Boost HPDC Efficiency by 158%: The Power of High Performance Copper Alloy Chill Vents

This technical summary is based on the academic paper "Development of High Performance Copper Alloy Chill Vent for High Pressure Die Casting" by Duoc T Phan, Syed H Masood, Syed H Riza, and Harsh Modi, published in the International Journal of Mechanical Engineering and Robotics Research (2020). It has been analyzed and summarized for technical experts by CASTMAN with the assistance of AI.

Keywords

- Primary Keyword: High Performance Chill Vent

- Secondary Keywords: High Pressure Die Casting (HPDC), Copper Alloy Chill Vent, Thermal Analysis, MoldMAX, Cooling Rate, Porosity Reduction

Executive Summary

A 30-second overview for busy professionals.

- The Challenge: Conventional tool steel chill vents in High Pressure Die Casting (HPDC) have low thermal conductivity, leading to inefficient cooling, slower cycle times, and quality defects like porosity.

- The Method: Researchers used validated finite element analysis (FEA) to model and compare the thermal performance of a conventional H13 steel chill vent against a high-conductivity beryllium copper alloy (MoldMAX) chill vent.

- The Key Breakthrough: The copper alloy chill vent increased the cooling efficiency of the solidifying aluminum alloy by approximately 158% compared to the conventional steel vent.

- The Bottom Line: Switching to high-performance copper alloy chill vents can dramatically reduce cooling times and improve casting quality by enabling significantly faster heat transfer and gas release.

The Challenge: Why This Research Matters for HPDC Professionals

In the competitive world of High Pressure Die Casting, efficiency and quality are paramount. Chill vents are critical components for removing residual air and gases from the mould cavity, which helps prevent defects like porosity. However, the conventional tool steel used for these vents presents a significant bottleneck.

Due to the relatively low thermal conductivity of steel, heat dissipation is slow. This not only extends the cooling time for each cycle but also makes it difficult to prevent molten metal from flushing through the air venting surfaces, leading to flashing defects. The industry needs a material for chill vents that offers both high strength and superior thermal conductivity to accelerate the solidification rate and improve the overall effectiveness of the HPDC process. This research directly addresses this need by investigating a high-performance alternative.

The Approach: Unpacking the Methodology

To quantify the performance difference between vent materials, the research team developed a numerical heat transfer model.

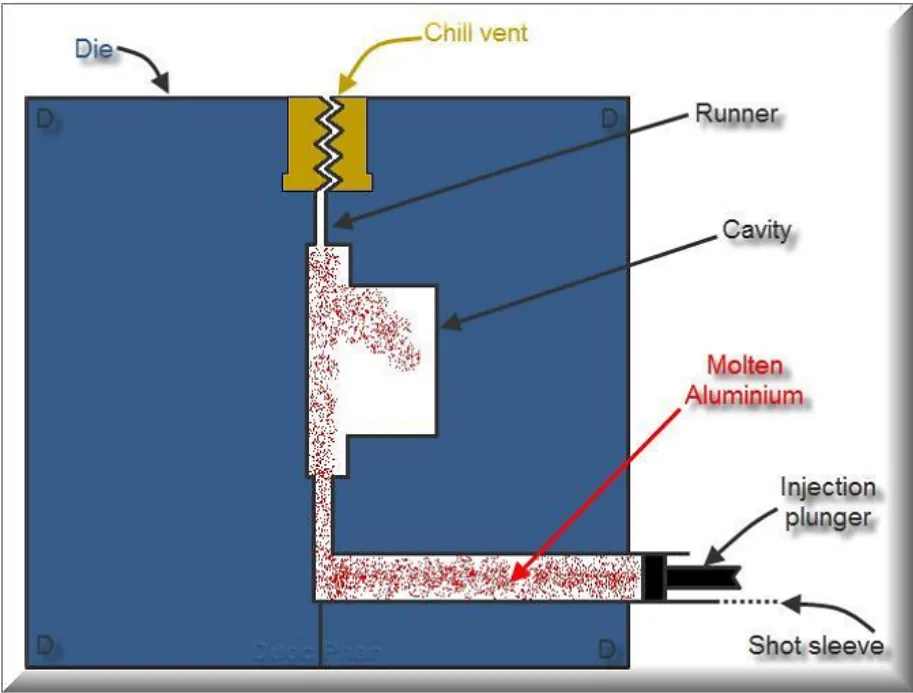

- Modeling: A 3D computer-aided design (CAD) model of a chill vent with zigzag surfaces was created and imported into the ANSYS® Workbench package for finite element analysis (FEA).

