Slash Cycle Times by 28%: How Additive-Made Conformal Cooling Channels Are Revolutionizing Die Casting

This technical summary is based on the academic paper "An experimental investigation of the cooling and heating performance of a gravity die casting mold with conformal cooling channels" published by Karani Kurtulus, Ali Bolatturk, Ahmet Coskun, and Barış Gürel in Applied Thermal Engineering (2021). It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: Conformal Cooling Channels

- Secondary Keywords: Gravity Die Casting, Additive Manufacturing, Mold Cooling, Cycle Time Reduction, Microstructure Quality, Die Casting Mold Design

Executive Summary

(In 3-4 bullet points, provide a high-level summary of the core problem, the approach taken, and the single most important finding. This is for the reader who only has 30 seconds.)

- The Challenge: Conventional, linearly drilled cooling channels in die casting molds lead to non-uniform cooling, causing defects like hot spots, increasing cycle times, and compromising part quality.

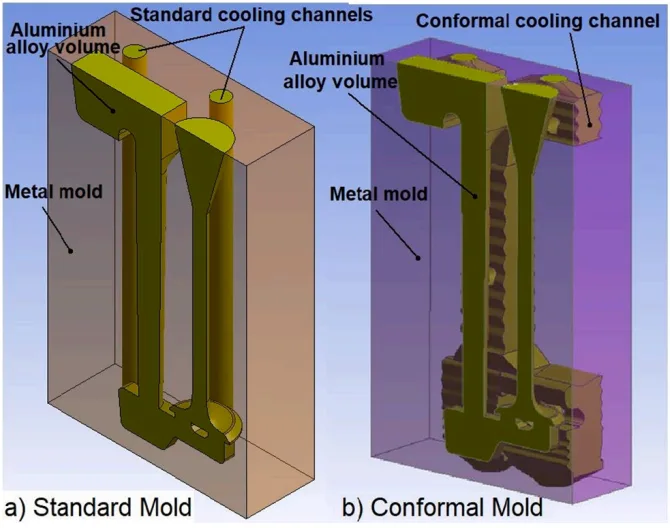

- The Method: Researchers designed and built two gravity die casting molds: a standard mold with linear cooling channels and a conformal cooling mold made with additive manufacturing (DMLS). They experimentally compared heating performance, cycle times, and the final cast part's microstructure.

- The Key Breakthrough: The mold with conformal cooling channels achieved a more homogeneous temperature distribution, resulting in a 28% shorter cycle time and a 13.5% smaller average grain size in the final product.

- The Bottom Line: Additive manufacturing enables the creation of complex conformal cooling channels that follow the part's geometry, dramatically improving cooling efficiency, reducing production time, and enhancing the mechanical properties of cast parts.

The Challenge: Why This Research Matters for HPDC Professionals

In any die casting operation, from gravity to high-pressure, cooling is king. It directly dictates production speed, unit cost, and the final quality of the cast component. For decades, engineers have been constrained by conventional manufacturing methods, forced to drill cooling channels in straight lines. This fundamental limitation means channels often cannot reach critical areas of the mold, such as near complex features, cores, or pusher pins (Ref. [1]).

The result is non-homogeneous cooling. Some areas of the mold run too hot, creating "hot spots" that lead to shrinkage, porosity, and distortions in the final part. Other areas may be over-cooled. This thermal imbalance not only increases defect rates but also extends the cycle time needed for the part to solidify properly, directly impacting throughput and profitability (Ref. [2]). This study tackles this core industry challenge head-on by exploring a game-changing solution: conformal cooling.

The Approach: Unpacking the Methodology

To quantify the benefits of conformal cooling, the researchers conducted a direct, side-by-side comparison.

They designed two symmetrical molds to produce an Al-6061 alloy exhaust poppet valve (Figure 1).

