Next-Gen HPDC Magnesium Alloys: A Guide to Higher Strength, Ductility, and Performance

This technical summary is based on the academic paper "Recent developments in high-pressure die-cast magnesium alloys for automotive and future applications" by Gerry Gang Wang and J.P. Weiler, published in Journal of Magnesium and Alloys (2023).

![Fig. 1. Aging curves of T4 heat treated AT72 HPDC specimens aged at

175 °C and 200 °C respectively [19] (Copyright 2013 by The Minerals,

Metals & Materials Society. Used with permission).](https://castman.co.kr/wp-content/uploads/image-3696.webp)

Keywords

- Primary Keyword: HPDC Magnesium Alloys

- Secondary Keywords: Automotive lightweighting, high-strength magnesium alloys, high-ductility magnesium, thermal conductivity, Mg-Al alloys, Al-free Mg alloys, die castability

Executive Summary

- The Challenge: The automotive industry requires HPDC magnesium alloys with properties superior to conventional grades like AZ91D and AM60B to meet the demands of more complex and lightweight structural components.

- The Method: The paper reviews recent developments in both traditional Mg-Al based and newer Al-free magnesium alloy systems, evaluating their mechanical properties, castability, and performance for transportation applications.

- The Key Breakthrough: New alloy families have been developed that offer targeted improvements, including superior ductility (Mg-Al-Zn-Mn, MRI 260D), a better balance of strength and ductility (AT72), enhanced high-temperature creep resistance (AE44 with Mn), and high thermal conductivity for EV applications (DSM-1).

- The Bottom Line: A new, diverse portfolio of specialized HPDC magnesium alloys is now available, enabling engineers to select materials with tailored properties that overcome the limitations of traditional alloys for specific, high-performance applications.

The Challenge: Why This Research Matters for HPDC Professionals

For decades, the automotive industry has relied on a handful of standard HPDC magnesium alloys—AZ91D for strength, AM50/AM60 for ductility, and AE44 for high-temperature applications. While effective, these alloys represent a compromise. As vehicle designs evolve, particularly with the rise of electric vehicles (EVs) and the unceasing demand for lightweighting, the need for materials with enhanced, specific properties has become critical.

Engineers are increasingly facing challenges where standard alloys fall short. They need materials with higher ductility for energy absorption in crash-related structural parts, better creep resistance for powertrain components in hotter environments, and higher thermal conductivity for EV motor housings and electronics. This research addresses this critical industry gap by summarizing the new generation of HPDC magnesium alloys designed to solve these specific engineering problems.

The Approach: Unpacking the Methodology

This paper provides a comprehensive review of emerging HPDC magnesium alloys, classifying them into distinct families based on their alloying additions and performance characteristics. The authors synthesized data from numerous studies to compare these new materials against conventional industry standards.

Method 1: Evaluating Mg-Al Based Alloy Enhancements

The study first examines modifications to the traditional Mg-Al system. This includes:

- Sn (Tin) Additions: Investigating alloys like AT72 (Mg-7Al-2Sn) to understand their effect on strength, ductility, and age-hardening response.

- Zn (Zinc) Additions: Analyzing a new Mg-Al-Zn-Mn alloy family to evaluate its die castability, surface quality, and the ability to tailor ductility and strength by varying Al and Zn content.

- RE (Rare Earth), Ca (Calcium), and Ba (Barium) Additions: Reviewing alloys designed for improved high-temperature performance (like AE44 with modified Mn content and the DieMag series) or enhanced thermophysical properties (like AZEX4441 and DSM-1 for thermal conductivity).

Method 2: Assessing Novel Al-Free Alloy Systems

The review also explores alloys that move away from the Mg-Al system entirely, opening new avenues for property optimization. This includes:

- Mg-Zn-Zr-RE Systems: Detailing the properties of the MRI 240D/250D/260D family, which is notable for its exceptional ductility and good strength.

- Mg-RE and Mg-Y Based Systems: Discussing alloys developed for high-temperature strength and creep resistance, including GW63K and a new WZA631 (Mg-Y-Zn-Al) alloy with potential for aerospace applications.

