산업경영시스템학회지 = Journal of society of Korea industrial and systems engineeringv.40 no.1 , 2017년, pp.35 - 40 권홍규 (남서울대학교 산업경영공학과)

Abstract

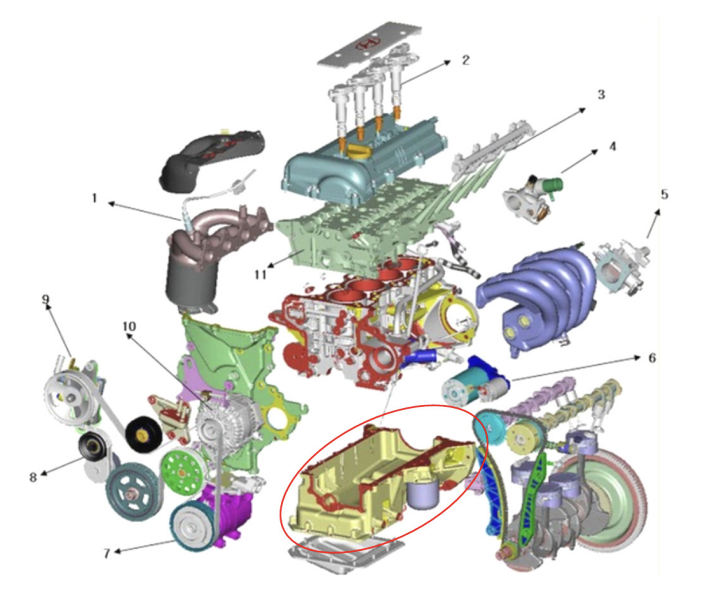

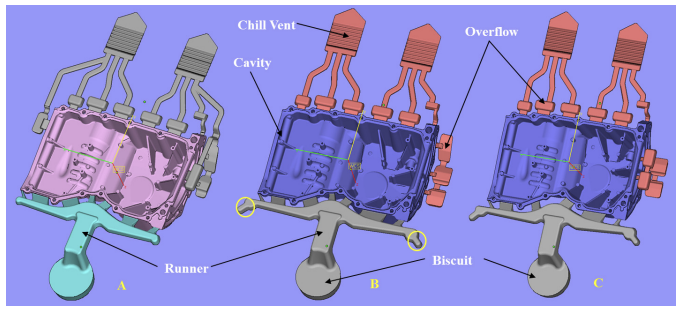

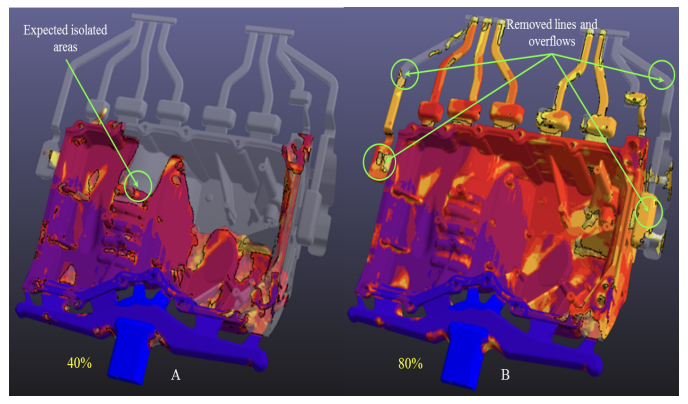

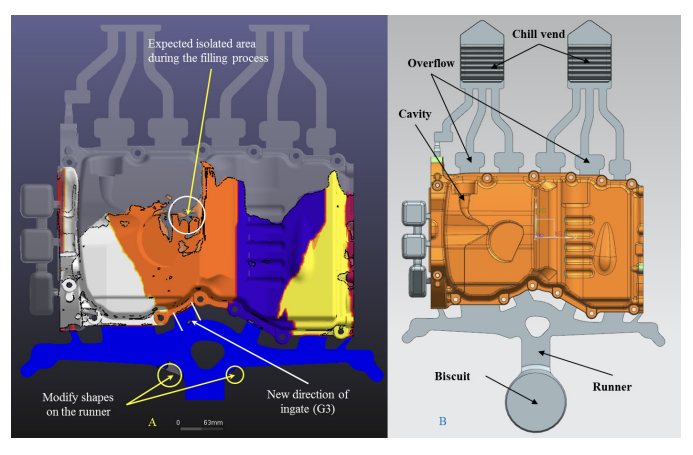

A most important progress in civilization was the introduction of mass production. One of main methods for mass production is die-casting molds. Due to the high velocity of the liquid metal, aluminum die-casting is so complex where flow momentum is critical matter in the mold filling process. Actually in complex parts, it is almost impossible to calculate the exact mold filling performance with using experimental knowledge. To manufacture the lightweight automobile bodies, aluminum die-castings play a definitive role in the automotive part industry. Due to this condition in the design procedure, the simulation is becoming more important. Simulation can make a casting system optimal and also elevate the casting quality with less experiment. The most advantage of using simulation programs is the time and cost saving of the casting layout design. For a die casting mold, generally, the casting layout design should be considered based on the relation among injection system, casting condition, gate system, and cooling system. Also, the extent or the location of product defects was differentiated according to the various relations of the above conditions. In this research, in order to optimize the casting layout design of an automotive Oil Pan_BR2E, Computer Aided Engineering (CAE) simulation was performed with three layout designs by using the simulation software (AnyCasting). The simulation results were analyzed and compared carefully in order to apply them into the production die-casting mold. During the filling process with three models, internal porosities caused by air entrapments were predicted and also compared with the modification of the gate system and overflows. With the solidification analysis, internal porosities occurring during the solidification process were predicted and also compared with the modified gate system.

Keywords

#Oil Pan #Gate System #Casting Layout #CAE Simulation #Melt Flow

References

- 1. Garber, L.W., Theoretical analysis and experimental observation of air entrapment during cold chamber filling, Die Casting Engineer, 1980, Vol. 24, No. 2, pp. 24-26.

