Slash Scrap Rates: A Pareto-Lorenz HPDC Defect Analysis for EN AC-435000 Alloy

This technical summary is based on the academic paper "DEFECT ANALYSIS OF EN AC-435000 ALLOY DIE CASTINGS USING THE PARETO-LORENTZ DIAGRAM" by Mariusz HEJNE, Jarosław PIĄTKOWSKI, and Robert WIESZAŁA, published in SCIENTIFIC PAPERS OF SILESIAN UNIVERSITY OF TECHNOLOGY ORGANIZATION AND MANAGEMENT SERIES NO. 172 (2023). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: HPDC Defect Analysis

- Secondary Keywords: EN AC-435000, Pareto-Lorenz Diagram, Casting Defects, Ishikawa Diagram, Die Casting Quality Control

Executive Summary

- The Challenge: Reducing the high rate of defects in complex, thin-walled die castings made from EN AC-435000 alloy, a material critical to the automotive and aerospace industries.

- The Method: Employing a two-stage analysis using an Ishikawa diagram to qualitatively classify all potential defects and a Pareto-Lorenz diagram to quantitatively rank the most frequent defects from production data.

- The Key Breakthrough: The discovery that just six specific defect types account for 78% of all production nonconformities, with casting temperature identified as a critical process parameter influencing overall defect rates.

- The Bottom Line: A systematic, data-driven approach to HPDC defect analysis is essential for identifying the "vital few" causes of scrap, enabling targeted process optimization and significant improvements in quality and yield.

The Challenge: Why This Research Matters for HPDC Professionals

In the relentless drive for lighter, more efficient vehicles and aircraft, aluminum-silicon alloys like EN AC-435000 have become indispensable. Their excellent strength-to-weight ratio and corrosion resistance make them ideal for everything from engine components to structural parts. However, the high-pressure die casting (HPDC) process used to manufacture these parts, while fast and cost-effective, is prone to numerous defects.

Defects such as porosity, cracks, underfilling, and blistering can compromise the structural integrity and performance of the final product, leading to costly scrap and production delays. For engineers and managers, the challenge is not just acknowledging that defects occur, but identifying which ones matter most and what process variables are the root cause. This research addresses that exact problem by providing a clear, methodical framework for analyzing and prioritizing defects in EN AC-435000 castings.

The Approach: Unpacking the Methodology

The researchers implemented a comprehensive, two-part methodology to move from a general understanding of defects to a specific, actionable plan.

First, an Ishikawa (fishbone) diagram was created to map out the universe of potential casting defects. This qualitative tool organized defects into four main categories: shape defects, internal defects, raw surface defects, and continuity breaks. This provided a complete picture of everything that could go wrong.

Second, to understand what was going wrong most frequently, a Pareto-Lorenz analysis was conducted on production data. This quantitative method involved analyzing a periodic quality report of manufactured die castings to rank defects by their frequency of occurrence. The core of the study focused on the EN AC-435000 alloy and investigated how the liquid alloy's temperature—a critical process parameter—influenced the type and number of defects.

The Breakthrough: Key Findings & Data

The analysis yielded precise, data-driven insights into the root causes of production nonconformity, allowing for targeted corrective actions.

