Unlocking a Tenfold Improvement in Aluminum Casting Microstructure with Laser Surface Remelting

This technical summary is based on the academic paper "Cellular Automaton Finite Element Method Applied for Microstructure Prediction of Aluminium Casting Treated by Laser Beam" by J. Hajkowski, P. Popielarski, Z. Ignaszak, published in ARCHIVES of FOUNDRY ENGINEERING (2019).

Keywords

- Primary Keyword: Aluminum Casting Microstructure

- Secondary Keywords: Laser Remelting, Dendrite Arm Spacing (DAS), AlSi7Mg Alloy, Cellular Automaton, Surface Hardness, Tribology

Executive Summary

- The Challenge: Conventional casting methods cannot achieve the ultra-fine microstructures (Dendrite Arm Spacing below a dozen microns) demanded by high-performance automotive and aerospace applications.

- The Method: A laser beam was used to rapidly remelt and solidify the thin surface layer of an AlSi7Mg alloy casting, creating a highly refined local microstructure.

- The Key Breakthrough: The laser treatment reduced the Dendrite Arm Spacing (DAS) by approximately tenfold, from 30-40 µm in the base material to just 2-3 µm in the treated surface layer.

- The Bottom Line: Laser surface remelting is a viable technique for dramatically enhancing the surface properties of aluminum castings, achieving levels of structural refinement and hardness unattainable by direct casting alone.

The Challenge: Why This Research Matters for HPDC Professionals

In the automotive and aerospace industries, the demand for aluminum alloy components with superior mechanical and tribological properties is relentless. A key indicator of a casting's quality is its structural compactness, often measured by Dendrite Arm Spacing (DAS). The finer the structure (i.e., the lower the DAS), the better the wear resistance and overall performance.

However, industrial casting methods, even with advanced techniques like chills, face a fundamental limit in how fine a structure they can produce. Customers are now requesting DAS values of less than a dozen microns, a target that is often out of reach. This limitation necessitates exploring novel post-casting treatments to enhance surface properties without altering the bulk component. This research addresses this exact challenge by investigating laser remelting as a method to achieve extreme surface refinement.

The Approach: Unpacking the Methodology

The study combined physical experimentation with advanced simulation to validate the laser treatment process.

Method 1: Laser Surface Remelting Experiment

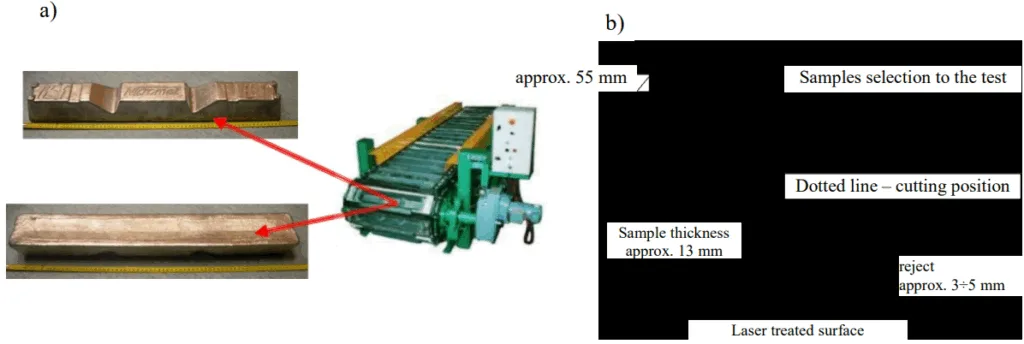

- Material: Gravity die-cast samples of AlSi7Mg (A356) aluminum alloy.

- Equipment: A Trumpf TruLaser Cell 3008 with a TruDisk 1000 laser generator was used to treat the surface of the cast samples.

- Process: The laser beam was passed over the sample surface, creating a series of overlapping "beads." This process rapidly melted a thin surface layer (a fraction of a mm to a single mm thick), which then immediately re-solidified due to the rapid heat extraction by the cold bulk material underneath.

- Key Variables: Researchers tested different laser parameters, including power (600 W), feed rate (5.5 mm/s and 7.5 mm/s), and laser spot diameter (1.09 mm), resulting in different energy densities applied to the surface.

