optimization based on rheological properties by isothermal compression tests at thixo temperatures extracted, Computational Materials Science, Vol. 59, 2011, pp. 133-139.

- [24] K. Domkin, J.H. Hattel and J. Thorborg Modeling of high temperature- and diffusion-controlled die soldering in aluminum high pressure die casting, Journal of Materials Processing Technology, Vol. 209, 2009, pp. 4051-4061.

- [25] H. Zhao, Y. Bai, X. Ouyang and P. Dong Simulation of mold filling and prediction of gas entrapment on practical high pressure die castings, Transactions of Nonferrous Metals Society of China, Vol. 20, 2010, pp. 2064-2070.

- [26] G.O. Verran, R.P.K. Mendes and M.A. Rossi Influence of injection parameters on defects formation in die casting All2Si1,3Cu alloy: Experimental results and numeric simulation, Journal of Materials Processing Technology, Vol. 179, 2006, pp. 190–195.

- [27] C. Tiana, J. Lawb, J. van der Touwc, M. Murraya, J.-Y. Yaod, D. Grahamd and D. St. John Effect of melt cleanliness on the formation of porosity defects in automotive aluminium high pressure die castings, Journal of Materials Processing Technology, Vol. 122, 2002, pp. 82-93.

- [28] S.G. Lee and A.M. Gokhale Formation of gas induced shrinkage porosity in Mg-alloy high-pressure die-castings, Scripta Materialia, Vol. 55, 2006, pp. 387-390.

Expert Q&A: Your Top Questions Answered

Q1: Why was a hybrid approach of empirical tests and simulation chosen over a more traditional Design of Experiments (DOE)?

A1: The paper shows that a traditional approach focused only on process parameters was insufficient. The initial 81 empirical trials did not yield a conclusive trend or a defect-free part; in fact, they produced contrasting results. Simulation was necessary to understand the underlying physics of the material flow, which was identified as the true root cause of the surface defects. The hybrid approach allowed the team to diagnose the problem with simulation and then validate the solution with targeted empirical tests.

Q2: The paper concludes that "pressure should be low." How low is "low," and isn't that counterintuitive for filling a complex part?

A2: In the context of this study, "low" pressure was 2 bar, which was optimal compared to the higher 4 bar or the extremely low 0.3 bar levels tested. While it seems counterintuitive, the research demonstrates that for thin-walled aesthetic parts, forcing material into the mould with high pressure creates excessive turbulence, which leads to surface defects. The study found that optimizing the mould design for smooth, laminar flow was far more critical for achieving a quality finish than simply increasing pressure to ensure filling.

Q3: What was the single most significant change made to the mould design based on the simulation?

A3: The most significant change was inverting the mould's orientation. The original setup caused turbulent flow. The simulation in Figure 5 showed that by inverting the part, the molten metal would fill the central, concave area first. This created a more stable and progressive filling pattern towards the outer edges, dramatically reducing turbulence and improving the final surface quality.

Q4: The study used Zamak 5. Are these guidelines applicable to other alloys like aluminum or magnesium?

A4: While the paper focuses exclusively on Zamak 5, the core principles of the methodology are broadly applicable to other alloys in High-Pressure Die Casting. The fundamental concepts of minimizing turbulence, using simulation to optimize material flow, strategically designing runners and gates, and orienting the part correctly in the mould are universal. However, the specific parameter values (pressure, time, temperature) would need to be re-established for alloys like aluminum or magnesium due to their different thermal and flow properties.

Q5: What specific defects did the optimized process eliminate?

A5: The initial trials, documented in Table 2, produced a range of defects including "Lack of filling," "Small surface depression and crack," and "Really bad surface quality." The final optimized process, which combined the redesigned mould with fine-tuned parameters, produced a part (Figure 6) that was deemed high-quality enough to "avoid intermediate steps before coating." This indicates that these major surface defects were successfully resolved.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a powerful blueprint for solving one of the most persistent challenges in High-Pressure Die Casting: producing complex aesthetic parts without the need for costly secondary finishing. The key takeaway is that a holistic, hybrid approach is essential. Focusing on process parameters alone is not enough; true optimization is achieved when advanced simulation is used to guide intelligent mould design. By prioritizing smooth material flow through changes in orientation, runners, and risers, manufacturers can achieve superior surface quality directly from the die.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Establishing Guidelines to Improve the High-Pressure Die Casting Process of Complex Aesthetics Parts" by "F.J.G. SILVA, Raul D.S.G. CAMPILHO, Luís Pinto FERREIRA and Maria Teresa PEREIRA".

- Source: doi: 10.3233/978-1-61499-898-3-887

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.