1. Overview:

- Title: A study of an industrial counter pressure casting process for automotive parts

- Author: Jun Ou, Chunying Wei, Savanna Logue, Steve Cockcroft, Daan Maijer, Yacong Zhang, Zhi Chen, Lateng A

- Year of publication: 2021

- Journal/academic society of publication: Journal of Materials Research and Technology

- Keywords: CPC process, Plant trial, Data acquisition, Model development, ProCAST

2. Abstract:

Counter pressure casting (CPC) is emerging in the automotive manufacturing industry as an alternative to low-pressure die casting (LPDC) due to its reported superior capabilities in aluminum parts production. This study presents the first comprehensive investigation of how CPC's characteristic feature (applied chamber pressure) influences the fluid flow and heat transport occurring in the process and its effect on casting quality. A large amount of high-quality data was acquired from a commercial CPC process for the production of automotive suspension control arms with two process conditions (standard production and low back-pressure condition). Analysis of the data shows that there are no significant differences between the two process pressure conditions with respect to heat transfer during solidification, as-cast microstructure nor mechanical properties. Generally, in-die measured temperatures exhibited a difference within 10 °C for the two process conditions examined and the ultimate tensile strengths (UTSs) of the samples obtained from castings were within 7% for the two process conditions. Furthermore, there was no measurable difference observed in the Secondary Dendrite Arm Spacings (SDASs) obtained under the two process conditions. However, the implementation of chamber back pressure noticeably reduces the venting rate during the filling stage, leading to 12 s delay in the filling time relative to the low back-pressure condition. A computational modelling methodology, originally developed for LPDC, was applied to simulate the CPC process. The model required only an adjustment to pressure curve to account for the delay of filling owing to the reduced venting rate observed for the higher back-pressure condition. The predicted results were found to correlate well with the measured data, demonstrating that the modelling methodology is broadly applicable to permanent die casting processes.

3. Introduction:

Driven by regulations and societal pressure for energy efficiency, the automotive industry is increasingly using lightweight aluminum components to replace ferrous castings. Low-pressure die casting (LPDC) and high-pressure die casting (HPDC) are the most common methods for producing these parts. Counter-pressure casting (CPC) is a relatively new technology emerging as an alternative, claiming to produce superior quality parts compared to LPDC by filling the die against a back pressure. While computer-based simulation is now a key tool for optimizing casting processes, its application to CPC is limited, and there is a lack of high-quality industrial data to validate both the process claims and simulation models. This study provides an extensive characterization of a commercial CPC process to quantitatively assess the influence of back pressure on filling and solidification behavior and to validate a computational modelling methodology.

4. Summary of the study:

Background of the research topic:

The CPC process is a variation of LPDC where the die system is enclosed in a pressure chamber. By pressurizing this chamber, both the filling and solidification stages occur under a higher absolute pressure than in conventional LPDC. It is claimed that this increased pressure improves casting quality by reducing turbulence, enhancing heat transfer for a more refined microstructure, and minimizing shrinkage porosity (Ref. [9], [18]). However, there is a lack of published, peer-reviewed evidence from industrial production to substantiate these claims.

Status of previous research:

Previous research on the CPC process is limited. Some computational modeling work has been reported, focusing on predicting porosity formation (Ref. [10]) or comparing CPC and LPDC processes (Ref. [19]). Fundamentally, both processes can be described by the same modeling principles, with the primary difference being the pressure regime during filling and solidification. However, a comprehensive experimental investigation using industrial-scale equipment to validate these models and the purported benefits of CPC has been absent from the literature.

Purpose of the study:

The primary purpose of this study is to comprehensively and quantitatively investigate the influence of the applied chamber pressure (back pressure) in the CPC process on the fluid flow, heat transport, and resulting casting quality. A second objective is to apply a computational modelling methodology, originally developed for LPDC, to the CPC process to assess its accuracy and robustness for simulating permanent die casting processes more broadly.

