Beyond the Spec Sheet: Using Density Index to Predict Piston Casting Defects in Al-Si Alloys

This technical summary is based on the academic paper "Evaluation of the Technological Properties of the Al-Si Eutectic Alloy Based on Density Index Test" by M. Starczewski, A.J. Dolata, and M. Dyzia, published in ARCHIVES of FOUNDRY ENGINEERING (2025).

Keywords

- Primary Keyword: Density Index Al-Si Alloys

- Secondary Keywords: Piston Casting Defects, AlSi12CuNiMg, Shrinkage Porosity, Melt Quality, Foundry Engineering

Executive Summary

- The Challenge: A foundry experienced a high defect rate (30-40%) in Al-Si piston castings despite using an alloy that met all chemical composition standards.

- The Method: Researchers compared the high-defect alloy (Melt I) with a low-defect alloy (Melt II) using thermal analysis, fluidity tests, and density index (DI) tests at multiple production stages.

- The Key Breakthrough: The high-defect alloy exhibited an excessively low Density Index, which correlated with an increase in shrinkage porosity, challenging the conventional wisdom that lower gas content is always better.

- The Bottom Line: The Density Index test is a critical tool for predicting and preventing casting defects in Al-Si alloys, revealing quality issues that a standard chemical analysis will miss.

The Challenge: Why This Research Matters for HPDC Professionals

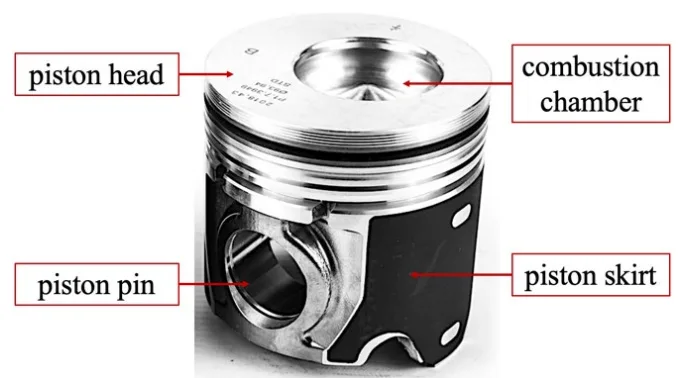

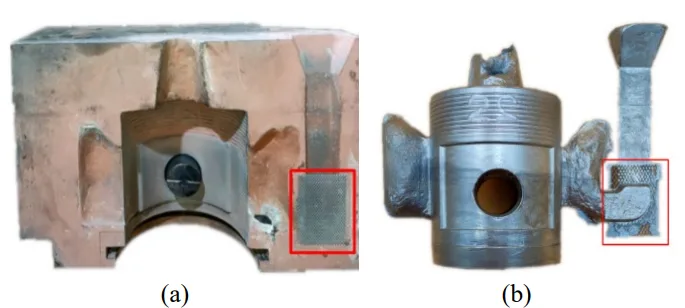

Every foundry professional has faced this frustrating scenario: a sudden spike in scrap rates for a complex part, like an engine piston, with no obvious cause. The raw material certificates confirm the AlSi12CuNiMg alloy is perfectly within the PN-EN 1676:2020-09 standard, and the casting process parameters are unchanged. Yet, defects, often revealed only after costly machining, are leading to rejection rates as high as 30-40%.

This was the exact problem faced at the Złotecki Sp. z o.o. production facility. Standard quality checks based on chemical composition were insufficient to predict the quality of the final piston casting. This research was initiated to dig deeper and identify the hidden technological parameters responsible for these costly defects, aiming to find a reliable method for monitoring liquid alloy quality before it enters the mould.

The Approach: Unpacking the Methodology

To isolate the root cause of the defects, the researchers conducted a comparative analysis of two AlSi12CuNiMg alloys with near-eutectic silicon content (~12%).

- Melt (I): The problematic alloy from a supplier, associated with a high defect rate of 30-40%.

- Melt (II): The standard production alloy, associated with a low, acceptable defect rate of 5%.

