Beyond the Surface: A Deep Dive into Ultrasonic Attenuation for Flawless Castings

This technical summary is based on the academic paper "Evaluating the Attenuation in Ultrasonic Testing of Castings" by M. Boháčik, M. Mičian, A. Sládek, published in ARCHIVES of FOUNDRY ENGINEERING (2018).

![Fig. 1. Testing of anisotropic material – good direction of testing (left), direction with big attenuation (right) [2]](https://castman.co.kr/wp-content/uploads/image-3583.webp)

Keywords

- Primary Keyword: Ultrasonic Attenuation

- Secondary Keywords: Ultrasonic Testing, Castings, AlSi alloy, Cast Iron, NDT (Non-Destructive Testing), Casting Defects, Process Parameters

Executive Summary

- The Challenge: The coarse, anisotropic grain structure inherent in cast materials scatters ultrasonic waves, making reliable non-destructive testing (NDT) for internal defects notoriously difficult.

- The Method: The study systematically measured ultrasonic attenuation in AlSi7, AlSi12, grey cast iron, and ductile cast iron samples produced using different casting parameters, including gravity casting and casting under pressure.

- The Key Breakthrough: Casting pressure and alloy composition have a profound impact on ultrasonic inspectability; hypoeutectic AlSi7 cast gravitationally was unmeasurable, while the same alloy cast under pressure yielded a clear, quantifiable average attenuation of 0.227 dB.mm⁻¹.

- The Bottom Line: To ensure accurate internal defect detection, engineers must tailor ultrasonic testing parameters, particularly probe frequency and gain settings, to the specific alloy and casting method used.

The Challenge: Why This Research Matters for HPDC Professionals

For engineers working with forgings and rolled materials, ultrasonic testing is a straightforward, reliable tool. However, the world of castings presents a unique and persistent challenge. The very nature of the casting process creates a coarse, anisotropic grain structure. Unlike the uniform structure of wrought materials, these large, randomly oriented grains act like a dense fog for an ultrasonic beam, scattering its energy in multiple directions. This phenomenon, known as ultrasonic attenuation, can weaken the return signal so much that it becomes impossible to distinguish a critical internal defect from background noise. This research was necessary to move beyond guesswork and quantify how specific casting choices—alloy composition, mold temperature, and the use of pressure—directly impact this "ultrasonic fog," paving the way for more reliable NDT protocols in the foundry.

The Approach: Unpacking the Methodology

The study employed a rigorous experimental approach to isolate the effects of different casting variables on ultrasonic attenuation.

Method 1: Material Preparation and Casting

- Aluminum Alloys: Two common Al-Si alloys were used: a hypoeutectic AlSi7 (approx. 7% Si) and a eutectic AlSi12 (approx. 12% Si). Samples were produced by both gravity casting and casting under pressure (30 MPa and 150 MPa) using a hydraulic press. Mold temperatures were also varied (150°C to 250°C).

- Cast Iron: Samples of grey cast iron (GJL) and ductile cast iron (GJS) were produced by gravity casting into steel molds.

- Sample Finalization: All cylindrical castings were precisely machined to ensure consistent geometry and surface finish for testing (e.g., Ø 30 x 43mm for aluminum alloys).

Method 2: Ultrasonic NDT Measurement

- Equipment: An OmniScan MX2 modular defectoscope from Olympus was used for all measurements.

- Probes: Two different probes were used to assess the impact of frequency on the results: a 5 MHz probe (C126) and a 3.5 MHz probe (A550S-SM).

- Procedure: Testing was performed from the flat forehead of each cylindrical sample. The equipment recorded the initial pulse, the first back-wall echo (the signal after traveling through the material once), and the second back-wall echo. The attenuation was calculated based on the reduction in amplitude between these echoes.

The Breakthrough: Key Findings & Data

The experimental results provide clear, data-driven guidance on how casting choices affect inspectability.