Core study:

The core of the study involved an extensive in-plant characterization campaign on a commercial CPC machine producing an A356 aluminum alloy automotive control arm. Two process conditions were compared: a standard production condition with high back pressure (CPC-SP) and a condition with atmospheric chamber pressure to mimic the LPDC process (CPC-LP). The study included detailed in-die temperature measurements, post-casting analysis of microstructure (SDAS) and mechanical properties (UTS), and porosity assessment via CT scanning. These experimental results were then used to validate a computational model of the CPC process developed in ProCAST.

5. Research Methodology

Research Design:

The research was designed as a comparative experimental study. An industrial CPC process was instrumented to produce automotive control arms under two distinct conditions:

- CPC-SP (Standard Production): The standard process with elevated furnace and chamber pressures.

- CPC-LP (Low Back-Pressure): The chamber pressure was set to atmospheric (0 mbar-gauge) to emulate a conventional LPDC process.

All other process parameters, including the pressure differential driving the filling and the water-cooling schedules, were kept identical between the two conditions to isolate the effect of the chamber back pressure.

Data Collection and Analysis Methods:

- In-plant Data Acquisition: A total of 65 type-K thermocouples were installed in the die sections, cooling channels, and surrounding environment. Data was collected at 4 Hz using a data acquisition (DAQ) system to monitor the thermal evolution of the die under cyclic steady-state conditions.

- Casting Characterization:

- Porosity: Castings were examined using X-Ray Computed Tomography (CT) to identify shrinkage-based porosity.

- Microstructure: Samples were taken from two locations in the casting to characterize the Secondary Dendrite Arm Spacing (SDAS) using optical microscopy and the line-intercept method.

- Mechanical Properties: Tensile samples were machined from three locations and tested according to ASTM B 557M standards to determine the ultimate tensile strength (UTS).

- Computational Modelling: The CPC process was simulated using ProCAST, a Finite Element Method (FEM) software. The model was adapted from a previously validated LPDC model (Ref. [17]) and used to predict the die temperature evolution and solidification sequence.

Research Topics and Scope:

The research focused on an industrial CPC process for an A356 aluminum alloy automotive control arm. The scope covered the entire process, from die filling and solidification to post-casting analysis. The key topics investigated were the influence of chamber back pressure on:

- Die filling dynamics and time.

- The thermal field within the die during a casting cycle.

- The resulting as-cast microstructure (SDAS) and mechanical properties (UTS).

- The formation of shrinkage-based porosity.

- The applicability and accuracy of an LPDC-based computational model for simulating the CPC process.

6. Key Results:

Key Results:

- Filling Delay: The primary effect of applying chamber back pressure (CPC-SP condition) was a significant delay in die filling of approximately 12 seconds compared to the low back-pressure condition (CPC-LP). This delay is attributed to reduced venting efficiency, as the higher pressure increases the viscosity of the air that must be evacuated from the die cavity.

- Thermal Field: After accounting for the filling delay, the temperature evolution within the die was very similar for both process conditions. The measured temperature differences were generally within 10 °C, indicating that the chamber back pressure does not have a significant impact on the thermal field or the die/casting interfacial heat transfer. This contradicts claims that CPC enhances cooling rates.

- Microstructure and Mechanical Properties: There were no significant differences observed in the as-cast microstructure or mechanical properties between the two conditions. The Secondary Dendrite Arm Spacings (SDASs) and Ultimate Tensile Strengths (UTSs) were statistically comparable, suggesting that the casting quality is not measurably improved by the application of back pressure in this case.

- Computational Model Validation: A computational model originally developed for LPDC was successfully applied to the CPC process. The model accurately predicted the experimental temperature data after a simple adjustment to the pressure curve to account for the observed filling delay. This demonstrates that the modelling methodology is robust and broadly applicable to permanent mold casting processes.

- Porosity: Both model predictions and CT scan results for the CPC-SP condition showed that directional solidification was largely achieved, with only small, distributed porosity observed in one region, consistent with late-stage solidification shrinkage.