- Materials Compared: The study modeled two chill vent materials:

- Conventional: Hot work tool steel (H13).

- High-Performance: Beryllium copper alloy (MoldMAX), which has approximately six times the thermal conductivity of steel.

- Process Simulation: The model simulated the casting of ADC12 aluminum alloy, using realistic initial conditions derived from experimental tests on a commercial 800-tonne die casting machine. This included a pouring temperature of 615°C and an ejection temperature of 94°C after 15.9 seconds for the steel vent.

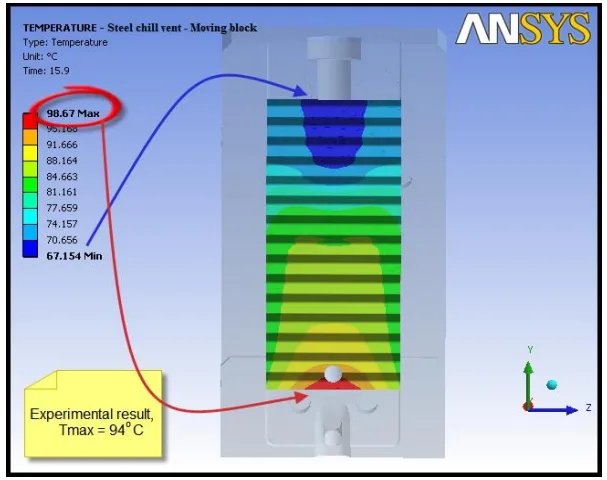

- Validation: To ensure accuracy, the simulation results for the steel chill vent were validated against real-world experimental data. The temperature distribution on the chill vent surface was captured at the moment of ejection using a high-speed FLIR infrared camera, confirming a strong correlation (less than 5% difference) between the simulated and measured temperatures.

The Breakthrough: Key Findings & Data

The validated model was then used to compare the performance of the H13 steel vent against the MoldMAX copper alloy vent. The results were definitive.

Finding 1: Cooling Time Slashed by More Than 50%

The primary function of a chill vent is to extract heat rapidly. The study found that the copper alloy vent achieved the target ejection temperature far more quickly than the steel vent.

As shown by the simulation data, the H13 tool steel chill vent required 15.9 seconds to cool the part to the ejection temperature of approximately 98.7°C (Figure 4). In stark contrast, the MoldMAX copper alloy chill vent reached the same temperature in just 6.70 seconds (Figure 6). This represents a significant reduction in the required cooling time, directly impacting cycle time and productivity.

Finding 2: Cooling Efficiency Increased by 158%

The study calculated the cooling rates to quantify the efficiency of heat extraction for both materials. The results demonstrated the profound impact of higher thermal conductivity.

The cooling rate for the flashing aluminum part was 32.5°C/s when using the steel chill vent. When using the MoldMAX copper alloy chill vent, the cooling rate jumped to 77°C/s. This equates to a 158% increase in cooling efficiency, confirming that the copper alloy material removes heat from the solidifying aluminum at a much faster rate. Figure 7 clearly illustrates the different thermal histories, with the MoldMAX vent reaching its peak temperature and cooling down much more rapidly than the steel vent.

Practical Implications for R&D and Operations

[Based on the paper's Discussion and Conclusion sections, provide conditional insights for different professional roles.]

- For Process Engineers: This study suggests that implementing high-conductivity copper alloy chill vents can directly contribute to reducing cycle times. The 57% reduction in cooling time (from 15.9s to 6.7s) could lead to a substantial increase in machine throughput.

