This technical summary is based on the academic paper "Quality Assurance Testing for Screening Defective Aluminum Die-cast Rotors of Squirrel Cage Induction Machines" published by Jeong, M., Yun, J., Park, Y., Lee, S.B. and Gyftakis, K. in IEEE (2017). It was analyzed and summarized for HPDC experts by CASTMAN with the support of AI.

Keywords

Primary Keyword: aluminum die-cast rotor testing

Secondary Keywords: rotor porosity, quality assurance, flux injection test, squirrel cage induction motor, non-destructive testing, HPDC defects

Executive Summary

The Challenge: Porosity is an unavoidable defect in aluminum die-cast rotors that degrades motor performance and reliability.[1][2] Traditional quality assurance methods are often expensive, insensitive to minor or distributed porosity, or unable to detect certain fault patterns, making comprehensive screening difficult.[1]

The Method: Researchers developed a new off-line quality assurance test using an electromagnetic flux injection probe.[1][2] The test is performed on rotors after casting but before assembly. By exciting individual rotor bars and measuring changes in equivalent resistance (Req), the method can identify both localized and distributed porosity.[1]

The Key Breakthrough: This flux injection method provides a quantitative assessment of rotor bar condition with high sensitivity.[1] It successfully detects defects that are missed by other methods, such as symmetric faults, and can also assess the overall porosity level of the entire rotor cage.[1]

The Bottom Line: The proposed aluminum die-cast rotor testing method offers a more reliable and sensitive way to screen for porosity during manufacturing. This research suggests that integrating this test could significantly improve quality control, reduce field failures, and provide valuable data for process optimization in HPDC operations.

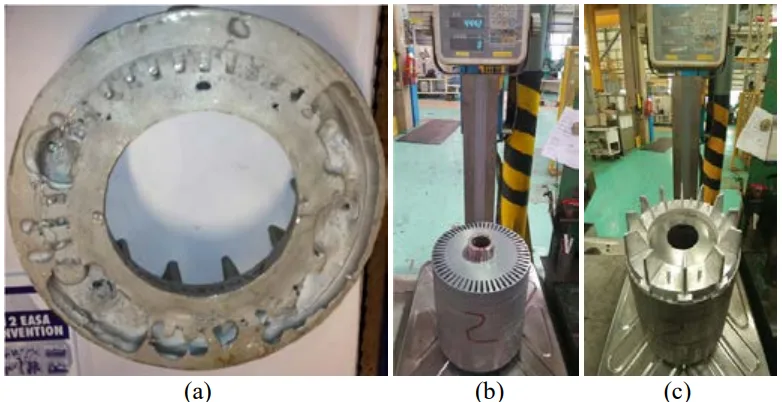

The Challenge: Why This Research Matters for HPDC Professionals

In the manufacturing of squirrel cage induction motors, aluminum die-cast rotors have become a mainstay for cost-competitiveness. However, the die-casting process inevitably introduces defects, with porosity being a primary concern.[1] As aluminum shrinks by approximately 6% in volume during cooling, voids and pores can form within the rotor bars and end rings.[1] This porosity increases rotor resistance and asymmetry, leading to degraded motor efficiency, torque pulsation, and increased vibration.[1]

For HPDC professionals, the challenge lies in effectively detecting this porosity. Existing methods have significant drawbacks:

- Weight Measurement & X-Ray Scanning: While accurate, these methods are too costly and slow for 100% inspection, limiting their use to sample-based process qualification.[1]

- Motor Current Signature Analysis (MCSA) & Single-Phase Rotation Tests: These on-line or assembled tests lack the sensitivity to detect minor, distributed, or symmetrically located porosity that doesn't produce a clear asymmetric signal.[1]

- Traditional Growler Tests: These are often simple pass/fail tests and cannot provide a quantitative measure of distributed porosity below a certain threshold.[1]

These limitations mean that rotors with subtle but significant porosity can pass inspection, potentially leading to performance issues or premature failure in high-output motors.

