The Hidden Cost of Melt Holding: Unpacking the Effects of Cyclic Thermal Exposure on AlSi8Cu2Fe Alloy

This technical summary is based on the academic paper "The Influence of Thermal History on the Microstructure and Mechanical Properties of AlSi8Cu2Fe Alloy" by Jan Šerák, Dalibor Vojtěch, and Cyril Šimon, published in Manufacturing Technology (2020).

![Fig. 1 Turbulence and dross formation in the melt at the outlet of holding furnace [1]](https://castman.co.kr/wp-content/uploads/image-3477.webp)

Keywords

- Primary Keyword: Cyclic Thermal Exposure

- Secondary Keywords: AlSi8Cu2Fe alloy, melt thermal history, mechanical properties, microstructure, casting defects, hydrogen porosity, oxide inclusions

Executive Summary

- The Challenge: Long-term or cyclic heating of molten aluminum alloys in holding furnaces can degrade their properties, but the specific effects of temperature fluctuations into the semi-solid state are not well-documented.

- The Method: Researchers subjected AlSi8Cu2Fe alloy to up to 100 thermal cycles (liquid to semi-solid state) and compared its properties to an alloy held at a constant high temperature for 100 hours.

- The Key Breakthrough: Cyclic thermal exposure significantly increased casting defects like oxide inclusions and hydrogen porosity, depleted key alloying elements (Mg, Ti), and drastically reduced hardness and strength compared to simple long-term holding.

- The Bottom Line: Uncontrolled thermal fluctuations in molten metal are far more damaging to final casting quality than steady-state holding, posing a significant risk to the reproducibility and performance of finished components.

The Challenge: Why This Research Matters for HPDC Professionals

In any modern foundry, maintaining large volumes of molten aluminum alloy in a holding furnace is standard practice. However, this process is not without risks. Long-term exposure of the melt to the atmosphere can lead to the oxidation of aluminum and other key alloying elements, forming dross and internal oxide inclusions. This, in turn, increases the melt's susceptibility to hydrogen absorption, leading to porosity in the final casting.

The situation becomes even more complex when temperature fluctuations occur, for instance, during melt transport from the furnace to the mold or in continuous furnaces. If the temperature drops into the semi-solid range (between liquidus and solidus), the very foundations of crystallization can be altered. This research addresses a critical knowledge gap: What is the cumulative effect of these thermal cycles on the alloy's composition, microstructure, and, most importantly, its final mechanical properties? Understanding this is essential for ensuring the production of castings with consistent, reliable, and reproducible quality.

The Approach: Unpacking the Methodology

To isolate and quantify the effects of thermal history, the researchers designed a comparative experiment using a commercial AlSi8Cu2Fe alloy (ČSN 42 4339), a workhorse material for complex and dynamically stressed castings.