- For Quality Control Teams: The data in the paper illustrates the effect of rapid heat transfer on process stability. The faster solidification and more effective gas release enabled by the copper alloy vent can directly lead to a reduction in porosity and flashing defects, improving first-pass yield.

- For Design Engineers: The findings indicate that the material selection for chill vents is a critical design consideration that directly impacts die performance and part quality. Specifying high-strength, high-conductivity copper alloys for venting systems can be a proactive measure to prevent common casting defects.

Paper Details

Development of High Performance Copper Alloy Chill Vent for High Pressure Die Casting

1. Overview:

- Title: Development of High Performance Copper Alloy Chill Vent for High Pressure Die Casting

- Author: Duoc T Phan, Syed H Masood*, Syed H Riza, and Harsh Modi

- Year of publication: 2020

- Journal/academic society of publication: International Journal of Mechanical Engineering and Robotics Research Vol. 9, No. 7, July 2020

- Keywords: High pressure die casting; Chill vents; Thermal analysis; Copper alloy; Thermal conductivity; Cooling rates

2. Abstract:

In High Pressure Die Casting (HPDC) process, chill vents are used to allow residual air and gases to exhaust out from the mould cavity. The objective of this paper is to design and develop a high-performance chill vent for high pressure die casting using a new type of copper alloy material, which has high strength and high thermal conductivity, compared to conventional tool steel. Finite element analysis is applied to develop a numerical heat transfer model for chill vent and validated by experimental results. The model is used to compare the performance of copper alloy chill vent with conventional steel chill vent. It was found that the change in the chill vent material had a significant improvement on the cooling time, cooling rate as well as on the internal die temperature distribution. Results show that the copper chill vent increases the cooling efficiency of the solidifying aluminium alloy by about 158% compared to the conventional steel chill vents. It is concluded that the use of high strength copper alloy chill vents will enhance the efficiency and effectiveness of HPDC process with rapid heat transfer and faster release of gases, thus reducing porosity and flashing defects in the parts.

3. Introduction:

High Pressures Die Casting (HPDC) is widely used in the automotive industry to manufacture light weight metal parts. In high pressure die casting process, molten metal is injected under high pressure into a tool steel mould or die cavity. Chill vent is a common method in high pressure die casting to remove the air from the die cavity, consisting of a pair of metal blocks with a zigzag venting path. Chill vents help to reduce defects like porosity. In conventional steel chill vents, low thermal conductivity is a limitation. A material with high strength and high thermal conductivity, such as beryllium copper alloy (MoldMAX), would be more appropriate. MoldMAX exhibits six times higher thermal conductivity compared to steel. This study investigates the performance of beryllium copper alloys for manufacturing chill vents in HPDC in comparison to steel vents.

4. Summary of the study:

Background of the research topic:

The study focuses on improving the efficiency of the High Pressure Die Casting (HPDC) process by enhancing a critical component: the chill vent. Conventional steel chill vents are limited by their low thermal conductivity, which slows down the casting cycle and can contribute to defects.

Status of previous research:

While numerous simulation studies have analyzed various HPDC process parameters, the paper notes that little attention has been paid specifically to the design and development of chill vents and the air venting problem. This investigation aims to fill that research gap.

Purpose of the study:

The objective was to design, develop, and evaluate a high-performance chill vent using a new type of copper alloy material (MoldMAX) and compare its performance against a conventional tool steel (H13) chill vent. The goal was to demonstrate improvements in cooling time, cooling rate, and overall process efficiency.

Core study:

The core of the study involved creating a finite element analysis (FEA) heat transfer model to simulate the thermal behavior of both a steel and a copper alloy chill vent during the HPDC process. The model was first validated using experimental data from a real-world casting process. It was then used to conduct a comparative analysis of the two materials, focusing on key performance metrics like cooling time and cooling rate.

5. Research Methodology

Research Design:

The study employed a comparative research design using both numerical simulation and experimental validation. A 3D CAD model of a chill vent was subjected to thermal analysis using the finite element method to predict its performance with two different materials (H13 steel and MoldMAX copper alloy).