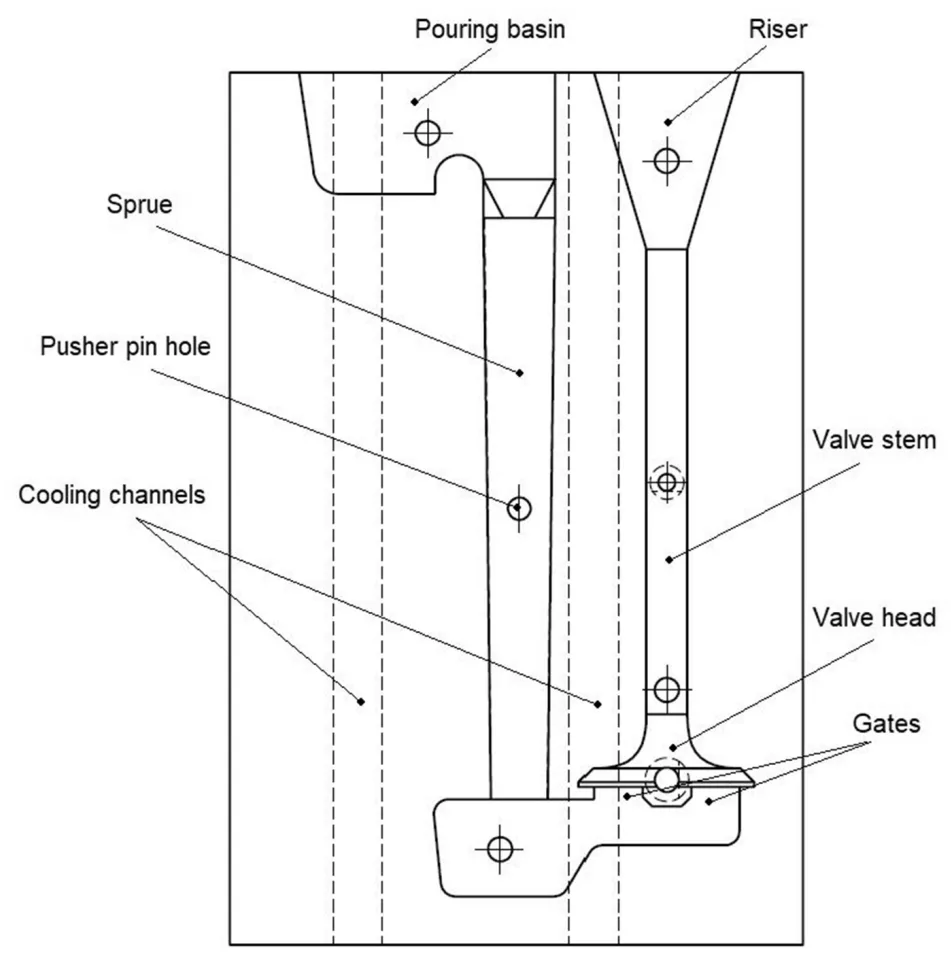

- Standard Mold: Manufactured conventionally from GGG-50 nodular ductile iron, featuring standard linear, circular cooling channels (Figure 2).

