This article introduces the paper ['Advances in Metal Casting Technology: A Review of State of the Art, Challenges and Trends—Part II: Technologies New and Revived'] presented at the ['Metals']

1. Overview:

- Title: Advances in Metal Casting Technology: A Review of State of the Art, Challenges and Trends—Part II: Technologies New and Revived

- Author: Dirk Lehmhus

- Publication Year: 2024

- Publishing Journal/Academic Society: Metals, MDPI

- Keywords: Metal Casting Technology, Review, State of the Art, Challenges, Trends, Technologies, Semi-Solid Processing, Compound Casting, Hybrid Casting, Complexity, Smart Castings, Digital Twins

![Figure 1. An overview of topics covered in the present text. The graphic shows the areas of interest discussed in the previously published first part of this editorial (PART I in the diagram, see [1]) as well as those focused on in this second part. While Part I concentrated on boundary conditions, Part II is technology oriented.](https://castman.co.kr/wp-content/uploads/image-598-1024x507.webp)

2. Research Background:

Background of the Research Topic:

The present text is the second part of an editorial written for a Special Issue entitled "Advances in Metal Casting Technology". It follows Part I, published in November 2022, which provided an overview of the global metal casting industry and highlighted market changes and product evolution drivers such as e-mobility and environmental pressures. Part II shifts focus to technological developments within the industry, examining both new and revived technologies as general trends or responses to preceding challenges.

Status of Existing Research:

The paper notes that the casting industry is experiencing cyclical technology evolution, influenced by technology-centered models like the Gartner hype cycle, economy-level observations such as Kondratiev waves, new ideas, market needs, and patent expirations. Semi-solid metal processing, though not a new topic, has seen renewed interest, demonstrated by both industrial adoption and academic publications. Compound and hybrid casting are presented as alternatives to Gigacasting for large structural components. Complexity in casting is being addressed through advancements in core technologies and additive manufacturing. Smart castings and digitalization are emerging trends within the context of Industry 4.0.

Necessity of the Research:

The research is necessary to provide an updated overview of the technological advancements in metal casting, particularly in response to evolving market demands and industry challenges. It aims to discuss both novel and revitalized technologies, offering readers a comprehensive perspective and identifying areas for further investigation. The review is motivated by the need to contextualize contributions to the Special Issue within the broader landscape of metal casting technology.

3. Research Purpose and Research Questions:

Research Purpose:

The primary purpose of this editorial is to review and summarize the state-of-the-art, challenges, and trends in metal casting technologies, focusing on technologies that are either new or have experienced a revival in recent times. It aims to provide a handbook-level overview of these technologies, contextualizing them within the broader industry landscape and highlighting their relevance to current challenges and future directions.

Key Research:

The key research areas explored in this paper are:

- Semi-Solid Processing: Examining the renewed interest in rheocasting and thixomolding, particularly rheocasting's "slurry on demand" principle and its advantages over HPDC.