Data Collection and Analysis Methods:

- Simulation: A numerical heat transfer model was developed in ANSYS® Workbench. Boundary conditions (temperatures, material properties, convection loads) were defined based on a real-world HPDC process for ADC12 aluminum alloy.

- Experimental Validation: The simulation was validated by comparing its temperature predictions for the steel vent with data collected from a commercial 800-tonne HPDC machine. A high-speed infrared camera (FLIR PM850) was used to capture the actual surface temperature distribution of the chill vent at the moment of part ejection.

- Analysis: The validated model was used to compare the cooling time curves and calculate the cooling rates for both the steel and copper alloy vents to determine the improvement in cooling efficiency.

Research Topics and Scope:

The research was scoped to the thermal performance of chill vents in HPDC. The primary variables were the chill vent material (H13 steel vs. MoldMAX copper alloy). The key performance indicators were cooling time, surface temperature distribution, and cooling rate. The study focused on the casting of ADC12 aluminum alloy.

6. Key Results:

Key Results:

- The finite element model was successfully validated, with the simulated maximum surface temperature (98.67°C) showing good agreement (less than 5% difference) with the experimentally measured temperature (94°C) for the steel chill vent.

- The time required to cool the casting to the ejection temperature was reduced from 15.9 seconds for the H13 steel vent to 6.70 seconds for the MoldMAX copper alloy vent.

- The calculated cooling rate for the copper alloy chill vent was 77°C/s, compared to 32.5°C/s for the steel vent.

- The use of the copper alloy chill vent resulted in a 158% increase in cooling efficiency compared to the conventional steel chill vent.

Figure Name List:

- Figure 1. Schematic diagram of a typical HPDC process.

- Figure 2. A CAD model of the chill vent used in HPDC

- Figure 3. Heat generation rate and Heat flux values used for thermal analysis.

- Figure 4. Temperature distribution at the surface of moving block - Steel chill vent.

- Figure 5. Experimental temperature distribution on the chill vent surface measured by infrared camera

- Figure 6. Temperature distribution at the surface of moving block - MoldMAX copper alloy chill vent

- Figure 7. Comparison of cooling time curves during casting process using the steel and copper chill vents.

7. Conclusion:

The study concluded that using a high-strength, high-thermally conductive copper alloy (MoldMAX) as a chill vent material provides a significant improvement over conventional tool steel. The copper alloy chill vent dramatically enhanced the cooling time, cooling rate, and internal die temperature distribution. The 158% increase in cooling efficiency demonstrates that this material improves the performance and chilling ability of permanent molds in HPDC, leading to more effective gas release and a reduction in porosity and flashing defects.

8. References:

- [1] A Kaye, A Street. Die Casting Metallurgy. Butterworth and Co Ltd., 1982

- [2] F. Bonollo, N. Gramegna, and G. Timelli, "High-pressure die-casting: contradictions and challenges," The Minerals, Metals & Materials Society, JOM, vol. 67, no. 5, pp. 901-908, 2015.

- [3] L. H. Wang. "Mathematical modelling of air evacuation in die casting process via CASTvac and other venting devices," Int Journal of Cast Metals Research, vol. 20 pp. 191-197, 2007.

- [4] MoldMAX HH Material Property Data, Materion Performance Alloys, Materion Corporation 2017.

- [5] I. Rosindale and K. Davey, "Steady state thermal model for the hot chamber injection system in the pressure die casting process," Journal of Materials Processing Technology, vol. 82, no. 1, pp. 27-45, 1998.

- [6] M. T. A. Rasgado, "Bi-metallic dies for rapid die casting," Journal of Materials Processing Technology vol. 175, pp. 109-116, 2006.

- [7] S. R. Ahmed, K. D. Devi, and S. V. S. Himathejeswini, "Design & analysis of heat sink high-pressure die casting component," International Journal of Current Engineering and Technology, 2016

- [8] H. J. Kwon, H. K. Kwon, "Computer Aided Engineering (CAE) simulation for the design optimization of gate system on high pressure die casting (HPDC) process," Robotics and Computer-Integrated Manufacturing vol. 55 pp. 147-153, 2018.

