Unlocking Super-Sized Automotive Castings: How a Pinch of Lanthanum Transforms AM60 Alloy Performance

This technical summary is based on the academic paper "Low Cost High Performance HPDC AM60 Based Alloys for Super-Sized Integrated Automotive Components" by Jing Wang, Jiangfeng Song, Bin Jiang, and Fusheng Pan, presented at The 75th World Foundry Congress (2024).

Keywords

- Primary Keyword: High Performance Magnesium Alloy

- Secondary Keywords: HPDC, AM60, magnesium alloy, automotive components, super-sized casting, Lanthanum, mechanical properties, corrosion resistance.

Executive Summary

- The Challenge: The automotive industry requires low-cost, high-performance die-cast magnesium alloys capable of forming super-sized, integrated structural components.

- The Method: Researchers introduced microalloying elements Mn, Ce, and La (in quantities less than 0.2 wt.%) into the commercial AM60 magnesium alloy.

- The Key Breakthrough: The addition of just 0.2 wt.% Lanthanum (creating the AM60-0.2La alloy) resulted in the best overall performance, significantly improving tensile strength, elongation, corrosion resistance, and fluidity.

- The Bottom Line: A minor, inexpensive modification to AM60 alloy creates a superior material (AM60-0.2La) that is ideal for producing large, complex, and high-performance automotive parts using High Pressure Die Casting (HPDC).

The Challenge: Why This Research Matters for HPDC Professionals

The push for vehicle light-weighting has put a spotlight on magnesium alloys for large, integrated automotive structures like body-in-white components and battery enclosures. However, producing these "super-sized" parts via HPDC presents a significant challenge. Standard alloys may lack the necessary fluidity to fill massive, complex molds or the combination of strength, ductility, and corrosion resistance required for demanding structural applications. The industry is in critical need of a material solution that is not only high-performance but also cost-effective to enable widespread adoption. This research directly addresses this need by exploring simple, low-cost modifications to the widely used AM60 alloy to elevate its performance to meet these next-generation demands.

The Approach: Unpacking the Methodology

The study was designed as a comparative analysis to isolate the effects of specific microalloying elements on the properties of AM60.

Method 1: Alloy Preparation and Casting

Four AM60-based alloys were prepared: a baseline commercial AM60, AM61 (AM60 with increased Mn), AM60-0.2Ce (AM60 + 0.2 wt.% Cerium), and AM60-0.2La (AM60 + 0.2 wt.% Lanthanum). The alloys were melted in an electric resistance furnace at 720°C and then cast using a 650 T High Pressure Die Casting (HPDC) machine.

Method 2: Mechanical and Corrosion Testing

Directly die-cast tensile specimens with a gauge length of 60 mm and a diameter of 6.4 mm were used for mechanical property evaluation. For corrosion testing, samples measuring 20 mm × 20 mm × 3 mm were immersed in a 3.5 wt.% NaCl solution at room temperature for 7 days to measure corrosion rates.

The Breakthrough: Key Findings & Data

The introduction of just 0.2 wt.% Lanthanum yielded remarkable, multi-faceted improvements, establishing the AM60-0.2La alloy as the top performer across all key metrics.

Finding 1: Unprecedented Mechanical Properties Achieved

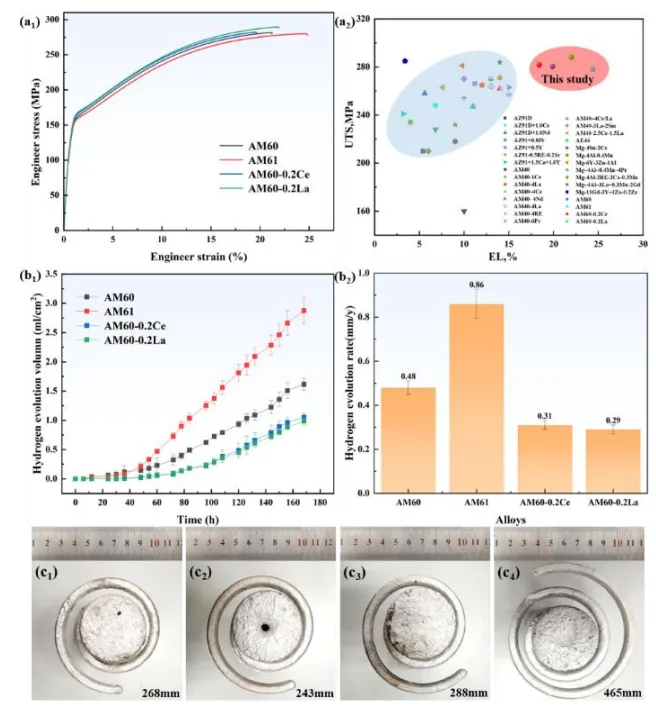

The AM60-0.2La alloy demonstrated a superior combination of strength and ductility. As shown in Figure 1 (a1), it achieved an ultimate tensile strength (UTS) of 288.0±1.7 MPa, a yield strength (YS) of 158.0±1.0 MPa, and an elongation (EL) of 22.0±3.0%. These values represent a significant enhancement over the baseline AM60 (UTS: 280.3 MPa, YS: 152 MPa, EL: 19.9%) and place the alloy at the top tier of performance when compared to other commercial and experimental HPDC magnesium alloys (Figure 1 (a2)). The improvements are attributed to effective grain refinement and a reduction in casting porosity.