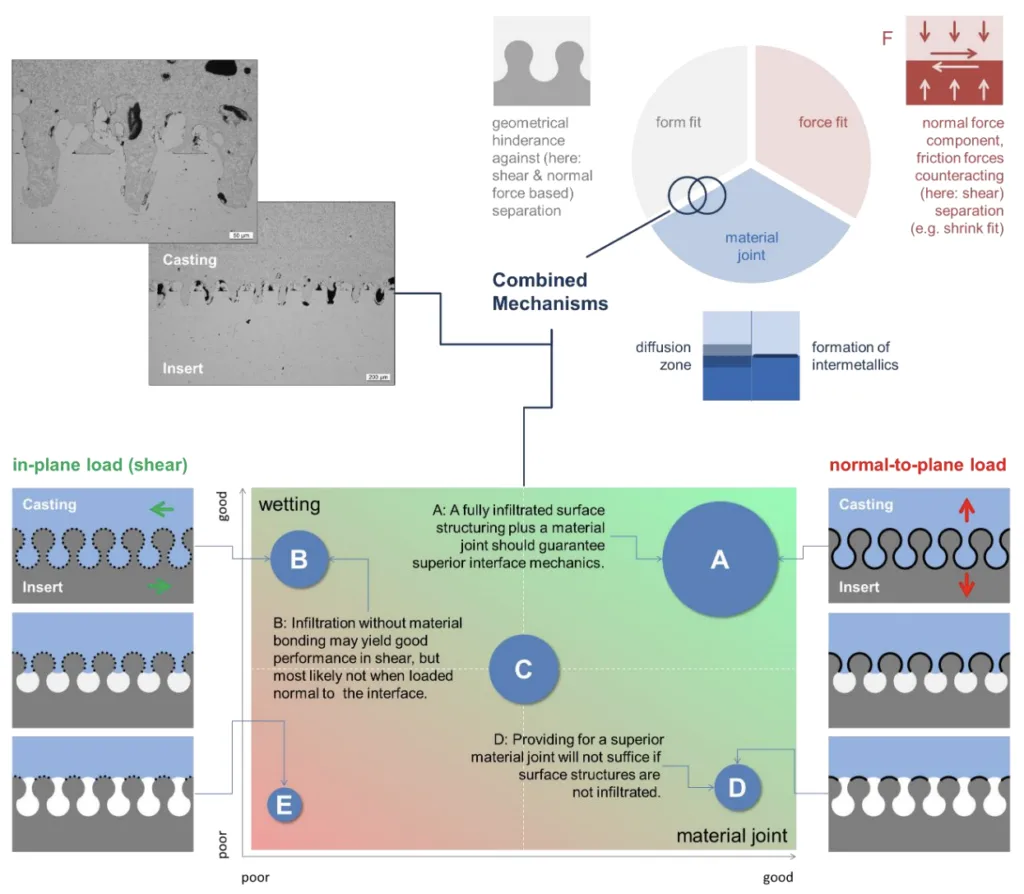

- Compound & Hybrid Casting: Analyzing compound casting (joining metals of the same class) and hybrid casting (joining metals with different classes like polymers or ceramics) as alternatives to Gigacasting, focusing on interface bonding methods (material joints, form fit, force fit).

- Complexity: Discussing methods to achieve increased casting complexity through new core technologies, additive manufacturing of molds and cores, and design optimization.

- Smart Castings: Reviewing the integration of sensors and intelligent systems into castings for monitoring, control, and data acquisition within the framework of Industry 4.0.

- Virtual Worlds: Modelling, Simulation and Optimization: Exploring advancements in casting simulation, defect prediction, and the emergence of digital twins and metamodels for process optimization and control.

Research Hypotheses:

As a review paper, there are no explicit research hypotheses. However, the paper implicitly posits that:

- Revived technologies like semi-solid processing offer viable solutions to modern casting challenges.

- Compound and hybrid casting present a compelling alternative to Gigacasting for specific applications.

- Additive manufacturing and advanced core technologies are key enablers for achieving increased casting complexity.

- Smart casting and digital twin concepts are crucial for the future evolution of the metal casting industry within Industry 4.0.

4. Research Methodology

Research Design:

This paper employs a descriptive review design. It is structured as an editorial providing an expert overview of the field of metal casting technology. The design is thematic, organized around key technology areas: Technologies New and Revived, Complexity, Smart Castings, and Virtual Worlds.

Data Collection Method:

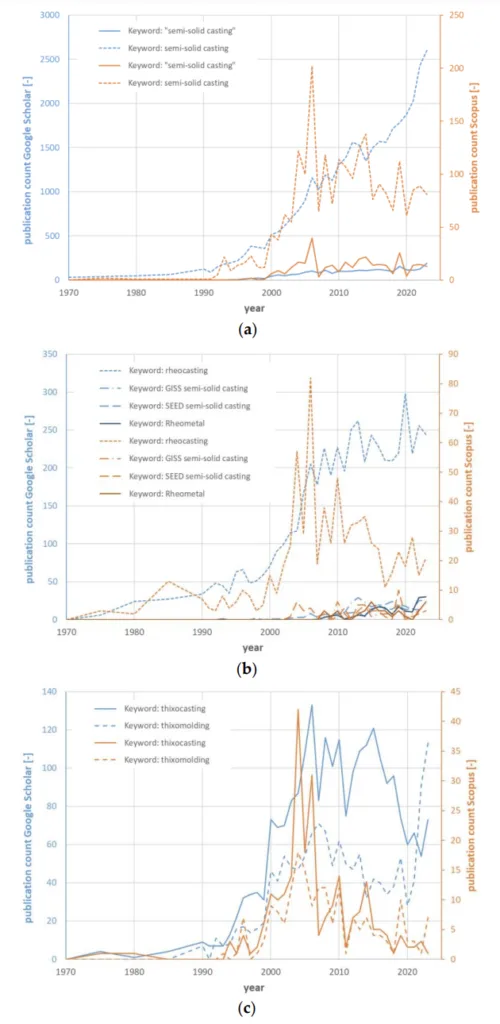

The data collection method is based on a comprehensive literature review and expert analysis. The author, a leading expert in die casting technology, draws upon existing publications, research, and industrial trends to synthesize the current state of the art. Publication data from Google Scholar and Scopus are used to illustrate trends in semi-solid casting research.

Analysis Method:

The analysis method is qualitative and descriptive. The author analyzes and synthesizes information from various sources to identify key trends, challenges, and opportunities within each technology area. The analysis is structured around the identified research areas, providing detailed descriptions and contextualization of each technology.

Research Subjects and Scope:

The research subjects are primarily metal casting technologies, with a focus on:

- Semi-solid processing (rheocasting, thixomolding)

- Compound and hybrid casting

- Core technologies and additive manufacturing for complexity

- Smart castings and sensor integration

- Casting simulation, digital twins, and metamodels

The scope is limited to technologies relevant to advancements in metal casting, particularly high-pressure die casting (HPDC) of aluminum alloys, reflecting the author's expertise and potential bias. The review focuses on technologies applicable to industrial practice and future research directions.

5. Main Research Results:

Key Research Results:

- Semi-Solid Processing: Rheocasting is highlighted as a revived technology with significant advantages, including the "slurry on demand" principle, enabling the use of conventional alloys and recycling of scrap. Rheocasting is closer to conventional HPDC in terms of tooling and process parameters than thixocasting. Publication data indicates a renewed interest in rheocasting.

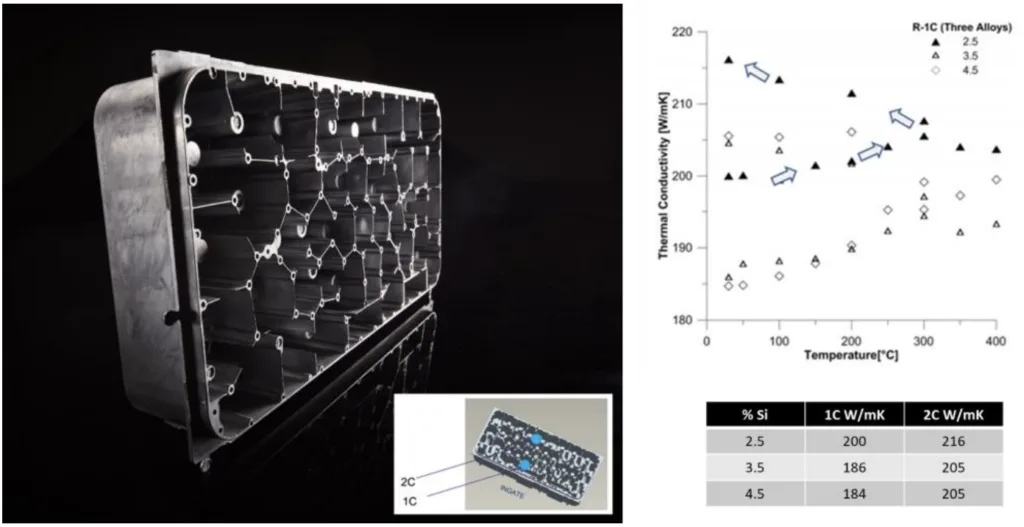

- Compound & Hybrid Casting: These technologies offer alternatives to Gigacasting, potentially reducing locking force requirements and optimizing material usage. Three main bonding principles are identified: material joints, form fit, and force fit. Al-steel and Al-Cu systems are prominent research areas, with applications in structural components and thermal management.