Method 1: Cyclic Thermal Exposure

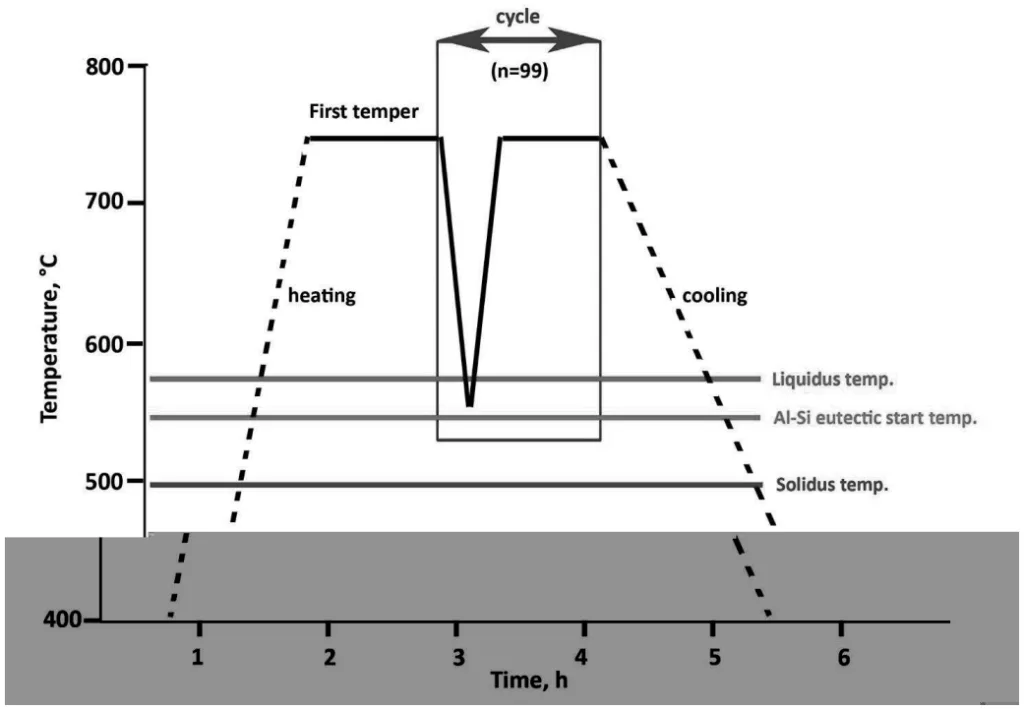

The alloy was placed in a graphite crucible and heated to 750°C in an electric resistance furnace without a protective atmosphere. Each cycle consisted of removing the crucible from the furnace, mixing the melt with a graphite rod, and allowing it to cool freely for 15 minutes, which brought the alloy into the semi-solid state. The crucible was then returned to the 750°C furnace for 1 hour to complete the cycle. Samples were cast into a massive brass mold after 1, 2, 4, 8, 16, 32, 64, and 100 cycles.

Method 2: Comparative Continuous Exposure

For comparison, a second batch of the same alloy was melted and held continuously in the furnace at 750°C for 100 hours. Samples were taken and cast at 8, 16, 32, 64, and 100 hours to serve as a reference. All cast samples were then subjected to analysis of their microstructure, chemical composition, Brinell hardness, and uniaxial pressure properties.

The Breakthrough: Key Findings & Data

The study revealed that cyclic thermal exposure is significantly more detrimental to the alloy's quality than continuous holding at a high temperature.

