Optimizing Aluminum Casting: A Deep Dive into Mechanical Properties of Automotive Knuckles

This technical summary is based on the academic paper "Comparative Study of Mechanical Properties and Structure of Knuckles Intended for Application in the Running Gear of Automotive" by Anna MANEVA, Serguei STANEV, Mihail GEORGUIEV, Lilyana NENOVA, published in International Journal “NDT Days" (2021).

Keywords

- Primary Keyword: Aluminum Casting Optimization

- Secondary Keywords: AlSi7Mg Alloy, Automotive Knuckle, Mechanical Properties, Microstructure Analysis, Secondary Dendrite Arm Spacing (DAS), Low Pressure Casting (LPC)

Executive Summary

- The Challenge: To optimize the Low Pressure Casting (LPC) process for critical automotive components like knuckles by ensuring consistent mechanical properties and microstructural integrity across different designs and casting zones.

- The Method: Researchers conducted a comparative analysis of five AlSi7Mg alloy knuckles with four different designs, evaluating mechanical properties (Rp0,2, Rm, A5), hardness (HBW), and microstructure (DAS) in three characteristic areas of each casting.

- The Key Breakthrough: The study quantified the significant variation in mechanical properties and Secondary Dendrite Arm Spacing (DAS) across different knuckle designs and even within a single casting, highlighting the direct impact of solidification conditions on final part performance.

- The Bottom Line: Achieving uniform mechanical properties in complex aluminum castings requires rigorous control over the solidification process, and monitoring DAS is a critical tool for predicting and ensuring the performance and fatigue life of safety-critical components.

The Challenge: Why This Research Matters for HPDC Professionals

In the production of safety-critical automotive components like steering knuckles, consistency is paramount. Even minor variations in the casting process can lead to significant differences in mechanical properties, potentially compromising the part's durability and fatigue life. The industry faces the ongoing challenge of ensuring that every part, regardless of design complexity, meets stringent performance requirements. This research was initiated to optimize the Low Pressure Casting (LPC) process by systematically collecting and analyzing data on mechanical properties and structure from characteristic areas of knuckles. The goal is to build a robust database that helps control and refine foundry technology, ensuring every component meets the high standards required for automotive running gear.

The Approach: Unpacking the Methodology

The study provides a clear and systematic framework for evaluating cast aluminum components. This methodology ensures that the findings are reliable and directly applicable to industrial quality control and process optimization.

Method 1: Material and Sample Preparation

The investigation was performed on five automotive knuckles of four different designs, cast from AlSi7Mg alloy using the Low Pressure Casting (LPC) method in industrial conditions. This alloy is noted for its good casting properties and durability. All samples underwent a T6 heat treatment regime. From each knuckle, test specimens were cut from three characteristic, high-stress areas to evaluate local properties.

Method 2: Mechanical and Microstructural Analysis

A comprehensive set of tests was conducted. Mechanical properties, including 0.2% proof stress (Rp0,2), ultimate tensile strength (Rm), and elongation (A5), were measured. Brinell hardness (HBW) was also determined. For microstructural evaluation, the researchers measured the Secondary Dendrite Arm Spacing (DAS), a key indicator of solidification time and cooling rate. The local time of crystallization (LCT) was then calculated using the formula: LCT = (DAS / 10)³.

Method 3: Quality Assessment

To provide a holistic assessment of both strength and ductility, the researchers calculated a quality index (Q) for each sample using the formula: Q = Rm + 150 log A5. This index has a known correlation with fatigue strength, with values above 400 MPa being desirable for ensuring a fatigue life of over 10⁷ cycles at 90 MPa loading.

The Breakthrough: Key Findings & Data

The research revealed critical variations in properties across the samples, providing valuable data for process engineers aiming to achieve greater consistency and performance.

Finding 1: Significant Variation in Microstructure (DAS) Across Designs

The study highlighted a dramatic difference in the microstructure, specifically the Secondary Dendrite Arm Spacing (DAS), between different knuckle designs. As shown in Table 6, Knuckle 3.1 exhibited significantly higher DAS values (average 37.8 µm) compared to other knuckles. For instance, Knuckle 1/L had an average DAS of 16.4 µm (Table 2), and Knuckle 2/R had an average of 15.08 µm (Table 4). This indicates a much slower local solidification time for Knuckle 3.1 (calculated LST of ~54.5 s vs. ~4 s for Knuckles 1 and 2), which directly impacts the final mechanical properties.

