The content of this introduction paper is based on the article 'Copper Rotor Motors: A Step toward Economical Super-Premium Efficiency Motors?' published by 'ACEEE'.

1. Overview:

- Title: Copper Rotor Motors: A Step toward Economical Super-Premium Efficiency Motors?

- Author: Nicole Kaufman Dyess, Emmanuel Agamloh, Ph.D., Advanced Energy

- Year of publication: 2007

- Journal/academic society of publication: ACEEE Summer Study on Energy Efficiency in Industry

- Keywords: Copper Rotor Motors, Motor Efficiency, NEMA Premium, Induction Motors, Die-Casting, Energy Efficiency

2. Abstract:

NEMA Premium® motors made significant changes to the motor stator for improved efficiency. Copper rotor motors seek to improve motor efficiency by addressing, among other things, conductor losses in the rotor. The Copper Development Association (CDA) has worked for years to promote the advantages of this technology and support research and development, particularly in relation to die-casting processes. Siemens Electric and Automation (Siemens) is the first to begin large-scale manufacturing of these motors, now available on the market. These motors are being sold for prices comparable to their NEMA Premium® aluminum-rotor counterparts with a promise of higher efficiencies. Advanced Energy performed, limited, non-destructive motor build inspection analyses, efficiency tests (IEEE Std.112B), and performance characterizations (steady-state temperature rise, torque-speed performance) on six motors spanning the commercially available range to compare these motors to aluminum rotor motor performance and construction and to determine the potential effects of this technology on the industrial motor population. Advanced Energy's experience in construction and test results with aluminum rotor motors spans 16 years. Our data base of test results is used in comparison, no additional testing of aluminum rotor motors was done for this analysis.

3. Introduction:

The introduction traces the evolution of motor efficiency standards, from the first NEMA guidelines in 1977 to the EPAct of 1992 and the subsequent rise of NEMA Premium® motors. It highlights the increasing focus on energy efficiency due to rebate programs, rising energy costs, and competitiveness. The central question posed is: what comes next after NEMA Premium®? The paper proposes copper rotors in medium horsepower motors as the next potential leap in motor efficiency.

4. Summary of the study:

Background of the research topic:

The background discusses the historical context of motor efficiency improvements, noting the evolution from initial NEMA guidelines to the mandate of minimum efficiency levels. It also mentions the shift in focus to NEMA Premium® motors and the optimization of motor applications.

Status of previous research:

Previous research focused on reducing losses in five primary categories: stator I²R losses, rotor I²R losses, core losses, windage and friction losses, and stray load losses. Design changes included using more copper in windings, larger rotor bars, thinner laminations, and minimizing the air gap.

Purpose of the study:

The purpose of the study is to compare the performance and construction of die-cast copper rotor motors to aluminum rotor motors and to determine the potential effects of this technology on the industrial motor population.

Core study:

