Unlocking HPDC Strength: Does Squeeze Pin Technology Weaken High-Stress Components?

This technical summary is based on the academic paper "EFFECT OF MATERIAL SEGREGATIONS DUE TO SQUEEZE PARAMETERS ON MECHANICAL PROPERTIES OF HIGH PRESSURE DIECAST PARTS" by Ferencz PETI and Petru SERBAN, published in Acta Marisiensis. Seria Technologica (2020).

Keywords

- Primary Keyword: Squeeze Pin Technology

- Secondary Keywords: HPDC, AlSi9Cu3(Fe), material segregation, mechanical properties, internal material health, shrinkage

Executive Summary

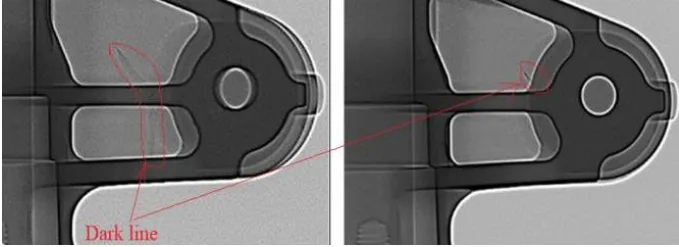

- The Challenge: While squeeze pins in HPDC are effective at eliminating shrinkage porosity in thick sections, they can create dark lines on X-rays, raising concerns that this material segregation could compromise the mechanical strength of critical components.

- The Method: Researchers subjected AlSi9Cu3(Fe) automotive steering components with the most severe segregation lines to rigorous static and dynamic breakage tests, including post-corrosion analysis after a three-week salt spray test.

- The Key Breakthrough: In every test, the components passed all validation criteria; failures occurred at high torque values in other areas of the assembly, while the segregated bracket area remained intact and showed no signs of weakness or crack propagation.

- The Bottom Line: For the AlSi9Cu3(Fe) components studied, the material segregation caused by squeeze pin technology does not negatively impact mechanical properties, confirming that this method is a safe and effective way to improve the internal health of die-cast parts.

The Challenge: Why This Research Matters for HPDC Professionals

In high pressure die casting (HPDC), ensuring the internal material health of components is a constant challenge, especially in parts with thick walls that are prone to shrinkage porosity. Squeeze pin technology is a widely used solution to compact the material during solidification, effectively eliminating these voids.

However, this solution introduces a secondary effect: the appearance of a dark, compact line in the squeezed area, visible on X-ray analysis. This raises a critical question for any engineer or quality manager: Is this "dark line" simply a cosmetic artifact, or is it a zone of material segregation that creates a weak point in the component? For structural, mechanical, and hydraulic parts like the automotive pinion housings studied here, any potential weakness is unacceptable. This research was essential to determine if the benefits of using squeeze pins outweigh the potential risks associated with the resulting material segregation.

The Approach: Unpacking the Methodology

The research focused on the fixing bracket of a pinion steering housing, a massive area of the part made from AlSi9Cu3(Fe) alloy where squeeze pin technology was applied to eliminate shrinkage. The samples selected for testing were those showing the most prominent "dark lines" on X-ray analysis.

Method 1: Static Breakage Test

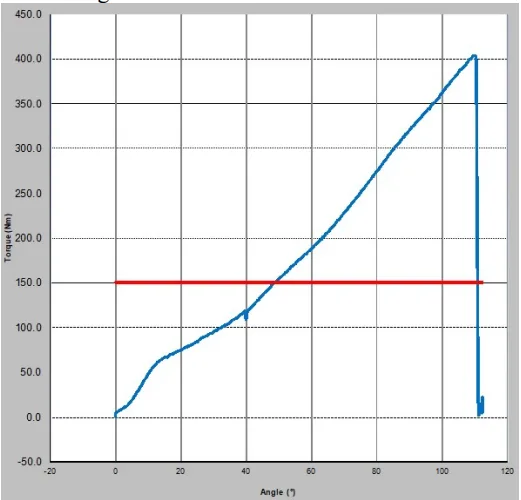

- Objective: To determine the maximum torque and failure angle the component could withstand.