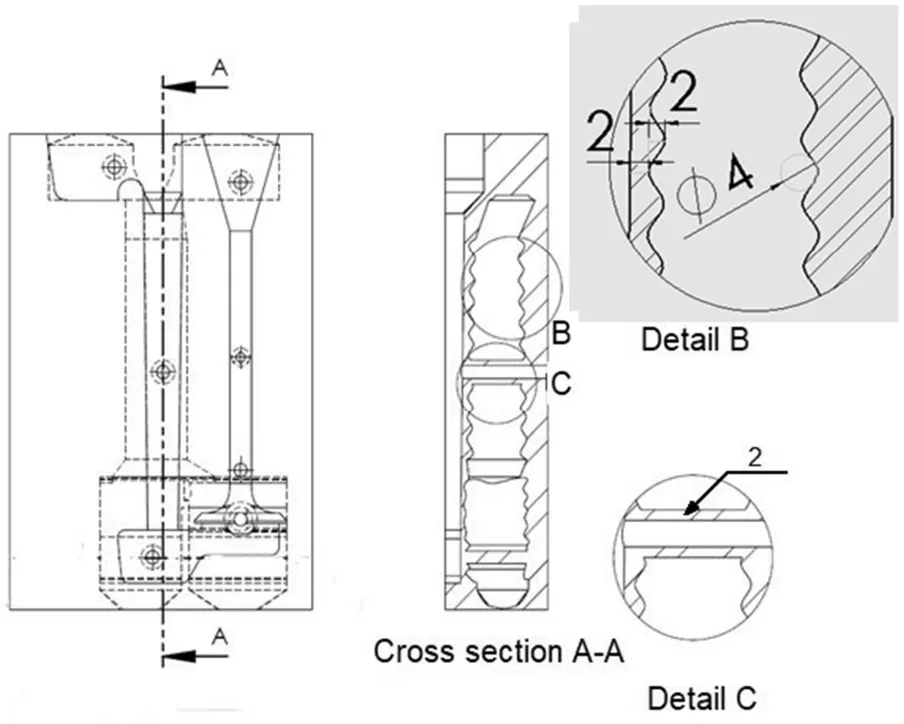

- Conformal Mold: Produced using Direct Metal Laser Sintering (DMLS), a form of additive manufacturing, from Inconel-625. This allowed for the creation of complex cooling channels that "conform" to the shape of the part cavity, even in difficult-to-reach areas (Figure 4). The channels were designed to be just 2 mm from the cavity wall in some regions.

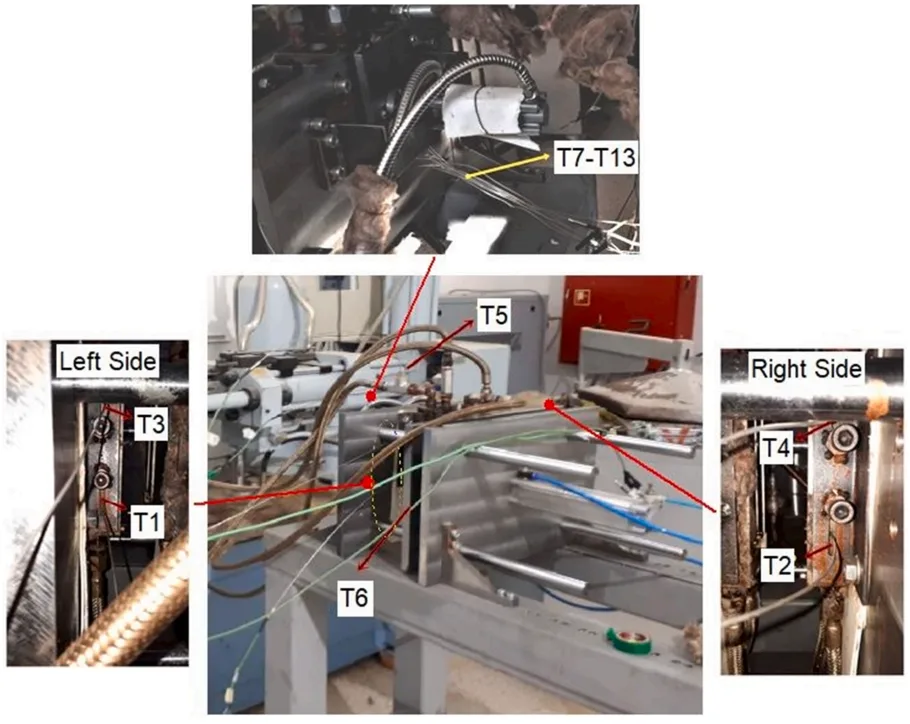

An experimental setup was created with a pneumatic gravity casting machine, a mold regulator, and extensive thermocouple instrumentation to measure temperatures on the mold surface, within the casting, and at the cooling fluid inlet/outlet (Figure 9, Figure 10). This allowed for precise measurement of mold heating performance, solidification rates, and overall cycle times.

The Breakthrough: Key Findings & Data

The experimental and numerical results clearly demonstrate the superiority of the conformal cooling design.