The Approach: Unpacking the Methodology

The researchers proposed a new off-line flux injection test designed to overcome the limitations of existing methods. The test is performed directly on the aluminum die-cast rotor after manufacturing, and can be integrated into the rotor balancing stage.[1]

The setup consists of a U-shaped electromagnetic probe that is placed near the rotor surface, as shown in the test schematic (Fig. 5). As the rotor is turned, the probe injects a magnetic flux into each rotor bar individually. By processing the probe's voltage and current, the system calculates the equivalent resistance (Req) for that specific section of the rotor cage.[1]

The core principle is that porosity or other defects in a rotor bar will increase its electrical resistance. This change is detected as a local increase in the measured Req value. By plotting Req as a function of the rotor's position, a detailed profile of the entire rotor cage's integrity can be created. This approach allows for the separation of resistive changes (due to porosity) from reactive changes (due to airgap variations), increasing sensitivity.[1]

The Breakthrough: Key Findings & Data

The study validated the method through both 3D Finite Element Analysis (FEA) and experimental testing on 5.5 kW motor rotors.

Finding 1: The method accurately detects localized defects with proportional severity.

The 3D FEA simulation showed a clear, localized increase in Req when the probe passed over a defective bar. A bar with emulated porosity caused a 5.1% increase in Req, while a fully broken bar caused a 13.5% increase, confirming the test's ability to quantify defect severity (Fig. 9).[1]

Finding 2: The flux injection test identifies symmetric defects invisible to other methods.

In a comparative test, two broken bars were created 90 electrical degrees apart to create a symmetric fault. MCSA was unable to reliably detect this condition, with the fault signal dropping from -48.8 dB (one broken bar) to -54.6 dB (two broken bars), which is close to the healthy rotor signal of -56.8 dB (Fig. 14(a)). The proposed test, however, clearly identified both defects as distinct peaks in the Req measurement (Fig. 14(c)).[1]

Finding 3: The test can quantify overall, distributed porosity.

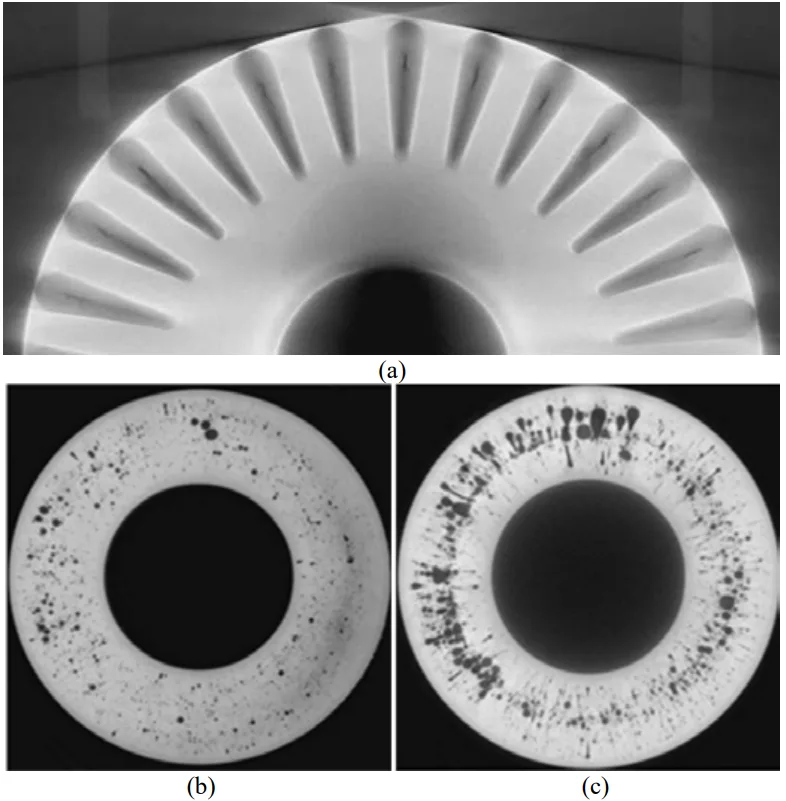

By drilling holes in an end ring to emulate uniformly distributed porosity, researchers found that the average Req value for the entire rotor increased significantly. Removing just 0.8% of the aluminum material led to a 10.6% increase in the average Req (from 0.923 Ω to 1.021 Ω) (Fig. 15). This demonstrates its potential for screening out rotors with a low fill factor, even if there are no single large defects.[1]

Practical Implications for HPDC Products

This research into advanced aluminum die-cast rotor testing has direct and practical implications for HPDC manufacturers and their customers.