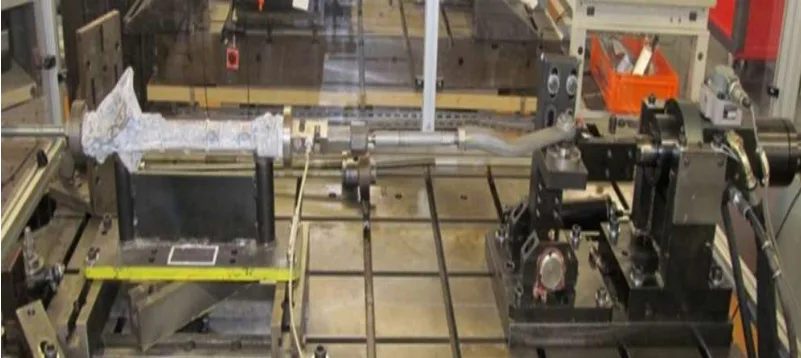

- Setup: The housing was fixed to a workbench, and a motor applied rotational torque via an internal rack and pinion until failure occurred (Figure 3).

- Variables: Tests were conducted on samples with and without prior exposure to a three-week, 1% NaCl salt spray test to assess performance under corrosive conditions. The acceptance criterion was no breakage below 150 Nm.

Method 2: Dynamic Bracket Stress Test

- Objective: To simulate long-term operational stress and fatigue on the component.

- Setup: The housing was mounted on a hydraulic test workbench connected to an MTS steering test system (Figure 4).

- Procedure: The test involved two steps:

1. 25,000 cycles at 0.1Hz with a 571 daN load.

2. 100 cycles at 0.25Hz with a 1178 daN load.

- Analysis: Samples were analyzed with X-ray before and after the stress test to check for any evolution or crack formation in the segregated area.

The Breakthrough: Key Findings & Data

The results from both static and dynamic testing conclusively demonstrated that the segregated area did not constitute a mechanical weak point.

Finding 1: Squeezed Areas Withstood Extreme Torque in Static Tests

In all static breakage tests, the failure did not occur in the squeezed bracket area. Instead, other parts of the assembly broke at torque values far exceeding the 150 Nm acceptance limit.

- As shown in Table 3, Sample 1 (no salt spray) failed in the pinion at a torque of -420.8 Nm. The squeezed bracket remained intact (Figure 6).

- Sample 4 (with salt spray) failed in the housing itself at a torque of 404.1 Nm, again leaving the bracket area undamaged (Figure 12).

- This proves that even with the most severe visual segregation, the squeezed zone is stronger than other parts of the final assembly.

Finding 2: No Defect Evolution After Intense Dynamic Stress Testing

The dynamic tests were designed to initiate and propagate cracks from any potential weak points. The before-and-after X-ray analyses showed no change in the segregated area.

- As seen by comparing the X-ray images of Sample 6 before the test (Figure 15) and after the test (Figure 16), the dark line caused by segregation did not evolve, grow, or initiate any cracks.

- Macroscopic analysis of the parts after the test (Figures 17 and 18) confirmed the X-ray findings: the samples passed the dynamic breakage test with no fractures or deformation.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting squeeze pin parameters to eliminate porosity is a safe and validated strategy. The secondary effect of segregation, in this case, does not compromise part integrity, allowing engineers to focus on optimizing for material health without fear of creating a mechanical weakness.

- For Quality Control Teams: The data in Table 3 and the X-ray images (Figures 14-16) illustrate that the presence of a dark line from a squeeze pin is not, by itself, a cause for rejection. This can inform and refine quality inspection criteria, preventing the unnecessary scrapping of functionally sound parts.

- For Design Engineers: The findings indicate that incorporating squeeze pins in the design of thick-walled components is a robust method for ensuring material homogeneity. This research provides confidence that this design feature can be used to meet stringent mechanical requirements in structural parts.