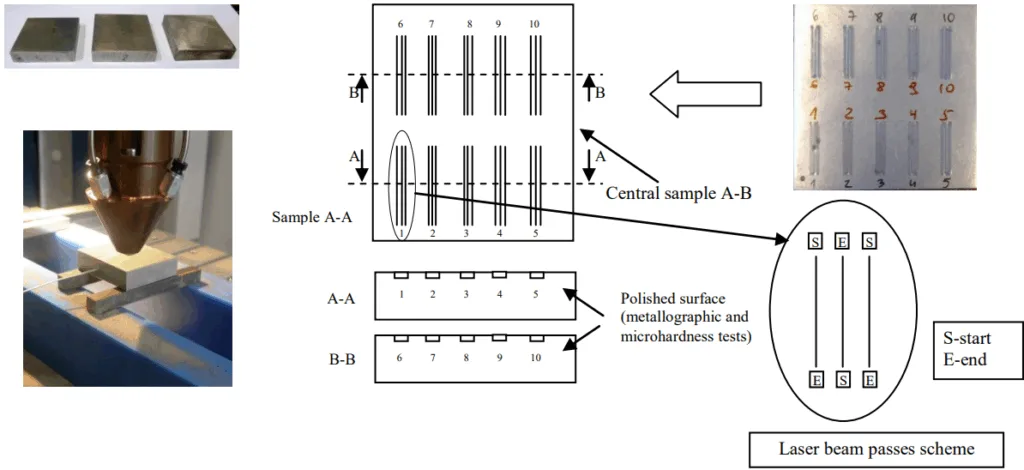

Method 2: Microstructure and Hardness Analysis

- Analysis: Polished cross-sections of the treated samples were examined to measure the depth and width of the remelted zone.

- Measurement: The Dendrite Arm Spacing (DAS) was measured in both the remelted and non-remelted zones. Microhardness tests (Vickers) were performed inside and outside the treated area to quantify the improvement in mechanical properties.

Method 3: CAFE Simulation and Validation

- Software: The Calcosoft CAFE (Cellular Automaton Finite Element) code was used to simulate the process.