Finding 1: Severe Increase in Foundry Defects and Microstructure Coarsening

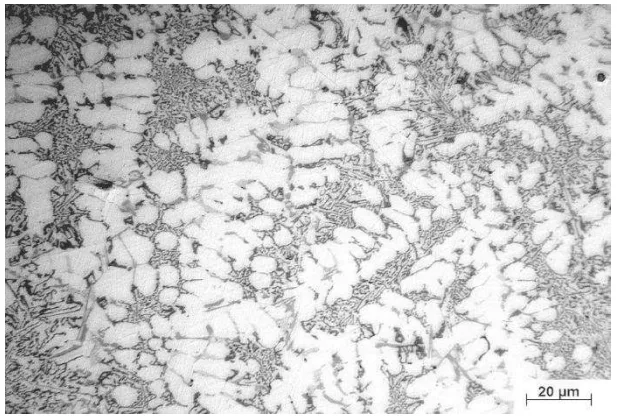

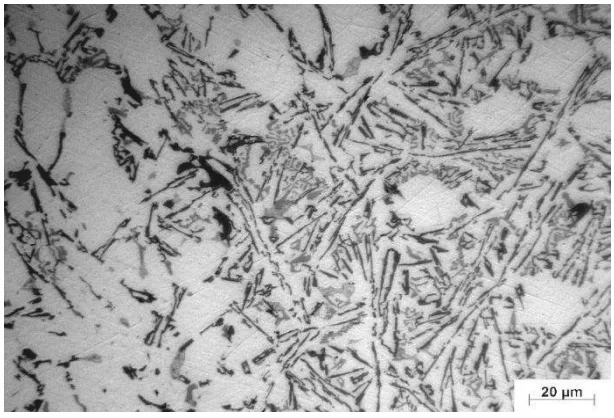

With an increasing number of thermal cycles, the alloy's microstructure showed a dramatic increase in foundry defects. Figure 4 clearly shows large oxide membranes that disrupt structural homogeneity. Figure 5 reveals significant hydrogen porosity. Furthermore, a comparison with the base alloy (Figure 3) shows that the cyclic process caused a significant coarsening of both the α-Al primary dendrites and the Al-Si eutectic structure, indicating that the thermal cycles negatively affected the crystallization nuclei. While the reference alloy also showed some coarsening after 100 hours (Figure 6), the level of defects was not nearly as pronounced.

Finding 2: Critical Depletion of Key Alloying Elements

The cyclic exposure caused significant changes in the alloy's chemical composition. As shown in Figure 7, the magnesium (Mg) content dropped from an initial ~0.48 wt% to below 0.2 wt% after 100 cycles. Similarly, titanium (Ti), a crucial element for grain refinement, decreased from ~0.05 wt% to ~0.02 wt% (Figure 9). Conversely, the relative iron (Fe) content increased. For the reference alloy held at a constant temperature, these changes were "always less pronounced." This loss of essential alloying elements directly impacts the final properties of the casting.

Finding 3: Drastic Reduction in Mechanical Properties

The degradation in microstructure and composition translated directly into a significant loss of mechanical strength.

- Hardness: As shown in Figure 10, the Brinell hardness of the cyclically exposed alloy plummeted from approximately 125 HBW to 85 HBW after 100 cycles. The reference alloy saw a much smaller drop to around 110 HBW.

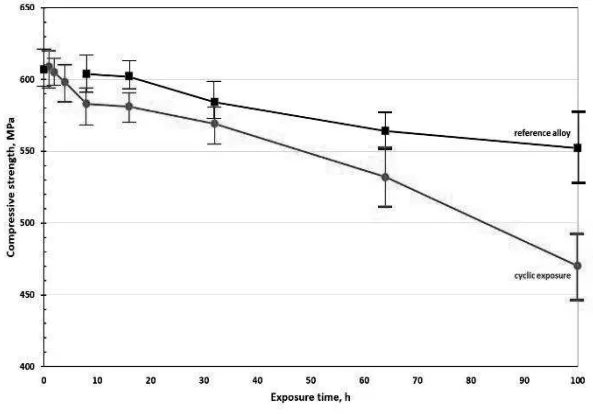

- Strength: The yield strength in compression fell from over 320 MPa to about 240 MPa for the cycled alloy, while the reference alloy remained near 280 MPa (Figure 11). The ultimate compressive strength showed a similar trend, dropping from over 600 MPa to below 500 MPa, a far more severe decline than in the reference samples (Figure 12).

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that minimizing temperature fluctuations in holding furnaces and launders is critical. The finding that significant degradation appears after just 8 cycles underscores the need for robust process control to prevent the melt from dropping into the semi-solid temperature range.

- For Quality Control Teams: The data in Figures 10, 11, and 12 of the paper illustrates the direct link between thermal history and mechanical performance. This could inform new quality inspection criteria, such as requiring more frequent chemical analysis for Mg and Ti or performing melt cleanliness checks after any known process upset involving temperature instability.

- For Design Engineers: The findings indicate that the processing history of AlSi8Cu2Fe alloy profoundly influences its final properties. This reinforces the importance of collaborating with foundry partners to ensure that melt handling protocols are sufficient to prevent the degradation seen in this study, thereby ensuring the finished part meets its design specifications.

