Boosting Wear Resistance in Al-Si Alloys: A Breakthrough with V2O5 Particles in In-Situ Composites

This technical summary is based on the academic paper "Tribological Behaviour of Cast In-situ Al-Al2O3 Composite Developed by Stir Casting Using V2O5 Particles" by Amneesh Singla, Rajnish Garg, and Yashvir Singh, published in the Journal of the Chinese Society of Mechanical Engineers (2020).

Keywords

- Primary Keyword: Al-Al2O3 Composite

- Secondary Keywords: Stir Casting, V2O5 Particles, Tribological Behaviour, Wear Resistance, Al-7Si alloy, in-situ composite

Executive Summary

- The Challenge: Widely used Al-Si foundry alloys offer excellent fluidity for casting but suffer from poor tribological properties, limiting their reliability in high-wear industrial applications.

- The Method: Researchers developed an in-situ Al-Al2O3 composite by adding varying amounts (1, 3, and 5 wt.%) of Vanadium Pentoxide (V2O5) particles to an Al-7Si alloy using a controlled stir casting process.

- The Key Breakthrough: A small addition of just 1 wt.% V2O5 yielded the optimal composite, significantly increasing hardness by over 20% and reducing wear-related volume loss by 47.3% compared to the base alloy.

- The Bottom Line: For HPDC professionals, this research demonstrates that a precisely controlled, low-percentage addition of V2O5 is a highly effective and practical method for enhancing the wear performance of cast Al-Si components without complex alloying.

The Challenge: Why This Research Matters for HPDC Professionals

Aluminum-silicon (Al-Si) alloys are the workhorses of the casting industry, accounting for over 70% of castings due to their excellent fluidity and low weight. However, their widespread use in demanding applications like automotive and aerospace components is often hampered by their "unpromising tribological properties." This means they wear down quickly under friction and load, leading to premature component failure and increased maintenance costs.

The industry has long sought a cost-effective way to improve the strength, hardness, and wear resistance of these alloys. While creating Aluminum Matrix Composites (AMCs) by adding external ceramic particles is a known solution, it often leads to issues like poor bonding and contamination at the particle-matrix interface. This research tackles the problem by exploring an "in-situ" method, where the reinforcing particles are chemically formed within the molten metal, promising a cleaner, stronger bond and superior performance.

The Approach: Unpacking the Methodology

The researchers employed a meticulous and industrially relevant methodology to develop and test the new composite materials. This robust approach ensures the findings are reliable and replicable.

Method 1: In-Situ Composite Development via Stir Casting

The composites were fabricated using an Al-7Si alloy as the base material. The key process involved melting the alloy in a bottom-pouring furnace and then introducing extra-pure Vanadium Pentoxide (V2O5) particles. A stainless-steel stirrer (coated with graphite to prevent dissolution) operating at 600-700 RPM dispersed the particles for 10 minutes. This process triggers a chemical reaction where V2O5 reacts with the molten aluminum to form hard, reinforcing Al2O3 (alumina) particles directly within the melt.

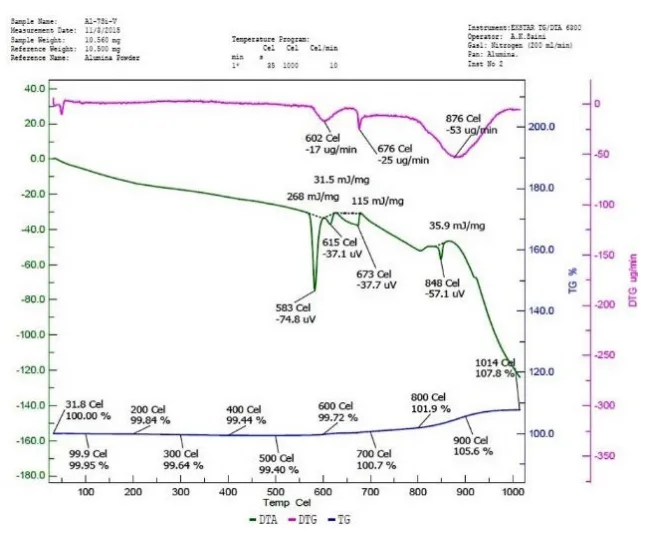

Key process parameters were carefully controlled based on Differential Thermal Analysis (DTA), as detailed in the paper's Table 2:

- Melt Temperature: 700°C ± 50

- Particle Preheating Temperature: 250°C

- Mould Temperature: 250°C

- V2O5 Added: 1, 3, and 5 wt.%

Method 2: Tribological Performance Evaluation

To quantify the improvement in wear resistance, the team conducted standardized Pin-on-Disc tests according to ASTM G99-95.