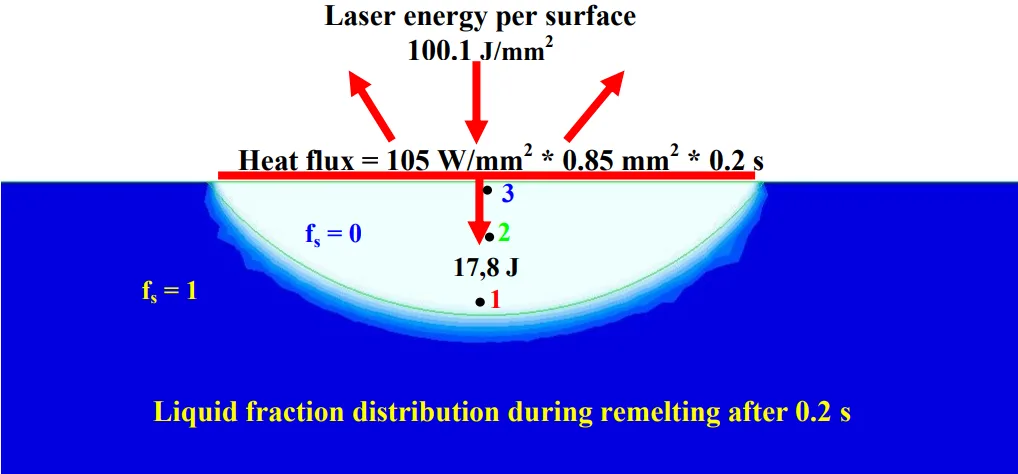

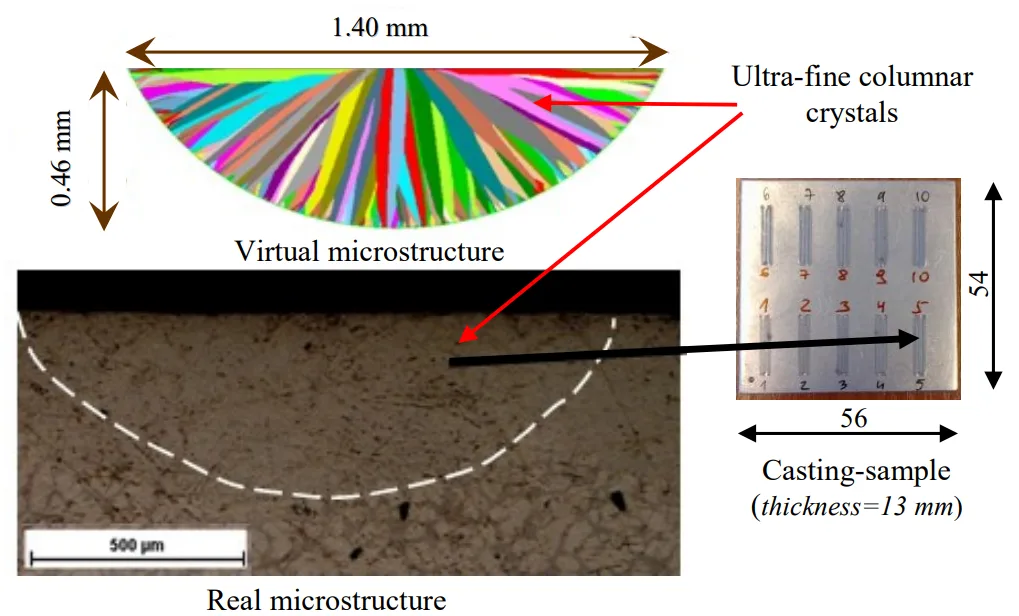

- Process: First, a thermal simulation was run to model the heating and rapid cooling caused by the laser, matching the simulated melt pool geometry to the experimental results. This temperature data was then used in the CAFE module to predict the resulting microstructure (crystal formation). The virtual microstructure was then compared to the real microstructure observed in the experiments for validation.

The Breakthrough: Key Findings & Data

The results demonstrate a dramatic and precisely controlled improvement in the surface properties of the aluminum casting.

Finding 1: Tenfold Refinement of Aluminum Casting Microstructure

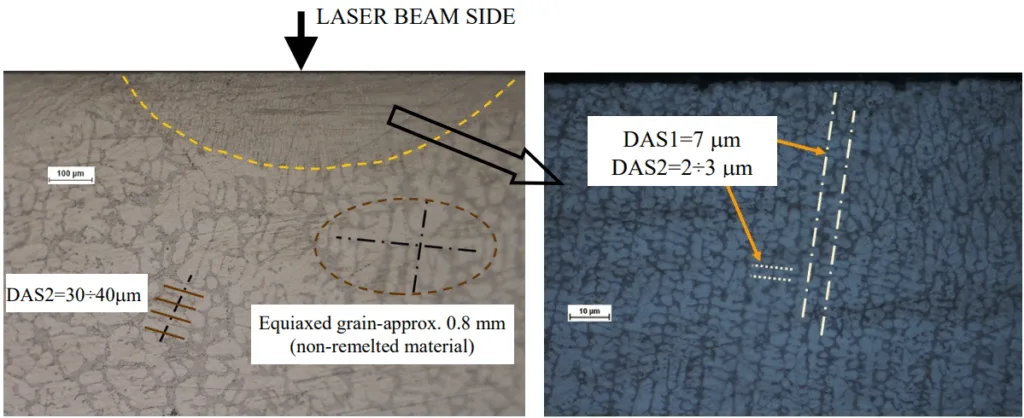

The laser treatment produced an exceptional refinement of the dendritic structure. In the non-remelted base material, the secondary Dendrite Arm Spacing (DAS2) was measured at 30-40 µm. Within the laser-remelted zone, the DAS2 was reduced to just 2-3 µm. As shown in Figure 5, this represents an approximate tenfold decrease in the spacing between dendrite arms, resulting in a significantly more compact and homogenous surface layer.