Finding 1: Casting Pressure is a Game-Changer for Hypoeutectic AlSi7

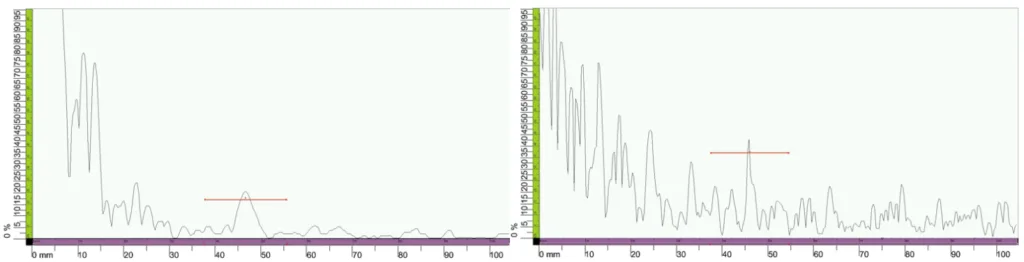

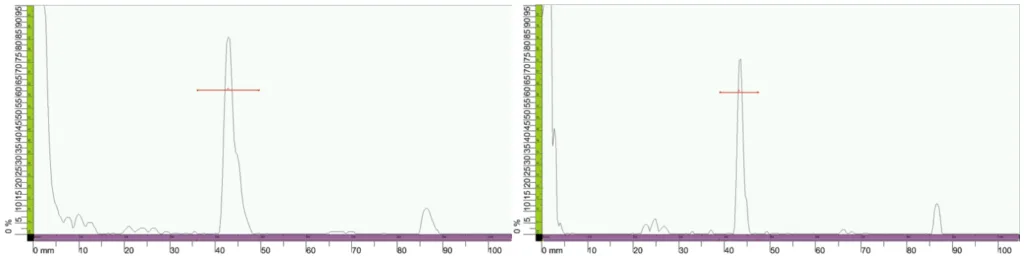

The most dramatic result was observed in the AlSi7 alloy. For the sample created by gravity casting (Sample No. 1), the ultrasonic attenuation was so severe that it was impossible to capture a usable back-wall echo. As shown in Figure 2, the signal was lost in the noise. However, when the same AlSi7 alloy was cast under 30 MPa of pressure (Sample No. 2), it became fully inspectable. The study measured a clear average attenuation of 0.227 dB.mm⁻¹ with the 3.5 MHz probe (Table 3). This demonstrates that applying pressure during solidification can fundamentally alter the material structure to make it more transparent to ultrasound.

Finding 2: Eutectic AlSi12 Alloy Shows Superior Ultrasonic Transmissibility

The study revealed that alloy composition plays a major role. The eutectic AlSi12 alloy exhibited significantly lower attenuation than the hypoeutectic AlSi7, even under gravity casting conditions. For the gravitationally cast AlSi12 (Sample No. 3), the average attenuation was 0.107 dB.mm⁻¹ (Table 5), which is less than half the attenuation of the pressure-cast AlSi7. This suggests that the finer, more uniform solidification structure of the eutectic alloy is inherently less disruptive to the ultrasonic beam. Applying pressure to the AlSi12 alloy further reduced attenuation, though less dramatically than in the AlSi7.

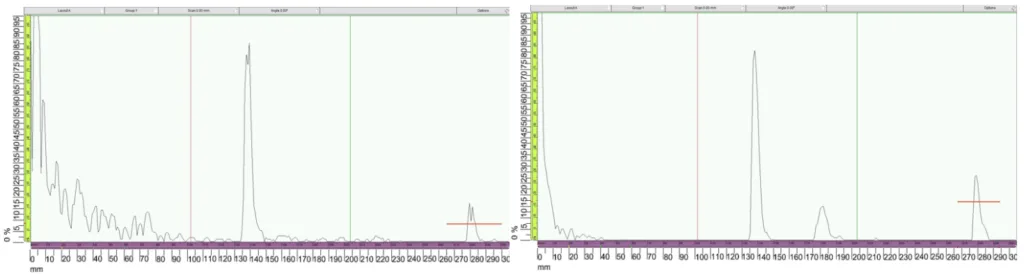

Finding 3: Minimal Attenuation Difference Between Grey and Ductile Cast Iron

Interestingly, while the type of graphite (flakes in grey iron vs. nodules in ductile iron) is known to affect mechanical properties, its impact on ultrasonic attenuation was found to be minimal in this study. As detailed in Table 7, the average attenuation for grey cast iron (GJL) was 0.033 dB.mm⁻¹, while for ductile cast iron (GJS), it was 0.034 dB.mm⁻¹. Both values are significantly lower than those measured for the aluminum alloys, indicating better overall inspectability under these test conditions.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting casting pressure is a powerful tool for improving the NDT inspectability of alloys prone to high attenuation, such as hypoeutectic AlSi7.