- Complexity: Additive manufacturing (AM) of sand molds and cores is identified as a key enabler for achieving complex casting geometries. Collapsible cores are presented as a novel approach for simplifying decoring. AM also facilitates conformal cooling and heat spreading in die design.

- Smart Castings: Sensor integration into castings is an emerging trend, categorized by four principles: simplify, distribute, harden, and protect. Applications include structural health monitoring and process optimization.

- Virtual Worlds: Modelling, Simulation and Optimization: Casting simulation has become a standard technique, with ongoing advancements in usability and predictive capabilities. Digital twins and metamodels are emerging as tools for process optimization and control, requiring advanced simulation techniques and data analytics.

![Figure 4. Overview of rheocast and high-pressure die-cast aluminum and magnesium alloys in as-cast and T6 states in terms of yield strength, ultimate tensile strength and elongation at failure. The latter is represented by the size of the spheres. Data are sourced from [20,32-43]](https://castman.co.kr/wp-content/uploads/image-601-1024x662.webp)

![Figure 6. Sample images of parts produced by compound (a–c) and hybrid casting (d); (a,b) AlSi7Mg0.3 LPDC subsize front axle carrier frame demonstrator with integrated EN AW-6060 extrusion, general (a) and detail view (b); (c) AlSi9Cu3 HPDC e-motor housing demonstrator with integrated aluminum tubes as cooling channels, cast by ae group AG, Gerstungen, Germany; (d) aerospace secondary structure hybrid bracket combining a CFRP and an aluminum HPDC component [131] (all images by Fraunhofer IFAM).](https://castman.co.kr/wp-content/uploads/image-603-1024x768.webp)

Figure Name List:

- Figure 1. An overview of topics covered in the present text.

- Figure 2. Publication numbers sourced from Google Scholar and Scopus on semi-solid casting technologies.

- Figure 3. Radio filter produced by means of the RSF/RheoMetalTM process.

- Figure 4. Overview of rheocast and high-pressure die-cast aluminum and magnesium alloys in as-cast and T6 states.

- Figure 5. An overview of principles controlling strength in compound casting.

- Figure 6. Sample images of parts produced by compound (a-c) and hybrid casting (d).

- Figure 7. The fundamental principle behind the concept of collapsible cores.

- Figure 8. (a) S-Max Pro sand printer as offered by ExOne, (b) examples of a printed core package.

- Figure 9. How to enable sensors and electronic systems to survive integration in metal castings—general principles.

- Figure 10. Schematic diagram describing a concept for constant product evolution relying on monitoring of in-service loads and conditions.

- Figure 11. Digitalization meets the HPDC challenge.

- Figure 12. The Lambda Architecture, an example of a compromise between securing accuracy and speed in data analytics.

- Figure 13. Ways of making use of data analytics—a general scheme.

- Figure 14. Combining advanced simulation and modelling and AI or MOR techniques to realize a digital twin in casting technology.

6. Conclusion:

Summary of Main Results:

The review summarizes key advancements and trends in metal casting technologies, including the resurgence of semi-solid processing, the development of compound and hybrid casting, innovations in achieving casting complexity, the emergence of smart castings, and the increasing role of virtual worlds through simulation and digital twins. It highlights the industry's response to market demands for lightweighting, e-mobility, and environmental sustainability.

Academic Significance of the Research:

This editorial provides a valuable academic contribution by synthesizing a broad range of recent developments in metal casting technology. It offers a structured overview of these advancements, contextualizing them within the evolving landscape of the industry and identifying key research directions. The review serves as a comprehensive resource for researchers and experts in the field, highlighting areas of innovation and future research opportunities.

Practical Implications:

The practical implications of this review are significant for the metal casting industry. It provides foundries and casting designers with insights into:

- Viable alternative technologies like rheocasting and compound/hybrid casting.

- Advanced techniques for achieving complex geometries and functional integration.

- The potential of smart castings and digital twins for process optimization and quality control.

- The importance of data-driven approaches and advanced simulation tools for future competitiveness.

Limitations of the Research

As an editorial review, this paper is inherently limited by its scope and potential for author bias towards HPDC of aluminum alloys. It is not exhaustive and cannot cover every aspect of metal casting technology in detail. The review relies on existing literature and expert analysis, and does not involve original experimental research. The rapidly evolving nature of the field means that some aspects may become quickly outdated.

