Optimize Automotive Die Casting: A Guide to Simulation for Defect Reduction and Efficiency

This technical summary is based on the academic paper "Apply simulation application optimize production process for car industry" by Phan Van Tong.

Keywords

- Primary Keyword: Die Casting Simulation

- Secondary Keywords: HPDC, process optimization, automotive casting, porosity defects, stress analysis, solidification simulation

Executive Summary

- The Challenge: The increasing complexity of automotive components produced via High Pressure Die Casting (HPDC) leads to a higher risk of manufacturing defects like porosity and cracking, which compromise performance and increase costs.

- The Method: The research leverages process simulation software to create a digital twin of the die-casting process, analyzing critical phases like mold filling, solidification, and stress formation.

- The Key Breakthrough: Die Casting Simulation accurately predicts the location and type of defects—including gas porosity, shrinkage, and hot tears—by analyzing the interplay of gating design, filling dynamics, and thermal conditions.

- The Bottom Line: Proactively using simulation enables engineers to optimize die and process parameters before manufacturing begins, dramatically reducing scrap rates, shortening development cycles, and ensuring higher-quality final components.

The Challenge: Why This Research Matters for HPDC Professionals

In the competitive automotive industry, mass-producing parts from aluminum, magnesium, and zinc alloys via HPDC is standard practice. This method is valued for its ability to create complex shapes with high precision and cost-efficiency. However, as part designs become more intricate to meet demands for light-weighting and performance, the manufacturing process becomes fraught with challenges.

The complexity of a part is a major factor in its manufacturability. Intricate geometries can lead to a variety of defects, including porosity, incomplete filling, and high residual stresses that can cause cracks. Key process and design parameters—such as runner position, gating location, molten metal temperature, and die surface temperature—must be perfectly optimized to minimize these defects. Traditionally, this optimization has relied on trial-and-error, a costly and time-consuming approach. This paper explores how simulation provides a data-driven, predictive solution to this critical industry problem.

The Approach: Unpacking the Methodology

The study outlines a systematic approach to optimizing the HPDC process using computational simulation. This method transforms a 3D CAD model into a dynamic digital prototype, allowing for in-depth analysis before any metal is poured.

Method 1: Pre-Processing and Enmeshment

The process begins with a complete 3D model of the casting, which includes the part itself, in-gates, overflows, vacuum channels, and die segments. This entire assembly is then "enmeshed," or broken down into a fine grid of elements (using finite volume or finite element methods). This mesh forms the foundation for the mathematical calculations that drive the simulation.

Method 2: Full-Process Simulation

State-of-the-art simulation software is used to model the entire casting cycle. This is not limited to just one phase but provides a holistic view:

- Die Filling: Simulates the high-speed injection of molten metal (30-140 m/s), visualizing the turbulent, multi-phase flow to identify potential air entrapment and uneven filling patterns.

- Solidification: Models the cooling and phase change from liquid to solid, identifying "hot spots" where shrinkage porosity is likely to form.

- Stress Analysis: Calculates the formation of residual stresses and distortion as the part cools, predicting areas at risk for hot tears or cracks.

Method 3: Post-Processing and Evaluation

The simulation results are prepared in colored graphics and animations. This visualization allows engineers to easily interpret complex data, document operations, and compare the outcomes of different design iterations (e.g., changes to gating or cooling lines). This data-driven evaluation enables sound decision-making to improve the final product.

The Breakthrough: Key Findings & Data

The research demonstrates that simulation is not just a theoretical tool but a powerful predictive instrument for solving real-world casting problems.