The Breakthrough: Key Findings & Data

The review highlights several new alloys with performance characteristics that significantly surpass traditional grades.

Finding 1: New Mg-Al-Zn-Mn Alloys Deliver Superior Ductility and Castability

A newly developed Mg-Al-Zn-Mn alloy system demonstrated significant improvements over the workhorse AM-series alloys. As shown in Figure 4(a), the bending ductility of the new "Group 1" to "Group 3" alloys was higher than or equal to AM50A, the more ductile benchmark. Furthermore, the castability was superior; Table 5 shows the new alloys had fewer surface anomalies and significantly lower gross porosity (0.6-1.2%) compared to the AM50A/AM60B baseline (4.8%). This indicates a more robust and reliable material for complex, thin-walled structural parts.

Finding 2: Al-Free MRI 260D Achieves Unprecedented Elongation

The development of the Al-free MRI alloy family represents a major leap in ductility. As detailed in Table 13, the MRI 260D alloy achieved a total fracture elongation of 28%. This is nearly three times higher than the 10% elongation of AM50A and the 8% of AM60B, making it an exceptional candidate for components requiring high energy absorption during a crash, such as body-in-white structures.

Finding 3: DSM-1 Alloy Matches Aluminum's Thermal Conductivity for EV Applications

For EV and HEV applications where thermal management is critical, the development of alloys with high thermal conductivity is a game-changer. Table 12 shows that the DSM-1 alloy has a thermal conductivity of 98.0 W/m-K. This is nearly double the conductivity of AZ91D (approx. 53 W/m-K) and is comparable to that of the widely used A380 aluminum alloy (96 W/m-K), providing a lightweight alternative for motor housings, battery trays, and inverters without compromising thermal performance.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that many new alloys, such as the Mg-Al-Zn-Mn family, exhibit excellent die castability and surface quality, potentially allowing for integration into existing HPDC processes with minimal disruption.

- For Quality Control Teams: The data in Table 9 and Table 13 of the paper illustrates the wide range of achievable mechanical properties. This information can be used to establish new quality inspection criteria for components made from these advanced alloys, ensuring they meet design specifications for strength and ductility.

- For Design Engineers: The findings provide a new toolbox of materials for component optimization. The exceptional ductility of MRI 260D (Table 13) makes it a prime candidate for crash-relevant structural parts, while the high thermal conductivity of DSM-1 (Table 12) makes it ideal for EV thermal management systems.

Paper Details

Recent developments in high-pressure die-cast magnesium alloys for automotive and future applications

1. Overview:

- Title: Recent developments in high-pressure die-cast magnesium alloys for automotive and future applications

- Author: Gerry Gang Wang, J.P. Weiler

- Year of publication: 2022 (Available online 26 October 2022, published in journal volume 2023)

- Journal/academic society of publication: Journal of Magnesium and Alloys

- Keywords: High-pressure die cast (HPDC), Magnesium alloys, Automotive applications, Mechanical properties, Ductility, High-temperature properties, Thermal conductivity

2. Abstract:

The use of magnesium alloy high pressure die cast (HPDC) components for structural applications, especially in the automotive and transportation industries, where weight reduction is of a great concern, is increasing. As new applications are developing and existing applications are becoming more complex, there is a need for improved properties from magnesium HPDC alloys. This paper reviews the recent developments in HPDC magnesium alloys for transportation applications. Compared to the conventional HPDC magnesium alloys, i.e. AZ91D, AM50A/AM60B and AE44, these new alloys have one or more of the following properties: higher strength, higher ductility, superior high-temperature properties or higher thermal conductivities. In this work, characteristics which are important in product manufacturing or product performance will be evaluated and discussed, including die castability of powertrain component or thin-walled structural component, mechanical properties at elevated temperatures and ductility. Results indicate that these alloys have great potentials to be added to the current magnesium HPDC alloy family and being used in actual automotive and other transport applications.