Both alloys were melted and refined under identical conditions using an argon gas refining process. Samples were taken at three key stages: 1) after melting, 2) after refining, and 3) after holding for 1.5 hours (simulating production time). Three distinct measurement methods were employed to evaluate the alloys' technological properties.

Method 1: Thermal Analysis (TA)

Standard Quick Cup ceramic crucibles with K-type thermocouples were used to record solidification curves. This analysis determined the precise start and end temperatures of solidification, providing insight into the alloys' thermal behavior.

Method 2: Fluidity Test (FT)

Using a Metal Health® System, the alloys' ability to fill a mould was tested. The test casting featured a five-arm structure with rods of varying cross-sections, and the total length of the filled rods served as the fluidity index.

Method 3: Density Index (DI) Test

This was the pivotal test. A 3VT basic vacuum casting device was used to create two samples from each melt: one solidified under atmospheric pressure (988 mbar) and the other under reduced pressure (80 mbar). The difference in their densities, calculated using a hydrostatic balance, yields the Density Index (DI), a direct measure of the alloy's gas content and propensity for porosity.

The Breakthrough: Key Findings & Data

The investigation revealed that while both alloys were chemically similar, their technological properties differed significantly, with the Density Index proving to be the critical indicator of quality.

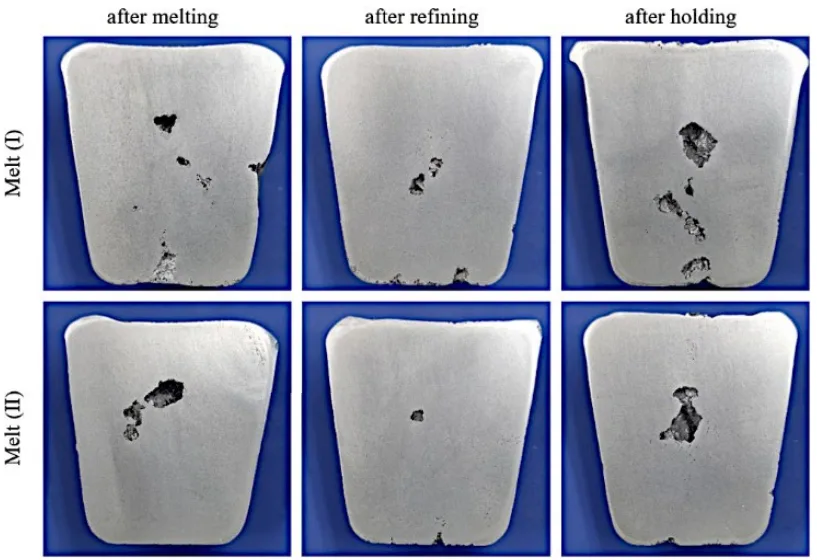

Finding 1: An Excessively Low Density Index Correlated with High Defect Rates

The most significant finding was the direct correlation between the Density Index and the observed defect rates. As shown in Figure 17 of the paper, the DI values told a clear story. After holding for 1.5 hours, the high-defect Melt (I) had a DI of only 0.57%. In contrast, the high-quality Melt (II) had a DI of 1.58%. While both alloys showed a low DI of ~0.40% immediately after argon refining, Melt (I) remained at a very low level, whereas Melt (II) showed a greater tendency to absorb hydrogen during holding, leading to a higher DI. This suggests that an excessively low gas level in Melt (I) may have contributed to an increase in shrinkage porosity, a defect type that can be more prevalent when gas porosity is minimal.