- [9] W. B. Yu, Y. Y. Cao, X. B. Li et al, "Determination of interfacial heat transfer behavior at the metal/shot sleeve of high pressure die casting process of AZ91D alloy," Journal of Materials Science & Technology vol. 33 pp. 52-58, 2017

- [10] S. I. Jeong, C. K. Jin, H. Y. Seo et al, "Mould design for clutch housing parts using a casting simulation of high pressure die casting," International Journal Of Precision Engineering And Manufacturing, vol. 17, no. 11, pp. 1523-1531, 2016

- [11] R. W. R. W. Jeppson, Analysis of Flow in Pipe Networks, Butterworth Publications, 1976

- [12] MatWeb Material Property Data, Aluminum ADC12 Die Casting Alloy, Automation Creations, Inc 2009.

- [13] K. N. Prabhu, "Casting/mold thermal contact heat transfer during solidification of Al-Cu-Si alloy (LM 21) plates in thick and thin molds," Journal of Materials Engineering and Performance, ASM International vol. 14, no. 5, pp. 604-609, 2005.

Expert Q&A: Your Top Questions Answered

Q1: How can we be sure the simulation results are accurate and not just theoretical?

A1: The researchers addressed this by validating their model against real-world data. They performed an experimental die casting run on a commercial 800-tonne machine and used a high-speed infrared camera to measure the actual temperature of the steel chill vent at the moment of ejection (Figure 5). The simulated maximum temperature of 98.67°C was less than 5% different from the measured average temperature of 94°C, establishing a high degree of confidence in the model's predictive accuracy.

Q2: What specific copper alloy was used and why was it chosen over other materials?

A2: The paper identifies the material as a beryllium copper alloy, also known as MoldMAX. It was chosen for its unique combination of high strength and exceptionally high thermal conductivity. The paper states that MoldMAX exhibits six times higher thermal conductivity than conventional H13 tool steel, making it an ideal candidate for rapidly extracting heat from the molten aluminum, which is the primary function of a chill vent.

Q3: The paper mentions a 158% increase in cooling efficiency. How was this specific value calculated?

A3: This value was derived by comparing the cooling rates of the solidifying aluminum part when using the two different vent materials. The cooling rate with the steel vent was calculated to be 32.5°C per second. With the MoldMAX copper alloy vent, the rate increased to 77°C per second. The 158% improvement reflects how much faster the copper alloy vent can remove thermal energy from the casting compared to the steel vent.

Q4: Is the benefit only about faster cooling, or are there other advantages to using a copper alloy chill vent?

A4: While faster cooling is the main driver, it leads to other critical advantages. The paper concludes that the rapid heat transfer and faster release of gases help to reduce porosity and flashing defects. Furthermore, the paper notes that steel vents can chemically react with molten aluminum, causing sticking, whereas the copper alloy forms a preventive oxide film, which can help it maintain a larger, more effective vent gap over its operational life.

Q5: What was the peak temperature reached by the chill vent surfaces during the cycle?

A5: According to the thermal history graph in Figure 7, the conventional H13 steel chill vent reached a peak temperature of about 124.1°C during the cycle. In contrast, the MoldMAX copper alloy vent, due to its superior ability to dissipate heat, reached a significantly lower peak temperature of about 108.7°C before cooling down much more rapidly.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides compelling, data-driven evidence that the material choice for chill vents is a critical, high-impact decision in High Pressure Die Casting. By replacing conventional tool steel with a high-conductivity copper alloy, manufacturers can achieve a dramatic 158% increase in cooling efficiency. This isn't just a theoretical improvement; it translates directly to shorter cycle times, higher productivity, and better-quality parts with reduced porosity and flashing. The study validates the move toward a High Performance Chill Vent as a strategic upgrade for any modern die casting operation.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "Development of High Performance Copper Alloy Chill Vent for High Pressure Die Casting" by "Duoc T Phan, Syed H Masood, Syed H Riza, and Harsh Modi".

- Source: https://doi.org/10.18178/ijmerr.9.7.943-948

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.