- Test Samples: Cylindrical pins (5mm radius) were made from the base Al-7Si alloy and the three new Al-Al2O3 composites.

- Counterface: A hardened EN31 steel disc was used as the mating surface.

- Test Conditions: The tests were run under dry sliding conditions for a distance of 1000m at a velocity of 0.83 m/s, with applied loads of 10N, 20N, and 30N.

- Measurements: A tribometer recorded the coefficient of friction, and precise weight measurements were taken before and after each test to determine material loss due to wear.

The Breakthrough: Key Findings & Data

The experimental results clearly demonstrate a significant improvement in the material properties, with the 1% V2O5 composite emerging as the top performer.

Finding 1: Hardness Peaks at 1% V2O5 Addition

The formation of hard Al2O3 particles within the aluminum matrix led to a substantial increase in hardness. However, the effect was not linear. As shown in Table 4 and Figure 4, the composite with 1 wt.% V2O5 (ASV1) achieved the highest microhardness of 64.1 HV. This represents a 24% increase over the base alloy's hardness of 51.7 HV. Interestingly, adding more V2O5 (3% and 5%) resulted in lower hardness, which the study attributes to the agglomeration of alumina particles, creating incoherency in the matrix.

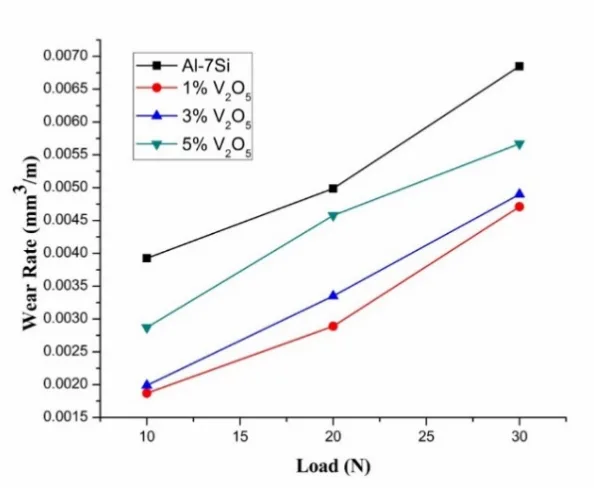

Finding 2: Optimal Wear Resistance Achieved with 1% V2O5

The tribological tests confirmed that improved hardness translated directly to superior wear resistance. The 1% V2O5 composite consistently outperformed the base alloy and the other composites across all load conditions.

- Reduced Volume Loss: Figure 6 shows that the 1% V2O5 composite exhibited the lowest volume loss due to wear. The study quantifies this improvement, stating, "The average decrease in volume loss observed for Al-7Si-1%...composite was 47.3%."

- Lower Coefficient of Friction: The 1% composite also demonstrated the lowest coefficient of friction (Figure 5). At a 10N load over 1000m, the coefficient of friction was reduced by 32.8% compared to the base Al-7Si alloy. This indicates a smoother, more resilient surface interaction under load.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the addition of V2O5 to a precise level of ~1 wt.% during stir casting is critical for maximizing wear resistance. Over-addition is counterproductive, leading to particle clustering and diminished mechanical properties.

- For Quality Control Teams: The data in Table 4 of the paper illustrates a clear correlation between V2O5 content and microhardness. This suggests that hardness testing can serve as an effective and rapid quality inspection criterion to verify the successful formation of the composite structure.

- For Design Engineers: The findings indicate that components designed with the Al-7Si-1%V2O5 composite can be specified for applications requiring significantly higher wear resistance. This could allow for the replacement of more expensive alloys or eliminate the need for secondary surface treatments, leading to cost savings.

Paper Details

Tribological Behaviour of Cast In-situ Al-Al2O3 Composite Developed by Stir Casting Using V2O5 Particles

1. Overview:

- Title: Tribological Behaviour of Cast In-situ Al-Al2O3 Composite Developed by Stir Casting Using V2O5 Particles

- Author: Amneesh Singla, Rajnish Garg and Yashvir Singh

- Year of publication: 2020

- Journal/academic society of publication: Journal of the Chinese Society of Mechanical Engineers, Vol.41, No.3

- Keywords: Al-7Si alloy; V2O5; in situ; Hardness; dry sliding wear; Al2O3.