Paper Details

The Influence of Thermal History on the Microstructure and Mechanical Properties of AlSi8Cu2Fe Alloy

1. Overview:

- Title: The Influence of Thermal History on the Microstructure and Mechanical Properties of AlSi8Cu2Fe Alloy

- Author: Jan Šerák, Dalibor Vojtěch, Cyril Šimon

- Year of publication: 2020

- Journal/academic society of publication: MANUFACTURING TECHNOLOGY

- Keywords: Aluminum Alloys, Microstructure, Mechanical Properties, Heat Treatment, Gravity Casting

2. Abstract:

In this work the influence of cyclic thermal history on the microstructure and mechanical properties of AlSi8Cu2Fe alloy was studied. The commercial aluminum alloy was subjected to a special heat treatment during which the alloy repeatedly changed from a liquid to a semi-solid state. During this process, samples were taken, and the castings were subjected to another study. Gradual changes in the microstructure, chemical composition of the alloy, hardness and mechanical properties under pressure at normal temperatures have been documented. The content of alloying elements, especially magnesium, decreased significantly, the proportion of casting defects increased, especially hydrogen bubbles, microshrinkage and oxide inclusions in the alloy, with the increasing number of cycles. These changes also led to a decrease in the mechanical properties of the alloy. A series of samples without cyclic heat loading was also prepared for comparison.

3. Introduction:

This study investigates the influence of a specific cyclic thermal history on the microstructure and mechanical properties of the commercial AlSi8Cu2Fe alloy (ČSN 42 4339). The melt was exposed to long-term cyclic thermal exposure, where the alloy transitioned between a fully liquid state and a partially crystallized state (between liquidus and solidus temperatures). This process simulates conditions that can occur in foundry production. Long-term exposure of the melt to the atmosphere can lead to the oxidation of aluminum and other elements, forming oxide phases that can become inclusions. These oxides can increase the melt's susceptibility to hydrogen absorption. Temperature fluctuations, especially those into the semi-solid range, can further complicate this by affecting heterogeneous crystallization nuclei. While the properties of AlSi8Cu2Fe alloy are generally well-documented, no prior scientific work has systematically studied the effects of this specific type of cyclic thermal loading in detail.

4. Summary of the study:

Background of the research topic:

The study focuses on the commercial AlSi8Cu2Fe alloy, a hypoeutectic aluminum alloy widely used for die casting complex and dynamically stressed components such as automotive gearboxes and engine blocks. It is also considered an "ecologic alloy" due to its tolerance for higher levels of recycled elements like iron. The properties of such alloys are sensitive to processing conditions.

Status of previous research:

The paper notes that while the influence of various alloying elements and standard heat treatments on AlSi8Cu2Fe alloy is relatively well-documented, there is a lack of systematic scientific studies dealing specifically with the influence of long-term cyclic thermal exposure that involves transitioning between liquid and semi-solid states.

Purpose of the study:

The purpose of this work was to document the influence of a specific cyclic thermal history on the microstructure, chemical composition, and selected mechanical properties of the AlSi8Cu2Fe alloy. The study aimed to simulate and quantify the degradation that may occur during certain technological processes in foundry production.

Core study:

The core of the study was an experimental investigation where AlSi8Cu2Fe alloy was subjected to a cyclic heat treatment for up to 100 cycles. Each cycle involved heating to 750°C, cooling into the semi-solid temperature range, and reheating. The properties of samples taken at various cycle intervals were compared to a reference set of samples from an alloy held at a constant 750°C for 100 hours. The study documented changes in microstructure, the content of elements like Mg, Fe, and Ti, and mechanical properties including hardness and compressive strength.

5. Research Methodology

Research Design:

The research was designed as a comparative experimental study. One set of experiments involved subjecting the AlSi8Cu2Fe alloy to a cyclic thermal exposure regimen. A second, parallel experiment was conducted as a reference, where the alloy was held at a constant high temperature for a long duration. This design allowed for the direct comparison of the effects of cyclic versus continuous thermal loading.

Data Collection and Analysis Methods:

Samples were taken at predefined intervals (number of cycles or hours of exposure) and cast into a massive brass mold. The resulting cylindrical samples were analyzed using several methods:

- Microstructure: Conventional metallographic techniques and light microscopy (Olympus PME 3) were used to study the microstructure and identify defects.