Figure Name List:

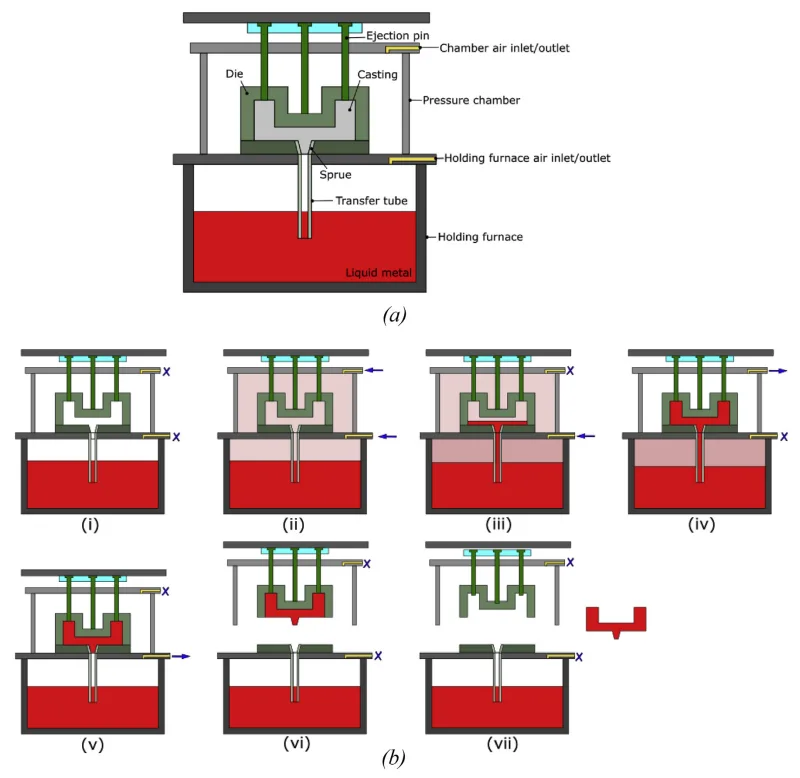

- Fig. 1 – Schematic of the CPC machine and process procedure (a) Structure of the CPC machine (b) Major steps of the CPC process: (i) pressure chamber closed; (ii) furnace and pressure chamber are pressurized; (iii) furnace pressure is further increased slowly; (iv) chamber pressure is quickly released; (v) furnace pressure is released; (vi) chamber and die are opened; and (vii) the cast part is ejected.

- Fig. 2 – Geometry of the die sections and the cast component (control arm) and the mesh used for analysis.

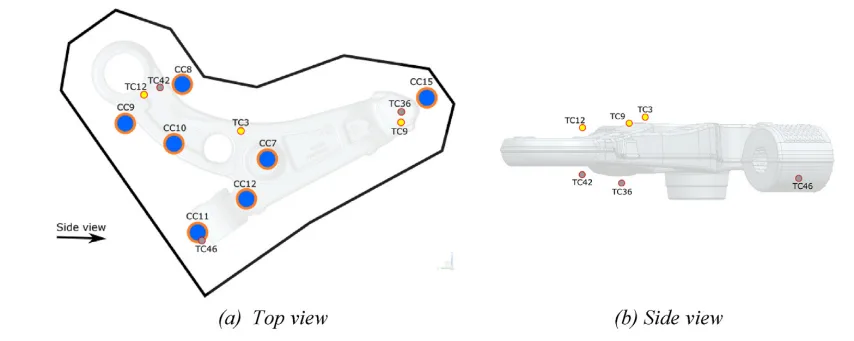

- Fig. 3 – Schematic showing locations of the cooling elements and TCs. Note: the distances between the TCs and die/casting interface are given in Table 2.