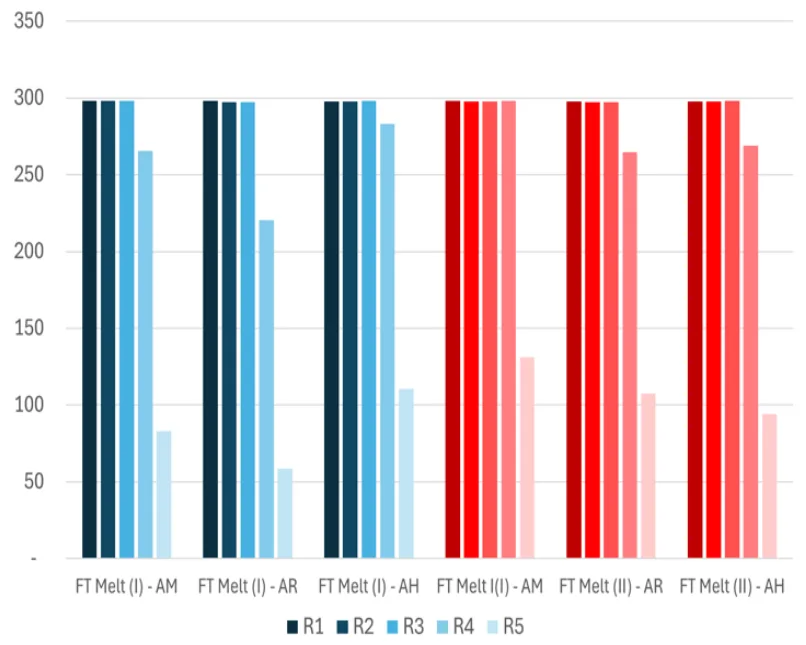

Finding 2: Fluidity Was Not the Root Cause

The fluidity tests showed that Melt (I) actually had slightly better fluidity than Melt (II), with a total rod length of 1287 mm compared to 1257 mm after holding (Figure 13). However, the researchers concluded this was not the cause of the defects. The minor differences in fluidity were only observed in the thinnest test channels (2-3 mm), whereas the wall thickness of the actual piston castings exceeded 5 mm. Therefore, the alloy's ability to fill the mould was not the limiting factor.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that simply minimizing gas content via refining is not enough. An optimal Density Index range may exist for specific castings. Process engineers should consider implementing DI testing as a standard pre-casting quality check and potentially develop a secondary gassing process to bring an over-refined melt back into the optimal DI window.

- For Quality Control Teams: The data in Figure 17 of the paper illustrates that two chemically compliant alloys can have vastly different DI values, directly impacting final part quality. This supports adding the Density Index test to incoming material inspection and in-process control protocols to catch problematic melts before they result in scrap.

- For Design Engineers: The findings indicate that for castings with significant variations in wall thickness, like the pistons studied, the melt's propensity for shrinkage porosity (linked to a low DI) is a critical factor. This reinforces the need to consider solidification dynamics and potential porosity types during the design phase.

Paper Details

Evaluation of the Technological Properties of the Al-Si Eutectic Alloy Based on Density Index Test

1. Overview:

- Title: Evaluation of the Technological Properties of the Al-Si Eutectic Alloy Based on Density Index Test

- Author: M. Starczewski, A.J. Dolata, M. Dyzia

- Year of publication: 2025

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING

- Keywords: Al-Si alloys, Piston, Solidification, Fluidity, Density index

2. Abstract:

Aluminium-silicon alloys are widely used in industrial practice due to their many advantages, including light weight and relatively high strength. The consumption of these light engineering materials is constantly increasing, especially in the automotive industry, due to new greenhouse gas (GHG) emission standards. The sustainable development strategy in the foundry industry is related to reducing the amount of waste and pollution generated during the production process. In turn, reducing the number of production shortages and waste requires the production of good quality Al-Si castings, and thus the appropriate selection and monitoring of technological parameters affecting the quality of the liquid alloy, including the level of purity and the degree of its gasification. The main objective of the research conducted to evaluate the technological properties of the AlSi12CuNiMg (AlSi12) alloy was to identify the causes of increased defect rates in piston castings during the production process at the Złotecki Sp. z o.o. The tests were carried out using two Al-Si alloys with silicon content close to eutectic (approx. 12%) used for piston castings, from two different suppliers. Three measurement methods were used to evaluate the technological properties of the tested AlSi12 alloys: thermal analysis, fluidity test and density index for gasification measurement. Based on the analysis of the results, it was concluded that an excessively low-density index level might be the cause of the increased casting defect rates observed in the production of pistons for internal combustion engines and compressors, particularly for castings with significant variations in wall thickness.