Finding 2: Direct Correlation Between Elongation (A5) and Quality Index (Q)

The data clearly demonstrates how ductility (elongation A5) impacts the overall quality index (Q). Knuckle 3.2 showed the lowest average elongation at 3.4% and consequently had the lowest average quality index of 389 MPa (Table 7). In contrast, Knuckle 3.1, despite its coarse microstructure, had a high average elongation of 9.3% and the highest average quality index of 477 MPa (Table 6). This reinforces that achieving high strength (Rm) alone is insufficient; good ductility is essential for a high-quality, fatigue-resistant component.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting cooling rates and solidification paths within the mold is critical for controlling DAS. The significant variation in DAS for Knuckle 3.1 (Table 6) points to a potential process control issue that could be addressed by optimizing cooling channels or modifying the casting parameters to achieve more uniform solidification and, consequently, more consistent mechanical properties.

- For Quality Control Teams: The data in Table 2 and Table 7 illustrates the effect of microstructure on mechanical properties. The low elongation (1.4%) and Quality Index (325 MPa) in Zone 2 of Knuckle 3.2 is a clear red flag. This suggests that DAS measurement could be implemented as a key quality inspection criterion to predict areas of potential weakness that might not be caught by hardness testing alone.

- For Design Engineers: The findings indicate that part geometry heavily influences local solidification time. The stark difference in DAS values between the designs (e.g., Knuckle 3.1 vs. Knuckle 2/R) suggests that design features like section thickness and junctions are critical factors. This data provides a valuable consideration in the early design phase to create components that are inherently easier to cast with a uniform, fine-grained microstructure.

Paper Details

Comparative Study of Mechanical Properties and Structure of Knuckles Intended for Application in the Running Gear of Automotive

1. Overview:

- Title: Comparative Study of Mechanical Properties and Structure of Knuckles Intended for Application in the Running Gear of Automotive

- Author: Anna MANEVA, Serguei STANEV, Mihail GEORGUIEV, Lilyana NENOVA

- Year of publication: 2021

- Journal/academic society of publication: International Journal “NDT Days", Volume IV, Issue 5, Bulgarian Society for NDT

- Keywords: Castings for automotive knuckles, mechanical properties, structure, aluminum-silicon alloy

2. Abstract:

The study was conducted in order to be optimized the process of Low Pressure Casting (LPC). Data from a study of the mechanical properties and the structure in characteristic areas of castings for automotive knuckles made of aluminum alloys have been collected and processed.

3. Introduction:

The study was performed on samples from 3 characteristic areas of 5 knuckles with four different designs (№1, №2, №3.1, №3.2, and №4). The knuckles were cast in industrial conditions from AlSi7Mg alloy using the LPC method and subsequently heat-treated by a T6 regime. The AlSi7Mg alloy, with a low Fe content, offers good casting properties and is suitable for components requiring high cyclic fatigue durability. The properties of the alloy can be tailored for high strength or high elongation by varying the natural aging duration post-T6 treatment. Test specimens were prepared from specified areas to test mechanical indicators (Rp0,2, Rm, A5), hardness (HBW), and to calculate a quality coefficient (Q). Microstructural analysis focused on comparing DAS values, the presence of oxide films and non-metallic inclusions, and the morphology of eutectic Si particles, with the goal of achieving uniform DAS values across all zones of the casting. DAS is used to predict mechanical properties and calculate the local time of crystallization (LCT).

4. Summary of the study:

Background of the research topic:

The research addresses the need for process optimization in the manufacturing of critical automotive components, specifically knuckles, made from aluminum alloys. Ensuring consistent and high-quality mechanical properties is essential for the safety and durability of vehicle running gear.

Status of previous research:

The paper references prior work establishing the properties of AlSi7Mg alloy, including its response to T6 heat treatment and the relationship between the quality index (Q) and fatigue strength. It also cites standards for heat treatment (ASTM B917 / B917M 2008) and builds upon established methods for microstructural analysis and mechanical testing [2, 3, 4, 5, 6]. Average mechanical parameters for a similar knuckle design are noted as Rp0,2: 225-249 MPa, Rm: 284-309 MPa, A5: 6.7-9.5%, HB > 104, and FEL > 85 MPa.

Purpose of the study:

The primary purpose is to optimize the Low Pressure Casting (LPC) process by collecting and processing data on the mechanical properties and structure of automotive knuckles. The study aims to create a comparative analysis of different knuckle designs to understand variability and improve foundry technology for producing such responsible parts.