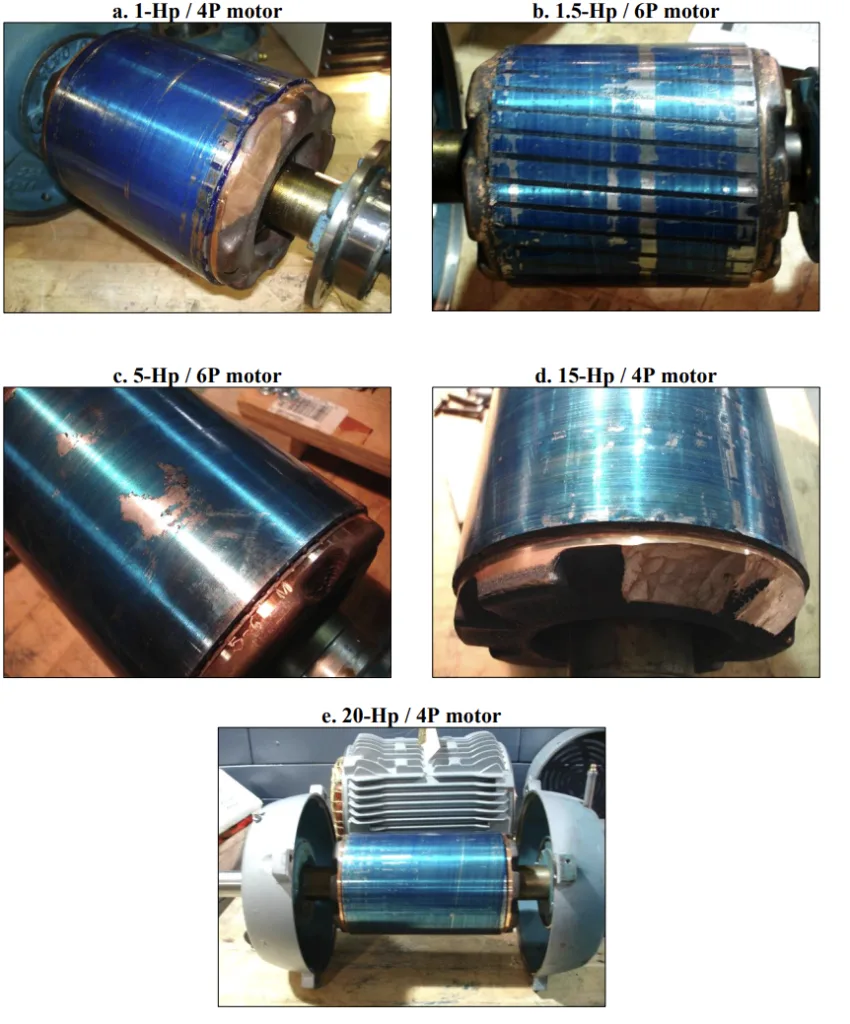

The core study involves limited, non-destructive motor build inspection analyses, efficiency tests (IEEE Std. 112B), and performance characterizations on six commercially available copper rotor motors from Siemens.

5. Research Methodology

Research Design:

A comparative analysis was performed between copper rotor motors and aluminum rotor motors. The study included build inspection and performance testing.

Data Collection and Analysis Methods:

Data collection involved non-destructive build inspection, efficiency tests according to IEEE Std. 112B, and performance characterizations (steady-state temperature rise, torque-speed performance). Test results were compared to a database of aluminum rotor motor test results.

Research Topics and Scope:

The research focused on commercially available copper rotor motors (1-20 Hp) manufactured by Siemens. The scope included build inspection, efficiency testing, and torque-speed performance analysis.

6. Key Results:

Key Results:

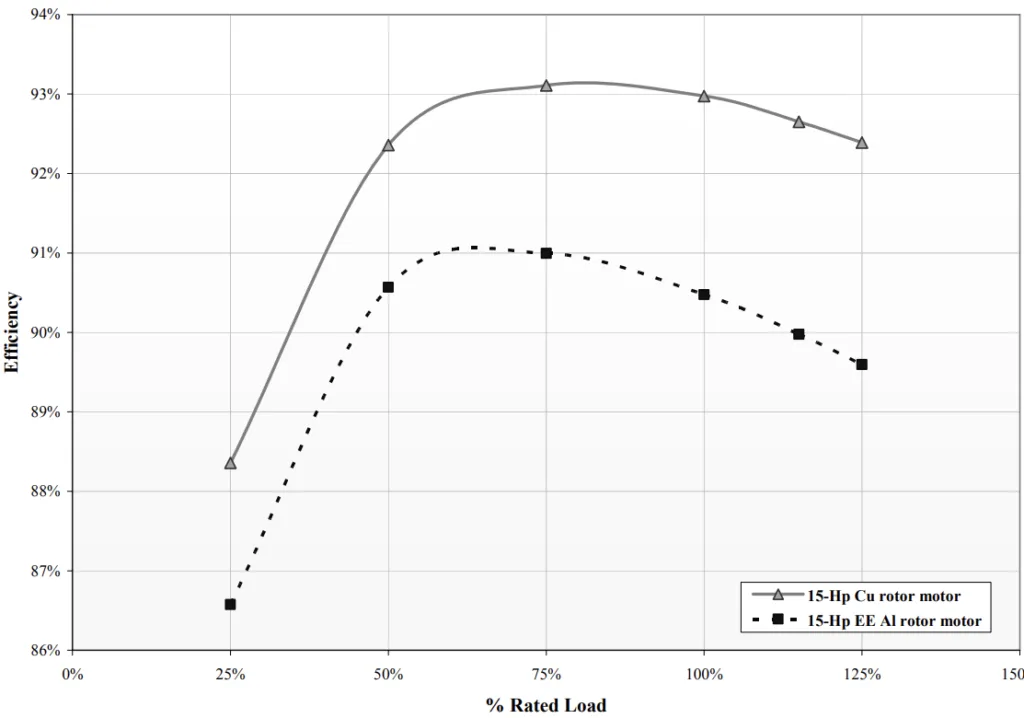

- Copper rotor motors showed a significant reduction in rotor, core, and stray-load losses compared to energy-efficient aluminum rotor motors.

- Efficiency gains were achieved while maintaining performance characteristics like torque-speed performance and locked rotor current.

- The tested copper rotor motors exhibited higher efficiencies than their corresponding cast aluminum counterparts, exceeding NEMA Premium® levels.