3. Introduction:

Aluminium-silicon (Al-Si) alloys are widely utilized in foundry applications due to their favorable properties such as light weight, high strength-to-weight ratio, corrosion resistance, and good conductivity. Their recyclability and ease of machining make them cost-effective for various industries, including automotive, where they are used for components like engine blocks, wheels, and pistons. The production of high-quality, complex Al-Si castings like pistons is challenging, and casting defects are a significant issue affecting product quality and production costs. The sustainable development of the foundry industry necessitates reducing waste and scrap, which requires precise control over the liquid alloy's quality, including its purity and gas content. This study was motivated by varying defect levels observed in serially produced piston castings at Złotecki Sp. z o.o., suggesting that chemical composition analysis alone is insufficient for predicting casting quality.

4. Summary of the study:

Background of the research topic:

The research addresses the persistent issue of casting defects in the production of near-eutectic Al-Si alloy pistons. Defects such as shrinkage and gas porosity are major concerns that impact the mechanical properties and service life of these critical automotive components. The study focuses on the premise that metallurgical quality, particularly gas content and purity, is a primary determinant of final casting integrity.

Status of previous research:

The literature confirms that porosity in Al-Si castings is influenced by hydrogen content, chemical composition, and solidification conditions. Work by Dispinar et al. has also highlighted a correlation between porosity and the presence of oxides in the melt. However, the specific problem of high defect rates in castings made from alloys that meet chemical specifications required a more focused investigation into other technological properties.

Purpose of the study:

The main objective was to identify the root causes of increased defect rates in AlSi12CuNiMg piston castings produced at Złotecki Sp. z o.o. The study aimed to evaluate and compare the technological properties of two alloys from different suppliers—one associated with high defect rates and one with low defect rates—to find a reliable indicator of melt quality beyond standard chemical analysis.

Core study:

The core of the study involved a comparative analysis of two AlSi12CuNiMg alloys, designated Melt (I) and Melt (II). Three key technological properties were evaluated: solidification behavior via thermal analysis (TA), mould-filling ability via a fluidity test (FT), and gas content via the density index (DI) test. These tests were performed at three distinct stages of the melt handling process: after initial melting, after argon refining, and after a 1.5-hour holding period at 730 ± 5 °C.

5. Research Methodology

Research Design:

The study employed an experimental research design to compare two commercially available AlSi12CuNiMg alloys under simulated industrial conditions. One alloy (Melt I) was identified as problematic due to a high in-production defect rate (30-40%), while the other (Melt II) served as a baseline with a low defect rate (5%). Both materials were processed identically to isolate differences in their intrinsic properties.

Data Collection and Analysis Methods:

- Materials Preparation: Two 200 kg charges of each alloy were melted in identical Nabertherm T 80/10 resistance furnaces. Refining was performed with granulated Ecosal AL 113.M and argon gas barbotage using a URO-200 XR device with a Foseco rotor.

- Thermal Analysis (TA): Samples were poured into standard Quick Cup crucibles with K-type thermocouples. Data was recorded at 10 Hz using an HBM Octopus data logger and Catman 3.0 software to determine solidification start (tpk) and end (tkk) temperatures.

- Fluidity Test (FT): The Metal Health® System was used with a five-arm test mould maintained at 300°C. The total length of the cast rods served as the fluidity index.

- Density Index (DI): A 3VT basic vacuum casting device was used to solidify samples under atmospheric (988 mbar) and reduced pressure (80 mbar). Densities were measured using an MK 3000 hydrostatic balance, and the DI was calculated using the formula DI = [(ρA – ρV) / ρA] * 100%.

Research Topics and Scope:

The research focused on the evaluation of solidification characteristics, fluidity, and gasification level of two near-eutectic Al-Si alloys used for piston manufacturing. The scope was limited to identifying correlations between these technological properties and the observed historical defect rates in an industrial production setting.

6. Key Results:

Key Results:

- Thermal Analysis: Both alloys had a similar initial solidification temperature (tpk) of approximately 566 ± 1 °C. However, the final solidification temperature (tkk) differed, with Melt (I) at 493 °C and Melt (II) at 501 ± 1 °C, likely due to minor variations in Si, Cu, and Ti content.

- Fluidity: Melt (I) demonstrated slightly higher fluidity than Melt (II) across all test conditions. However, the difference was not considered significant enough to explain the large discrepancy in defect rates, especially since the actual casting walls were thicker than the test channels where differences were most pronounced.