2. Abstract:

The reinforcement of Al2O3 in aluminum metal matrix composites is very popular these days because of their large number of applications. Al-Al2O3 composites covers a lot of sectors like automotive, aerospace, aeronautical and defense due to their low weight & excellent mechanical properties like strength, hardness etc. In the current study, Al- Al2O3 composites have been produced by adding a different amount of V2O5 particles in Al-Si alloy. The influence of V2O5 addition on wear has investigated. The influence of sliding distance, amount of V2O5 addition and sliding velocity effect on wear behavior have been analyzed experimentally and discussed. An improvement in wear behavior has been observed in developed composite as compare with base alloy. The development of hard Al2O3 particles within the melt increases the composite hardness which in turn improves the wear behavior. The coefficient of friction of cast in-situ Al- Al2O3 composites was determined at different loads by tribotester. The research revealed that the coefficient of friction and wear loss increases with the load.

3. Introduction:

Al-Si alloys are widely used foundry alloys known for their great fluidity. However, despite their extensive use in casting, these alloys exhibit unpromising tribological properties. The addition of oxide particles to create Aluminum Matrix Composites (AMCs) can enhance these mechanical and tribological properties. The wear behavior of AMCs is complex, depending on hardness, strength, sliding velocity, load, and operating conditions. AMCs can be prepared through various methods, with in-situ fabrication being particularly advantageous. The in-situ method involves a chemical reaction of oxide particles with the molten metal, forming reinforcing alumina particles within the melt. This results in a clean particle surface and enhanced interfacial bonding strength. Previous studies have explored reinforcing aluminum alloys with various ceramics and oxides like CuO, ZnO, and TiO2. This study focuses on producing Al-Al2O3 in-situ composites using V2O5 particles via stir casting and investigating the tribological behavior.

4. Summary of the study:

Background of the research topic:

Al-Si alloys are prevalent in industrial casting but possess inadequate tribological properties. Aluminum Matrix Composites (AMCs), particularly those reinforced with Al2O3, offer a solution by improving mechanical characteristics such as hardness and wear resistance.

Status of previous research:

Prior research has established the benefits of reinforcing aluminum alloys with various oxides and ceramics (e.g., CuO, ZrB2, TiB2) to improve wear resistance. The in-situ fabrication method is noted for creating stronger interfacial bonds compared to ex-situ methods. Nanoparticles of V2O5 have been shown to increase antiwear properties when used as an oil additive.

Purpose of the study:

The purpose of this work is to produce an Al-Al2O3 in-situ composite by adding vanadium pentoxide (V2O5) to an Al-7Si alloy using the stir casting method. The study aims to experimentally investigate and discuss the influence of key factors—namely the amount of V2O5 addition (1, 3, and 5 wt.%), sliding distance, and applied load—on the resulting composite's wear behavior.

Core study:

The core of the study involved the fabrication of Al-7Si composites with 1, 3, and 5 wt.% V2O5. These composites, along with the base alloy, were subjected to mechanical and tribological characterization. Hardness and tensile properties were measured. Dry sliding wear tests were conducted using a pin-on-disc tribometer under varying loads (10, 20, 30N) to determine the coefficient of friction and volume loss. The results were analyzed to understand the relationship between V2O5 content and the tribological performance of the composites.

5. Research Methodology

Research Design:

The study employed an experimental research design to compare the properties of a base Al-7Si alloy with three in-situ composites developed by adding 1, 3, and 5 wt.% of V2O5 particles. The primary variables investigated were the percentage of V2O5 reinforcement and the applied load during wear testing.