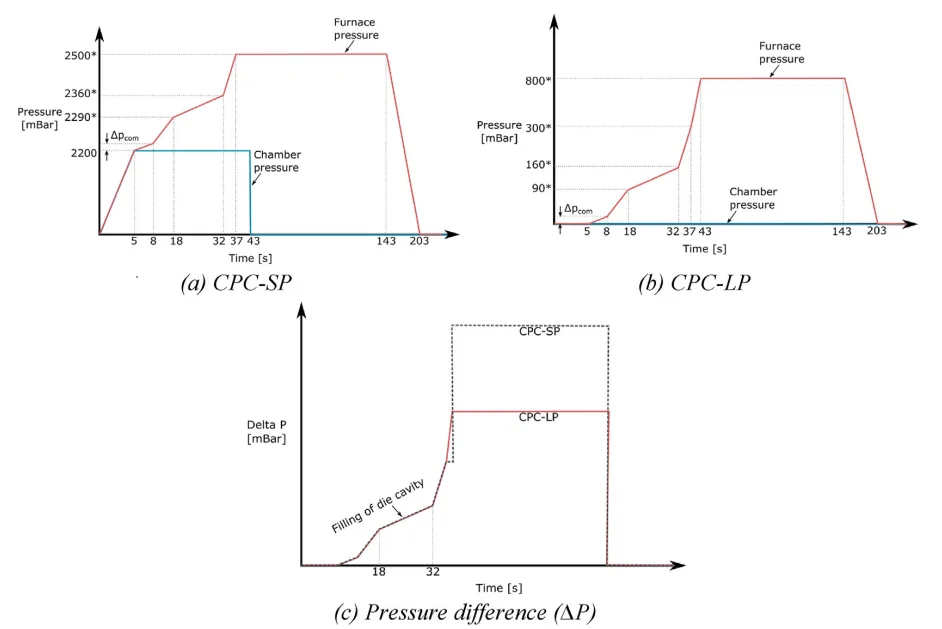

- Fig. 4 – Furnace pressure, chamber pressure and resulting pressure differential variation with time for the CPC-SP and CPC-LP process conditions.

- Fig. 5 – Cooling timings - refer to Fig. 3 (a) for the locations of cooling channels on the top die.

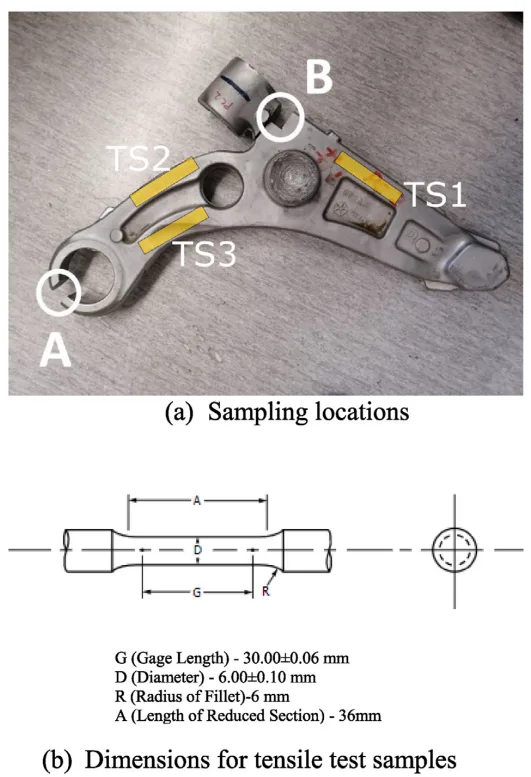

- Fig. 6 – Samples removed from the control arm for microstructural analysis and tensile tests.

- Fig. 7 – Schematic of spot or finger-type cooling element used in the CPC process.

- Fig. 8 – Temperatures measured from three sequential cycles.

- Fig. 9 – Temperatures measured by different TCs from a cyclic steady state cycle.

- Fig. 10 – Comparison of temperatures measured from different process conditions.

- Fig. 11 – Optical microscopy observation of the samples.

- Fig. 12 – SDAS measurements.

- Fig. 13 – Tensile test results.

- Fig. 14 – Temperature comparison between the model results and measured data.

- Fig. 15 – Solidification sequence - represented by contours of solid fraction limited to 0.7.

- Fig. 16 – Location of porosity detected by CT scanning.

7. Conclusion:

This study provides the first comprehensive investigation into the effects of applied chamber pressure in an industrial CPC process. The analysis of extensive in-plant data and post-casting characterization reveals that the primary effect of the increased counter pressure is a significant delay in die filling (~12 s), likely caused by reduced venting efficiency. Contrary to some industry claims, the study found no significant influence of chamber pressure on the evolution of the thermal field within the die, nor any measurable improvement in the microstructure (SDAS) or mechanical properties (UTS) of the final casting. Furthermore, the research successfully demonstrated that a computational modelling methodology originally developed for LPDC is broadly applicable to the CPC process with only minor modifications, confirming its robustness for simulating various permanent die casting operations.