7. Future Follow-up Research:

- Directions for Follow-up Research

- Further research is needed to fully realize the potential of semi-solid processing, particularly in expanding its application across various alloys and component types.

- Continued investigation into interface bonding mechanisms and predictive simulation tools for compound and hybrid casting is crucial for wider industrial adoption.

- Further exploration of additive manufacturing for core production and die design optimization is warranted, focusing on cost-effectiveness and scalability.

- Research into robust and cost-effective sensor integration methods for smart castings and the development of standardized data protocols for digital twins are essential for Industry 4.0 implementation.

- Areas Requiring Further Exploration

- The long-term viability and market penetration of revived technologies like rheocasting need continued monitoring.

- The economic and technical feasibility of hybrid casting for large-scale automotive structural components requires further validation.

- Standardizing complexity metrics and developing design guidelines for complex castings produced via AM are areas needing further exploration.

- Addressing data security and interoperability challenges in implementing digital twins in casting environments is crucial.

- Investigating the environmental impact and sustainability aspects of new and revived casting technologies is increasingly important.

8. References:

- [1] Lehmhus, D. Advances in Metal Casting Technology: A Review of State of the Art, Challenges and Trends—Part I: Changing Markets, Changing Products. Metals 2022, 12, 1959.

- [2] Steinert, M.; Leifer, L. Scrutinizing Gartner's Hype Cycle Approach. In PICMET 2010 Proceedings: Technology Management for Global Economic Growth; Kocaoglu, D.F., Anderson, T.R., Daim, T.U., Eds.; IEEE: Phuket, Thailand, 2010; pp. 1–13.

- [3] Campani, M.; Vaglio, A. A simple interpretation of scientific/technological research impact leading to hype-type evolution curves. Scientometrics 2015, 103, 75-83.

- [4] Gartner Hype Cycle. Available online: https://www.gartner.com/en/research/methodologies/gartner-hype-cycle (accessed on 4 January 2023).

- [5] Kondratjew, N.D. Die langen Wellen der Konjunktur. Arch. Für Sozialwissenschaft Und Sozialpolitik 1926, 56, 573–609.

- [6] Flemings, M.C.; Riek, R.C.; Young, K.P. Rheocasting. Mater. Sci. Eng. A 1976, 25, 103-117.

- [7] Young, R.M.K. The Processing of Metals as Semi-Solid Slurries. Ph.D. Thesis, University of Surrey, Guildford, UK, 1986.

- [8] Jorstad, J.L. Semi-Solid Metal Processing from an Industrial Perspective: The Best is Yet to Come! Solid State Phenom. 2016, 256, 9-14.

- [9] Czerwinski, F. Semisolid Processing—Origin of Magnesium Molding. In Magnesium Injection Molding; Springer: New York, NY, USA, 2008; pp. 81–147.

- [10] Decker, R.; LeBeau, S. Thixomolding. Adv. Mater. Process. 2008, 166, 28–29.

- [11] Huang, J.; Arbel, T.; Ligeski, L.; McCaffrey, J.; Kulkarni, S.; Jones, J.; Pollock, T.; Decker, R.; LeBeau, S. On Mechanical Properties & Microstructure of TTMP Wrought Mg Alloys. In Magnesium Technology 2010; Agnew, S., Ed.; The Minerals, Metals and Materials Society (TMS): Warrendale, PA, USA, 2010; pp. 489-493.

- [12] Zhu, Y.; Midson, S. The Status of Magnesium Injection Molding in China. Solid State Phenom. 2019, 285, 436-440.

- [13] Decker, R.; LeBeau, S.; Wilson, B.; Reagan, J.; Moskovich, N.; Bronfin, B. Thixomolding® at 25 years. Solid State Phenom. 2016, 256, 3-8.

- [14] Mohammed, N.N.; Omar, M.Z.; Salleh, M.S.; Alhawari, K.S.; Kapranos, P. Semisolid Metal Processing Techniques for Nondendritic Feedstock Production. Sci. World J. 2013, 2013, 752175.

- [15] Kapranos, P. Current State of Semi-Solid Net-Shape Die Casting. Metals 2019, 9, 1301.