Paper Details

EFFECT OF MATERIAL SEGREGATIONS DUE TO SQUEEZE PARAMETERS ON MECHANICAL PROPERTIES OF HIGH PRESSURE DIECAST PARTS

1. Overview:

- Title: EFFECT OF MATERIAL SEGREGATIONS DUE TO SQUEEZE PARAMETERS ON MECHANICAL PROPERTIES OF HIGH PRESSURE DIECAST PARTS

- Author: Ferencz PETI, Petru SERBAN

- Year of publication: 2020

- Journal/academic society of publication: Acta Marisiensis. Seria Technologica, Vol. 17 (XXXIV) no. 1

- Keywords: HPDC, AlSi9Cu3(Fe), squeeze pin, internal material health, shrinkage, segregation

2. Abstract:

This article is a research on the effect of material segregations due to squeeze parameters on mechanical properties of high pressure die cast parts. The technology of squeezing is applied in high pressure die casting technology with the aim to improve the internal material health of the castings from aluminium alloys, such as AlSi9Cu3(Fe), components incorporated in assemblies as mechanical and hydraulic parts. The objective of this article is to determinate the influence of the secondary effects of squeeze technology on the mechanical properties of parts produced from AlSi9Cu3(Fe) alloys, with HPDC technology.

3. Introduction:

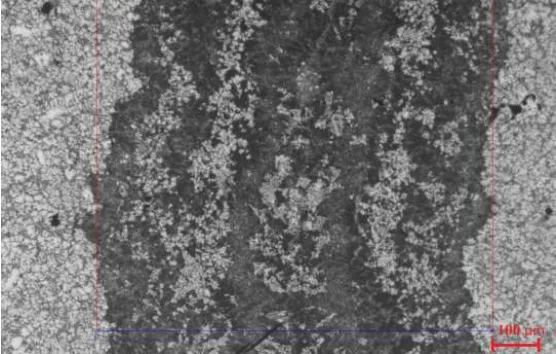

In the manufacturing of high pressure die-cast components, a persistent challenge is improving and controlling the internal material health and homogeneity. This depends on numerous variables, including speeds, temperatures, pressures, and die configuration. Previous studies by the authors identified solutions to improve the internal health of automotive components and correlated squeeze parameters with the optimization of material in thick-walled sections. A secondary effect observed was the appearance of a dark line in the squeezed area, correlated with squeeze parameters like squeeze time and delay. This dark line, visible on X-ray, suggests a macro segregation of alloying elements, and this article aims to determine its effect on the mechanical properties of the parts.

4. Summary of the study:

Background of the research topic:

The application of squeeze technology in high pressure die casting (HPDC) is intended to improve the internal material health of castings, particularly in thick sections, by eliminating defects like shrinkage porosity. However, this process can lead to secondary effects, such as material segregation visible as dark lines on radiographs.

Status of previous research:

Earlier studies by the authors identified the causes of poor internal material health and proposed solutions. They also correlated squeeze parameters with material health optimization and noted the appearance of dark lines as a secondary effect. An increase in squeeze entrance delay was found to increase the size of this dark line.

Purpose of the study:

The objective of this article is to determine the influence of the secondary effects of squeeze technology—specifically, the material segregation appearing as dark lines—on the mechanical properties of parts produced from AlSi9Cu3(Fe) alloys with HPDC technology.

Core study:

The study investigated the fixing bracket zone of a pinion steering housing made from AlSi9Cu3(Fe) alloy. Samples exhibiting the largest dark lines from a pool of 360 die-cast pieces were selected. These samples were subjected to static breakage tests and dynamic bracket stress tests to evaluate their mechanical resistance. Some samples were also subjected to a three-week salt spray test before mechanical testing to assess performance under corrosive conditions. The results were analyzed against design validation standards from RENAULT and JTEKT.

5. Research Methodology

Research Design:

The research employed an experimental design to test the mechanical properties of HPDC parts with known material segregation. The worst-case samples (those with the biggest dark lines) were selected for destructive and non-destructive testing to determine if the segregation constituted a failure point.

Data Collection and Analysis Methods:

- Radiographical Analysis: An Yxlon MU2000 machine was used for X-ray analysis to identify samples with segregation and to analyze parts before and after dynamic stress testing.