Finding 1: Gating System Design is Crucial for Flow Control

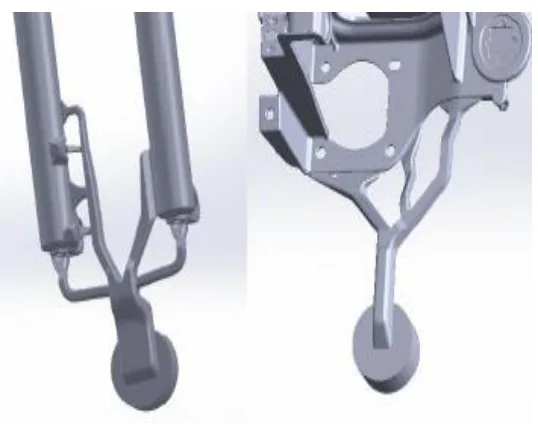

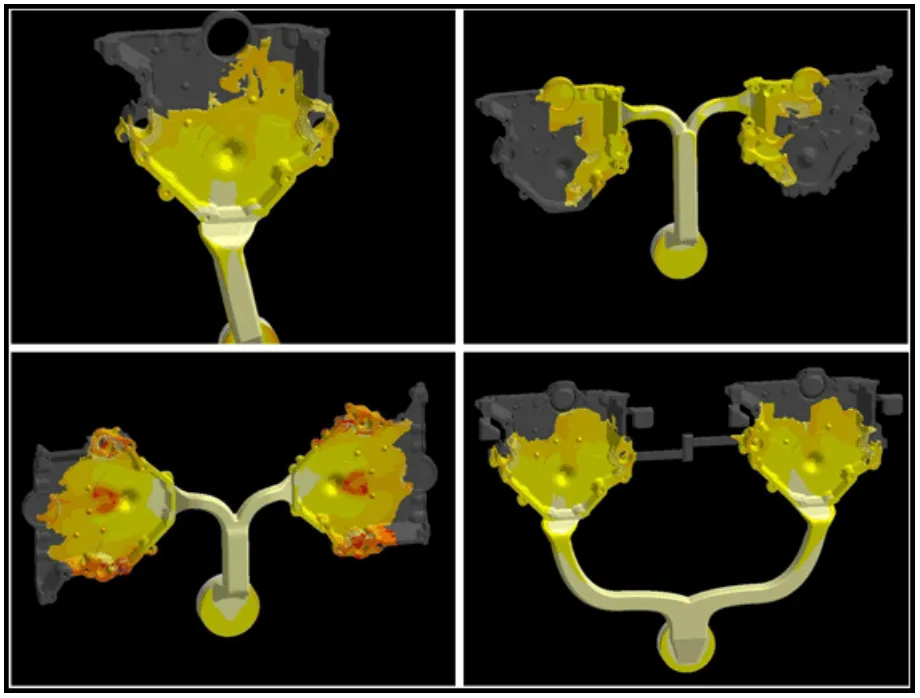

The simulation of the filling process reveals how critical the gating system is to casting quality. As shown in Figure 5, which visualizes the filling of a real casting, simulation allows engineers to evaluate how different gating designs affect the flow of molten metal. The goal is to reduce turbulence, which can cause entrapped gas, and to ensure the melt fronts merge in a controlled manner. Figure 2 illustrates different gating system concepts that can be tested virtually to find the optimal design for consistent flow velocity and proper cavity filling.

Finding 2: Accurate Prediction of Porosity and Cracking Defects

Simulation provides a clear roadmap to potential defect locations, which has been validated against real-world parts.