Data Collection and Analysis Methods:

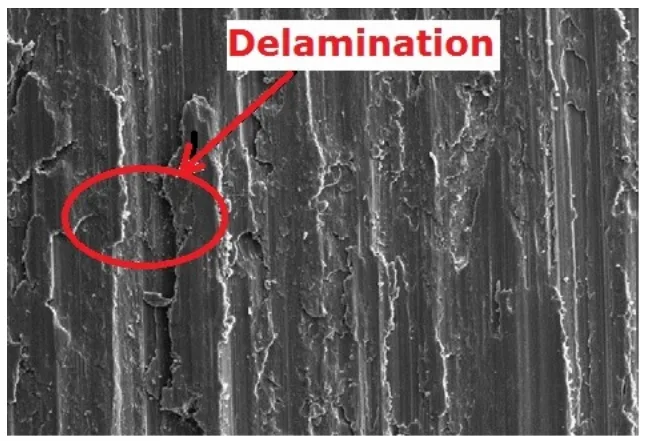

Composites were developed using a bottom pouring furnace and stir casting. Process parameters were determined using Differential Thermal Analysis (DTA). The elemental composition of the base alloy was determined by a spectrometer. Mechanical properties, including microhardness (HV) and ultimate tensile strength (UTS), were measured. Tribological properties were evaluated using a pin-on-disc tribometer as per ASTM G99-95 standards. Data on frictional force and weight loss were collected to calculate the coefficient of friction and volume loss. Worn surfaces were examined using Scanning Electron Microscopy (SEM).

Research Topics and Scope:

The research is focused on the development and tribological characterization of an in-situ Al-Al2O3 composite. The scope is limited to an Al-7Si base alloy, reinforcement via V2O5 additions of 1, 3, and 5 wt.%, and fabrication via stir casting. The investigation covers the effect of these additions on microhardness, tensile properties, and dry sliding wear behavior under loads ranging from 10N to 30N.

6. Key Results:

Key Results:

- The addition of 1 wt.% V2O5 increased the microhardness of the Al-7Si alloy by approximately 24%, from 51.7 HV to a peak of 64.1 HV. Further additions of V2O5 (3% and 5%) resulted in a decrease in hardness.

- The composite with 1 wt.% V2O5 exhibited the lowest coefficient of friction under all tested loads. At a 10N load and 1000m sliding distance, the coefficient of friction was reduced by 32.8% compared to the base alloy.

- All in-situ composites showed lower volume loss from wear compared to the base alloy. The 1 wt.% V2O5 composite demonstrated the most significant improvement, with an average decrease in volume loss of 47.3%.

- Wear rate and volume loss increased with higher applied loads for all materials. However, the wear performance of the composites degraded at higher V2O5 concentrations (3% and 5%), attributed to the agglomeration of Al2O3 particles and increased porosity, leading to delamination under load.

Figure Name List:

- Fig. 1. Bottom pouring furnace.

- Fig. 2. Differential thermal analysis curve carried out at 10°C per minute.

- Fig 3. Pin On Disc Tribotester

- Fig. 4. Micro hardness with respect to V2O5 addition.

- Fig. 5 (a) Coefficient of friction at 10N load.

- Fig. 5. (b) Coefficient of friction at 20N load.

- Fig. 5 (c) Coefficient of friction at 30N load.

- Fig. 5. (d) Variation of COF with different loads at 1000m distance

- Fig. 6. Variation of volume loss with load at 1000 m Sliding distance.

- Fig. 7. (a) wear of different composite with respect to the different load applied

- Fig. 7. (b) wear rate of the different composite at different loads.

- Fig. 8. (a) SEM of 5% V2O5 composite.

- Fig. 8. (b) worn surface image of 5% V2O5 composite

7. Conclusion:

- Wear rate in Al-Si alloy decrease by addition of particles and 1% addition of V2O5 shows the better results as compared to the composites having a high percentage of particles.

- At higher loads and sliding velocity more heat is generated which dismantle the tribo layer formed between the contacting surfaces and ultimately the wear rate increases.

- The great reduction in volume loss has been detected in composite with 1% addition of V2O5 particles as compared to other cast composites.

- A reduction in the coefficient of friction at 1000m was about 32.8% for the 1 wt.% sample, 20.96% for 3 wt.% sample and in the case of 5 wt.% it was almost similar to Al-Si alloy at 10 N load

- The great improvement in the wear behavior found which is calculated experimentally.

8. References:

- Al-Qutub, A.M., Allam, I.M., Abdul Samad, M.A., 2008. "Wear and friction of Al-Al2O3 composites at various sliding speeds," J. Mater. Sci. 43, 5797-5803.

- Archard, J.F., 1953. "Contact and Rubbing of Flat Surfaces," J. Appl. Phys. 24, 981–988.

- Banerji, A., Surappa, M.K., Rohatgi, P.K., 1983. "Cast aluminum alloys containing dispersions of zircon particles," Metall. Trans. В 14, 273-283.