Core study:

The core of the study involves the detailed examination of five knuckles representing four distinct designs. Samples were extracted from three specific zones on each knuckle. These samples underwent comprehensive testing to determine their chemical composition, mechanical properties (yield strength, ultimate tensile strength, elongation), hardness, and microstructural characteristics (specifically Secondary Dendrite Arm Spacing - DAS). The results were tabulated and presented graphically to compare the performance of each knuckle design and identify inconsistencies within individual castings.

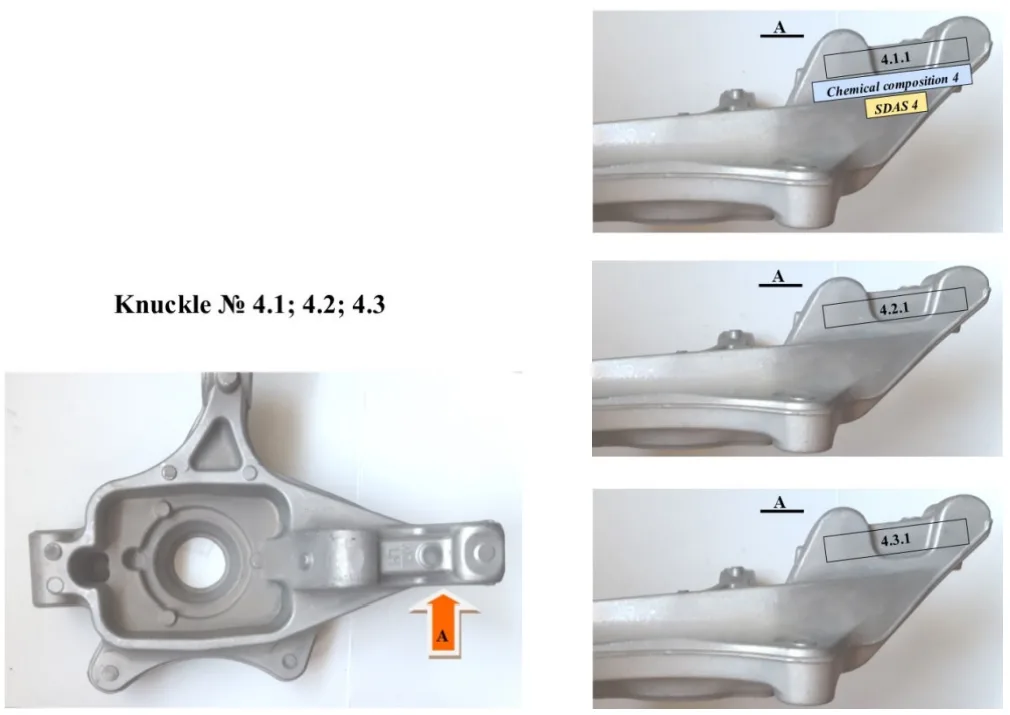

5. Research Methodology

Research Design:

The research employs a comparative experimental design. Five knuckle castings from four different designs (1/L, 2/R, 3.1, 3.2, 4) were selected. For each knuckle, samples were systematically taken from three predefined characteristic zones for analysis.

Data Collection and Analysis Methods:

Data was collected through destructive testing of specimens. Mechanical properties (Rp0,2, Rm, A5) were determined via tensile testing. Hardness was measured using the Brinell scale (HBW) and Vickers scale (HV). Chemical composition was analyzed to confirm alloy specifications. Microstructural analysis was performed to measure the Secondary Dendrite Arm Spacing (DAS). From the DAS values, the Local Crystallization Time (LCT) was calculated. A Quality Index (Q) was also calculated using the formula Q = Rm + 150 lg A5. The collected data was then averaged for each knuckle and presented in tables and graphs for comparative analysis.

Research Topics and Scope:

The scope is limited to automotive knuckles made of AlSi7Mg alloy, cast using the LPC method and heat-treated to a T6 condition. The research focuses on the relationship between casting design, microstructure (DAS), and the resulting mechanical properties (Rp0,2, Rm, A5, HBW) and quality index (Q) in specific zones of the castings.

6. Key Results:

Key Results:

- The study successfully characterized the mechanical and microstructural properties of five knuckles across four designs.

- Average values for the knuckles were: Rp0,2 from 206-254 MPa, Rm from 294-333 MPa, A5 from 3.4-9.3%, HBW from 109.5-117.9, and Q from 389-477 MPa.

- Knuckle 3.1 showed significantly higher DAS values (average 37.8 µm) compared to the others (e.g., Knuckle 2/R at 15.08 µm), indicating a much slower solidification rate.