For Process Engineers:

This study suggests that the flux injection method could provide a quantitative, bar-by-bar quality metric. This data could be correlated with HPDC process parameters (e.g., injection pressure, temperature, die design) to better understand and control the conditions that lead to porosity.

For Quality Control:

The findings indicate the potential benefit of integrating this test into the post-manufacturing balancing station. It offers a sensitive, quantitative, and automated method for 100% inspection, capable of catching distributed and symmetric porosity that other common tests like MCSA might miss, as highlighted in Fig. 14.[1]

For Die Design:

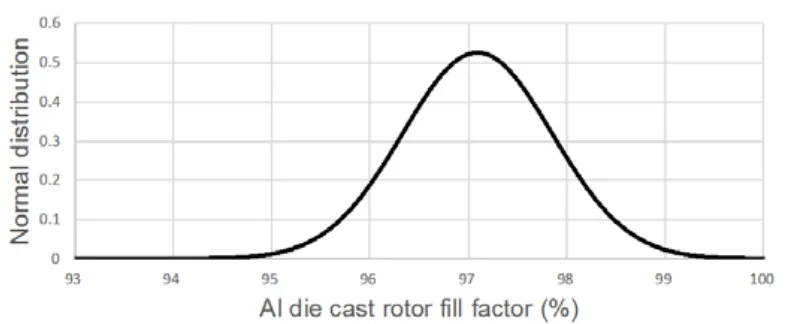

The paper's X-ray scans show that porosity is often concentrated in the center of rotor bars and on the inside of the end ring near the rotor core (Fig. 3).[1] This insight, combined with quantitative data from the proposed test, could provide valuable feedback for optimizing die and gating designs to improve metal flow and reduce porosity in these critical areas.

Paper Details

Title

Quality Assurance Testing for Screening Defective Aluminum Die-cast Rotors of Squirrel Cage Induction Machines

Author

Jeong, M., Yun, J., Park, Y., Lee, S.B. and Gyftakis, K.

Year

2017

Journal/academic society

IEEE

Keywords

Aluminum Die-cast Rotor, Fault Detection, Induction Machines, Porosity, Quality Assurance, Squirrel Cage Rotor

Abstract

The paper proposes a new off-line test method using flux injection to provide a sensitive assessment of porosity in aluminum die-cast squirrel cage rotors. It demonstrates that the method can screen out rotors with minor and distributed porosity that are difficult to detect with other tests. The approach is verified through 3D finite element analysis and experimental testing on 5.5 kW induction motor rotors.[1]

Introduction

The introduction highlights the industry trend of using aluminum die-cast rotors for cost-competitiveness and notes that porosity is an inevitable manufacturing defect that degrades motor performance and reliability.[1] It reviews existing quality assurance tests, pointing out their limitations in terms of cost, sensitivity, or inability to provide quantitative assessments, thereby establishing the need for a new method.[1]

Summary of the Study

The study details the development and validation of an off-line quality assurance test based on electromagnetic flux injection. A probe excites individual rotor bars, and the resulting change in equivalent resistance (Req) is measured to detect local and distributed porosity. The method's effectiveness was confirmed with 3D FEA simulations and experimental tests on rotors with intentionally introduced defects. Results showed superior sensitivity compared to conventional methods, especially for symmetric faults and distributed porosity.[1]