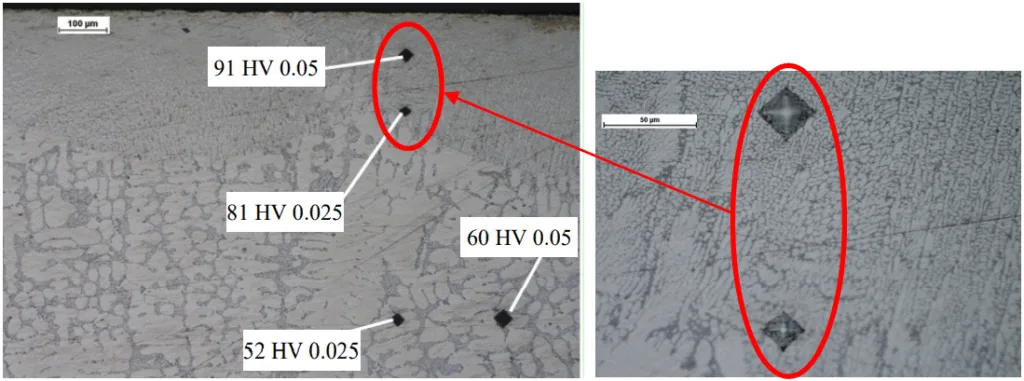

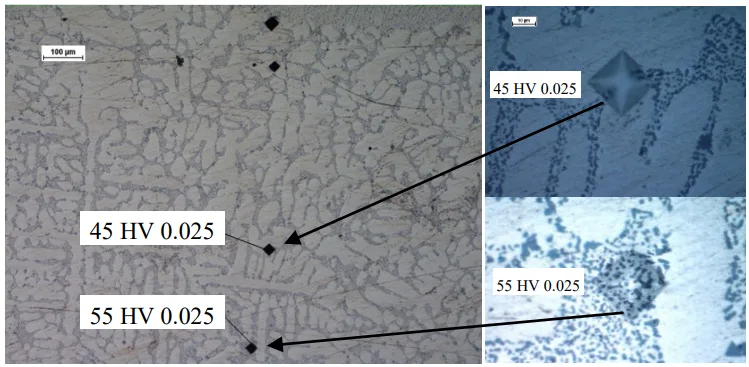

Finding 2: Significant Increase in Surface Microhardness

This structural refinement translated directly into improved mechanical properties. Microhardness tests revealed a substantial increase in the remelted zone compared to the parent casting. As detailed in Figure 3, the hardness inside the remelted zone reached values as high as 91 HV 0.05, while the non-remelted material just outside the boundary measured only 52 HV 0.025. This confirms that the finer microstructure creates a much harder, more wear-resistant surface.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that laser surface treatment can be integrated as a post-casting process to selectively enhance critical surfaces on components, such as bearing faces or high-wear areas, without affecting the entire part.

- For Quality Control Teams: The data in Figures 3 and 5 of the paper illustrates the direct correlation between laser energy input, the resulting DAS value, and the final surface hardness. This could inform new quality inspection criteria for components requiring superior surface performance.

- For Design Engineers: The findings indicate that components can be designed with the bulk properties of a standard casting while specifying laser treatment for localized areas that require exceptional hardness and wear resistance. This allows for more optimized and cost-effective component design.

Paper Details

Cellular Automaton Finite Element Method Applied for Microstructure Prediction of Aluminium Casting Treated by Laser Beam

1. Overview:

- Title: Cellular Automaton Finite Element Method Applied for Microstructure Prediction of Aluminium Casting Treated by Laser Beam

- Author: J. Hajkowski, P. Popielarski, Z. Ignaszak

- Year of publication: 2019

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING, Volume 19, Issue 3/2019

- Keywords: Cellular automaton, Dendrite arm spacing, Remelting by laser beam, Aluminium alloys, Tribology

2. Abstract:

The paper addresses the challenge of improving the structure of castings beyond what is achievable through direct solidification from the liquid state and subsequent heat treatment. The study was motivated by casting engineers' requirements to reduce Dendrite Arm Spacing (DAS) to less than a dozen microns. The authors present results from the modification of the surface microstructure of an AlSi7Mg alloy casting via laser beam treatment, which induces rapid remelting and solidification of the superficial zone. This local treatment affects a thickness from a fraction to a single millimeter and is intended for non-machined casting surfaces to utilize the enhanced properties. Tests were conducted on a machined casting surface, where the laser treatment produced a microstructural refinement, measured by DAS, that is not attainable directly by casting. The study employed the Calcosoft CAFE (Cellular Automaton Finite Element) code for experimental-simulation validation.