- Chemical Composition: The chemical composition of the base alloy was determined, and changes in specific elements were tracked throughout the experiments.

- Mechanical Properties: Brinell hardness was measured using a Heckert WPM machine. Uniaxial pressure tests were performed on a universal tensile machine (LabTest 5.250SP1) to determine yield strength and compressive strength.

Research Topics and Scope:

The study was focused on a single commercial aluminum alloy, AlSi8Cu2Fe (ČSN 42 4339). The scope of the investigation covered the impact of two different thermal histories (cyclic and continuous) on:

1. Microstructural evolution, including phase morphology, coarsening, and the formation of foundry defects like oxide inclusions and porosity.

2. Changes in the chemical composition of the alloy, with a focus on key elements such as Mg, Fe, and Ti.

3. The resulting degradation of mechanical properties, specifically hardness, yield strength, and compressive strength.

6. Key Results:

Key Results:

- With an increasing number of thermal cycles, the microstructure of the AlSi8Cu2Fe alloy gradually coarsened, and the proportion of foundry defects, particularly oxide inclusions (membranes) and hydrogen porosity, increased.

- The chemical composition of the alloy changed significantly during cyclic exposure. The most significant decrease in content was observed for magnesium and titanium. Conversely, an increase in the content of iron was observed.

- The changes in microstructure and chemical composition led to a corresponding decrease in mechanical properties. Brinell hardness, yield strength in compression, and compressive strength all decreased significantly with the increasing number of cycles.

- In the case of the reference alloys, which were not exposed to cyclic thermal stress but held at a constant temperature, the changes in all studied properties were significantly less pronounced.

- The study noted that significant changes in the alloy's properties did not appear until after 8 cycles.

Figure Name List:

- Fig. 1 Turbulence and dross formation in the melt at the outlet of holding furnace [1]

- Fig. 2 Scheme of cyclic regime of thermal exposure of the AlSi8Cu2Fe alloy

- Fig. 3 Microstructure of base AlSi8Cu2Fe alloy

- Fig. 4 Microstructure of AlSi8Cu2Fe alloy after 100 cycles of cyclic themal exposure – oxide membranes

- Fig. 5 Microstructure of AlSi8Cu2Fe alloy after 100 cycles of cyclic themal exposure – hydroen porosity

- Fig. 6 Microstructure of AlSi8Cu2Fe alloy after 100 hours of themal exposure (reference alloy)

- Fig. 7 Dependence of Mg content in the casting on the time of thermal exposure

- Fig. 8 Dependence of Fe content in the casting on the time of thermal exposure

- Fig. 9 Dependence of Ti content in the casting on the time of thermal exposure

- Fig. 10 Dependence of Brinell hardness of casting on the time of thermal exposure

- Fig. 11 Dependence of yield strength of casting on the time of thermal exposure

- Fig. 12 Dependence of compressive strength of casting on the time of thermal exposure

7. Conclusion:

It was documented that the microstructure and mechanical properties of the AlSi8Cu2Fe alloy were adversely affected by cyclic thermal exposure. With an increasing number of cycles, the microstructure gradually coarsens, and the proportion of foundry defects increases, which corresponds with a decrease in mechanical properties. Significant changes also occur in the chemical composition of the melt, with the most significant decrease in content found for magnesium and titanium, and an increase for iron. In the case of reference alloys not subjected to cyclic stress, the changes in properties were significantly less pronounced. Cyclic thermal exposure of the alloy poses a risk in the production of castings with reproducible properties. Significant changes in properties did not appear until after 8 cycles, but for permanent or long-term foundry equipment, cyclic thermal loading can have a very negative effect.

8. References:

- [1] DISPINAR D., CAMPBELL J. (2007). Effect of casting conditions on aluminium metal quality, Journal of Materials Processing Technology, 182, pp. 405-410.

- [2] MA, Z., et al. (2010). Parameters controlling the microstructure of Al-11Si-2.5Cu-Mg alloys. Materials & Design, 2010. 31(2) pp. 902-912.