Methodology

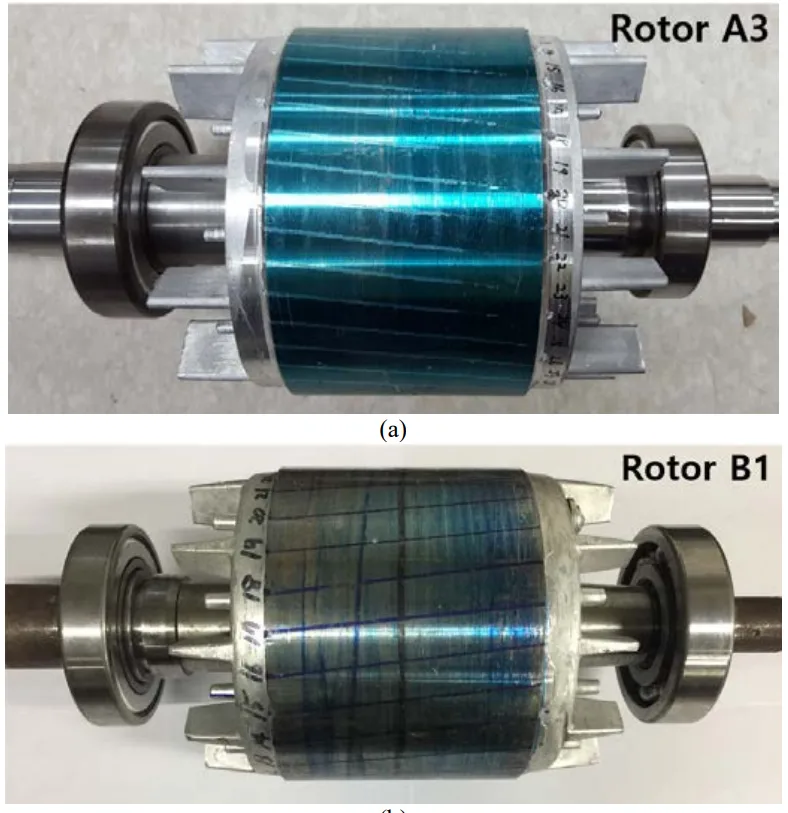

The proposed test uses a U-shaped electromagnetic probe to inject flux into the rotor surface while the rotor is rotated. The probe's voltage and current are measured to calculate the equivalent impedance (Zeq), from which the equivalent resistance (Req) is derived (Fig. 6).[1] An increase in Req indicates a local defect like porosity. For validation, defects were emulated in 44-bar semi-open slot and 28-bar closed slot rotors by drilling holes to break bars or reduce material in the end ring.[1] These rotors were then tested and compared against results from MCSA and single-phase rotation tests.[1]

Key Results (with figure list)

The key results demonstrate the method's high sensitivity. 3D FEA predicted a 5.1% Req increase for porosity and a 13.5% increase for a broken bar (Fig. 9). Experimentally, the test clearly detected damaged bars in both semi-open and closed slot rotors (Fig. 13). Critically, it identified two symmetric broken bars that were not clearly observable with MCSA (Fig. 14). The test also showed that average Req increases with distributed porosity, with a 10.6% increase for a 0.8% material loss (Fig. 15).[1]

Conclusion

The paper concludes that the proposed off-line flux injection test is an effective method for obtaining a quantitative measure of individual rotor bar conditions, allowing for sensitive detection of both concentrated and distributed porosity.[1] It was shown to detect defects that are not observable with existing test methods. The method can be used during post-manufacturing balancing and can be applied to both closed and open slot rotor designs to prevent low-performance motors or costly outages due to rotor defects.[1]

References (exactly as in paper)

[1] A.H. Bonnett, and T. Albers, "Squirrel-cage rotor options for AC induction motors," IEEE Trans. Ind. Appl., vol. 37, no. 4, pp. 1197-1209, Jul. 2001.

[2] S. Williamson, R.C. Healey, J.D. Lloyd, and J.L. Tevaarwerk, "Rotor cage anomalies and unbalanced magnetic pull in single-phase induction motors," IEEE Trans. on Ind. Appl., vol. 33, no. 6, pp. 1553-1562, Nov./Dec. 1997.