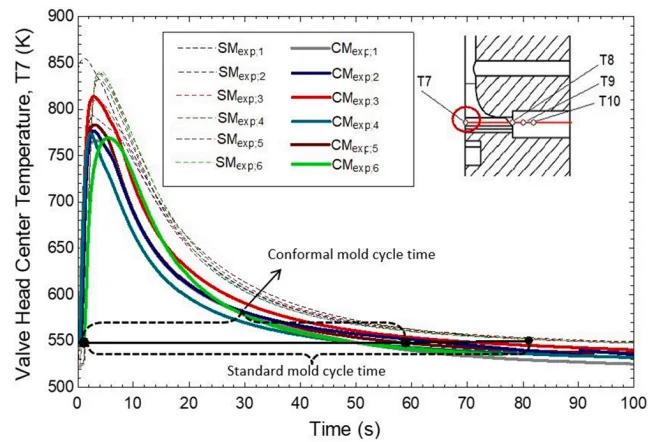

Finding 1: Drastic Cycle Time Reduction: The most significant outcome for any production manager is speed. The conformal cooling mold achieved a cycle time of just 59 seconds, compared to 82 seconds for the standard mold. This represents a 28% reduction in cycle time, enabling significantly higher production output (Figure 21).

Finding 2: Superior Thermal Management: The conformal mold exhibited a much more uniform temperature distribution across its surface. The temperature variation between different points on the conformal mold was only 6 K on average, whereas the standard mold showed a variation of 22 K (Figure 15). This homogeneity reduces thermal stresses in both the mold and the cast part.

Finding 3: Enhanced Part Quality and Microstructure: The rapid, uniform cooling of the conformal mold produced a finer and more homogeneous grain structure in the cast aluminum part. The average grain size was 13.5% smaller than in parts cast with the standard mold. In the most effectively cooled region (Zone A), the grain size was reduced by an incredible 49% (Figure 24). This finer microstructure is directly linked to improved mechanical properties like tensile and yield strength.

Finding 4: Faster, More Efficient Heat Extraction: Despite being made from Inconel-625 (which has a lower thermal conductivity than GGG-50 iron), the conformal mold's design resulted in a higher heat transfer rate. After 300 seconds, the conformal mold was extracting heat at an average rate of 3 kW, compared to 2.5 kW for the standard mold (Figure 16). This proves that intelligent channel design is more impactful than the raw thermal conductivity of the mold material alone.

Practical Implications for HPDC Products

While this study was conducted using gravity die casting, the principles and results are directly transferable and highly relevant for High-Pressure Die Casting (HPDC) operations. The challenges of hot spots, long cycle times, and part quality are universal.

For Process Engineers: The demonstrated 28% cycle time reduction is a compelling business case. This research suggests that investing in additive-manufactured dies with conformal cooling for HPDC can lead to a substantial increase in throughput and a lower cost-per-part. The ability to achieve faster solidification without sacrificing quality is a primary goal in any casting facility.

For Quality Control: The link between uniform cooling and a finer, more homogeneous microstructure (Figure 22) is critical. For applications requiring high strength and fatigue resistance (e.g., automotive structural components, aerospace parts), conformal cooling offers a pathway to superior and more consistent mechanical properties, reducing part-to-part variation.

For Die Design: This study fundamentally changes the constraints of die design. Additive manufacturing liberates designers from the "tyranny of the straight drill line." Cooling can now be placed precisely where it's needed most, navigating around ejector pins and following complex part contours. This allows for the production of more intricate and challenging HPDC parts that were previously impossible to cool effectively.

Paper Details

An experimental investigation of the cooling and heating performance of a gravity die casting mold with conformal cooling channels

1. Overview:

- Title: An experimental investigation of the cooling and heating performance of a gravity die casting mold with conformal cooling channels

- Author: Karani Kurtulus, Ali Bolatturk, Ahmet Coskun, Barış Gürel

- Year of publication: 2021

- Journal/academic society of publication: Applied Thermal Engineering

- Keywords: Gravity die casting, Conformal cooling, Computational fluid dynamics, Additive manufacturing

2. Abstract:

In the gravity die casting process, cooling directly affects the unit cost and microstructure quality of casting products. In the conventional manufacturing methods, cooling channels in gravity casting molds are usually produced linearly in circular profiles. When cooling is not conformal, molding defects such as hot spots and distortions form in the products. This study investigated the effects of cooling channels on the casting steps and final properties of the products in standard and conformal cooling gravity die casting molds. Numerical analysis results were compared with the experimental data and then were verified. The pressure losses in cooling channels, the times for molds to reach the required temperature and the cycle times were all measured. The pressure losses in standard and conformal cooling channels were measured at 5250 Pa and 12100 Pa, respectively. In addition, a more homogeneous mold surface temperature distribution was achieved in the conformal cooling mold, as well as a 28% shorter cycle time. The average particle size of the parts cast with conformal molds was 13.5% smaller than those cast with standard molds. Finally, the mechanical properties of the parts cast with conformal cooling channel molds were found to be better than those cast with standard channel molds.