Finding 1: The "Vital Few" Defects Causing 78% of Rejections

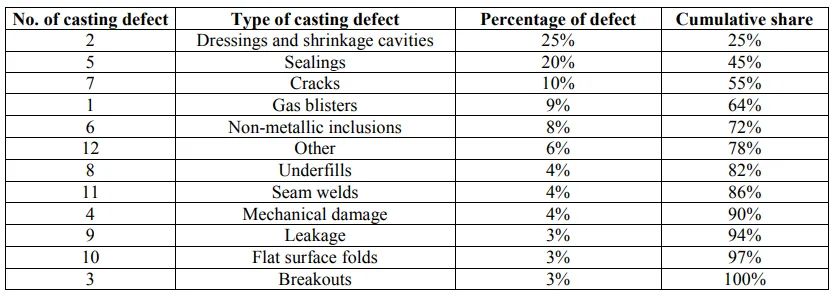

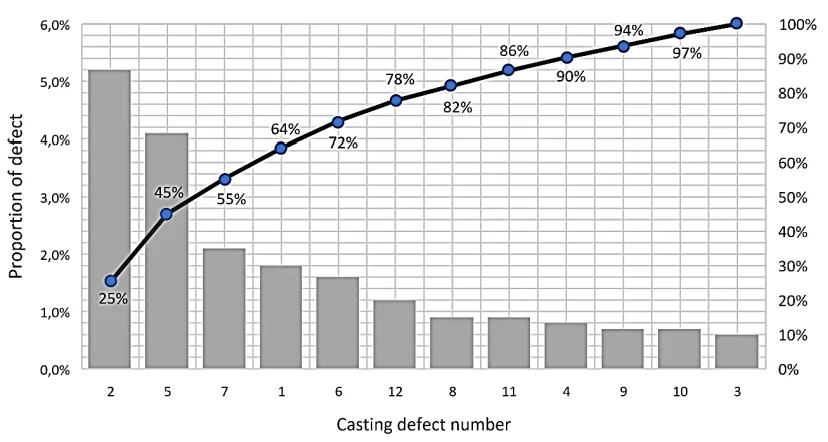

The Pareto-Lorenz analysis revealed a classic 80/20 distribution, where a small number of defect types were responsible for the majority of the problems. The study found that the top six most common defects accounted for a cumulative 78% of all rejected parts. As shown in Table 1 and the corresponding Pareto-Lorenz chart (Figure 4), these critical defects were:

1. Dressings and shrinkage cavities: 25%

2. Sealings: 20%

3. Cracks: 10%

4. Gas blisters: 9%

5. Non-metallic inclusions: 8%

6. Other: 6%

This finding is crucial because it allows engineering teams to focus their limited resources on solving the few problems that will yield the greatest improvement in overall quality.

Finding 2: The Critical Role of Casting Temperature

The research demonstrated that even small deviations from optimal process parameters can have a dramatic impact on quality. The study analyzed defect rates at three different casting temperatures for the EN AC-435000 liquid alloy.

- At 735°C, the defect rate was highest, with 49% of all manufactured products being defective.

- At 760°C, the process was optimized, achieving the lowest defect rate of just 19%.

- At 775°C, the defect rate increased again to 39%.

As illustrated in Figure 3 of the paper, this data confirms that there is a specific, optimal processing window for temperature. Deviating either too low or too high leads directly to a significant increase in casting defects.

Practical Implications for R&D and Operations

Based on the paper's conclusions, the findings offer actionable insights for various technical roles in an HPDC facility.

- For Process Engineers: This study suggests that adjusting the superheating temperature of the liquid alloy may contribute to reducing gasification and subsequent porosity. The data strongly supports implementing systematic verification of the chemical composition and minimizing turbulence during mold filling to prevent non-metallic inclusions and gas entrapment.

- For Quality Control Teams: The data in Figure 3 illustrates the effect of temperature on defect rates, which could inform new quality inspection criteria and process control limits. The paper recommends more frequent verification of the temperature measurement systems throughout the production process, as well as additional control of the cooling rate and heat dissipation.

- For Design Engineers: The findings indicate that the prevalence of defects like "Dressings and shrinkage cavities" (25%) and "Underfills" (4%, see Table 1) could be influenced by the mold's gating system, overflows, and vents. This suggests that a thorough Design for Manufacturability (DFM) review focusing on mold flow and solidification is a valuable consideration in the early design phase.

Paper Details

DEFECT ANALYSIS OF EN AC-435000 ALLOY DIE CASTINGS USING THE PARETO-LORENTZ DIAGRAM

1. Overview:

- Title: DEFECT ANALYSIS OF EN AC-435000 ALLOY DIE CASTINGS USING THE PARETO-LORENTZ DIAGRAM

- Author: Mariusz HEJNE, Jarosław PIĄTKOWSKI, Robert WIESZAŁA

- Year of publication: 2023

- Journal/academic society of publication: SCIENTIFIC PAPERS OF SILESIAN UNIVERSITY OF TECHNOLOGY, ORGANIZATION AND MANAGEMENT SERIES NO. 172

- Keywords: Pareto-Lorentz diagram, EN AC-435000 alloy, defect analysis.