- 2. Hong, S.K., Series I : Melting and casting of Aluminum Alloys, Journal of The Korea Foundry Society, 2008, Vol. 28, No. 2, pp. 45-51.

- 3. Information on Anycasting, http://anycastsoftware.com/en/software/fluid.php, 2013.

- 4. Jang, I.K. and Lee, M.S., A Study on the advanced verified process for the optimum production of automobile parts; Methodology linking the QUEST & Time-Prism, Journal of the Korea Institute of Plant Engineering, 2015, Vol. 20, No. 1, pp. 91-99.

- 5. Jeong, M.G. and Kwon, H.K., A Case Study for Developing Automobile Part (Housing) by Filling and Solidification Analysis, Journal of the Society of Korea Industrial and Systems Engineering, 2015, Vol. 38, No. 1, pp. 44-51. 원문보기 상세보기

- 6. Kim, E.S., Park, J.Y., Kim, Y.H., Son, G.M., and Lee, K.H., Evaluation of Diecasting Mold Cooling Ability by Decompression Cooling System, Journal of The Korea Foundry Society, 2009, Vol. 29, No. 5, pp. 238-243.

- 7. Kim, Y.C., Choi, S.W., Cho, J.I., Jeong, C.Y., and Kang, C.S., Optimization of the Thin-walled Aluminum Die Casting Die Design by Solidification Simulation, Journal of The Korea Foundry Society, 2008, Vol. 28, No. 4, pp. 190-194.

- 8. Kwon, H.K. and Jang, M.K., Case Study for Developing Automobile Part(Steering Wheel) using Vacuum Die-Casting Mold, Journal of the Society of Korea Industrial and Systems Engineering, 2012, Vol. 35, No. 2, pp. 195-202.

- 9. Kwon, H.Y., Yoon, T.H., and Lee, B.J., Computer Simulation on the High-Pressure Die Casting (HDPC) Process by Filling and Solidification Analysis, International Journal of Applied Engineering Research, 2015, Vol. 10, No. 90, pp. 142-145.

- 10. Park, J.Y., Kim, E.S., Park, Y.H., and Park, I.M., Optimization of Casting Design for Automobile Transmission Gear Housing by 3D Filling and Solidification Simulation in Local Squeeze Diecasting Process, Korean Journal of Materials Research, 2006, Vol. 16, No. 11, pp. 668-675.

- 11. Park, Y.K. and Yang, J.M., Scheduling of a Casting Sequence Under Just-In-Time(JIT) Production, Journal of the Society of Korea Industrial and Systems Engineering, 2009, Vol. 32, No. 3, pp. 40-48.

- 12. Shin, H.W., Chung, Y.J., and Kang, S.G., A Study on Die Casting Process of the Automobile Oil Pan Using the Heat Resistant Magnesium Alloy, Journal of KSEM, 2009, Vol. 17, No. 3, pp. 45-53.