[3] W.R. Finley, and M.M. Hodowanec, "Selection of copper versus aluminum rotors for induction motors," IEEE Trans. on Ind. Appl., vol. 37, no. 6, pp. 1563-1573, Nov/Dec 2001.

[4] J.H. Dymond and R.D. Findlay, "Some commentary on the choice of rotor bar material for induction motors," IEEE Trans. on Energy Convers., vol. 10, no. 3, pp. 425-430, Sept. 1995.

[5] H.J. Ahn, K.W. Kim, J.H. Choi, E.S. Kim, Y.C. Lim, "Rotor design for an efficient single-phase induction motor for refrigerator compressors," Energies, vol. 9(3) 158, pp. 1-16, 2016.

[6] J. Yun, S. Lee, M. Jeong, S.B. Lee "Influence of die-cast rotor fill factor on the starting performance of induction machines," Proc. of Compumag, June 2017.

[7] W.T. Thomson, and M. Fenger, "Current signature analysis to detect induction motor faults," IEEE Ind. Appl. Mag., vol. 7, no. 4, pp. 26-34, July/Aug. 2001.

[8] S.B. Lee, D. Hyun, T. Kang, C. Yang, S. Shin; H. Kim, S. Park, T. Kong, H. Kim, "Identification of false rotor fault indications produced by on-line MCSA for medium voltage induction machines," IEEE Trans. on Ind. Appl., vol. 52, no.1, pp. 729-738, Jan./Feb. 2016.

[9] G.C. Stone, I. Culbert, E.A. Boulter, and H. Dhirani, Electrical insulation for rotating machines - design, evaluation, aging, testing, and repair, IEEE Press Series on Power Eng., John Wiley and Sons, 2014.

[10] T. Bishop, "Squirrel cage rotor testing," Proc. of EASA Conv., June 2003.

[11] D. Hyun, S. Lee, J. Hong, S.B. Lee, S. Nandi, "Detection of Airgap Eccentricity for Induction Motors using the Single Phase Rotation Test," IEEE Trans. on Energy Convers., vol. 27, no. 3, pp. 689-696, Sept. 2012.

[12] T. Kang, J. Kim, S.B. Lee, and C. Yung, "Experimental evaluation of low voltage off-line testing for induction motor rotor fault diagnostics," IEEE Trans. on Ind. Appl., vol. 51, no. 2, pp. 1375-1384, Mar./Apr. 2015.

[13] S.W. Clark, and D. Stevens, "Squirrel cage induction motor cast rotor defect detection with magnetic field analysis," in Proc. Int. Conf. Elect. Mach. Syst. (ICEMS'15). Oct. 25-28, 2015, Paper 27P4-9.

[14] S. W. Clark, "A new method of testing rotor bars," Elect. Apparatus, vol. 68, pp. 29-33, Sep. 2015.

[15] S.W. Clark, D. Stevens, "Induction motor rotor bar damage evaluation with magnetic field analysis," IEEE Trans. Ind. Appl., vol. 52, no. 2, pp. 1469-1476, Mar./Apr. 2016.

[16] S.L. Nau, et. al., "Methods to evaluate the quality of stator and rotor of electric motors," Proc. of IEEE SDEMPED, pp. 64-70, Aug. 2015.

[17] J.R. Cameron, W.T. Thomson, and A.B. Dow, "Vibration and current monitoring for detecting airgap eccentricity in large induction motors," Proc. Inst. Elect. Eng., vol. 133, pt. B, no. 3, pp. 155-163, May 1986.

[18] D.G. Dorrell, W.T. Thomson, and S. Roach, "Analysis of airgap flux, current, and vibration signals as a function of the combination of static and dynamic airgap eccentricity in 3 phase induction motors," IEEE Trans. Ind. Appl., vol. 33, no. 1, pp. 24-34, Jan./Feb. 1997.