- Knuckle 3.2 exhibited the lowest average elongation (3.4%) and the lowest average quality index (389 MPa).

- Knuckle 3.1, despite its coarse microstructure, had the highest average elongation (9.3%) and the highest average quality index (477 MPa).

- The results demonstrate considerable variation in properties not only between different designs but also between different zones of the same casting.

Figure Name List:

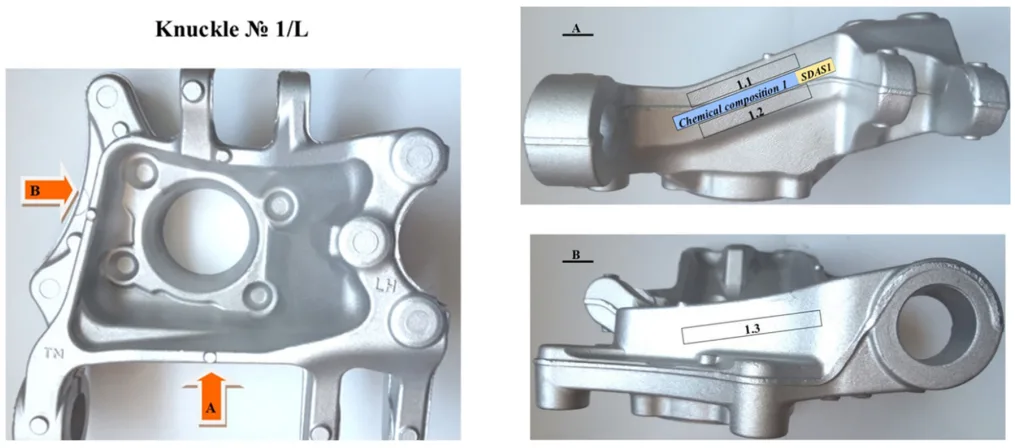

- Fig. 1. Scheme of sampling for chemical, microstructural analysis and testing of mechanical properties (left knuckle)

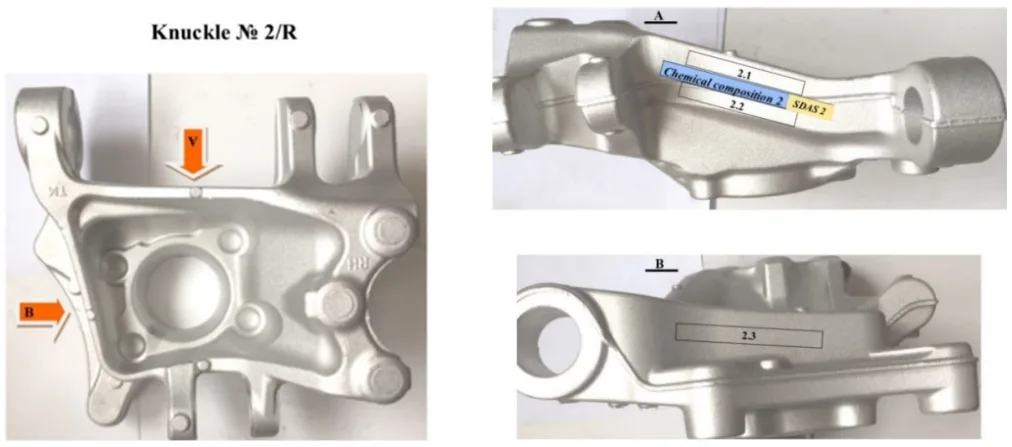

- Fig. 2. Scheme of sampling for chemical, microstructural analysis and testing of mechanical properties (right knuckle)

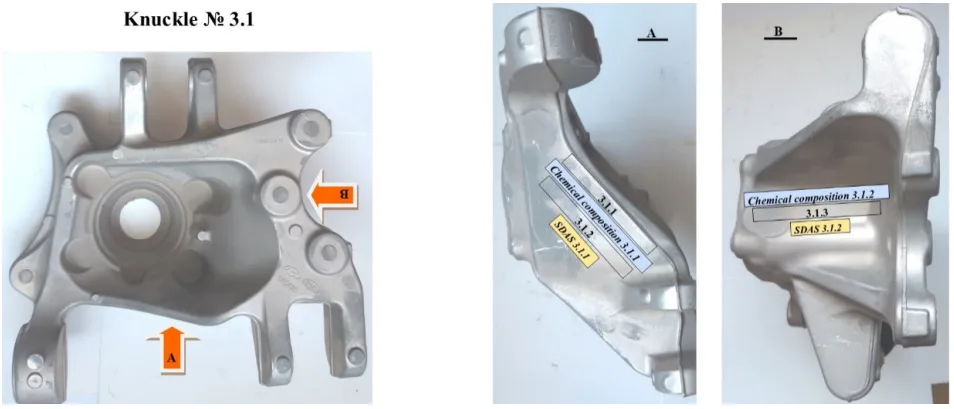

- Fig. 3. Scheme of sampling for chemical, microstructural analysis and testing of mechanical properties (knuckle № 3.1)

