This article introduces the paper "A super-ductile alloy for the die-casting of aluminium automotive body structural components".

1. Overview

- Title: A super-ductile alloy for the die-casting of aluminium automotive body structural components

- Authors: Douglas Watson, Shouxun Ji, Zhongyun Fan

- Year of Publication: 2014

- Journal/Conference: Materials Science Forum Vols. 794-796

- Keywords: Aluminium alloys, High pressure die casting, Automotive, Mechanical properties, Microstructure

2. Research Background

This research is based on the premise that weight reduction through the use of lightweight materials in the manufacturing of fuel-efficient transportation systems is an effective method for improving fuel economy and reducing harmful emissions. The increasing use of aluminum alloys in the automotive industry presents significant opportunities for weight reduction and achieving environmental goals. High-Pressure Die Casting (HPDC) is a popular manufacturing process for producing near-net-shape parts with tight dimensional tolerances, requiring minimal machining.

There's a growing trend towards using more aluminum in automotive body structures. Both wrought and cast aluminum alloys are essential in the space-frame and monocoque designs of aluminum-intensive passenger cars. However, the mechanical properties, particularly the ductility, of currently available die-cast alloys are insufficient to meet industrial demands.

3. Research Objectives and Questions

- Research Objective: To develop a super-ductile die-cast aluminum alloy suitable for automotive body structural components.

- Key Research Questions: What is the optimal composition of a die-cast aluminum alloy that meets the mechanical property requirements for automotive body structural parts? How do alloying elements affect the microstructure and mechanical properties?

- Research Hypothesis: Optimizing the composition of an Al-Mg-Si system alloy will enable the development of a super-ductile die-cast aluminum alloy that meets the requirements for automotive body structural components.

4. Research Methodology

- Research Design: Experimental design. Die casting specimens were produced with varying compositions of Al-Mg-Si alloys, followed by mechanical property testing and microstructural analysis.

- Data Collection Methods: Optical microscopy, Scanning Electron Microscopy (SEM), Energy Dispersive Spectroscopy (EDS), tensile testing.

- Analysis Methods: Quantitative metallography, phase equilibrium analysis, EDS analysis for microstructural characterization, and analysis of tensile test results.

- Research Subjects and Scope: Al-Mg-Si alloys.

5. Main Research Findings

- Key Findings: An Al-Mg-Si alloy with a composition of 5wt-%Mg, 1.5wt-%Si, 0.6wt-%Mn, and 0.2wt-%Ti exhibited optimal super-ductility, achieving a yield strength of 150MPa, an ultimate tensile strength of 300MPa, and an elongation of 15%. Mg contributed more significantly to the improvement of mechanical properties than Si. Controlling the proportion of the Mg₂Si phase in the microstructure is crucial for enhancing ductility.