- Static Breakage Test: A custom workbench with a torque sensor and angular speed motor was used to apply torque until failure. Maximum torque and failure angle were recorded.

- Dynamic Bracket Stress Test: An MTS steering test system with specimen transducers and MTS RPC software was used to apply cyclical loads.

- Corrosion Test: A salt spray test was conducted with a 1% NaCl solution at pH4 for three weeks.

Research Topics and Scope:

The research focused on AlSi9Cu3(Fe) alloy components produced by HPDC. The scope was limited to the fixing bracket of a specific pinion steering housing where squeeze technology was applied. The study evaluated the effect of material segregation on mechanical properties through static and dynamic testing, both with and without prior corrosion exposure.

6. Key Results:

Key Results:

- Static Breakage Tests: All tested samples passed the acceptance criteria of no breakage under 150 Nm. Failures occurred at much higher torque values (387.4 Nm to 456.1 Nm) and were located in other areas of the assembly (e.g., housing, pinion, mechanical stopper), not in the squeezed bracket area with material segregation.

- Dynamic Bracket Stress Tests: Samples passed the two-step dynamic test (25,000 cycles at 571 daN and 100 cycles at 1178 daN) with no breakage or fractures.

- X-ray Analysis: Comparison of X-ray images taken before and after the dynamic stress test showed no evolution, crack initiation, or propagation in the material segregation zone.

- General Conclusion: The bracket area with dark lines indicating material segregation passed all validation tests, demonstrating that this secondary effect of the squeeze process did not compromise the mechanical integrity of the component.

Figure Name List:

- Fig. 1: Identification of the secondary squeeze effect (dark lines) during X-Ray analyze

- Fig. 2: Optical micrograph of dark area on microscope on a cut sample

- Fig. 3: Scheme of the static breakage test

- Fig.4: Workbench with the sample for the bracket stress test

- Fig. 5: Diagram of the static breakage test Sample 1 without salt spray test

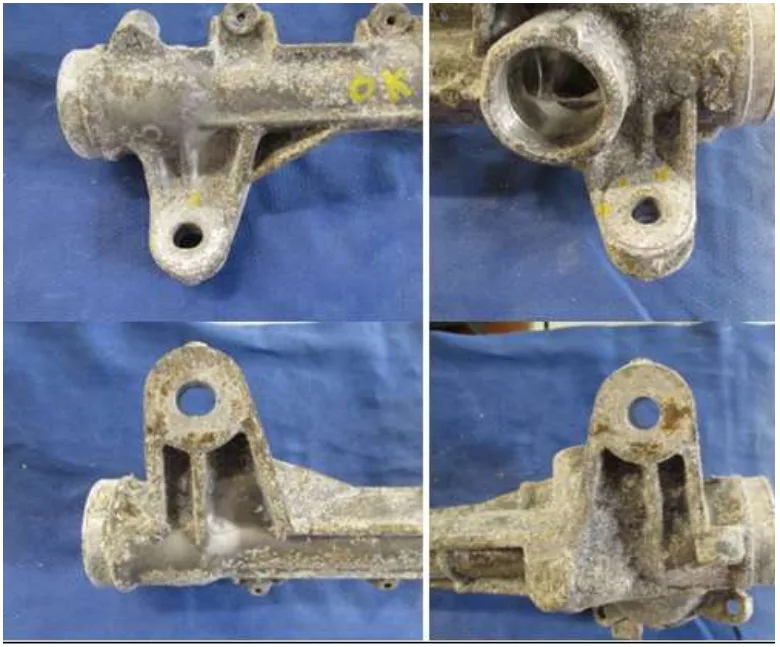

- Fig.6: Pictures of the sample 1 without salt spray test after the static breakage test

- Fig.7: Diagram of the static breakage test Sample 2 without salt spray test

- Fig. 8: Pictures of the sample 2 without salt spray test after the static breakage test

- Fig. 9: Diagram of the static breakage test Sample 3 with salt spray test

- Fig. 10: Pictures of the sample 3 with salt spray test after the static breakage test

- Fig. 11: Diagram of the static breakage test Sample 4 with salt spray test

- Fig. 12: Pictures of the sample 4 with salt spray test after the static breakage test