2. Abstract:

Purpose: The purpose of this research is to describe the most important defects in die castings made of EN AC-435000 alloy and to present preventive measures and to rank these defects using Pareto-Lorenz analysis.

Design/methodology/approach: The paper provides a comprehensive look at the causes of defects in finished products. During the analysis, Ishikawa and Pareto-Loretnz diagrams were used to get information on what are the main defects in finished products and what steps should be taken to optimize the production process.

Findings: An research was used a typical material applied in the aerospace and automotive industries. The article shows that even small deviations from the accepted technological assumptions, in this case temperature, leading to products that deviate from the accepted quality assumptions.

Practical implications: The article is intended not only for the scientific community, including students, but also for technologists working in industry. It shows the process of identifying the locations and types of damage to finished products and what steps should be taken to avoid them in the future.

Originality/value: Demonstration, difficulties in optimizing the die casting process for EN AC-435000 alloy.

3. Introduction:

In recent years, research in the automotive and aviation fields has focused on reducing the environmental impact of vehicles, primarily by reducing weight. This has led to significant progress and increased use of modern aluminum alloys. These alloys offer significant specific mechanical properties and corrosion resistance, making them suitable for components from chassis and aircraft structures to piston and turbine engines. Aluminum-silicon alloys, like EN AC-435000, are widely used, with die-casting being the primary manufacturing method due to cost and speed. However, this process reveals numerous manufacturing defects.

4. Summary of the study:

Background of the research topic:

The manufacturing of automotive and aerospace components from aluminum-silicon alloys via die-casting is critical for lightweighting initiatives. However, the process is susceptible to defects that impact quality and cost. The number and type of defects are influenced by technological parameters and physicochemical phenomena.

Status of previous research:

Previous research and industry standards (like PN-85/H83105) have defined and categorized casting defects. The most characteristic defects in die casting are porosity, cracks, underfilling, subsurface blistering, and adhesion to the mold. These can be categorized as either visible surface defects or internal defects.

Purpose of the study:

The study aimed to describe the most important defects in EN AC-435000 alloy die castings, present preventive measures, and rank these defects using Pareto-Lorenz analysis to identify the most significant issues for process optimization.

Core study:

The study involved a multi-step analysis. First, typical defects in EN AC-435000 die castings were characterized. An Ishikawa diagram was used to classify these defects into broad categories. Finally, a Pareto-Lorenz analysis was performed on production data to quantify the frequency of each defect type and identify the "vital few" that contribute most to product rejection, with a specific focus on the influence of casting temperature.

5. Research Methodology

Research Design:

The research was designed as a case study analyzing production data from die castings made of EN AC-435000 alloy. It used established quality management tools to move from a broad classification of defects to a prioritized list for corrective action.

Data Collection and Analysis Methods:

Data was collected from a periodic quality report of manufactured die castings. The analysis involved:

1. Ishikawa Diagram: To qualitatively classify and visualize the potential causes of manufacturing nonconformity.

2. Pareto-Lorenz Diagram: To quantitatively analyze the frequency of occurrence for specific, identified defects and rank them by importance. The analysis also correlated defect rates with different liquid alloy temperatures (735°C, 760°C, and 775°C).

Research Topics and Scope:

The scope included the characterization and classification of typical defects in EN AC-435000 alloy die castings. The study focused on analyzing these defects using the Ishikawa and Pareto-Lorenz methods to identify and rank the most significant causes of non-conformity and propose preventive measures. All materials presented are the property of Magna Casting Poland.

6. Key Results:

Key Results:

- The highest number of casting defects (49%) occurred at a temperature of 735°C, while the lowest (19%) was achieved at 760°C.

- A Pareto-Lorenz analysis identified that the top six defect categories account for 78% of all defects.