3. Introduction:

High-pressure die-castings using magnesium alloys are a primary method for achieving lightweighting objectives in the automotive industry. Magnesium's low density (33% less than aluminum, 75% less than steel), high fluidity, and minimal affinity for tool steel make it highly suitable for the HPDC process, enabling the production of large, thin-walled, and complex near-net-shape components. Traditional industrial alloys like AZ91D (for strength), AM50A/AM60B (for ductility), and AE44 (for elevated temperatures) have been the standard for decades. However, in the last 10 years, new developments have emerged to address the need for further improved properties for more demanding automotive applications. This paper aims to summarize these recent developments in HPDC magnesium alloys.

4. Summary of the study:

Background of the research topic:

The study is set against the backdrop of increasing demand for lightweight materials in the automotive and transportation industries to improve fuel efficiency and performance. Magnesium HPDC components are a key technology in this area, but their expansion into more critical structural and powertrain applications is limited by the property profiles of conventional alloys.

Status of previous research:

Previous work established a family of standard Mg-Al based alloys (AZ91D, AM50A/AM60B, AE44) that offer a baseline of strength, ductility, and high-temperature performance. Research has focused on refining these systems or developing new alloy compositions to overcome their inherent trade-offs.

Purpose of the study:

The purpose of this paper is to review and consolidate the recent advancements in HPDC magnesium alloys. It aims to classify new alloy systems and evaluate their properties—such as strength, ductility, high-temperature performance, and thermal conductivity—in comparison to conventional alloys, highlighting their potential for current and future transportation applications.

Core study:

The core of the study is a systematic review of newly developed HPDC magnesium alloys. The review is structured into two main categories: Mg-Al based alloy developments and Al-free Mg alloy developments.

1. Mg-Al Based Alloys: This section analyzes alloys with additions of Sn (AT72, ATS alloys), Zn (Mg-Al-Zn-Mn family), and combinations of Rare Earths (RE), Ca, and Ba (AE44 modifications, DieMag alloys, AZEX4441, DSM-1). The focus is on how these additions influence mechanical properties, age-hardening response, creep resistance, and thermophysical properties.

2. Al-Free Alloys: This section examines newer systems, including Mg-Zn-Zr-RE (MRI 240D/250D/260D), Mg-RE based alloys, and Mg-Y based alloys (WZA631). These alloys are evaluated for their unique property combinations, particularly exceptionally high ductility or high-temperature strength.

For each alloy family, the paper discusses die castability, mechanical properties (at ambient and elevated temperatures), and potential applications.

5. Research Methodology

Research Design:

The research design is a comprehensive literature review. It synthesizes and organizes findings from a wide range of recent scientific papers, technical reports, and patents related to HPDC magnesium alloys.

Data Collection and Analysis Methods:

Data on chemical compositions, mechanical properties (tensile strength, yield stress, elongation), physical properties (thermal conductivity), and processing characteristics (die castability) were collected from published sources. The analysis involves a comparative assessment of these new alloys against established industrial benchmarks (AZ91D, AM50A, AM60B, AE44) to quantify their improvements and identify their most suitable applications.

Research Topics and Scope:

The scope of the review is focused on high-pressure die-cast magnesium alloys with potential for automotive and other transportation applications. The research topics cover the development of alloys with:

- Higher strength

- Higher ductility/elongation

- Improved high-temperature properties (creep resistance)

- Improved thermophysical properties (thermal conductivity)

6. Key Results:

Key Results:

- Mg-Al-Sn Alloys (AT72): These alloys provide a good combination of strength and ductility, with AT72 showing properties intermediate between AZ91D and AM50. They also exhibit a significant, albeit slow, age-hardening response.

- Mg-Al-Zn-Mn Alloys: This new family demonstrates improved soundness and surface quality in castings compared to AM50A/AM60B. Their mechanical properties can be tailored by adjusting Al and Zn content to prioritize either ductility or strength.

- AE44 with Mn Additions: Minor additions of Mn to AE44 were found to remarkably improve creep resistance at 175 °C and induce a significant age-hardening response, challenging the traditional understanding of this alloy's strengthening mechanisms.

- High Thermal Conductivity Alloys (DSM-1, AZEX4441): Alloys have been developed specifically for EV/HEV applications, with thermal conductivities (94-98 W/m-K) nearly double that of AZ91D and comparable to aluminum A380.