3. Introduction:

Aluminium alloys are extensively used in the automotive and aerospace industries, where components require good mechanical and tribological properties, including effective wear resistance derived from structural compactness. A characteristic of castings is the gradient in structure and mechanical properties, which can be controlled by varying mould materials (e.g., using chills). Current customer demands for finer structures, expressed by low DAS values, often exceed the capabilities of conventional industrial casting methods. This necessitates the exploration of alternative techniques. Laser remelting of a thin surface zone is presented as one such technique that meets these expectations. The study focuses on the laser modification of the local structure of an A356 (AlSi7Mg) alloy casting through rapid remelting and solidification.

4. Summary of the study:

Background of the research topic:

The research is grounded in the industrial need for aluminum alloy castings with superior surface properties, specifically a highly compact microstructure characterized by a low Dendrite Arm Spacing (DAS).

Status of previous research:

Conventional casting and heat treatment methods are often insufficient to meet increasingly stringent requirements for microstructural refinement. Laser remelting has been described in prior literature [3-5] as a promising technique for surface modification.

Purpose of the study:

The primary purpose was to investigate the extent to which the surface microstructure of an AlSi7Mg alloy casting could be improved using laser beam remelting. A secondary objective was to validate the results of this physical process using a Cellular Automaton Finite Element (CAFE) simulation model to predict the resulting microstructure.

Core study:

The core of the study involved treating the surface of a gravity die-cast AlSi7Mg sample with a laser to induce localized melting and rapid solidification. The resulting microstructure and microhardness of the treated zone were analyzed and compared to the non-treated base material. Concurrently, a computational model was developed using the Calcosoft CAFE system. An energetic model was first validated by matching the simulated melt pool geometry with experimental results. This thermal data was then used as an input for the CAFE module to predict the grain structure, which was subsequently compared with the actual metallographic cross-sections to validate the simulation's predictive capability for such high-cooling-rate processes.

5. Research Methodology

Research Design:

The study followed an experimental-simulation validation design. Physical experiments involving laser surface remelting were conducted, and the results were used to validate a numerical simulation model based on the Cellular Automaton Finite Element method.

Data Collection and Analysis Methods:

Samples were cut from a gravity die-cast AlSi7Mg ingot. The surface was treated with a Trumpf TruLaser Cell 3008 laser under varying parameters (feed rate). The treated samples were sectioned, polished, and analyzed metallographically to determine the dimensions of the remelted zone and the Dendrite Arm Spacing (DAS). Microhardness tests (Vickers) were conducted with loads of 0.025 kg and 0.050 kg. The simulation was performed using the Calcosoft system, involving a thermal module to simulate heating and cooling, and the CAFE module to predict microstructure formation.

Research Topics and Scope:

The research focused on the surface modification of AlSi7Mg alloy. The scope included the experimental application of laser remelting, characterization of the resulting microstructure (DAS) and microhardness, and the development and validation of a CAFE simulation model capable of predicting the microstructure under the rapid solidification conditions induced by the laser. The study examined two specific laser passes (beads no. 1.2 and 5.2) with different processing parameters.

6. Key Results:

Key Results:

- Laser treatment resulted in a microstructure characterized by a DAS value of a few microns, which is an order of magnitude lower than the original casting structure (30-40 µm vs. 2-3 µm).

- Microhardness in the laser-treated zone was significantly increased compared to the non-remelted zone (e.g., 91 HV 0.05 in the remelted zone vs. 52 HV 0.025 in the parent material).