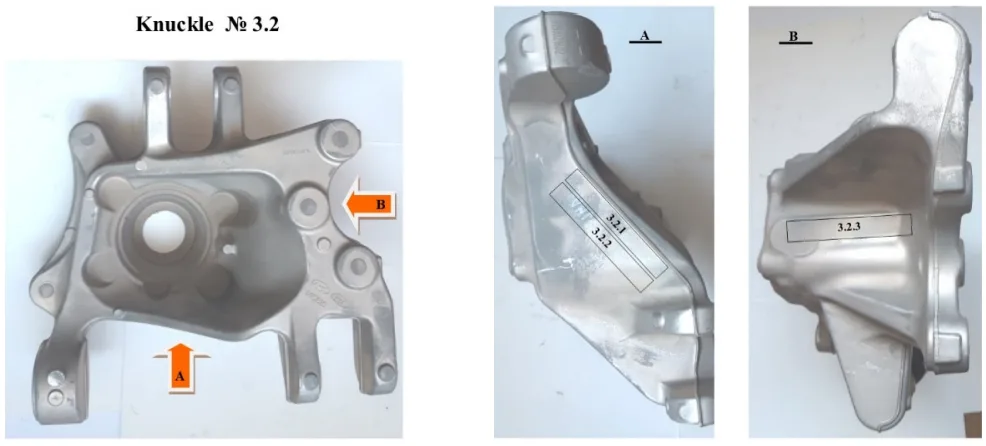

- Fig. 4. Scheme of sampling for chemical, microstructural analysis and testing of mechanical properties (knuckle № 3.2)

- Fig. 5. Scheme of sampling for chemical, microstructural analysis and testing of mechanical properties (knuckle № 4)

- Fig.6. Microstructures from the investigated areas

- Fig. 7. Protocol from the carried out tests of mechanical properties of a knuckle 3.1

- Fig.8. Graphs of the average values of the mechanical parameters - Rp0,2, Rm and A5, the hardness - HBW and the factor of quality - Q for the five castings.

7. Conclusion:

- The results of the conducted research on the structure and the main mechanical properties will enrich the database, helping to improve the quality of this type of responsible cast parts.

- The comparative analysis of the obtained average values from the conducted testing of the main mechanical properties shows that the investigated details - knuckles for the running gear of the car, meet the technical requirements for this class of aluminum castings.

- The data collected and processed contribute for the optimizing and controlling foundry technology at the production of such parts.

8. References:

- Emadi D., L.V. Whiting, M. Sahoo, J.H. Sokolowski, P. Burke, M. Hart, Optimal Heat Treatment of A356.2 alloy, Light Metals 2003, edited by Paul N. TMS (The Minerals, Metals & Materials Society), 2003, p.983-989;

- Kuzmanov P., Velikov A., Dimitrova R., Cherepanov A., Manolov V. Study of the Influence of Modification by Nanocompositions both on the Process of Crystallization and on the Structure of Aluminum Alloy AlSi7Mg. Journal of Nanomaterials & Molecular Nanotechnology, vol.8, Issue 3, 2019, ISSN:2324-8777 1-4;

- Dimitrova R., R. Petrov, P. Kuzmanov, A. Velikov, V. Manolov. Electron Microscopy Investigations of A356 Alloy Modified with Nanoparticles. Metals, 9, 12, MDPI, 2019, ISSN;2075-4701, DOI;10.3390/met9121294, 1-12;

- Kalchevska K., Y. Mirchev, M. Mihovski. Physical Basis, Methods, Means and Technologies for Visual-Optical and Measuring Non-Destructive Control. "Prof. Marin Drinov" Publishing House of BAS, Sofia, 2020;

- Drouzy M., S. Jacob, and M. Richard. Interpretation of Tensile Results by Means of Quality Index and Probable Yield Strength, AFS Int. Cast Met. J., 1980, 5, p. 43-50;

- Khomamizadeh F., A. Ghasemi, Evaluation of Quality Index of A-356 Aluminum Alloy by Microstructural Analysis, Scientia Jranica, Vol.11. № 4, pp. 386-391, October 2004.