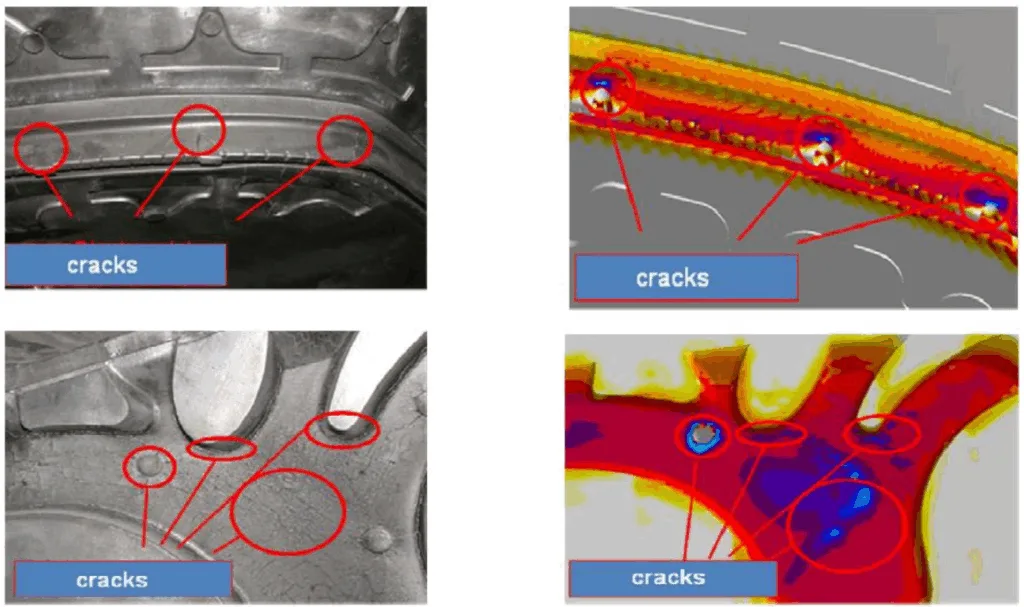

- Hot Tears: As seen in Figure 7, the simulation accurately predicts "Critical areas for hot tears," which correspond directly to defects found on the actual cast part. This allows for design modifications to mitigate stress concentrations in these zones.

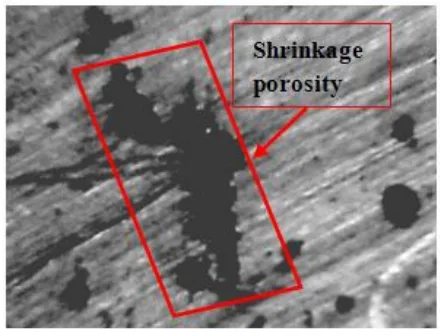

- Porosity: The paper explains how simulation can distinguish between gas porosity (from trapped air) and shrinkage porosity (from inadequate feeding during solidification). By analyzing filling patterns and solidification times, engineers can address the root causes, such as poor venting or thick sections that create isolated hot spots.

- Residual Stress Cracks: Figure 10 provides a compelling comparison of cracks predicted by stress simulation and actual cracks found in a cast engine block. The simulation identifies high-tensile-stress areas that are prone to failure, confirming that design (80%) is a greater factor than the casting process (20%) in stress formation.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting shot end parameters (first and second stage velocity), die temperature, and intensification pressure may contribute to reducing gas and shrinkage porosity. The detailed cause-and-effect lists in the paper provide a powerful diagnostic tool.

- For Quality Control Teams: The data in Figure 7 (hot tears) and Figure 10 (cracks) of the paper illustrates the effect of thermal and mechanical stress on defect formation, which could inform new, targeted quality inspection criteria for high-risk areas.

- For Design Engineers: The findings indicate that part geometry, specifically wall thickness variations, could influence defect formation during solidification. The paper's conclusion that design accounts for 80% of residual stress suggests that running simulations in the early design phase is invaluable for creating robust, manufacturable components.

Paper Details

Apply simulation application optimize production process for car industry

1. Overview:

- Title: Apply simulation application optimize production process for car industry

- Author: Phan Van Tong

- Year of publication:

- Journal/academic society of publication:

- Keywords: simulation, optimization, die-casting, production, stress analysis

2. Abstract:

This The paper discusses the role of process simulation in the automotive industry. Real-world applications of simulation in the die-casting plant car engine. Uses of simulation during the different phases of the process such as flow distribution, porosity, solidification, stress analysis. The result of this simulation will confirm that the finished components of engine block whether can perform in high efficiency operation or not. The limitation of simulation application is accuracy which depend on the experience of engineers and computer's capacity.

3. Introduction:

The high-pressure die-cast (HPDC) process is widely used for mass production of complex, high-precision parts for the automotive industry from aluminum, magnesium, copper, and zinc. The process involves injecting molten metal at high pressure into a die, where it fills the cavity, overflows, and vents. Various parameters, including initial shot speed, gating design, part geometry, filling time, and die temperature, influence the quality of the final part. When new parts with complex shapes are designed, they are susceptible to an increased number of manufacturing defects. Therefore, die-cast design and production parameters must be optimized. This research studies the effect of these parameters on part defects and utilizes software simulation to predict outcomes.

4. Summary of the study:

Background of the research topic:

The study is set against the backdrop of the automotive industry's reliance on the HPDC process for manufacturing millions of parts. The inherent complexity of modern components necessitates advanced methods to control production and ensure part integrity, as defects like porosity and cracks can compromise performance.