- The CAFE simulation, after calibration (suppressing volume nucleation), successfully predicted the formation of an exclusively oriented, columnar crystal structure (pseudo-dendrites) that was consistent with the real microstructure observed in the remelted zone.

- The initial temperature of the sample, influenced by previous laser passes, had a significant effect on the size of the subsequent remelted zone, which was successfully accounted for in the simulation.

Figure Name List:

- Fig. 1. Gravity die-casting process (a) and sample preparation for the laser beam treatment (b)

- Fig. 2. Samples cut from the casting and arrangement of individual beads

- Fig. 3. Photographs of polished cross-sections with imprints from microhardness tests inside and outside of the remelting zone. Two loads were used. Distance from the remelting boundary approx. 400µm – 52 HV 0.025

- Fig. 4. Photographs of polished cross-sections with imprints from microhardness tests outside of the remelting zone (distance from the remelting boundary – interface approx. 550 µm – 45 HV 0.025 and 850 µm – 55HV0.025)

- Fig. 5. Distances between dendrite arms – DAS 1 (primary) and DAS 2 (secondary) a) remelted and non-remelted zone, b) remelted zone

- Fig. 6. Experimental remelting result (laser - bead no. 1.2)

- Fig. 7. Result of the laser heating process simulation

- Fig. 8. Temperature curves as a simulation results of the laser heating process and next rapid cooling

- Fig. 9. Temperature distribution in the sample after heating, a – result of the heating simulation, b – layered average initial temperatures for CAFE calculations of structure

- Fig. 10. Averaged initial temperatures for the CAFE calculations of structure, laser pass no. 5.2

- Fig. 11. Real and virtual microstructure of melted zone - bead no. 1.2

- Fig. 12. Real and virtual microstructure of melted zone - bead no. 5.2

7. Conclusion:

The study demonstrated that laser beam heating can be effectively used to remelt the superficial zone of an Al-Si casting, leading to a high degree of structural refinement and a significant increase in microhardness upon rapid cooling. The improvement in mechanical properties is attributed to the intensive heat extraction from the remelted zone by the bulk casting. A parallel validation study using the Calcosoft-CAFE simulation system was performed. It was found that the initial temperature distribution, resulting from previous laser passes, significantly influences the structure formation. The simulation was successfully validated, showing that after modification of parameters (e.g., suppressing volume nucleation), it could accurately predict the columnar crystal structure observed experimentally. The work established a database of CAFE parameters suitable for modeling microstructure formation under the very high cooling rates associated with laser remelting.

8. References:

- [1] Campbell, J. (2015). Complete Casting Handbook. 2nd Edition., Butterworth-Heinemann.

- [2] Borowski, J. & Bartkowiak, K. (2010). Investigation of the influence of laser treatment parameters on the properties of the surface layer of aluminium alloys. Physics Procedia. 5, 449-456. DOI 10.1016/j.phpro.2010.08.167.

- [3] Opiekun, Z. & Orłowicz, W. (1996). Laser modification of aluminium alloys surface. Solidification of Metals and Alloys. 28, 135-143. (in Polish)

- [4] Konovalov, S., Gromov, V., Zaguliyaev, D., Ivanov, Y., Semin, A., Rubannikova, J. (2019). Dispersion of Al-Si Alloy Structure by Intensive Pulsed Electron Beam. Archives of Foundry Engineering. 19(2), 79-84.

- [5] Lopez-Botello, O., Martinez-Hernandez, U., Ramírez J., Pinna, Ch., & Mumtaz, K. (2017). Two-dimensional simulation of grain structure growth within selective laser melted AA-2024. Materials and Design. 113, 369-376. DOI 10.1016/j.matdes.2016.10.031.

- [6] Gandin, Ch.-A. & Rappaz, M. (1994). A Couplet Finite Element-Cellular Automaton Model for the Prediction of Dendritic Grain Structures in Solidification Processes. Acta Metallurgica et Materialia. 42, 2233-2246.