- Density Index: This test revealed the most critical differences. In the post-holding state, the high-defect Melt (I) had a very low DI of 0.57%, while the low-defect Melt (II) had a significantly higher DI of 1.58%. Although argon refining initially reduced the DI of both alloys to a similar low level (~0.4%), their behavior during subsequent holding diverged, indicating Melt (II) had a greater tendency to reabsorb hydrogen. The excessively low DI of Melt (I) was concluded to be a potential cause of increased shrinkage porosity.

Figure Name List:

- Fig. 1. View of the AlSi12CuNiMg combustion engine piston made by PMC

- Fig. 2. Casting defects revealed after machining in important piston parts: combustion chamber (a), piston head (b), piston pin hole (c), piston skirt (d) [unpublished own research]

- Fig. 3. Microstructure of the representative AlSil2CuNiMg piston obtained by PMC: (a) the dendritic structure (light grey) and eutectic Si particles (dark grey) are shown along with identified porosities (black) and (b) magnesium (Mg) oxide inclusion cluster [unpublished own research]

- Fig. 4. Filter mesh position: (a) casting mould, (b) casting

- Fig. 5. Casting furnaces used in the study

- Fig. 6. Gas refining device (a) and gas flow rotor (b)

- Fig. 7. Stand used for ST (a) and quick cup after test (b).

- Fig. 8. Metal Health® System stand used for FT

- Fig. 9. Casting of a fluidity sample (a), drawing of the cross-section of the bars (b)

- Fig. 10. Stand used for DI

- Fig.11. Hydrostatic balance MK 300

- Fig. 12. Solidification: Melt (I) i Melt (II), after melting

- Fig. 13. Fluidity index

- Fig. 14. Fluidity characteristic (AM – after melting, AR – after refining, AH - after holding)

- Fig. 15. Macrostructure of samples prepared in atmosphere

- Fig. 16. Macrostructure of samples prepared in 80 mbar vacuum

- Fig. 17. Density index results

![Fig. 2. Casting defects revealed after machining in important piston parts: combustion chamber (a), piston head (b), piston pin hole (c), piston skirt (d) [unpublished own research]](https://castman.co.kr/wp-content/uploads/image-3512.webp)

![Fig. 3. Microstructure of the representative AlSi12CuNiMg piston obtained by PMC: (a) the dendritic structure (light grey) and eutectic Si particles (dark grey) are shown along with identified porosities (black) and (b) magnesium (Mg) oxide inclusion cluster [unpublished own research]](https://castman.co.kr/wp-content/uploads/image-3513.webp)

7. Conclusion:

The obtained results indicate that even minor changes in the chemical composition of an alloy, while still within standard compliance, can significantly influence its technological properties and final casting porosity. The study concluded that the observed defects in piston castings made from Melt (I) were not related to the fluidity of the alloy. The Density Index (DI) test was identified as the most appropriate method for evaluating the degree of outgassing and its effect on gas porosity formation. The key finding is that the relatively low density index of the Melt (I) alloy (0.57% after holding) may have contributed to an increased number of defects associated with shrinkage porosity rather than gas porosity. This is supported by literature suggesting that at low H2 concentrations, voids associated with shrinkage may form. Further research is proposed to determine the optimal DI level for this application, potentially by developing a secondary gassing process to achieve a stable and predefined DI value.

8. References:

- [1] Dispinar, D., Kvithyld, A. & Nordmark, A. (2011). Quality assessment of recycled aluminium. In Stephen J. Lindsay(Eds.), Light Metals 2011. Springer, Cham.731-735. DOI: 10.1007/978-3-319-48160-9 127.

- [2] Kasińska, J., Bolibruchová, D. & Matejka, M. (2020). The influence of remelting on the properties of AlSi9Cu3 alloy with higher iron content. Materials. 13(3), 575, 1-13. DOI:10.3390/ma13030575.

- [3] Dursun, T. & Soutis, C. (2014). Recent developments in advanced aircraft aluminium alloys. Materials and Design. 56, 862-871. DOI: 10.1016/j.matdes.2013.12.002.