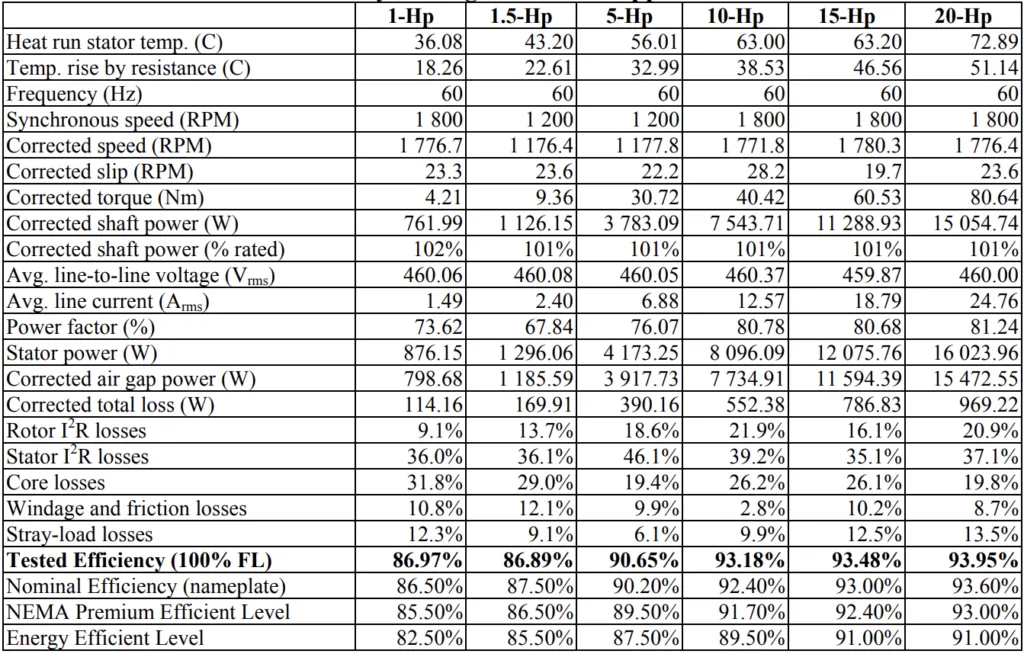

- The 15-Hp copper rotor motor showed a "flat-topped" efficiency curve, characteristic of NEMA Premium® motors.

- Rotor I²R losses were significantly lower in copper rotor motors.

- Stray load losses were also lower in the copper rotor design.