- Al-free MRI Alloys (MRI 240D/250D/260D): This family exhibits an outstanding combination of properties, most notably very high fracture elongation (up to 28% for MRI 260D) in the as-cast state, far exceeding that of any conventional ductile Mg alloy. They also show a good age-hardening response.

- Al-free High-Temperature Alloys (GW63K, WZA631): Mg-RE and Mg-Y based alloys show potential for high-strength applications at elevated temperatures, with properties that can be significantly enhanced through heat treatment.

Figure Name List:

![Fig. 2. Aging curves of T4 heat treated (420 °C/10 h) ATS and AT72 HPDC specimens aged at 200 °C [20] (Copyright 2016 by The Minerals, Metals & Materials Society. Used with permission)](https://castman.co.kr/wp-content/uploads/image-3697.webp)

![Fig. 4. Average bending angles of the Mg-Al-Mn-Zn alloy family versus AM alloys [28].](https://castman.co.kr/wp-content/uploads/image-3699-1024x342.webp)

- Fig. 1. Aging curves of T4 heat treated AT72 HPDC specimens aged at 175 °C and 200 °C respectively [19] (Copyright 2013 by The Minerals, Metals & Materials Society. Used with permission).

- Fig. 2. Aging curves of T4 heat treated (420 °C/10 h) ATS and AT72 HPDC specimens aged at 200 °C [20] (Copyright 2016 by The Minerals, Metals & Materials Society. Used with permission).

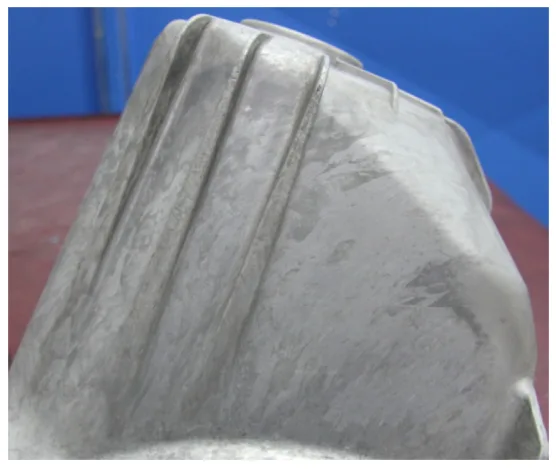

- Fig. 3. HPDC automotive component casting used in the Mg-Al-Zn-Mn alloy development.

- Fig. 4. Average bending angles of the Mg-Al-Mn-Zn alloy family versus AM alloys [28].

- Fig. 5. Creep properties at 175 °C and 90 MPa of the AE44 alloys with various Mn contents [35] (Copyright 2021 by Elsevier. Used with permission).

- Fig. 6. Pit-tail test result of HPDC MRI 260D tensile bar (as-cast).

7. Conclusion:

Newly developed HPDC magnesium alloys are targeting specific property improvements over conventional grades, including higher strength, higher ductility, superior high-temperature performance, and higher thermal conductivity. The main research focus remains on Mg-Al based systems, with new alloying elements like Sn being used to optimize precipitation hardening, and RE elements being used to improve high-temperature properties. A significant new trend is the development of alloys with high thermal conductivity to meet the demands of EV/HEV applications; some new alloys now match the performance of HPDC aluminum. Furthermore, new Al-free alloy systems offer novel property combinations, such as exceptionally high ductility. While only a few of these new alloys have been evaluated for industrial-scale die castability, they represent a significant expansion of the material options available for automotive and transportation applications.

8. References:

- [1] A. Lou, J Magn Alloys 1 (2013) 2-22.

- [2] A. Lou, Applications: aerospace, automotive and other structural applications of magnesium, in: P. Mihriban, K. Uainer, A. Kaya (Eds.), Fundamentals of Magnesium Alloy metallurgy, Woodhead Publishing Ltd, Cambridge, UK, 2013, pp. 266-310.

- [3] R. Berkmortel, G.G. Wang, J. Jekl, et al., Magnesium applications in the automotive industry and the developing trends, in: The Proceedings of The 10th China International Diecasting Congress, Shanghai, China, 2015 JulyArticle #5.

- [4] J.P. Weiler, J Magn Alloys 7 (2019) 297-304.