- [4] Javidani, M. & Larouche, D. (2014). Application of cast Al-Si alloys in internal combustion engine components. International Materials Reviews. 59(3), 132-158. DOI:10.1179/1743280413Y.0000000027.

- [5] Orłowicz, A.W., Tupaj M., Mróz, M. & Trytek, S. (2015). Combustion Engine Cylinder Liners Made of Al-Si Alloys. Archives of Foundry Engineering. 15(2), 71-74. DOI: 10.1515/afe-2015-0041.

- [6] Zeren, M. (2007). The effect of heat-treatment on aluminum-based piston alloys. Materials & Design. 28(9), 2511-2517. DOI: doi.org/10.1016/j.matdes.2006.09.010.

- [7] Kolmasiak, C. (2024). Decarbonization of production systems in foundries. Archives of Foundry Engineering. 24(2), 104-109. DOI: 10.24425/afe.2024.149276.

- [8] Jollya, M. & Katgerman, L. (2022). Modelling of defects in aluminium cast products. Progress in Materials Science. 123, 100824, 1-39. DOI: 10.1016/j.pmatsci.2021.100824.

- [9] Yang, Y., Yu, K., Li, Y., Zhao, D. & Liu, X. (2012). Evolution of nickel-rich phases in Al-Si-Cu-Ni-Mg piston alloys with different Cu additions. Materials and Design. 33, 220-225. https://doi.org/10.1016/j.matdes.2011.06.058.

- [10] Pasko J., Gaspar S. & Ružbarský J. (2014). Die casting defects of castings from silumin. Applied Mechanics and Materials. 510, 91-96. https://doi.org/10.4028/www.scientific.net/AMM.510.91.

- [11] Piątkowski, J., Roskosz, S. & Stach, S. (2024). The influence of selected high pressure die casting parameters on the porosity of EN AB-46000 alloy castings. Advances in Science and Technology Research Journal. 18(5), 361-371. DOI: 10.12913/22998624/191236.

- [12] Tiryakioğlu M. (2020). The effect of hydrogen on pore formation in aluminum alloy castings: myth versus reality. Metals. 10(3), 368, 1-17. DOI: 10.3390/met10030368.

- [13] Kucharčík, L., Brůna, M. & Sládek A. (2014). Influence of chemical composition on porosity in aluminium alloys. Archives of Foundry Engineering. 14(2), 5-8. ISSN (1897-3310).

- [14] Nicoletto G., Konečná, R. & Fintova, S. (2012). Characterization of microshrinkage casting defects of Al-Si alloys by X-ray computed tomography and metallography. International Journal of Fatigue. 41, 39-46. https://doi.org/10.1016/j.ijfatigue.2012.01.006.

- [15] Dispinar, D., Erzi, E., Gürsoy, Ö., Yüksel Ç. & Colak, M. (2019). Determination of acceptable quality limit for casting of A356 aluminium alloy: supplier's quality index (SQI). Metals. 9(9), 957, 1-14. DOI: 10.3390/met9090957.

- [16] Dispinar, D., Gursoy, O., Erzi, E. & Tur, K. (2020). Evolution of aluminium melt quality of A356 after several recycling. Archives of Foundry Engineering. 20(4), 61-66. DOI: 10.24425/afe.2020.133348.

- [17] Campbell, J. (2015). Complete casting handbook: Metal casting processes, metallurgy, techniques and design. UK: Butterworth-Heinemann.

- [18] Retrieved December 18, 2024, from https://zlotecki.pl/?lang=en

- [19] Haga, T., Imamura, S. & Fuse, H. (2021). Fluidity investigation of pure Al and Al-Si alloys. Materials. 14(18), 5372, 1-15. DOI: 10.3390/ma14185372.

- [20] Jang, H.S., Kang, H.J., Park, J.Y., Choi, Y.S. & Shin, S. (2020). Effects of casting conditions for reduced pressure test on melt quality of Al-Si alloy. Metals. 10(11), 1422, 1-14. DOI: 10.3390/met10111422.

- [21] Pietrowski, S. (2001). "Siluminy". Wydawnictwo Politechniki Łódzkiej. (in Polish).