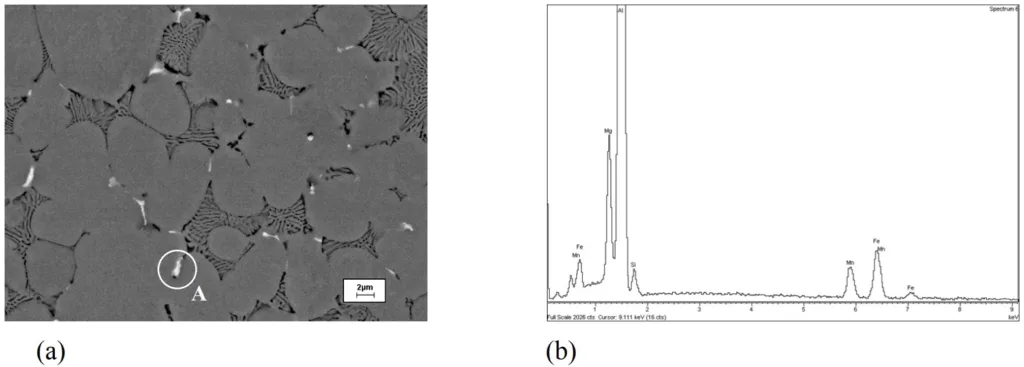

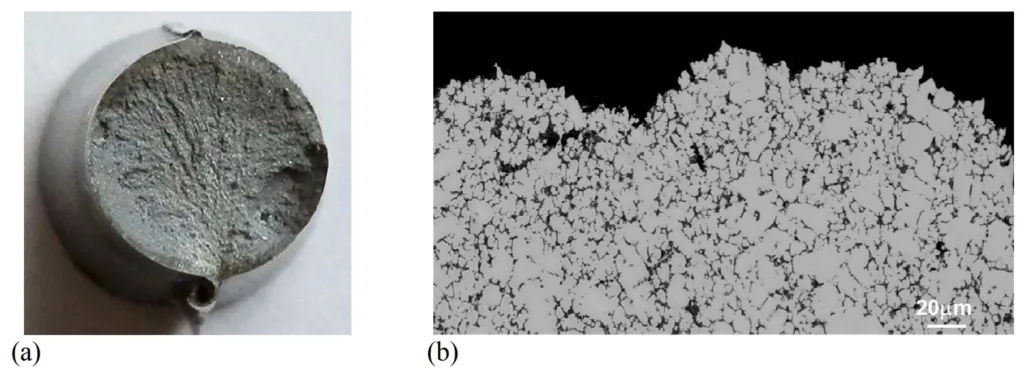

- Statistical/Qualitative Analysis Results: Figure 2 shows the effect of Mg and Si content on yield strength, ultimate tensile strength, and elongation. Figures 3 and 4 illustrate the microstructure (dendritic, globular, and eutectic phases) and distribution of the Mg₂Si phase in the optimized Al-Mg-Si alloy. Figures 5 and 6 show the macro and microstructures of the fracture surfaces, revealing a mixed brittle and ductile fracture mode.

- Data Interpretation: The optimized Al-Mg-Si alloy exhibits superior mechanical properties due to its fine and uniform microstructure and the appropriate distribution of the Mg₂Si phase.

- Figure List:

- Figure 1: The equilibrium phase diagrams (a) Al-Mg₂Si binary alloys, (b) Al-Mg-Si ternary alloys

- Figure 2: (a) Effect of magnesium and silicon on the yield strength, the ultimate tensile strength and the total elongation of Al-Mg-Si die-cast alloy (b) The yield strength, the ultimate tensile strength and the total elongation of Al-5Mg-1.5Si-Mn die-cast alloy at optimized composition.

- Figure 3: Microstructures of die-cast Al-5Mg-1Si

- Figure 4: (a) Backscattered SEM micrograph showing the distribution of intermetallics along grain boundaries in Al-5Mg-1.5Si die-cast alloy, and (b) EDS diagram showing the elements in particle A.

- Figure 5: Optical micrographs showing (a) the overall fracture surface, (b) the microstructure on a section perpendicular to the fractured surface of Al-5Mg-1.5Si die-cast alloy.

- Figure 6: SEM image on the fractured surface of Al-5Mg-1.5Si die-cast alloy

6. Conclusions and Discussion

This research identified the optimal composition of a super-ductile die-cast aluminum alloy suitable for automotive body structural components. The optimized alloy exhibits excellent mechanical properties and a relatively simple microstructure. These findings have significant implications for the manufacturing of automotive parts using HPDC. However, the mixed brittle and ductile fracture observed is a limitation.

7. Future Research

Future research should investigate the effects of various die-casting process parameters, explore microstructural and mechanical property control through different heat treatments, and focus on improving corrosion resistance. Further research is also needed to validate the findings in actual automotive part manufacturing.

8. References

[1] D. Codd, Advanced Lightweight Materials Development and Technology for Increasing

Vehicle Efficiency, KVA Inc., Escondido CA 92029 USA, 2008.

[2] T. Zeuner, L. Würker, Process Optimisation of Cast Aluminium Chassis Components WFO

Technical Forum 2003, p3.1-3.14.

[3] A.Tharumarajah, Resources Conservation and Recycling 52(2008)1185.

[4] W.S. Miller, L. Zhuang, J. Bottema, A.J. Wittebrood, P. DeSmet, A. Haszler, A. Vieregge,

Mater Sci Eng A 280 (2000)37.

[5] European Aluminium Association. Aluminium in cars. European Aluminium Association, 2008

[6] G. E. Tot, D. S, MacKenzie, Handbook of Aluminium Vol 7. Physical Metallurgy and

Processes, Marcel Dekker, Inc. New York, Basel ISBN: 0-8247-0494-0, 2003 1st ed.

[7] V. Raghavan, Al-Mg-Si Phase Diagram Evaluations, Journal of Phase Equilibria and Diffusion

28 (2007189–191.

Copyright

This document is based on the paper: A super-ductile alloy for the die-casting of aluminium automotive body structural components by Douglas Watson, Shouxun Ji, and Zhongyun Fan.

Source: doi:10.4028/www.scientific.net/MSF.794-796.526

This document is a summary based on the above paper and its unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.