3. Introduction:

Today, gravity die casting is used for parts with complex shapes and narrow dimensional tolerances manufactured in high volumes. The cooling of the metal mold directly affects the unit cost and microstructure quality of casting products. Conventionally, cooling channels are produced linearly, which can result in nonhomogeneous and insufficient cooling, especially in complex regions of the mold. This leads to problems like increased production time, casting defects, and shrinkage (Ref. [2]). To eliminate these problems, conformal cooling channels are necessary. Additive manufacturing has made it possible to create such complex channels, allowing for channel design as close as 2 mm to the casting cavity (Ref. [3-5]). While cast iron, a common mold material, cannot be produced with today's additive manufacturing, materials like 316 L stainless steel, Inconel alloy, and maraging steel can be (Ref. [8]). This study focuses on designing and producing a gravity casting mold with conformal cooling channels for an aluminum part to examine the effects on cycle time, heat transfer, and microstructure.

4. Summary of the study:

Background of the research topic:

The performance of die casting molds is heavily dependent on the efficiency of their cooling systems. Traditional, linear cooling channels are limited in their ability to provide uniform cooling, especially for complex part geometries. This inefficiency leads to production bottlenecks and quality issues.

Status of previous research:

Numerous studies have explored conformal cooling, particularly for plastic injection molding, showing benefits like shorter cycle times (Ref. [2, 14, 15]) and improved part quality. Some research has also been done on aluminum extrusion dies (Ref. [17]). However, there is a gap in the literature regarding the design, additive manufacturing, and experimental validation of conformal cooling for gravity die casting of aluminum parts.

Purpose of the study:

This study aimed to design, manufacture, and experimentally investigate a gravity die casting mold with conformal cooling channels. The goal was to compare its performance—specifically heating characteristics, cycle time, heat transfer rates, and resulting part microstructure—against a conventionally manufactured mold with standard cooling channels.

Core study:

The core of the study involved the parallel development and testing of two molds for an Al-6061 poppet valve. A standard mold was machined from GGG-50 iron, while a conformal mold was additively manufactured from Inconel-625 using DMLS. Both molds were subjected to heating and casting cycles under controlled experimental conditions. Temperature, pressure, and heat flux were measured, and the resulting cast parts were analyzed metallographically to compare grain structure.

5. Research Methodology

Research Design:

The study employed a comparative experimental design. Two distinct mold types (standard vs. conformal) were created for the same part. Numerical simulations (CFD) were first performed to model temperature, pressure, and fluid velocities in the cooling channels. These simulations were then validated against physical experiments.

Data Collection and Analysis Methods:

- Temperature Measurement: 13 K-type thermocouples were placed at various locations on the molds and within the casting area to record temperature data at a rate of 20 samples per second (Figure 10, Figure 11).

- Pressure Measurement: Diaphragm-type pressure transmitters measured pressure drops across the cooling channels.

- Metallographic Examination: Samples were taken from three distinct zones of the cast parts (Figure 12), polished, etched with Keller's solution, and examined under an optical microscope to analyze grain size and boundary areas using ImageJ software.

- Numerical Analysis: ANSYS-Fluent software was used for CFD analysis to simulate heat transfer and fluid dynamics within the molds.

Research Topics and Scope:

The research focused on the cooling and heating performance of gravity die casting molds. The scope included:

- Design of standard and conformal cooling channels.

- Additive manufacturing of the conformal mold.

- Numerical simulation and experimental validation of mold heating.

- Measurement of pressure loss, cycle time, and solidification behavior.

- Metallographic analysis of the cast Al-6061 alloy's microstructure.

6. Key Results:

Key Results:

- The cycle time for the conformal mold was 59 s, which was 28% shorter than the 82 s cycle time of the standard mold.

- The conformal mold produced a more homogeneous temperature distribution, with an average temperature difference of only 6 K across its surface, compared to 22 K for the standard mold.