- For Quality Control Teams: The data in Tables 3 through 7 illustrate that a single ultrasonic testing procedure is not sufficient for a range of cast products. The inspectability of AlSi7 vs. AlSi12 is vastly different, requiring tailored gain settings and potentially different probe frequencies to ensure reliable flaw detection.

- For Design Engineers: The findings indicate that the choice of alloy can have significant downstream implications for quality control. Selecting a eutectic alloy like AlSi12 over a hypoeutectic one may facilitate more effective ultrasonic inspection for internal defects later in the production process.

Paper Details

Evaluating the Attenuation in Ultrasonic Testing of Castings

1. Overview:

- Title: Evaluating the Attenuation in Ultrasonic Testing of Castings

- Author: M. Boháčik, M. Mičian, A. Sládek

- Year of publication: 2018

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING, Volume 18, Issue 2/2018

- Keywords: AlSi alloy, Cast Iron, Technological casting parameters, Ultrasound attenuation

2. Abstract:

This paper considers the assessment of attenuation in aluminium alloys castings and in cast iron prepared by gravity casting method and by casting under pressure. The issue of ultrasound attenuation is important in setting the conditions of non-destructive (NDT) testing, especially in casted materials. The characteristics of the ultrasonic technique and ultrasonic attenuation and the calculation of the attenuation and the velocity of ultrasound are presented in the theoretical part of this paper. For experimental measurements, cylindrical castings from AlSi alloy (a hypoeutectic alloy with a silicon content of about 7% - AlSi7 and a eutectic alloy with a silicon content of about 12% - AlSi12) and from grey and ductile cast iron were made. The ultrasonic records of the casting control, the calculation of ultrasound attenuation for individual samples are listed and described in the experimental part. The evaluation of measurements and comparison of calculated ultrasound attenuation is at the end of this article.

3. Introduction:

Ultrasonic testing is essential for detecting internal defects in materials where methods like X-Ray testing are not feasible. However, its application to cast materials is less widespread compared to other construction materials due to significant challenges. The primary problem is the coarse, anisotropic grain structure of castings, which scatters the ultrasonic beam because the material exhibits different mechanical and physical properties in each direction. This scattering is compounded by volume errors and randomly oriented defects that occur during production. In graphitic cast iron, attenuation is further influenced by the shape and dispersion of graphite in the base matrix. Consequently, selecting the appropriate probe frequency (ranging from 5 MHz down to less than 2 MHz for larger castings) is critical. Heat treatment can often reduce this attenuation.

4. Summary of the study:

Background of the research topic:

The reliability of ultrasonic testing on cast materials is limited by the phenomenon of ultrasound attenuation, where the energy of the ultrasonic wave decreases as it passes through the material. This attenuation is caused by two main mechanisms: absorption (conversion of mechanical energy to thermal energy due to internal friction) and scattering (reflection and refraction of the wave at microscopic interfaces like grain boundaries, inclusions, or pores). The degree of attenuation, particularly scattering, is strongly dependent on the relationship between the ultrasound wavelength and the size of the material's inhomogeneities, such as the grain size.

Status of previous research:

Prior work has established that materials with coarse or non-homogeneous structures, such as castings, exhibit higher attenuation than fine-grained or wrought materials. The choice of a lower frequency is a known strategy to mitigate high attenuation. The biggest problem with ultrasound testing in castings is identified as the coarse anisotropic grain structure on which the ultrasonic beam is scattered.

Purpose of the study:

The study aims to experimentally evaluate and quantify the ultrasonic attenuation in specific cast materials—two Al-Si alloys and two types of cast iron—produced under varying technological parameters. The goal is to understand how factors like casting method (gravity vs. pressure), alloy composition, and mold temperature influence attenuation, thereby affecting the conditions required for successful non-destructive testing.

Core study:

The core of the study involved casting cylindrical samples from AlSi7, AlSi12, grey cast iron (GJL), and ductile cast iron (GJS) using controlled casting parameters. These samples were then subjected to ultrasonic testing using 3.5 MHz and 5 MHz probes. The recorded ultrasonic signals were analyzed to calculate the coefficient of attenuation (α) and the velocity of the longitudinal ultrasonic wave (c_L) for each sample, allowing for a direct comparison of the effects of the different materials and casting processes.

5. Research Methodology

Research Design:

The research was designed as a comparative experimental study. Samples of four different materials were prepared under distinct and controlled casting conditions. The primary independent variables were the material type (AlSi7, AlSi12, GJL, GJS), the casting method (gravity or under pressure), and casting parameters (mold and casting temperatures, applied pressure). The primary dependent variable was the measured ultrasonic attenuation.