Status of previous research:

The literature review section references foundational theories of solidification and defect formation in the HPDC process, such as shrinkage porosity and nucleation models. It also acknowledges the use of established simulation software packages like ProCast and MAGMAsoft 3D FLOW for investigating casting processes and mentions the use of the AlSi binary phase diagram for understanding the solidification behavior of aluminum-silicon alloys.

Purpose of the study:

The purpose of this paper is to discuss and demonstrate the role of process simulation in optimizing the die-casting production process for the automotive industry. It aims to show how simulation of flow distribution, porosity formation, solidification, and stress analysis can be used to predict and improve the performance and efficiency of finished components, such as engine blocks.

Core study:

The core of the study is the application of computational simulation to analyze and optimize the HPDC process. The paper examines the entire simulation workflow, from 3D model enmeshment ('pre-processing') to the simulation of critical sub-processes like die filling and solidification, and finally to the evaluation of results ('post-processing'). It uses visual examples of simulations for various parts (wheel, engine components) to illustrate the prediction of flow patterns, filling times, hot tears, and cracks. The study also provides a comprehensive analysis of the causes of different porosity types (gas, shrinkage) and links them to specific design and process parameters that can be controlled.

5. Research Methodology

Research Design:

The paper employs a descriptive and illustrative research design. It explains the principles and applications of simulation in HPDC and uses a series of case examples, figures, and comparisons between simulation results and real-world defects to demonstrate the effectiveness of the technology.

Data Collection and Analysis Methods:

The methodology is centered on the use of computational optimization software (e.g., MAGMAsoft). The process involves:

1. Creating and enmeshing a complete 3D model of the casting and die assembly.

2. Running simulations to calculate and visualize operations during die filling, solidification, and cooling.

3. Analyzing the results through post-processors that generate colored graphics and animations depicting phenomena like melt flow, temperature distribution, porosity formation, and residual stress.

The analysis is qualitative, based on comparing simulation predictions with photographs of actual casting defects.

Research Topics and Scope:

The research scope is focused on the application of simulation to optimize the HPDC process specifically for the car industry. The topics covered include:

- Simulation of the entire casting process.

- Analysis of melt flow in the gating system and die cavity.

- Prediction and mitigation of defects, including gas porosity, shrinkage porosity, leakers, hot tears, and cracks.

- Analysis of residual stresses in complex castings like engine blocks.

- The influence of design and process parameters on casting quality.

6. Key Results:

Key Results:

- Simulation of the die filling process is identified as critical for optimizing the gating system to reduce turbulence, avoid entrapped gas, and control the merging of melt fronts.

- The study demonstrates a strong correlation between simulation predictions and actual manufacturing defects. Figure 7 shows simulation accurately identifying critical areas for hot tears, and Figure 10 compares simulated stress concentrations with real cracks in an engine block.

- A detailed breakdown of the causes of porosity is provided. Gas porosity is linked to factors like poor shot control and venting, while shrinkage porosity is attributed to thick sections, hot spots, and an inability to feed the casting during solidification.

- The research highlights that residual stresses in castings are influenced far more by design (80%) than by the casting process itself (20%), underscoring the importance of performing simulation early in the design phase.

Figure Name List:

- Figure 1

- Figure 2: Different Gating systems for Aluminum casting parts

- Figure 3: Binary Phase diagram

- Figure 4

- Figure 5: Filling simulation of the real Casting

- Figure 6. Filling simulation of simple part compared with cutting part

- Figure 7: Compared simulation of the real Casting of hot tears

- Fig. 8. Air Porosity in the section of an aluminium diecast part

- Figure 9

- Figure 10: Simulation compared with real casting of cracks

- Figure 11 Stress for engine block.

7. Conclusion:

The paper concludes that there is a significant opportunity for foundries to add value by proactively using simulation. Instead of passively receiving designs, the foundryman can use simulation to provide prompt and capable input during the design phase, highlighting manufacturing requirements related to gating, cooling channels, and overflows. This collaborative approach, involving designers and foundrymen early in the development chain, leads to integrated cost awareness and the creation of more cost-effective, manufacturable automotive components. Foundries should embrace this proactive role to move beyond being simple "metal pourers" and become integral partners in the manufacturing chain.