- [5] G.G. Wang, K. MacKenzie, C. Sweet, et al., SAE Int J Mater Manuf 13 (3) (2020).

- [6] G.G. Wang, J. Bos, J Magn Alloys 6 (2018) 114-120.

- [7] M. Videm, J. Skar, P. Bakke, Corrosion properties of die cast AM alloys, in: B. Mordike, K. Kainer (Eds.), Magnesium Alloys and Their Applications, 2000, pp. 432-437.

- [8] M. Avedesian, H. Baker, Magnesium and Magnesium Alloys, ASM International, U.S.A., 1999.

- [9] J. Skar, J. Willekens, Corrosion properties and protection of magnesium die castings, 12th Magnesium Automotive and End User Seminar, Aalan, Germany, 2004.

- [10] P. Bakke, K. Pettersen, D. Albright, The influence of Sb, Si and Sn on the mechanical properties of Mg-Al alloys, in: A.A. Luo (Ed.), Magnesium Technology 2004, TMS (The Minerals, Metals & Materials Society), 2004, pp. 289-296.

Expert Q&A: Your Top Questions Answered

Q1: Why investigate Sn (tin) additions, which have historically been known to sometimes reduce ductility?

A1: The paper shows that while some strengthening comes at the expense of ductility, a carefully controlled addition of Sn can create a superior overall balance of properties. For example, the AT72 alloy (Mg-7Al-2Sn) has a higher yield strength than AM50 and higher ductility than AZ91D (Table 2). This balanced profile makes it very attractive for applications that require a combination of strength and moderate ductility, filling a performance gap between the two most common conventional alloys.

Q2: What is the primary advantage of the new Mg-Al-Zn-Mn alloys over the standard AM series for structural parts?

A2: The primary advantage is a combination of improved castability and tailorable ductility. The study reports that this new alloy family produces castings with better surface quality and significantly less porosity than the AM50A/AM60B baseline (Table 5). This leads to more reliable and consistent parts. Additionally, engineers can adjust the Al and Zn content to either maximize ductility (surpassing AM50A) or increase strength, offering greater design flexibility.

Q3: For high-temperature powertrain applications, are complex rare earth (RE) alloys still the only option?

A3: Not necessarily. The paper highlights that minor additions of a common element like manganese (Mn) can have a remarkable effect. Adding just 0.3% Mn to the AE44 alloy significantly improved its creep resistance at 175°C (Figure 5). This was attributed to the precipitation of nano-scale Al-Mn particles. This finding suggests that cost-effective modifications to existing alloys can provide significant high-temperature performance gains.

Q4: How does the ductility of the new Al-free MRI 260D alloy compare practically to AM60B in an as-cast state?

A4: The difference is substantial. As shown in Table 13, MRI 260D has a fracture elongation of 28% in the as-cast condition. This is a 250% improvement over AM60B, which has an elongation of only 8%. This leap in ductility makes MRI 260D a transformative material for safety-critical components and body structures that must absorb significant energy during impact.

Q5: The paper mentions high thermal conductivity is crucial for EVs. Which new alloy is most promising, and why?

A5: The DSM-1 alloy is identified as the most promising for thermal management applications. Its thermal conductivity of 98.0 W/m-K is nearly double that of AZ91D and is on par with HPDC aluminum A380 (Table 12). This allows designers to use a much lighter magnesium component for applications like motor housings, inverters, or battery enclosures without sacrificing the ability to dissipate heat effectively, which is a critical requirement for EV performance and longevity.

Conclusion: Paving the Way for Higher Quality and Productivity

The landscape of HPDC Magnesium Alloys is evolving rapidly, moving beyond the one-size-fits-all approach of the past. The research summarized in this paper demonstrates that a new generation of specialized alloys is available to solve today's toughest engineering challenges in the automotive industry and beyond. Whether the goal is achieving unprecedented ductility for safety components, managing heat in high-performance EVs, or enhancing strength at elevated temperatures, there is likely a new alloy designed for the task.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Recent developments in high-pressure die-cast magnesium alloys for automotive and future applications" by "Gerry Gang Wang, J.P. Weiler".

Source: https://doi.org/10.1016/j.jma.2022.10.001

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.