Expert Q&A: Your Top Questions Answered

Q1: Can this test method detect internal porosity that isn't visible on the rotor surface?

A1: Yes, the study strongly indicates it can. The X-ray scans shown in Fig. 3 demonstrate that porosity is often concentrated in the center of the bars and end rings, not on the surface. Since the flux injection method measures the electrical resistance of the entire bar cross-section under the probe, it is sensitive to these internal-only voids that would be missed by a visual inspection.[1]

Q2: How does this method handle closed-slot rotors where the rotor bars are not exposed?

A2: The method is effective for closed-slot rotors, but it requires a higher excitation voltage. The paper explains that a higher voltage is needed to saturate the thin "slot bridge" of material covering the bar. This saturation forces the magnetic flux to penetrate deeper into the rotor bar itself, allowing the test to accurately measure the bar's resistance and detect porosity. The experimental results on a closed slot rotor (Rotor B1) in Fig. 13(b) confirm its effectiveness.[1]

Q3: Is this test just for go/no-go screening, or can it provide more detailed quality data?

A3: It provides detailed, quantitative data far beyond a simple pass/fail result. The test generates a resistance profile (Req) for the entire rotor, as seen in Fig. 14(c). Furthermore, by monitoring the average Req value across all bars, as shown in Fig. 15, quality teams can assess the overall fill factor and detect distributed porosity. This quantitative approach allows for setting precise quality thresholds and screening out units with high overall porosity levels.[1]

Q4: How does this test compare to Motor Current Signature Analysis (MCSA), a widely used electrical test?

A4: This proposed off-line test demonstrates a significant advantage over MCSA in specific scenarios. The paper shows that MCSA can fail to detect symmetric faults, such as two broken bars located 90 electrical degrees apart, because the asymmetries cancel each other out (Fig. 14(a)). The flux injection method, by scanning each bar individually, reliably detects both defects (Fig. 14(c)), preventing a false negative alarm and ensuring a more robust quality check.[1]

Q5: Can this method distinguish between a small, severe defect and a larger area of minor porosity?

A5: The method provides data that helps distinguish between these two cases. A small, severe defect like a broken bar will produce a sharp, high-magnitude peak in the Req measurement localized to one or two bars (as seen in Fig. 13). In contrast, a larger area of distributed porosity will cause a moderate increase in the average Req value across the entire rotor, without necessarily showing sharp peaks (as demonstrated in Fig. 15). By analyzing both the localized peaks and the overall average Req, an assessment of both defect types can be made.[1]

Conclusion & Next Steps

The challenge of detecting hidden porosity in high-pressure die castings is a critical hurdle in manufacturing high-performance motor rotors. This research introduces a highly sensitive aluminum die-cast rotor testing method that provides a quantitative and reliable way to screen for both localized and distributed defects. By moving beyond traditional pass/fail tests and insensitive electrical signature analysis, this flux injection technique offers a path to higher quality assurance and greater product reliability.

At CASTMAN, we are committed to applying the latest industry research to help customers achieve higher productivity and quality. If the issues discussed in this paper align with your operational goals, contact our engineering team to explore how we can implement these principles in your HPDC components.

Copyright

This material is a paper by "Jeong, M., Yun, J., Park, Y., Lee, S.B. and Gyftakis, K.". Based on "Quality Assurance Testing for Screening Defective Aluminum Die-cast Rotors of Squirrel Cage Induction Machines".

Source: https://dx.doi.org/10.1109/DEMPED.2017.8062361

Copyright © 2025 CASTMAN. All rights reserved.

Sourceshelp

- 3phi-reliability.com

- researchgate.net

- ed.ac.uk

- coventry.ac.uk

- yzdiecasting.com

- deltatronic.com

- deltatronic.com

- coventry.ac.uk

- aalto.fi

- researchgate.net

- aston.ac.uk

- researchgate.net

- voliro.com

- rotorcraftsupport.com

- rowtest.com

- chinatestequipments.com

- castman.co.kr

- whiterose.ac.uk