8. References:

- [1] Martin Kahl XB. Special report: vehicle lightweighting. 2016.

- [2] Isenstadt A, German J, Bubna P, Wiseman M, Venkatakrishnan U, Abbasov L, et al. Lightweighting technology development and trends in US passenger vehicles. Int. Counc. Clean Transp. Work. Pap. 2016;25.

- [3] Bonollo F, Urban J, Bonatto B, Botter M. Gravity and low pressure die casting of aluminium alloys: a technical and economical benchmark. La Metall Ital 2005:23–32.

- [4] Butler WA. High pressure die casting; encyclopedia of materials. Science and Technology; 2001.

- [5] Zhang B, Maijer DM, Cockcroft SL. Development of a 3-D thermal model of the low-pressure die-cast (LPDC) process of A356 aluminum alloy wheels. Mater Sci Eng, A 2007;464:295–305. https://doi.org/10.1016/j.msea.2007.02.018.

- [6] Collot J. Review OF new process technologies IN the aluminum die-casting industry. Mater Manuf Process 2001;16:595–617. https://doi.org/10.1081/AMP-100108624.

- [7] Hu H, Chen F, Chen X, Chu YL, Cheng P. Effect of cooling water flow rates on local temperatures and heat transfer of casting dies. J Mater Process Technol 2004;148:57–67. https://doi.org/10.1016/j.jmatprotec.2004.01.040.

- [8] Liu GW, Morsi YS, Clayton BR. Characterisation of the spray cooling heat transfer involved in a high pressure die casting process. Int J Therm Sci 2000;39:582–91. https://doi.org/10.1016/S1290-0729(00)00207-6.

- [9] Vijayaram TR. CounterPressure casting techniquefor aluminium foundries. 2012.

- [10] Katzarov IH, Arsov YB, Stoyanov P, Zeuner T, Buehrig-Polaczek A, Sahm PR. Porosity formation in axi-symmetric castings produced by counter-pressure casting method. Int J Heat Mass Tran 2001;44:111–9. https://doi.org/10.1016/S0017-9310(00)00085-5.

- [11] Ou J, Wei C, Maijer D, Cockcroft S, Zhang Y, Chen Z, et al. Modelling of an industrial die casting process for the production of aluminum automotive parts. In: Proceedings of the IOP conference series: materials science and engineering, vol. 861. Institute of Physics Publishing; 2020. p. 12030.

- [12] Zhu J, Cockcroft S, Maijer D. Modeling of microporosity formation in A356 aluminum alloy casting. Metall Mater Trans A 2006;37:1075–85. https://doi.org/10.1007/s11661-006-1027-5.

- [13] Reilly C, Duan J, Yao L, Maijer DM, Cockcroft SL. Process modeling of low-pressure die casting of aluminum alloy automotive wheels. JOM 2013;65:1111–21. https://doi.org/10.1007/s11837-013-0677-1.

- [14] Duan J, Maijer D, Cockcroft S, Reilly C. Development of a 3D filling model of low-pressure die-cast aluminum alloy wheels. Metall Mater Trans A 2013;44:5304–15. https://doi.org/10.1007/s11661-013-1654-6.

- [15] Yao L, Cockcroft S, Zhu J, Reilly C. Modeling of microporosity size distribution in aluminum alloy A356. Metall Mater Trans A 2011;42:4137–48. https://doi.org/10.1007/s11661-011-0811-z.

- [16] Ou J, Wei C, Cockcroft S, Maijer D, Zhu L, A L, et al. Advanced process simulation of low pressure die cast A356 aluminum automotive wheels — Part I, process characterization. Metals (Basel). 2020;10:563. https://doi.org/10.3390/met10050563.

- [17] Ou J, Wei C, Cockcroft S, Maijer D, Zhu L, A L, et al. Advanced process simulation of low pressure die cast A356 aluminum automotive wheels—Part II modeling methodology and validation. Metals (Basel). 2020;10:1418. https://doi.org/10.3390/met10111418.