Data Collection and Analysis Methods:

Cylindrical samples were cast and machined to precise dimensions. An OmniScan MX2 modular defectoscope was used to perform ultrasonic pulse-echo tests on each sample. Data on the amplitude of the first and second back-wall echoes (H₀ and H) were collected from the device screen. The attenuation coefficient (α) was calculated using the formula α = (20·log(H₀/H)) / (2h), where 'h' is the height of the sample. The velocity of sound was also calculated. Measurements were repeated three times for each sample to ensure reliability.

Research Topics and Scope:

The research focused on the ultrasonic attenuation properties of:

1. A hypoeutectic aluminum alloy (AlSi7).

2. A eutectic aluminum alloy (AlSi12).

3. Grey cast iron (GJL).

4. Ductile cast iron (GJS).

The scope for the aluminum alloys included an investigation into the effects of gravity casting versus casting under pressure (up to 150 MPa) and varying mold temperatures. The scope for cast iron was a direct comparison between the grey and ductile forms under gravity casting conditions.

6. Key Results:

Key Results:

- It was not possible to measure the ultrasonic attenuation in the gravitationally cast AlSi7 sample due to severe signal loss.

- For the pressure-cast AlSi7 sample, the average attenuation was determined to be 0.227 dB.mm⁻¹ (with a 3.5 MHz probe) and 0.225 dB.mm⁻¹ (with a 5 MHz probe).

- The eutectic AlSi12 alloy demonstrated significantly lower attenuation than the hypoeutectic AlSi7 alloy under comparable conditions.

- For the AlSi12 alloy, attenuation generally decreased with the application of casting pressure.

- The attenuation values for grey cast iron (GJL) and ductile cast iron (GJS) were minimal and very similar to each other, with average values of 0.033 dB.mm⁻¹ and 0.034 dB.mm⁻¹, respectively. These values were substantially lower than those for the aluminum alloys.

Figure Name List:

- Fig. 1. Testing of anisotropic material – good direction of testing (left), direction with big attenuation (right) [2]

- Fig. 2. Recording of evaluating attenuation of sample No. 1 (left – 3.5 MHz probe, right - 5 MHz probe frequency)

- Fig. 3. Recording of evaluating attenuation of sample No. 2 (left – 3.5 MHz probe, right - 5 MHz probe frequency)

- Fig. 4. Recording of evaluating attenuation of sample No. 3 (left – 3.5 MHz probe, right - 5 MHz probe frequency)

- Fig. 5. Recording of evaluating attenuation of sample No. 5 (left) and No. 6 (right) - 3.5 MHz probe frequency

7. Conclusion:

The coefficient of attenuation significantly influences the applicability of ultrasonic techniques for inspecting castings. The results demonstrate that cast materials have higher attenuation than formed alloys. For the AlSi7 material cast gravitationally, it was not possible to determine the attenuation. However, for the same alloy cast under pressure, the average attenuation was measured. For the AlSi12 alloy, attenuation decreased with increasing applied pressure. The study also concludes that the hypoeutectic Al-Si alloy results in greater attenuation than the eutectic composition. In the case of cast iron, a higher attenuation was reached in samples from ductile cast iron, but the difference between grey and ductile cast iron was minimal. The authors note that microstructural analysis has not yet been performed, and future work will focus on correlating the observed attenuation with microstructural features like grain size (sdas factor) and graphite length.

8. References:

- [1] Aweda, J.O., Adeyemi, M.B. (2012). Experimental Determination of Heat Transfer Coefficients During Squeeze Casting of Aluminium. An Overview of Heat Transfer Phenomena. Dr M. Salim Newaz Kazi (Ed.). ISBN 978-953-51-0827-6. InTech. DOI: 10.5772/52038.

- [2] Boháčik, M., Mičian, M. & Koňár, R. (2017). Evaluating the attenuation in ultrasonic testing for AlSi alloys castings. Manufacturing Technology: Journal for Science, Research and Production. 17(5), 669-674. ISSN 1213-2489.

- [3] Boháčik, M., Mičian, M., Koňár, R. & Hlavatý, I. (2017). Ultrasonic testing of butt weld joint by TOFD technique. Manufacturing Technology. 17(6), 842-847. ISSN 1213-2489.

- [4] Konar, R., Patek, M. & Zrak, A. (2015). Ultrasonic testing of non-ferrous materials in the foundry industry. Manufacturing Technology. 15(4), 557-562. ISSN 1213-2489.