- [7] Liu, D.R., Mangelinck-Noe, N., Gandin, Ch.-A., Zimmermann, G., Sturz, L., Nguyen-Thi, H. & Billia, B. (2015). Simulation of directional solidification of refined Al-7 wt.%Si alloys – Comparison with benchmark microgravity experiments. Acta Materialia. 93, 24-37. DOI 10.1016/j.actamat.2015.03.058.

- [8] Carozzani, T., Digonnet, H., Bellet, M., & Gandin, Ch.-A. (2012). 3D CAFE simulation of a macrosegregation benchmark experiment. IOP Conference Series: Materials Science and Engineering, 33.

- [9] Jin-long, Wang, Fu-ming, Wang, Yan-yu, Zhao, Jiong-ming & Zhang, Wei Ren (2009). Numerical simulation of 3D-microstructures in solidification processes based on the CAFE method. International Journal of Minerals, Metallurgy and Materials. 16(6), 640-645. DOI 10.1016/S1674-4799(10)60005-2.

Expert Q&A: Your Top Questions Answered

Q1: Why was the CAFE simulation necessary if the experimental results were already clear?

A1: The CAFE simulation serves as a predictive tool. By validating the simulation model against real-world experiments, as done in this study, engineers can then use the model to predict the outcomes of different laser parameters or alloy compositions without the time and expense of physical trials. It allows for rapid optimization of the process for different applications.

Q2: The paper mentions suppressing "volume nucleation" in the simulation. What does this mean and why was it done?

A2: In the simulation, "volume nucleation" refers to the formation of new, equiaxed crystals within the molten pool. The experimental results showed an exclusively columnar crystal structure growing from the solid-liquid interface, with no new grains forming in the liquid. To make the simulation match reality, the algorithm responsible for volume nucleation was suppressed (nᵥ=0), which correctly led to the formation of the oriented, columnar structure observed.

Q3: What were the specific laser parameters that yielded the best results?

A3: The paper details two specific "beads." Bead no. 1.2 used a laser power of 600 W, a feed rate of 5.5 mm/s, and an energy per surface of 100.1 J/mm². This resulted in a remelted zone 0.21 mm deep. Bead no. 5.2 used the same power but a faster feed rate of 7.5 mm/s (73.4 J/mm²), resulting in a deeper zone of 0.46 mm, likely due to the preheating effect from previous passes. Both produced the desired ultra-fine microstructure.

Q4: How does the cooling in laser remelting compare to using a traditional chill in casting?

A4: The cooling rate in laser remelting is extremely rapid and much higher than with a conventional chill. The bulk of the casting acts as a perfect, massive heat sink in intimate contact with the tiny molten pool, extracting heat almost instantaneously. This "self-quenching" is what enables the formation of the ultra-fine dendritic structure with a DAS of just 2-3 µm, a level of refinement that is not achievable even with the most effective metallic chills in a direct casting process.

Q5: The study was performed on a machined surface. Can this process be applied to as-cast surfaces?

A5: The paper explicitly states that these enhanced local properties should be considered for application on the surfaces of non-machined castings. While the experiment was conducted on a prepared surface for control, the intention is to use this technology on as-cast surfaces to leverage the excellent surface layer properties without the need for subsequent machining, potentially saving manufacturing steps and costs.

Q6: What is the next step for this research?

A6: The authors state in the conclusion that the next stage of their planned study will focus on the tribological properties of the remelted zones. Having established the ability to create a harder, finer microstructure, the next logical step is to quantify the practical improvement in wear resistance that this new surface provides.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of pushing beyond the limits of conventional casting is critical for innovation in high-performance industries. This research demonstrates a powerful and precise solution: using laser surface remelting to engineer a superior Aluminum Casting Microstructure on critical surfaces. The key breakthrough—a tenfold reduction in Dendrite Arm Spacing and a corresponding leap in hardness—opens new possibilities for creating components that are more durable, wear-resistant, and reliable. The successful validation with CAFE simulation further provides a pathway for optimizing this process efficiently.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Cellular Automaton Finite Element Method Applied for Microstructure Prediction of Aluminium Casting Treated by Laser Beam" by "J. Hajkowski, P. Popielarski, Z. Ignaszak".

Source: 10.24425/afe.2019.129620

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.