- [16] Midson, S.P. Rheocasting processes for semi-solid casting of aluminum alloys. Die Cast. Eng. 2006, 50, 48-51.

- [17] Midson, S.P.; Jackson, A. A Comparison of Thixocasting and Rheocasting. In Proceedings of the 67th World Foundry Congress, Harrogate, UK, 5–7 June 2006; Institute of Cast Metals Engineers (ICME): Tipton, UK, 2006; pp. 22/1-22/10, ISBN 9781604236767.

- [18] Bakhtiyarov, S.; Siginer, D.A. Rheoprocessing of Semisolid Aluminum Alloys. In Encyclopedia of Aluminum and Its Alloys, 1st ed.; Totten, G.E., Tiryakioğlu, M., Kessler, O., Eds.; Taylor & Francis Group: London, UK, 2018.

- [19] Jarfors, A.E.W. A Comparison Between Semisolid Casting Methods for Aluminium Alloys. Metals 2020, 10, 1368.

- [20] Li, G.; Qu, W.-Y.; Cheng, L.; Guo, C.; Li, X.-G.; Xu, Z.; Hu, X.-G.; Li, D.-Q.; Lu, H.-X.; Zhu, Q. Semi-solid processing of aluminum and magnesium alloys: Status, opportunity and challenge in China. Trans. Nonferrous Met. Soc. China 2021, 31, 3255-3280.

- [21] Wannasin, J. Applications of Semi-solid Slurry Casting using the Gas Induced Semi-Solid Technique. Solid State Phenom. 2013, 192-193, 28-35.

- [22] Kaufmann, H.; Uggowitzer, P.J. Fundamentals of the New Rheocasting Process for Magnesium Alloys. Adv. Eng. Mater. 2001, 3, 963-967.

- [23] Wabusseg, H.; Kaufmann, H.; Wahlen, A.; Uggowitzer, P.J. Theoretische Grundlagen und praktische Umsetzung von New Rheocasting von Al-Legierungen. Druckguss-Praxis 2002, 1, 16–19.

- [24] Uggowitzer, P.J.; Kaufmann, H. Evolution of Globular Microstructure in New Rheocasting and Super Rheocasting Semi-Solid Slurries. Steel Res. Int. 2004, 75, 525-530.

- [25] Wessén, M.; Cao, H. The RSF Technology: A Possible Breakthrough for Semi-Solid Casting Processes. In Proceedings of the International Conference of High Tech Die Casting, Vicenza, Italy, 21-22 September 2006.

- [26] Ratke, L.; Sharma, A.; Kohli, D. The RSF Technology for Semi-Solid Casting Processes. Indian Foundry J. 2011, 57, 33–36.

- [27] Doutre, D.; Hay, G.; Wales, P.; Gabathuler, J.-P. SEED: A new process for semi-solid forming. Can. Metall. Q. 2004, 43, 265–272.

- [28] Yurko, J.A.; Martinez, R.A.; Flemings, M.C. The Use of Semi-Solid Rheocasting (SSR) for Aluminum Automotive Castings. SAE Trans. J. Mater. Manuf. 2003, 112, 119–123.

- [29] Serving the Platform of Tomorrow! Available online: https://comptech.se/ (accessed on 11 March 2023).

- [30] Li, M.; Du, W.; Elwany, A.; Pei, Z.; Ma, C. Metal binder jetting additive manufacturing: A literature review. J. Manuf. Sci. Eng. 2020, 142, 090810.

- [31] Zetterström, S.; Comptech AB, Skillingaryd, Sweden. Private communication, 2022.

- [32] Chauke, L.; Möller, H.; Curle, U.A.; Govender, G. Industrial heat treatment of R-HPDC A356 automotive brake callipers. Solid State Phenom. 2013, 192–193, 533-538.

- [33] Dey, A.K.; Poddar, P.; Singh, K.K.; Sahoo, K.L. Mechanical and wear properties of rheocast and conventional gravity die cast A356 alloy. Mater. Sci. Eng. A 2006, 435–436, 521–529.

- [34] Govender, G.; Ivanchev, L.; Jahajeeah, N.; Bëan, R. Application of CSIR Rheocasting Technology for the Production of an Automotive Component. Solid State Phenom. 2006, 116–117, 501-504.