- The average grain size of the part cast in the conformal mold was 13.5% smaller than the part from the standard mold. The grain size reduction was as high as 49% in Zone A.

- The pressure loss was higher in the conformal channel (12100 Pa) compared to the standard channel (5250 Pa), but remained within acceptable design limits.

- The conformal mold design achieved a higher heat transfer rate (average 3.0 kW) compared to the standard mold (average 2.5 kW), despite being made of a lower-conductivity material.

Figure Name List:

- Fig. 1. Solid model and technical drawing of poppet valve.

- Fig. 2. Details of mold with standard cooling channel.

- Fig. 3. Solid models of mold designs: a) standard b) conformal cooling channel.

- Fig. 4. Details of mold with conformal cooling channel.

- Fig. 5. Mold preheating numerical analysis models: a) standard mold b) conformal mold.

- Fig. 6. Mesh structures used in analysis: a) standard mold b) conformal mold.

- Fig. 7. Boundary conditions.

- Fig. 8. Quadratic polynomials obtained at varying temperatures against time in the mold regulator.

- Fig. 9. Scheme for the experimental setup.

- Fig. 10. Thermocouple locations in the metal mold.

- Fig. 11. Thermocouple placement in the experimental setup.

- Fig. 12. Sampling zones for metallographic examinations.

- Fig. 13. Comparison of simulated and measured metal mold temperatures of the standard mold.

- Fig. 14. Comparison of the simulated and measured metal mold temperatures of the conformal mold.

- Fig. 15. Comparison of the measured standard and conformal metal mold temperatures.

- Fig. 16. Comparison of mold heating performances of standard and conformal cooling channel molds.

- Fig. 17. Comparison of simulated metal mold temperatures for Inconel-625 and GGG-50 CM mold materials.

- Fig. 18. Comparison of simulated metal mold average temperatures for different mold material and cooling channel types.

- Fig. 19. Variation of the heat flux at the valve head and stem against time, a. standard mold, b.conformal mold.

- Fig. 20. Comparison of the measured metal mold temperature differences for standard and conformal molds.

- Fig. 21. Comparison of valve head center temperatures in the standard and conformal molds.

- Fig. 22. Comparison of the optical micrographs of the casting parts for different sampling zones (A, B and C).

- Fig. 23. Comparison of the grain boundary areas for the standard and conformal molded samples from different zones.

- Fig. 24. Comparison of the average grain size for the standard and conformal molded samples from different zones.

7. Conclusion:

The study successfully demonstrated that additive manufacturing enables the production of gravity casting molds with conformal cooling channels that significantly outperform conventionally made molds. The conformal cooling design led to more uniform cooling, which in turn resulted in a 28% shorter cycle time and a finer, more homogeneous microstructure in the final part. This indicates better mechanical properties. Although the conformal mold was made from a material with lower thermal conductivity (Inconel-625), its superior channel design allowed for more rapid and efficient heat removal. The findings confirm that conformal cooling is a highly effective strategy for improving productivity and part quality in die casting processes.

8. References:

- [1] S. Aravind, P. Ragupathi, G. Vignesh, Numerical and experimental approach to eliminate defects in al alloy pump-crank case processed through gravity die casting route, Materials Today. Proceedings, 2020, 1772-1777. softhttps://doi.org/10.1016/j.matpr.2020.07.365.

- [2] F.H. Hsu, K. Wang, C.T. Huang, R.Y. Chang, Investigation on conformal cooling system design in injection molding, Adv. Prod. Eng. Manage. 8 (2) (2013) 107-115, https://doi.org/10.14743/apem2013.2.158.

- [3] J.G. Kovacs, F. Szabo, N.K. Kovacs, A. Suplicz, B. Zink, T. Tabi, H. Hargitai, Thermal simulations and measurements for rapid tool inserts in injection molding applications, Appl. Therm. Eng. 85 (2015) 44-51, https://doi.org/10.1016/j.applthermaleng.2015.03.075.

- [4] R. Holker, E. Tekkaya, Advancements in the manufacturing of dies for hot aluminum extrusion with conformal cooling channels, Int. J. Adv. Manuf. Technol. 83 (2016) 1209-1220, https://doi.org/10.1007/s00170-015-7647-4.