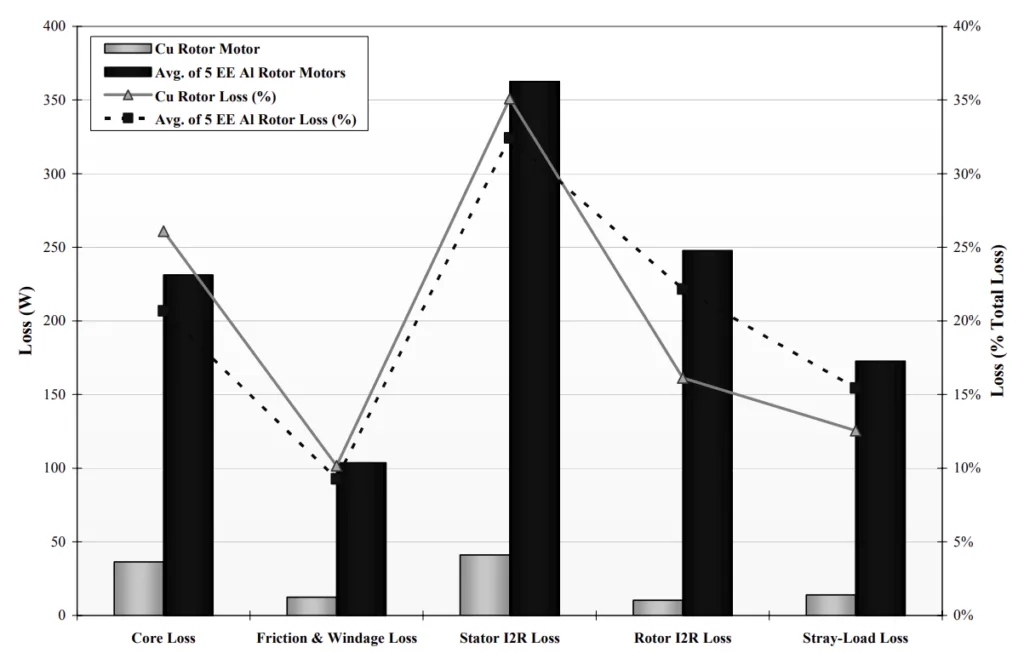

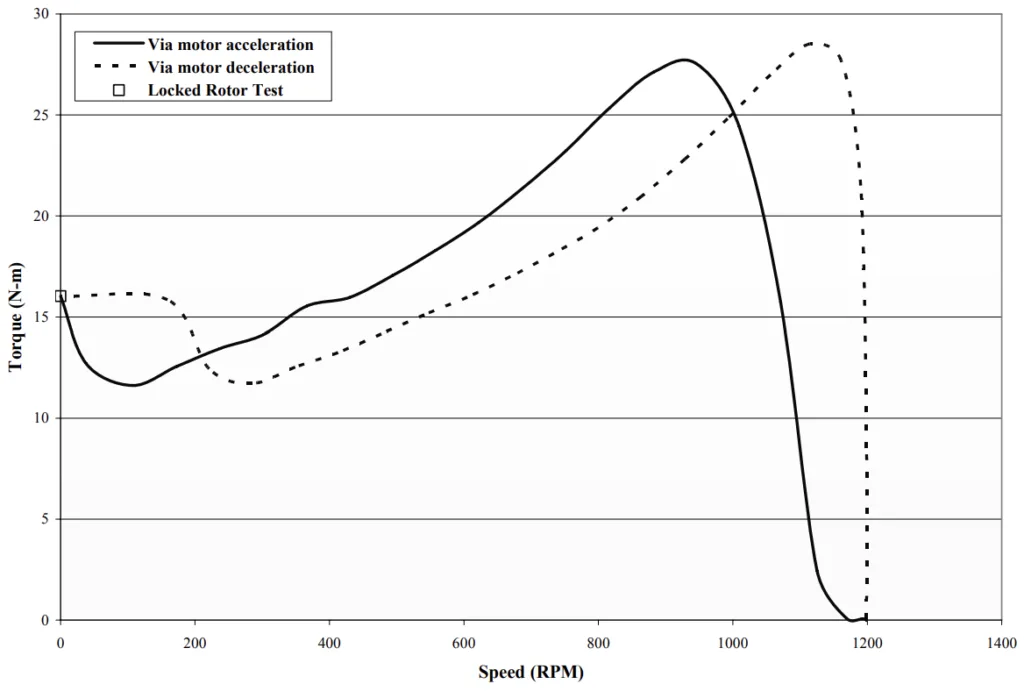

- Torque-speed test results were within NEMA Design B motor specifications.

Figure Name List:

- Figure 1. Die-Cast Copper Rotors

- Figure 2. Efficiency Curves for a 15-Hp Copper Rotor and Average of 5 x 15-Hp Energy Efficient Aluminum Rotor Motors

- Figure 3. Loss segregation of 15-Hp Copper Rotor and Energy Efficient Aluminum Rotor Motors

- Figure 4. Acceleration and Deceleration Torque-Speed Curves for 1.5-Hp Motor

7. Conclusion:

The use of die-cast copper rotors significantly reduces rotor, core, and stray-load losses, leading to higher efficiencies compared to aluminum rotor motors, while preserving key performance characteristics. Although copper cage rotors have existed in larger motors, improvements in die-casting technology have enabled the economical mass production of smaller copper rotor motors. These motors represent a logical advancement for polyphase squirrel cage induction motors, particularly in the 1-200 Hp range, offering a viable path to lower operating costs and improved industrial competitiveness.

8. References:

- Ayyub, Mohammad, S.S. Murthy and B.P. Singh. “Energy Conservation through Improved Design of Induction Motor.” IEEE Article 0-7803-2795-0: 458-63.

- Bonnett, Austin H. 1994. “An Update on AC Induction Motor Efficiency.” IEEE Transactions on Industry Applications 30 (5): 1362-72.

- Bonnett, Austin H. 1998. “An Overview of How AC Induction Motor Performance Has Been Affected by the October 24, 1997 Implementation of the Energy Policy Act of 1992." Paper PID 99-08 presented at the IEEE Petroleum and Chemical Industry Technical Conference, Indianapolis, Ind., September 28-30.

- Braun, Michael. Increasing the Efficiency of Induction Motors. Chicago, Ill.: PSW.

- "Super-Efficient Motors with Copper Rotors Enter U.S. Market." Copper Development Association. April 12, 2006. http://www.copper-rotor-motors.org.

- Malinowski, John, Jim McCormick and Kevin Dunn. 2003. “Advances in Construction Techniques of AC Induction Motors: Preparation for Super-Premium Efficiency Levels.” IEEE Transactions on Industry Applications 40 (6): 1665-70.

- Nailen, Richard L. 1992. Energy Efficient Motors—Myths vs. Reality. Chicago, Ill.: Barks Publications.

9. Copyright:

- This material is a paper by "Nicole Kaufman Dyess, Emmanuel Agamloh, Ph.D., Advanced Energy". Based on "Copper Rotor Motors: A Step toward Economical Super-Premium Efficiency Motors?".

- Source of the paper: Not provided in the OCR, assumed to be from the 2007 ACEEE Summer Study on Energy Efficiency in Industry proceedings.

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.