- [3] SOO, V.K., et al. (2018). Sustainable aluminium recycling of end-of-life products: A joining techniques perspective. In: Journal of Cleaner Production, 2018. 178. pp. 119-132.

- [4] GRIMAUD, G., PERRY, N., LARATTE, B. (2018). Aluminium cables recycling process: Environmental impacts identification and reduction. In: Resources, Conservation and Recycling, 2018. 135. pp. 150-162.

- [5] GRONOSTAJSKI, J., A. MATUSZAK, A. (2000). New methods of aluminium and aluminium-alloy chips recycling. In: Journal of Materials Processing Technology, 2000: pp. 34-39.

- [6] MICHNA, Š., LUKÁČ, I., OČENÁŠEK, V., KOŘENÝ, R., DRÁPALA, J., SCHNEIDER, H., MIŠKUFOVÁ, A. et. al. (2005). Encyklopedie hliníku, Adin, s. r. o., Prešov, ISBN 80-89041-88-4.

- [7] DOLEŽAL, J., BRYKSÍ STUNOVÁ, B., KUČERA, V. (2015). Současné poznatky o vlivu doprovodných prvků ve slitinách Al-Si, Slévárenství, Vol. LXIII. 2015. pp.345-348.

- [8] ŠERÁK, J., VOJTĚCH, D., REISER M. (2019). Influence of Sn, Pb, Bi and Sb on the Microstructure and Mechanical Properties of Commercial AlSi8Cu2 Alloy. Manufacturing Technology, Vol. 18, No. 5, 2019, pp. 658 - 691. J.E. Purkyne University in Usti and Labem. Czech Republic.

- [9] ŠERÁK, J., VOJTĚCH, D. (2017). Dispersion of Mechanical Properties of Commercial Aluminium Alloys within Their Material Standards. Manufacturing Technology, Vol. 17, No. 5, 2017, pp. 831-837. J.E. Purkyne University in Usti and Labem. Czech Republic.

- [10] DJURDJEVIC, M., VICARIO, I. (2013). Description of hypoeutectic Al-Si-Cu alloys based on their known chemical compositions. Revista de Metalurgia 2013, 49, 340-350.

- [11] ABDELAZIZ, M., SAMUEL, A., DOTY, H. (2019). Valtierra, S.; Samuel, F., Effect of additives on the microstructure and tensile properties of Al-Si alloys. Journal of Materials Research and Technology 2019, 8.

- [12] EFZAN, E., KONG, H.; KOK, C. K. (2013). Review: Effect of Alloying Element on Al-Si Alloys. Advanced Materials Research 2013, 845, 355-359.

- [13] LABISZ, K., MARIUSZ, K., DOBRZANSKI, L. (2009). Phases morphology and distribution of the Al-Si-Cu alloy. Journal of Achievements in Materials and Manufacturing Engineering 2009, 37.

- [14] BOLIBRUCHOVÁ D., ŽIHALOVÁ M. (2013). Possibilities of iron elimination in aluminum alloys by vanadium. Manufacturing Technology, Vol. 13, No. 3, 2013, pp. 289-296. J.E. Purkyne University in Usti and Labem. Czech Republic.

- [15] MARIUSZ, K., KRÓL, M.; MANIARA, R. (2018). Heat Treatment of Al-Si-Cu Alloys. Solid State Phenomena 2018, 275, 15-29.

- [16] MOHAMED, A. M. A., SAMUEL, F. (2012). A Review on the Heat Treatment of Al-Si-Cu-Mg Casting Alloys. 2012; pp 55-72.

- [17] BALDUCCI, E., CESCHINI, L., MORRI, A., MORRI, A., (2017). EN AW-4032 T6 Piston Alloy After High-Temperature Exposure: Residual Strength and Microstructural Features. Journal of Materials Engineering and Performance, 2017, 26.