- [5] B.B. Kanbur, S. Suping, F. Duan, Design and optimization of conformal cooling channels for injection molding: a review, Int. J. Adv. Manufact. Technol. 106 (7) (2020) 3253-3271, https://doi.org/10.1007/s00170-019-04697-9.

- [6] C. Tan, D. Wang, W. Ma, Y. Chen, S. Chen, Y. Yang, K. Zhou, Design and additive manufacturing of novel conformal cooling molds, Mater. Des. 196 (2020) 109-147, https://doi.org/10.1016/j.matdes.2020.109147.

- [7] E.S. Almaghariz, B. Conner, L. Lenner, R. Gullapalli, G.P. Manogharan, B. Lamoncha, M. Fang, Quantifying the role of part design complexity in using 3D sand printing for molds and cores, Int. J. Metal Cast. 10 (2016) 240-252, https://doi.org/10.1007/s40962-016-0027-5.

- [8] F. Biondani, G. Bissacco, P.T. Tang, H.N. Hansen, Additive manufacturing of mould inserts with mirror-like surfaces, Procedia Cirp. 68 (2018) 369-374, https://doi.org/10.1016/j.procir.2017.12.097.

- [9] C.M. Lin, A.S. Chandra, L. Morales-Rivas, S.Y. Huang, H.C. Wu, Y.E. Wu, H.L. Tsai, Repair welding of ductile cast iron by laser cladding process: microstructure and mechanical properties, Int. J. Cast Met. Res. 27 (6) (2014) 378-383, https://doi.org/10.1179/1743133614Y.0000000126.

- [List continues as in the paper...]

Expert Q&A: Your Top Questions Answered

Q1: How much can conformal cooling really reduce my cycle time?

A1: This study recorded a 28% reduction in cycle time, from 82 seconds with a standard mold to 59 seconds with the conformal mold. This was achieved by enabling faster and more uniform solidification of the aluminum part, as shown in the valve head temperature comparison in Figure 21.

Q2: Does conformal cooling actually improve the final part's quality?

A2: Yes, significantly. The rapid and uniform cooling promoted a finer microstructure. The average grain size was reduced by 13.5%, and by as much as 49% in certain areas (Figure 24). This finer grain structure is directly correlated with improved mechanical properties, such as strength and hardness, leading to a higher quality, more durable component.

Q3: The conformal mold was made of Inconel-625, which has lower thermal conductivity than the standard GGG-50 iron. How did it cool faster?

A3: This is a key finding. The strategic design of the conformal channels, which follow the part geometry and have a larger surface area, was more impactful than the material's bulk thermal conductivity. The conformal mold achieved a higher heat transfer rate (0.5 kW higher on average) because the cooling fluid was able to get closer to the heat source and remove heat more effectively (Figure 16).

Q4: Will conformal cooling channels lead to excessive pressure drop in the cooling system?

A4: The pressure loss in the conformal channels was higher (12100 Pa) than in the standard channels (5250 Pa) due to the more complex, fluted geometry. However, the paper notes that this value is well within acceptable limits for industrial heat exchanger and mold design criteria, and it did not prevent homogeneous cooling (Section 3.1).

Q5: Is this technology only for gravity casting, or can it be applied to HPDC?

A5: While this experiment was on a gravity die casting mold, the principles are directly applicable and arguably even more beneficial for HPDC. The intense thermal loads and high-speed production demands of HPDC make efficient cooling critical. The ability to reduce cycle times, minimize thermal stress on the die, and improve part quality are universal goals that conformal cooling, enabled by additive manufacturing, can help achieve.

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing thermal management in die casting. The findings offer a clear, data-driven path toward improving quality, reducing defects, and, most importantly, slashing cycle times. By moving beyond the limitations of linear cooling channels, additive manufacturing unlocks a new level of performance and design freedom.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "Karani Kurtulus, Ali Bolatturk, Ahmet Coskun, Barış Gürel". Based on "An experimental investigation of the cooling and heating performance of a gravity die casting mold with conformal cooling channels".

- Source of the paper: https://doi.org/10.1016/j.applthermaleng.2021.117105

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.