8. References:

- Yang, X., Jolly, M., Campbell, J., “Minimization of Surface Turbulence During Filling Using a Vortex-Flow Runner", Aluminum Transactions, Volume

- 2, Number 1, 2000, pp. 67-80. 2. Osborne, M., "Lost Foam Casting", Seminar Presentation, The Ohio State University, February, 2004.

- Schwam, D., Chang, Q., Wallace, J., "Flow of Molten Aluminum in Vertical Permanent Molds; Real Time X-Rays and Simulation", Department of Energy, Research Project Progress Report, February, 2000.

- MAGMASOFT 4.4: Manual, 2005

- Hartmann, Götz, R. Seefeldt: „Die zweite Generation von Simulationswerkzeugen“ Giesserei 91, Nr. 2, S. 38 - 42, Februar 2004

- Hartmann, Götz, A. Egner-Walter: "Optimierte Entwicklung für Magnesium- Gussteile und Gießprozesse. Wertschöpfung durch Anwendung der geschlossenen Prozesskette in der Entwicklung von Magnesium- Gussteilen für die Automobilindustrie", Magnesium Taschenbuch, S. 446-449, September

- Haldenwanger, H.-G.: “Casting simulation as an innovation in the motor vehicle development process.", Modeling of Casting, Welding and Advanced Solidification Process IX, SIM 2000, edited by R. Sahm, P.N. Hansen, J.G. Conley, S.XLIV-LI August 2000

Expert Q&A: Your Top Questions Answered

Q1: What are the most critical sub-processes in HPDC that simulation helps analyze?

A1: The paper identifies the casting filling stage as the most critical and influential sub-process in high-pressure die casting. This phase is characterized by high velocities (30-140 m/s) and turbulent, multi-phase flow (liquid and gas). Simulation provides an invaluable tool to visualize and analyze this complex flow, allowing engineers to optimize gating to control turbulence and prevent defects. Beyond filling, simulation also analyzes solidification, microstructure formation, and the development of residual stress.

Q2: The paper mentions two main types of porosity. How does simulation help differentiate and address them?

A2: Simulation helps distinguish the root causes of the two main porosity types. It can predict gas porosity by analyzing air entrapment during the filling simulation, which can be caused by a poor gating design, ineffective venting, or improper shot end control. It predicts shrinkage porosity by running a solidification analysis to identify "hot spots"—thick sections that solidify last and cannot be fed with additional molten metal, leading to internal voids.

Q3: According to the paper, what is the primary cause of residual stresses in engine blocks, and how can simulation mitigate this?

A3: The paper states that residual stresses primarily develop due to uneven cooling rates across the casting's different wall thicknesses. It makes the critical point that the part's design is the dominant factor, accounting for 80% of the influence on these stresses. Simulation can mitigate this by being performed at an early stage of the design process, allowing engineers to make geometric modifications to balance cooling, reduce stress concentrations, and keep tensile stresses safely below the material's failure threshold.

Q4: What specific gating system parameters does the paper suggest are important to control for a successful casting?

A4: The paper emphasizes several key considerations for gating system design that can be evaluated with simulation. These include: reducing turbulences in the melt to avoid entrapped gas; timing the melt flow through the gate to allow for the controlled merging of melt fronts; ensuring flow velocities are consistent, especially when using fan ingates; and achieving the desired direction of melt flow into the cavity.

Q5: What is the role of 'enmeshment' in the simulation process described?

A5: Enmeshment, also referred to as 'pre-processing', is the foundational step for the mathematical calculation in the simulation. It involves creating a digital mesh of the complete 3D model, which includes the raw casting, in-gates, overflows, and die segments. This mesh, generated using either the finite volume method or the finite element method, divides the model into a large number of small elements where the physical equations for fluid flow and heat transfer are solved.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of producing complex, defect-free automotive components is a constant in the HPDC industry. This paper demonstrates that the key breakthrough lies in shifting from a reactive, trial-and-error approach to a predictive, data-driven one. By using Die Casting Simulation, manufacturers can virtually test and optimize every aspect of the process—from gating design to thermal management—before a single tool is cut. This proactive strategy is essential for mitigating costly defects like porosity and cracking, ultimately leading to higher quality, reduced scrap, and improved productivity.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Apply simulation application optimize production process for car industry" by "Phan Van Tong".

Source:

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.