- [22] Orłowicz, A.W., Mróz, M., Tupaj, M., Betlej, J. & Płoszaj, F. (2009). Influence of refining process on the porosity of high pressure die casting alloy Al-Si. Archives of Foundry Engineering. 9(2), 35-40.

- [23] Samuel, A.M., Samuel, E., Songmene, V. & Samuel, F.H. (2023). A review on porosity formation in aluminum-based alloys. Materials. 16, 2047, 1-26. https://doi.org/10.3390/ma16052047.

- [24] Bogdanova, T.A., Merkulova, G.A., Gilmanshina, T.R., Kosovich, A.A., Lytkina, S.I., Cheglakov, A.V. & Antonov, Μ.Μ. (2021). Comparative evaluation of methods for determination of hydrogen and non-metallic inclusions content in aluminum alloys. ARPN Journal of Engineering and Applied Sciences. 16(3), 355-360. ISSN (1819-6608).

Expert Q&A: Your Top Questions Answered

Q1: Why was the Density Index (DI) test chosen as a primary evaluation method?

A1: The DI test was chosen because it provides a direct, quantitative measure of the gas content within the liquid metal. While defects can arise from many sources, gas porosity is a primary concern in Al-Si alloys. The test is highly effective at revealing the melt's propensity to form voids under reduced pressure, simulating the conditions that can lead to porosity during solidification in the actual casting process.

Q2: The paper suggests a low DI is problematic. Isn't low gas content usually the goal of melt refining?

A2: Yes, typically, the goal of refining is to remove hydrogen to minimize gas porosity. However, this study presents a more nuanced situation. The conclusion suggests that with an excessively low DI (and thus very low hydrogen content), the formation of shrinkage porosity becomes the dominant defect mechanism. A small, controlled amount of dissolved gas can help distribute porosity on a micro-scale, preventing the formation of larger, more harmful shrinkage voids. The key takeaway is that there is likely an optimal DI range, not just a minimum target.

Q3: What were the key chemical differences between the two alloys, and how might they have influenced the results?

A3: According to Table 1, both alloys were within the PN-EN 1676:2020-09 standard. However, there were minor differences. Melt (I) had slightly higher Si (12.44% vs 12.05%), Cu (1.03% vs 0.97%), and Mg (1.20% vs 1.14%), while Melt (II) had slightly higher Ti (0.030% vs 0.020%). The paper suggests these small variations likely caused the observed difference in the final solidification temperature (493°C for Melt I vs. 502°C for Melt II), which can affect solidification dynamics and porosity formation.

Q4: How effective was the argon refining process on the two melts?

A4: The refining process was very effective for both alloys initially. As shown in Figure 17, after refining, the DI for both Melt (I) and Melt (II) was reduced to a similar low level of 0.40% and 0.37%, respectively. This demonstrates that the process itself successfully degassed the liquid metal. The critical difference appeared during the subsequent 1.5-hour holding period, where the alloys exhibited different hydrogen reabsorption behaviors.

Q5: What is the proposed next step for the foundry based on this research?

A5: The paper proposes further research to determine the optimal Density Index level for this specific piston casting. The suggested method is to develop a process for secondary alloy gassing. This would involve first refining the melt to a very low DI level and then intentionally and controllably re-introducing a mixture of argon and hydrogen to raise the DI to a predefined, stable target value before casting.

Conclusion: Paving the Way for Higher Quality and Productivity

This research powerfully demonstrates that relying on chemical composition alone is a gamble. The true indicator of melt quality for complex Al-Si castings lies in its technological properties, and the Density Index Al-Si Alloys test is an invaluable tool for revealing them. The key breakthrough—that an excessively low DI can lead to shrinkage defects—provides a crucial insight for foundries struggling with unexplained scrap rates. By moving beyond the spec sheet and implementing in-process controls like DI measurement, manufacturers can gain precise control over melt quality, reduce defects, and lower production costs.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Evaluation of the Technological Properties of the Al-Si Eutectic Alloy Based on Density Index Test" by "M. Starczewski, A.J. Dolata, M. Dyzia".

Source: https://doi.org/10.24425/afe.2025.155349

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.