- Fig. 13: X-ray analysis of the sample 5 with salt spray before the bracket stress test

- Fig. 14: X-ray analysis of the sample 5with salt spray after the bracket stress test

- Fig. 15: X-ray analysis of the sample 6 with salt spray before the bracket stress test

- Fig. 16: X-ray analysis of the sample 6 with salt spray after the bracket stress test

- Fig. 17: Sample 5 with salt spray after the bracket stress test

- Fig. 18: Sample 6 with salt spray after the bracket stress test

7. Conclusion:

In the massive bracket area of the part where squeezing was applied, shrinkage porosity problems were eliminated, but a secondary effect appeared as a dark line visible on X-ray analysis. Samples with the biggest dark lines were analyzed for mechanical resistance. The conclusion for the static breakage test is that the results are good and meet all criteria, with failure observed well after 150 Nm and not linked to the segregation problem. The conclusion for the bracket stress test is also that the results are good, with no evolution observed before/after the test via X-ray analysis. As a general conclusion, the bracket area passed all validation tests, even when presenting dark lines that look like material segregations. Therefore, the use of squeeze technology and its determinate parameters is recommended.

8. References:

- [1] Bellisario, D., Boschetti, A., Constanza, G., Tata Maria, E., Quadrini, F., and Santo, L. (2012), Squeeze Casting of Al-Si Alloys, in Recent Researches in Metallurgical Engineering - From Extraction to Forming, Ed. Mohammad Nusheh, InTech Open, pp. 161-186

- [2] Reikher, A., Barkhudarov, M.R. (2007) Casting: An analytical approach, in Series: Engineering Materials and Processes, Ed. Springer-Verlag London.

- [3] Adamane, A.R., Arnberg, L., Fiorese, E. et al. (2015), Influence of Injection Parameters on the Porosity and Tensile Properties of High-Pressure Die Cast Al-Si Alloys: A Review, International Journal of Metalcasting, vol. 9(1), pp. 43-53.

- [4] Dong, X., Yang, H., Zhu, X, Ji, S., (2019), High strength and ductility aluminium alloy processed by high pressure die casting, Journal of Alloys and Compounds, vol. 773, pp. 86-96.

- [5] Jiao, X.Y, et. Al, (2019), Influence of slow-shot speed on PSPs and porosity of AlSi17Cu2.5 alloy during high pressure die casting, Journal of Materials Processing Technology, vol. 268, pp. 63-69.

- [6] Apparao, K.c., Birru, A.K, (2017), Optimization of Die casting process based on Taguchi approach, Materials Today, vol. 4(2A), pp.1852- 1859.

- [7] Jahangiri, A., Marashi, S.H.P., Mohammadaliha, M, Ashofte, V., (2017) The effect of pressure and pouring temperature on the porosity, microstructure, hardness and yield stress of AA2024 aluminum alloy during the squeeze casting process, Journal of Materials Processing Technology, vol. 245, pp. 1-6.

- [8] Battaglia, E., Bonollo, F., Timelli, G., Fiorese, E., Kral, G., (2016), Correlation between process, microstructure and properties in high pressure die casting aluminium-silicon alloys, Advances in Materials and Processing Technologies, vol. 3(1), pp. 111-124.

- [9] Peti, F., Grama, L., (2011), Analyse of the possible causes of porosity type defects in aluminium high pressure die cast parts, Scientific Bulletin of the „Petru Maior" University of Târgu Mureş, vol. 8 (XXV), no. 1, pp. 41-44.

- [10] Peti, F., Grama L., (2012), Researches concerning constructive and technological improvements of automotive gearbox suspension brackets, Proceedings of the 6th Interdisciplinarity in Engineering International Conference InterEng-2012, "Petru Maior" University Press, pp. 87-92.

- [11] Peti F., Strnad G., (2019) The effect of squeeze pin dimension and operational parameters on material homogenity of aluminium high pressure die cast parts, Acta Marisiensis. Seria Technologica Vol. 16 (XXXIII) no. 2,, ISSN 2668-4217, ISSN-L 2668-4217, pag.7-12

- [12] SR EN 1706 – Aluminium and aluminium alloys, (2000).