- Chandrashekharaiah, T.M., Kori, S.A., 2009. "Effect of grain refinement and modification on the dry sliding wear behaviour of eutectic Al-Si alloys," Tribol. Int. 42, 59–65.

- Clarke, J., Sarkar, A.D., 1979. "Wear characteristics of as-cast binary aluminium-silicon alloys," Wear 54, 7-16.

- Dai, W., Lee, K., Sinyukov, A.M., Liang, H., 2017. "Effects of Vanadium Oxide Nanoparticles on Friction and Wear Reduction," J. Tribol. 139, 061607.

- Deuis, R.L., Subramanian, C., Yellup, J.M., 1997. "Dry sliding wear of aluminium composites - A review," Compos. Sci. Technol. 57, 415–435.

- Dinaharan, I., Murugan, N., 2012. "Dry sliding wear behavior of AA6061/ZrB2in-situ composite," Trans. Nonferrous Met. Soc. China (English Ed. 22, 810-818.

- Dwivedi, D.K., 2010. "Adhesive wear behaviour of cast aluminium-silicon alloys: Overview," Mater. Des. 31, 2517-2531.

- Dwivedi, D.K., Sharma, A., Rajan, T. V., 2001. "Friction and wear behaviour of cast hypereutectic Al-Si alloy (LM28) at low sliding velocities," Trans. Indian Inst. Met. 54, 247-254.

- Gruzleski, J.E., Closset, B.M., 1990. "Liquid treatment to Al-Si alloys". AFS, Illinois 1-254.

- Hamid, A.A., Jain, S.C., Ghosh, P.K., Ray, S., 2006. "Characterization and Tribological Behavior of Cast In-Situ Al (Mg, Mo) -Al 2 O 3 (MoO 3) Composite," Metall. Mater. Trans. В 37, 519-529.

- Iwai, Y., Honda, T., Miyajima, T., Iwasaki, Y., Surappa, M.., Xu, J.., 2000. "Dry sliding wear behavior of Al2O3 fiber reinforced aluminum composites," Compos. Sci. Technol. 60, 1781-1789.

- JIANG, X., WANG, N., ZHU, D., 2014. "Friction and wear properties of in-situ synthesized Al2O3 reinforced aluminum composites," Trans. Nonferrous Met. Soc. China 24, 2352–2358.

- Kumar, S., Chakraborty, M., Subramanya Sarma, V., Murty, B.S., 2008. "Tensile and wear behaviour of in situ Al-7Si/TiB2particulate composites," Wear 265, 134–142.

- Kumari, S.S.S., Pillai, R.M., Pai, B.C., 2002. "Effect of iron in Al-7Si-0.3 Mg alloy," Indian Foundry J. 48, 27-31.

- Maity, P.C., Panigrahi, S.C., Chakraborty, P.N., 1993. "Preparation of aluminium-alumina in-situ particle composite by addition of titania to aluminium melt," Scr. Metall. Mater. 28, 549-552.

- Mandal, A., Chakraborty, M., Murty, B.S., 2007. "Effect of TiB2 particles on sliding wear behaviour of Al-4Cu alloy," Wear 262, 160–166.

- Ramesh, C.S., Ahamed, A., 2011. "Friction and wear behaviour of cast Al 6063 based in situ metal matrix composites," Wear 271, 1928–1939.

- Singla, A., Garg, R., Saxena, M., 2016. "Effect of Heat Treatment on Microstructure and Tensile Properties of A356/V2O5 Insitu Composites," Int. J. Manuf. Mater. Mech. Eng. 6, 1-10.

- Sivaprasad, K., Babu, S.P.K., Natarajan, S., Narayanasamy, R., Kumar, B.A., Dinesh, G., 2008. "Study on abrasive and erosive wear behaviour of Al 6063/TiB2 in situ composites," Mater. Sci. Eng. A 498, 495–500.

- Sulima, I., Mikulowski, B., 2006. "Influence of silicon on the wetting-bond strength-structure relationship in the AlSi11/Al2O3joints," Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 37, 3275-3281.

- Tjong, S.., Ma, Z.., 2000. "Microstructural and mechanical characteristics of in situ metal matrix composites," Mater. Sci. Eng. R Reports 29, 49-113.

- Torabian, H., Pathak, J.P., Tiwari, S.N., 1994. "Wear characteristics of Al-Si alloys," Wear 172, 49-58.