- [18] RADWAN, B. (2020). Treatment of a Liquid Al-Si Alloy: Quality Control and Comparison of Two Melt Degassing Processes. Dissertation, School of Engineering in Jönköping, 2020.

Expert Q&A: Your Top Questions Answered

Q1: Why was the specific alloy AlSi8Cu2Fe chosen for this study?

A1: The paper states that AlSi8Cu2Fe (ČSN 42 4339) is a common hypoeutectic alloy used for general purposes and die casting, often for dynamically stressed and complex parts like gearboxes or engine blocks. It's also considered an "ecologic alloy" that can contain significantly higher amounts of recycled elements like iron, making its behavior under various thermal conditions highly relevant to modern, sustainability-focused foundry operations.

Q2: The study mentions an increase in iron content during the cyclic exposure. Where did this additional iron come from?

A2: The paper does not explicitly state the source of the iron increase shown in Figure 8. However, it notes that commercial alloys contain many elements and that interdependent chemical reactions can occur in the melt. The observed increase is likely a relative change in concentration as other elements with high affinity for oxygen, such as aluminum and magnesium, are lost from the melt to form oxides (dross), thereby increasing the weight percentage of the remaining, more stable elements like iron.

Q3: What is the significance of cooling the alloy into the semi-solid state during each cycle?

A3: The paper's introduction highlights that temperature fluctuations which include cooling into the range where solid and liquid phases coexist can affect "heterogeneous crystallization nuclei." This implies that by repeatedly entering the semi-solid state (between its liquidus temperature of 582°C and solidus of 497°C), the process directly disturbs the conditions for subsequent solidification. This disturbance is a primary cause of the observed microstructural coarsening and contributes to the degradation of mechanical properties.

Q4: How significant was the decrease in mechanical properties compared to just holding the melt at temperature?

A4: The decrease was highly significant. For example, Figure 11 shows the yield strength in the cyclically exposed alloy dropped by about 25% (from ~320 MPa to ~240 MPa) after 100 cycles. In contrast, the reference alloy held at a constant temperature for 100 hours only saw its yield strength drop by about 12.5% (to ~280 MPa). This demonstrates that the fluctuating temperature profile is roughly twice as damaging to the alloy's strength as continuous long-term holding.

Q5: The paper concludes that significant changes appeared after 8 cycles. What does this mean in a practical foundry setting?

A5: The 8-cycle threshold is a critical finding for process control. It implies that melt quality degradation is not just a long-term issue but can begin after a relatively small number of process instabilities. If a holding furnace or launder system experiences several significant temperature drops and recoveries over a single production shift, the melt may already be compromised. This highlights that consistent, stable process control is paramount, as the damage is cumulative and can quickly impact casting reproducibility and quality.

Q6: Was a protective atmosphere used during the experiment, and why is that important?

A6: No, the paper explicitly states the experiment was performed "without the use of a protective atmosphere." This is a crucial detail because it was designed to simulate typical real-world foundry conditions where the molten metal surface is exposed to the surrounding air. This exposure is what allows for the oxidation of aluminum and magnesium and the absorption of hydrogen from atmospheric moisture, which are the root causes of the oxide inclusions and gas porosity defects documented in the study.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides clear, quantitative evidence that the thermal history of a melt has a profound impact on final casting quality. The core finding is unambiguous: Cyclic Thermal Exposure, where the melt repeatedly dips into the semi-solid state, is far more detrimental than simply holding the alloy at a constant temperature. This process accelerates the loss of critical alloying elements, promotes the formation of defects, and severely degrades mechanical properties. For foundries aiming for high-yield, high-quality production, these findings highlight that maintaining strict temperature stability in holding furnaces and throughout melt transfer is not just best practice—it is essential for predictable and reliable component performance.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "The Influence of Thermal History on the Microstructure and Mechanical Properties of AlSi8Cu2Fe Alloy" by "Jan Šerák, Dalibor Vojtěch, Cyril Šimon".

Source: http://dx.doi.org/10.21062/mft.2020.071

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.