- [13] DIN 1688 – Tolerances for pressure die casting, (1986).

- [14] ASTM E505 - Reference Radiographs for Inspection of Aluminium and Magnesium die castings (2002).

- [15] JTEKT SPECIFICATIONS 6000031339/-F Composants en alliage d'aluminium réalisés en fonderie pour systèmes de direction

- [16] RENAULT Norm 31-05-923-/A

- [17] VDG Specification P201 – Porosity of Metal Castings, (2002).

- [18] Company documentation CATIA, 2012.

- [19] Fundamentos de la fundicion a presion, CIE C. Vilanova, Spain, 2008.

- [20] Revision Tecnica del Producto, CIE C. Vilanova, Spain, 2008.

- [21] Company documentation Bühler, 2010.

- [22] Company documentation Idra, 2011.

- [23] Company documentation Italpresse, 2011.

- [24] Procedimiento IDT 05/1: Cuaderno de cargas de moldes, rev05, CIE Inyectametal, Spain, 2007.

- [25] Norma Ingenieria NCV21006C–Tiempo llenado del molde, CIE C. Vilanova, Spain, 2006

- [26] Norma Ingenieria NCV21007B–Velocidad en el ataque, CIE C. Vilanova, Spain, 2006

Expert Q&A: Your Top Questions Answered

Q1: What was the primary motivation for investigating the "dark lines" caused by the squeeze pin?

A1: The primary motivation was to determine if this visible segregation of alloying elements, a secondary effect of the squeeze process, created a mechanical weak point. While squeeze pins successfully eliminated primary defects like shrinkage porosity, the resulting dark line raised concerns about the structural integrity of the final part, which needed to be validated for use in critical mechanical and hydraulic assemblies.

Q2: What were the specific acceptance criteria for the static and dynamic tests?

A2: For the static breakage test, the criterion, as stated in Table 1, was "No breakage or fractures under 150Nm." For the dynamic bracket stress test, the acceptance criterion for a successful test was "No breakage or fractures" after completing both steps of the cyclical loading protocol.

Q3: Why were samples subjected to a salt spray test before mechanical testing?

A3: The salt spray test was used to simulate the effects of a corrosive environment on the component over its service life. By testing parts after three weeks of exposure to a salt solution, the researchers could determine if corrosion would preferentially attack the segregated area and compromise its mechanical strength. The results showed that even after the corrosion test, the segregated area remained robust and did not fail.

Q4: What specific parameters of the squeeze pin process were previously found to influence the size of the dark line?

A4: The paper references a previous study [11] which found that the appearance and size of the dark line are correlated with squeeze parameters. Specifically, it states that "an increase of the squeeze entrance delay allows a bigger size of the dark line," indicating that the timing of the squeeze pin's activation is a key factor.

Q5: The paper concludes that the use of squeeze pins is recommended. What future research does it suggest?

A5: Although the mechanical tests were successful, the paper recommends further investigation to fully characterize the segregated area. The proposed future research directions include: investigation of the alloy's density in the segregated area, hardness and micro-hardness testing within the bracket area, and a detailed investigation of the chemical composition of the segregated zone to quantify the elemental differences.

Conclusion: Paving the Way for Higher Quality and Productivity

This research addresses a critical concern in the HPDC industry: does the solution for one defect (shrinkage) create another, more dangerous one (mechanical weakness)? The study provides strong evidence that for AlSi9Cu3(Fe) components, Squeeze Pin Technology is a robust and reliable method. The material segregation it causes is not detrimental to the part's mechanical performance, even under extreme static, dynamic, and corrosive stress.

This validation allows engineers to confidently apply squeeze pins to improve the internal health and pressure tightness of complex castings, reducing scrap rates and ensuring component reliability.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "EFFECT OF MATERIAL SEGREGATIONS DUE TO SQUEEZE PARAMETERS ON MECHANICAL PROPERTIES OF HIGH PRESSURE DIECAST PARTS" by "Ferencz PETI and Petru SERBAN".

Source: https://doi.org/10.2478/amset-2020-0002

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.