- [18] Jahangiri A, Marashi SPH, Mohammadaliha M, Ashofte V. The effect of pressure and pouring temperature on the porosity, microstructure, hardness and yield stress of AA2024 aluminum alloy during the squeeze casting process. J Mater Process Technol 2017;245:1–6. https://doi.org/10.1016/j.jmatprotec.2017.02.005.

- [19] Georgiev GE, Stanev L, Georgiev M, Maneva A, Stanev S. Optimization OF the process OF casting formation BY CPC method using computer simulation. 2017.

- [20] Vandersluis E, Ravindran C. Comparison of measurement methods for secondary dendrite arm spacing. Metallogr. Microstruct. Anal. 2017;6:89–94. https://doi.org/10.1007/s13632-016-0331-8.

- [21] Wei C, Ou J, Fan P, Mehr F, Maijer D, Cockcroft S, et al. Toward the development of a thermal-stress model of an industrial counter pressure casting process. In: Proceedings of the IOP conference series: materials science and engineering, vol. 861. Institute of Physics Publishing; 2020. p. 12062.

9. Copyright:

- This material is a paper by "Jun Ou, et al.". Based on "A study of an industrial counter pressure casting process for automotive parts".

- Source of the paper: https://doi.org/10.1016/j.jmrt.2021.11.124

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.

Paper Summarize:

This study comprehensively investigates the effect of chamber back-pressure in the Counter Pressure Casting (CPC) process on an industrial automotive part. The results show that while back-pressure significantly delays die filling by ~12 seconds, it has no measurable impact on the thermal field, microstructure, or mechanical properties of the casting. The research also demonstrates that a computational modelling methodology for LPDC is broadly applicable to the CPC process with minor adjustments.

Key questions and answers about the research:

Q1. What is the most significant effect of applying chamber back-pressure during the die filling stage in the CPC process?

A1. The application of chamber back-pressure noticeably reduces the venting rate during filling, leading to a significant delay of approximately 12 seconds in filling time compared to a low back-pressure (LPDC-like) condition. (Source: "A study of an industrial counter pressure casting process for automotive parts", Abstract & Section 6)

Q2. Does the increased pressure in the CPC process improve the casting's mechanical properties or refine its microstructure compared to a low-pressure process?

A2. No, the study found no significant differences in mechanical properties or as-cast microstructure. The ultimate tensile strengths (UTSs) were within 7% for both process conditions, and there was no measurable difference in the Secondary Dendrite Arm Spacings (SDASs). (Source: "A study of an industrial counter pressure casting process for automotive parts", Abstract & Section 5.2)

Q3. It has been claimed that CPC enhances die-to-casting heat transfer. Does this study support that claim?

A3. No, this study does not support that claim. The analysis of in-die temperature data showed no significant differences between the high and low back-pressure conditions, with most temperature profiles differing by less than 10 °C, indicating that chamber pressure does not have a significant impact on the temperature field or interfacial heat transfer. (Source: "A study of an industrial counter pressure casting process for automotive parts", Section 5.1.1)

Q4. How does the thermal evolution within the die compare between the standard CPC process (CPC-SP) and the low back-pressure process (CPC-LP)?

A4. After accounting for the 12-second filling delay, the temperature evolution at various locations in the die is very similar between the two process conditions. Most locations exhibit a temperature difference within the range of 0-10 °C, indicating that the overall thermal field is not significantly influenced by the chamber pressure. (Source: "A study of an industrial counter pressure casting process for automotive parts", Section 5.1.1 & Figure 10)

Q5. Can computational models developed for the LPDC process be used to simulate the CPC process?

A5. Yes, the study demonstrated that a computational modelling methodology originally developed for LPDC can be successfully applied to simulate the CPC process. The model only required an adjustment to the pressure curve to account for the delay in filling caused by the reduced venting rate under high back-pressure. (Source: "A study of an industrial counter pressure casting process for automotive parts", Abstract & Section 6)

Q6. What was the cause of the observed ~12-second filling delay in the high back-pressure CPC process?

A6. The filling delay was speculated to be due to a larger resistance to venting. The elevated pressure in the chamber increases the viscosity of the air, which in turn inhibits its ability to escape through the die vents, slowing down the filling process despite an identical driving pressure differential. (Source: "A study of an industrial counter pressure casting process for automotive parts", Section 6)