Expert Q&A: Your Top Questions Answered

Q1: Why was the AlSi7Mg alloy specifically chosen for this study on automotive knuckles?

A1: The paper states that the AlSi7Mg alloy was chosen because it has a low content of Fe, possesses good casting properties, and satisfies the requirements for this type of component, including a maximum durability under cyclic fatigue. Furthermore, its mechanical properties can be tailored to achieve either high strength or high elongation simply by varying the post-T6 natural aging duration, making it a versatile choice for such a demanding application.

Q2: What is the significance of the Secondary Dendrite Arm Spacing (DAS), and how does it relate to the casting process?

A2: DAS is the measured distance between secondary dendrite arms in the microstructure. Its significance lies in its direct relationship with the solidification process. A smaller DAS value indicates a faster cooling rate, which generally leads to a finer microstructure and improved mechanical properties. The paper uses DAS to calculate the Local Time of Crystallization (LCT), providing quantitative information about the solidification process in different zones of the casting.

Q3: The paper mentions a Quality Index (Q). How is this calculated and what does it represent?

A3: The Quality Index (Q) is calculated using the formula Q = Rm + 150 lg A5, where Rm is the ultimate tensile strength and A5 is the percentage elongation. It serves as a single metric to assess both the strength and plastic properties (ductility) of the alloy. The paper notes a definite connection between Q and fatigue strength, stating that for AlSi7Mg, a Q value between 300-400 MPa corresponds to a fatigue strength of 80-100 MPa for 10⁷ cycles.

Q4: There's a very large difference in DAS values between Knuckle 3.1 (average ~38 µm) and the other knuckles (average ~15-25 µm). What does this imply?

A4: This large difference implies a significantly slower cooling and solidification rate for Knuckle 3.1 compared to the others. The calculated Local Solidification Time (LST) for Knuckle 3.1 is over 10 times longer than that of Knuckles 1 and 2. This suggests that the design of Knuckle 3.1, or the specific casting setup used for it, resulted in less efficient heat extraction, leading to a much coarser microstructure.

Q5: What is the T6 heat treatment regime mentioned in the paper, and why is it important?

A5: The T6 regime is a two-stage heat treatment process involving solution heat treatment followed by quenching and then artificial aging. While the paper doesn't detail the exact parameters, it notes the process is based on the ASTM Standard B917 / B917M 2008. This treatment is crucial for aluminum-silicon-magnesium alloys like AlSi7Mg because it dissolves the magnesium and silicon into the aluminum matrix and then precipitates them as fine Mg₂Si particles, which significantly strengthens the alloy.

Q6: What were the target mechanical properties for these knuckles?

A6: The paper provides target values determined for a knuckle with a similar design: Rp0,2 of 225-249 MPa, Rm of 284-309 MPa, A5 of 6.7-9.5%, HB > 104, and a fatigue endurance limit (FEL) > 85 MPa (at 1.0 x 10⁷ cycles). The results from the tested knuckles are compared against these benchmarks to assess their quality.

Q7: Did all the tested knuckles meet the required quality standards?

A7: The paper's second conclusion states that the investigated knuckles meet the technical requirements for this class of aluminum castings. However, the data shows some zones and one entire knuckle (Knuckle 3.2, with an average Q of 389 MPa) are on the lower end of the desired quality spectrum, where a Q value above 400 MPa is preferred to ensure high fatigue strength. This highlights the importance of process control to minimize such variations.

Conclusion: Paving the Way for Higher Quality and Productivity

This comprehensive study underscores the critical link between casting design, solidification conditions, and the final performance of automotive knuckles. The key takeaway is that achieving superior, consistent mechanical properties requires a deep understanding and precise control of the microstructure. By leveraging metrics like Secondary Dendrite Arm Spacing (DAS) and the Quality Index (Q), foundries can move beyond basic pass/fail criteria and engage in true Aluminum Casting Optimization. The data provides a clear roadmap for refining foundry technology to produce more reliable, durable, and safe components.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Comparative Study of Mechanical Properties and Structure of Knuckles Intended for Application in the Running Gear of Automotive" by "Anna MANEVA, Serguei STANEV, Mihail GEORGUIEV, Lilyana NENOVA".

Source: https://www.ndt.net/?id=30081

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.