- The most common defect was "Dressings and shrinkage cavities," contributing to 25% of all nonconformities.

- The second most common defect was "Sealings," accounting for 20% of the total.

- The analysis concluded that the most significant defects contributing to casting rejection are related to gas porosity of the alloy, often stemming from poor chemical composition, inadequate solidification temperature range, and insufficient cooling.

Figure Name List:

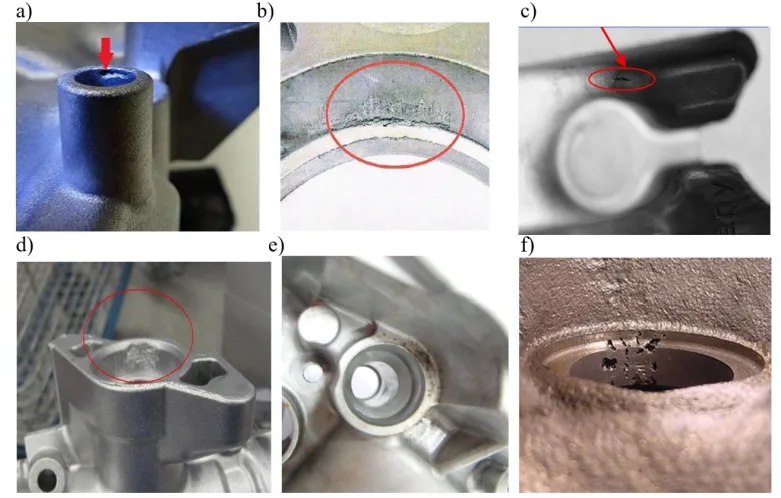

- Figure 1. Defects in the workpieces revealed in the production process: a) underfilling, b) sticking, c) cracks, d) breakouts, e) discoloration, f) macroporosity.

- Figure 2. Ishikawa diagram for die casting defects.

- Figure 3. Occurrence of major casting defects depending on the temperature value of the EN AC-435000 liquid alloy, where 1. Gas blisters, 2. Dressings and shrinkage cavities, 3. Breakouts, 4. Mechanical damage, 5. Sealings, 6. Non-metallic inclusions, 7. Cracks, 8. Underfills, 9. Leakage, 10. Flat surface folds, 11. Seam welds, 12. Other.

- Figure 4. Pareto - Lorentz chart of casting defects (defect numbers according to Table 2).

7. Conclusion:

The study successfully used the Ishikawa and Pareto-Lorenz diagrams to classify and rank casting defects. The analysis identified that a small number of defect types are responsible for the majority of quality issues. The most significant defects are related to gas porosity, which is influenced by chemical composition, solidification temperature, and cooling rate. The paper concludes that minimizing defects requires systematic verification of alloy composition, strict control of thermal parameters (superheating, cooling), minimization of turbulence, increased attention to metal bath cleanliness, and proper care during part handling. Metal quality control should begin at the melting stage to achieve a significant reduction in casting defects.

8. References:

- Alemayeehu, G., Firew, D., Nallamothu, R., Wako, A., Gopal, R. (2022). Operating parameters optimization for lower emissions in diesel engine with PCCI-DI mode using Taguchi and grey relational analysis. Heliyon, Vol. 8, Iss. 6, pp. e09679.

- Asus, Z., Madon, M., Che Daud, Z., Said, M., Aglzim, E., Talib, M., Ahmad, Z. (2022). Simulation analysis of fuel cell integration in a hybrid car. IOP Conference Series: Materials Science and Engineering, Vol. 736, pp. 032012.

- Dhisale, M., Vasavada, J., Tewari, A. (2022) An approach to optimize cooling channel parameters of Low pressure Die casting process for reducing shrinkage porosity in Aluminum alloy wheels. Materials Today: Proceedings, Vol. 62, Iss. 6, pp. 3189-3196.

- Gupta, A., Kumar, S., Chandna, P., Bhushan, G. (2020). Optimization of Process Parameters during Pressure Die Casting of A380: a Silicon-Based Aluminium Alloy Using GA & Fuzzy Methodology. Silicon, Vol. 13, pp. 2429-2443.