- XIU, Z., CHEN, G., WANG, X., WU, G., LIU, Y., YANG, W., 2010. "Microstructure and performance of Al-Si alloy with high Si content by high temperature diffusion treatment," Trans. Nonferrous Met. Soc. China 20, 2134-2138.

- Yang, B., Sun, M., Gan, G., Xu, C., Huang, Z., Zhang, H., Fang, Z.Z., 2010. "In situ Al2O3 particle-reinforced Al and Cu matrix composites synthesized by displacement reactions," J. Alloys Compd. 494, 261–265.

- Yang, J., Gu, W., Pan, L.M., Song, K., Chen, X., Qiu, T., 2011. "Friction and wear properties of in situ (TiB2 + TiC)/Ti3SiC2 composites," Wear 271, 2940-2946.

- Yılmaz, O., Buytoz, S., 2001. "Abrasive wear of Al2O3-reinforced aluminium-based MMCs," Compos. Sci. Technol. 61, 2381-2392.

- Zhu, H., Jar, C., Song, J., Zhao, J., Li, J., Xie, Z., 2012. "High temperature dry sliding friction and wear behavior of aluminum matrix composites (Al3Zr+a-Al2O3)/Al," Tribol. Int. 48, 78-86.

Expert Q&A: Your Top Questions Answered

Q1: Why was V2O5 chosen as the reactant to form the Al-Al2O3 composite?

A1: The paper utilizes an "in-situ" fabrication method, which relies on a chemical reaction within the molten metal to form the reinforcing particles. V2O5 was selected because it reacts with molten aluminum to form hard, stable Al2O3 (alumina) particles. This method ensures the reinforcing particles are clean, free of contamination, and have a strong interfacial bond with the aluminum matrix, which is critical for improving mechanical properties.

Q2: The results show that performance degraded when V2O5 content was increased beyond 1 wt.%. Why did this happen?

A2: The paper explains that while a small amount of V2O5 leads to a uniform dispersion of fine Al2O3 particles, a higher addition (3% and 5%) causes these particles to agglomerate into large clusters. This clustering creates incoherency at the grain boundaries and increases porosity. As a result, the overall hardness decreases, and the material becomes more prone to delamination and fracture during wear testing.

Q3: What was the purpose of adding magnesium during the casting process?

A3: According to the paper, "At 700°C, 5gm of Magnesium was added in order to promote wettability." In composite manufacturing, good wettability is essential for the molten metal matrix to make intimate contact with the reinforcing particles. The addition of magnesium improves the wetting between the molten Al-Si alloy and the newly formed Al2O3 particles, ensuring a strong bond and effective load transfer from the matrix to the reinforcement.

Q4: The paper mentions the formation of a "tribo layer." What is its significance in the wear process?

A4: The study explains that during the dry sliding test, a "tribo layer" forms on the contact surfaces. This layer is composed of oxidized material (like Fe2O3 from the steel disc) and compacted wear debris. At low loads, this layer acts as a solid lubricant, protecting the surfaces and reducing the wear rate. However, at higher loads, the increased stress and heat cause this protective layer to break apart and pull away (delaminate), leading to direct metal-to-metal contact and a sharp increase in wear.

Q5: How was the specific melt temperature of 700°C selected for the experiments?

A5: The processing temperature was chosen based on the results of a Differential Thermal Analysis (DTA), shown in Figure 2. The DTA curve identified the melting points of the Al-7Si alloy (583°C) and the V2O5 reactant (673°C). A processing temperature of 700°C ensures that both the base alloy and the reactant are fully molten, allowing the chemical reaction and the dispersion of the resulting Al2O3 particles to proceed effectively before casting.

Conclusion: Paving the Way for Higher Quality and Productivity

This research effectively addresses a persistent challenge in the casting industry: the inherent trade-off between the excellent castability and poor wear resistance of Al-Si alloys. The key breakthrough is the demonstration that a minimal, controlled 1 wt.% addition of V2O5 can create a high-performance Al-Al2O3 Composite with significantly enhanced hardness and tribological properties. For R&D and operations teams, this provides a clear, data-backed pathway to producing more durable and reliable components for demanding applications.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Tribological Behaviour of Cast In-situ Al-Al2O3 Composite Developed by Stir Casting Using V2O5 Particles" by "Amneesh Singla, Rajnish Garg and Yashvir Singh".

Source: Journal of the Chinese Society of Mechanical Engineers, Vol.41, No.3, pp 337~344 (2020)

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.