- [35] Guo, H.M.; Yang, X.J.; Wang, J.X. Microstructure and mechanical properties of Al alloys by semi-solid processing with LSPSF technology. Mater. Sci. Forum 2009, 628–629, 477-482.

- [36] Gupta, R.; Sharma, A.; Pandel, U.; Ratke, L. Effect of heat treatment on microstructures and mechanical properties of A356 alloy cast through rapid slurry formation (RSF) process. Int. J. Cast Met. Res. 2017, 30, 283–292.

- [37] Möller, H.; Govender, G.; Stumpf, W.E.; Knutsen, R.D. Influence of temper condition on microstructure and mechanical properties of semisolid metal processed Al-Si-Mg alloy 356. Int. J. Cast Met. Res. 2009, 22, 417-421.

- [38] Möller, H.; Govender, G.; Stumpf, W.E. Comparison of the heat treatment response of SSM-HPDC 6082 and 6004 wrought alloys with A356 and F357 casting alloys. Mater. Sci. Forum 2011, 690, 53-56.

- [39] Anticorodal®—Unendlich Anpassungs Fähig. Available online: https://rheinfelden-alloys.eu/legierungen/anticorodal/ (accessed on 21 February 2022).

- [40] Rosso, M.; Peter, I.; Villa, R. Effect of T5 anfd T6 Heat Treatments Applied to Rheocast A356 Parts for Automotive Applications. Solid State Phenom. 2008, 141-143, 237-242.

- [41] Rosso, M. Thixocasting and rheocasting technologies, improvements going on. J. Achiev. Mater. Manuf. Eng. 2012, 54, 110–119.

- [42] Tahamtan, S.; Fadavi Boostani, A.; Nazemi, H. Mechanical properties and fracture behavior of thixoformed, rheocast and gravity-cast A356 alloy. J. Alloys Compd. 2009, 468, 107-114.

- [43] Zhang, L. Technology Innovation & Green Development—Chinese Foundry Industry Status and Outlook. Chinese Foundry Association. 2015. Available online: https://www.foundry-planet.com/fileadmin/redakteur/pdf-dateien/18.09.2015BRICS_2015_China.pdf (accessed on 13 May 2020).

- [44] Atkinson, H.V. Alloys for Semi-Solid Processing. Solid State Phenom. 2012, 192–193, 16-27.

- [45] Curle, U.A. Semi-solid near-net shape rheocasting of heat treatable wrought aluminum alloys. Trans. Nonferrous Met. Soc. China 2010, 20, 1719-1724.

- [46] Li, G.; Lu, H.; Hu, X.; Lin, F.; Li, X.; Zhu, Q. Current Progress in Rheoforming of Wrought Aluminum Alloys: A Review. Metals 2020, 10, 238.

- [47] Sauermann, R.; Friedrich, B.; Bünck, M.; Bührig-Polaczek, A.; Uggowitzer, P.J. Semi-Solid Processing of Tailored Aluminium-Lithium Alloys for Automotive Applications. Adv. Eng. Mater. 2007, 9, 253-258.

- [48] Bünck, M.; Küthe, F.; Bührig-Polaczek, A.; Arnold, A.; Friedrich, B.; Sauermann, R. Semi-solid Casting of High-reactive Wrought Alloys by Means of the Alloy AlLi2.1Mg5.5ScZr (AA1420*). Solid State Phenom. 2008, 141–143, 145-150.

- [49] Langlais, J.; Lemieux, A. The SEED Technology for Semi-solid Processing of Aluminum Alloys: A Metallurgical and Process Overview. Solid State Phenom. 2006, 116–117, 472-477.

- [50] Langlais, J.; Andrade, N.; Lemieux, A.; Chen, X.G.; Bucher, L. The Semi-Solid Forming of an Improved AA6061 Wrought Aluminum Alloy Composition. Solid State Phenom. 2008, 141-143, 511-516.

9. Copyright:

- This material is "Dirk Lehmhus"'s paper: Based on "Advances in Metal Casting Technology: A Review of State of the Art, Challenges and Trends—Part II: Technologies New and Revived".

- Paper Source: https://doi.org/10.3390/met14030334

This material was summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.