- Satyarth, G., Rohan, S., Vibhuti, A., Sangwan, G., Mahanta, T., Feroskhan, N. (2022). Thermal barrier coatings for internal combustion engines: A review. Materials Today: Proceeding, Vol. 51, Iss. 3, pp. 1554-1560.

- Saxena, A., Godara, S., Chouhan, M., Saxena, K. (2021). Effect of die geometry on thermal fatigue analysis of aluminum alloy (A02240) dies of low melting point alloys casting using pressure die casting process. Advance in Materials and Processing Technologies, Vol. 8, Iss.3, pp. 1622-1634.

- Vamsikrishna, A., Shruti, M., Divya Sharma, S. (2021). Six sigma in piston manufacturing. In: F. Chaari, F. Gherardini, V. Ivanov (Eds.), Lecture Notes in Mechanical Engineering (pp. 589-597). Springer.

Expert Q&A: Your Top Questions Answered

Q1: Why were both the Ishikawa and Pareto-Lorenz diagrams necessary for this analysis?

A1: The two diagrams serve distinct but complementary purposes. The Ishikawa diagram was used first as a qualitative tool to brainstorm and categorize all possible types of defects that could occur in the die casting process. The Pareto-Lorenz diagram was then used as a quantitative tool to analyze actual production data and rank those defects by frequency, allowing the researchers to identify the "vital few" defects that cause the majority of problems.

Q2: The paper highlights temperature as a key factor. What was the optimal temperature found for the EN AC-435000 alloy?

A2: According to the data presented in Figure 3, the optimal casting temperature in this study was 760°C. At this temperature, the percentage of defective castings was at its lowest point of 19%. Deviating from this optimum, either to a lower temperature of 735°C or a higher temperature of 775°C, resulted in a sharp increase in defect rates to 49% and 39%, respectively.

Q3: What were the top two most significant defects identified in the study?

A3: The analysis in Table 1 clearly identifies the two most critical defects by frequency. "Dressings and shrinkage cavities" was the single largest contributor, accounting for 25% of all defects. The second most frequent defect was "Sealings," which was responsible for another 20% of the total defects.

Q4: The paper's conclusion states the first four defects account for 78% of issues, but Table 1 suggests it's the first six. Can you clarify this?

A4: That's an excellent observation. The paper's conclusion on page 8 states that "The first four defects listed turned out to account for 78% of all defects." However, a direct analysis of the data presented in Table 1 on page 7 shows that the first four defects ("Dressings and shrinkage cavities," "Sealings," "Cracks," and "Gas blisters") sum to a 64% cumulative share. The 78% cumulative share is achieved after including the top six defects. For practical application, this analysis focuses on the detailed data from Table 1, which identifies six defects as the primary area for improvement efforts.

Q5: Beyond controlling temperature, what other key process controls did the study recommend to reduce defects?

A5: The study recommended several crucial measures based on its findings. These include systematic and regular verification of the alloy's chemical composition, additional control of the cooling rate and heat dissipation, minimization of turbulence during casting and mold filling to prevent oxide inclusions, and increased attention to the overall cleanliness of the metal bath.

Conclusion: Paving the Way for Higher Quality and Productivity

This research powerfully demonstrates that a structured HPDC Defect Analysis is not an academic exercise but a practical roadmap to higher quality and lower scrap rates. By moving beyond simple defect logging to a systematic classification and prioritization using tools like the Pareto-Lorenz diagram, manufacturers can focus their efforts where they will have the most impact. The key breakthrough—identifying that just six defect types cause 78% of rejections in EN AC-435000 castings and that temperature control is paramount—provides a clear path for process optimization and tangible improvements in productivity.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "DEFECT ANALYSIS OF EN AC-435000 ALLOY DIE CASTINGS USING THE PARETO-LORENTZ DIAGRAM" by "Mariusz HEJNE, Jarosław PIĄTKOWSKI, and Robert WIESZAŁA".

- Source: http://dx.doi.org/10.29119/1641-3466.2023.172.18

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.