- [5] Lehocká, D., Hlavatý, I. & Hloch, S. (2016). Rationalization of Material Flow in Production of Semitrailer Frame for Automotive Industry. Tehnicki Vjesnik-Technical Gazette. 23(4), 1215-1220.

- [6] Vasková, I., Hrubovčáková, M., Malik, J. & Eperješi, Š. (2014). Influence of technological parameters of furane-mixtures on shrinkage creation in ductile cast iron castings. Archives of Metallurgy and Materials. 59(3), 1037-1040. DOI: 10.2478/amm-2014-0174.

- [7] Lee, J.H., Kim, H.S., Won, C.W. & Cantor, B. (2002). Effect of the gap distance on the cooling behavior and the microstructure of indirect squeeze cast and gravity die cast 5083 wrought Al alloy. Materials Science & Engineering A. 338(1-2), 182-190. Elsevier.

- [8] Gucwa, M., Winczek, J., Bęczkowski, R. & Dośpiał, M. (2016). Structure and properties of coatings made with self-shielded cored wire. Archives of Foundry Engineering. 16(3), 39-42.

- [9] Bruna, M., Bolibruchova, D. & Pastircak, R. (2017). Reoxidation Processes Prediction in Gating System by Numerical Simulation for Aluminium Alloys. Archives of Foundry Engineering. 17(3), 23-26.

Expert Q&A: Your Top Questions Answered

Q1: Why was it impossible to measure attenuation in the gravitationally cast AlSi7 sample?

A1: The paper indicates that the gravitationally cast AlSi7 sample likely formed a very coarse and anisotropic grain structure. This structure severely scattered the ultrasonic beam, preventing a clear, reflected back-wall echo from returning to the probe. As shown in Figure 2, the signal was indistinguishable from the background noise, making a quantitative measurement of attenuation impossible with the equipment used.

Q2: What was the primary reason for including two different alloys, AlSi7 and AlSi12?

A2: The two alloys were chosen to investigate the effect of composition and solidification behavior on ultrasonic attenuation. AlSi7 is a hypoeutectic alloy, while AlSi12 is eutectic. These alloys have different solidification patterns, which results in different microstructures. The study successfully showed that the eutectic AlSi12 alloy, which typically forms a finer structure, has significantly lower attenuation and is therefore easier to inspect than the hypoeutectic AlSi7.

Q3: The paper concludes that increased pressure decreases attenuation. What is the proposed physical mechanism for this?

A3: The paper suggests in its conclusion that "the increased pressure would have to temper the grain size." A finer grain structure reduces the size of the interfaces that cause ultrasonic scattering. When the grain size is smaller relative to the ultrasound wavelength, the beam can travel through the material with less disruption, resulting in lower measured attenuation and a clearer signal for NDT.

Q4: How did the attenuation in the cast iron samples compare to the aluminum alloys?

A4: The cast iron samples, both grey (GJL) and ductile (GJS), exhibited significantly lower ultrasonic attenuation (0.033-0.034 dB.mm⁻¹) compared to even the best-performing pressure-cast aluminum alloys (0.091-0.227 dB.mm⁻¹). This indicates that, under the conditions of this study, the cast iron structures were more transparent to the 3.5 MHz ultrasonic waves than the Al-Si alloy structures.

Q5: What are the key limitations of this study and the planned next steps for the research?

A5: The primary limitation explicitly stated in the paper is the lack of microstructural analysis. While the study effectively links casting parameters to attenuation, it does not yet provide direct evidence correlating the attenuation values to specific microstructural features. The authors state that the next stage of research will be to "produce microstructural samples and suitably describe them structurally and search for the magnitude of the ultrasound attenuation from the individual parameters of test samples microstructure," such as the SDAS factor in aluminum and graphite precipitate length in cast iron.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of reliably inspecting castings for internal flaws is a constant battle against the material's own structure. This research cuts through the complexity by providing clear evidence that process control is the key to success. The findings demonstrate that factors like alloy selection and the application of pressure during casting can dramatically reduce Ultrasonic Attenuation, transforming a previously un-inspectable component into one that can be confidently cleared by NDT. By understanding and applying these principles, foundries can enhance their quality control protocols, reduce scrap rates, and deliver more reliable components.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Evaluating the Attenuation in Ultrasonic Testing of Castings" by "M. Boháčik, M. Mičian, A. Sládek".

Source: https://doi.org/10.24425/122519

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.