Finding 2: Superior Fluidity and Corrosion Resistance

The ability to fill large, complex molds is critical for super-sized components, and the AM60-0.2La alloy excelled in this area. Fluidity tests showed a flow length of 465 mm for AM60-0.2La, a dramatic 73% improvement over the 268 mm flow length of standard AM60 (Figure 1 (c1) vs (c4)). Furthermore, the alloy exhibited the best corrosion resistance. As detailed in Figure 1 (b2), AM60-0.2La had the lowest corrosion rate of all tested alloys at just 0.29 mm/y, compared to 0.86 mm/y for the baseline AM60. This dual improvement in castability and durability makes it exceptionally well-suited for demanding automotive applications.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adopting the AM60-0.2La alloy could significantly expand the processing window for large castings. Its superior fluidity may allow for lower injection pressures or temperatures, potentially reducing cycle times and energy consumption while minimizing defects like misruns in thin-walled sections.

- For Quality Control Teams: The data in Figure 1(a1) and 1(b2) of the paper provides new performance benchmarks for modified AM60 alloys. The paper links these superior properties to microstructural features like "grain refinement strengthening" and "low porosity," giving QC teams specific indicators to look for during metallographic analysis to ensure part quality.

- For Design Engineers: The findings indicate that the exceptional fluidity of AM60-0.2La (465 mm flow length) empowers greater design freedom. Engineers can confidently design larger, more complex, and thinner-walled integrated components that were previously unfeasible with standard alloys, enabling further part consolidation and vehicle light-weighting.

Paper Details

Low Cost High Performance HPDC AM60 Based Alloys for Super-Sized Integrated Automotive Components

1. Overview:

- Title: Low Cost High Performance HPDC AM60 Based Alloys for Super-Sized Integrated Automotive Components

- Author: Jing Wang, Jiangfeng Song, Bin Jiang, Fusheng Pan

- Year of publication: 2024

- Journal/academic society of publication: The 75th World Foundry Congress

- Keywords: Magnesium alloys, High pressure die casing, Microstructure, Mechanical properties.

2. Abstract:

Magnesium alloy super-sized integrated high pressure die casting for automotive structural components has a bright application prospect and attracted much attention. Low cost and high-performance die cast magnesium alloys for super-sized integrated components application are in great need. In this work, microalloying element Mn, Ce and La with an adding content less than 0.2 wt.% were introduced into the commercial AM60 die cast alloys. The ultimate tensile strength, yield strength, elongation of 288.0±1.7 MPa, 158.0±1.0 MPa, and 22.0±3.0 % were achieved in AM60-0.2La alloy. Besides, AM60-0.2La alloy exhibited the best corrosion resistance (0.29 mm/y) and fluidity among the investigated four alloys. The excellent mechanical properties and corrosion resistance are mainly attributed to grain refinement strengthening, low porosity and low content of large shrinkage pores. The current findings offer valuable guidance for the alloy design for magnesium alloy super-sized integrated high pressure die casting application.

3. Introduction:

This study addresses the need for improved High Pressure Die Casting (HPDC) magnesium alloys suitable for large-scale automotive components. It focuses on the widely used commercial AM60 alloy and investigates the effects of adding small quantities of alloying elements Mn, Ce, and La. The objective is to analyze the impact of these elements on the microstructure, defects, fluidity, mechanical properties, and corrosion resistance of the AM60 alloy, with the aim of formulating an alloy with superior comprehensive properties for this application.

4. Summary of the study:

Background of the research topic:

There is a growing industrial demand for super-sized, integrated automotive structural components produced via HPDC. This trend requires the development of low-cost magnesium alloys that exhibit high performance characteristics.

Status of previous research:

The commercial AM60 alloy is widely used in HPDC. Prior research, cited in the references, has indicated that rare-earth (RE) elements and Mn can influence the properties of magnesium alloys, such as by purifying the melt or forming specific intermetallic phases.

Purpose of the study:

The study aims to systematically investigate the impact of microalloying AM60 with Mn, Ce, and La on its key properties. The ultimate goal is to develop a cost-effective, high-performance AM60-based alloy suitable for super-sized integrated HPDC applications.

Core study:

The core of the study is a comparative analysis of four HPDC alloys: AM60 (baseline), AM61 (higher Mn), AM60-0.2Ce, and AM60-0.2La. The investigation covers mechanical properties (UTS, YS, EL), corrosion behavior, fluidity, and the underlying microstructural changes and defect formation.

5. Research Methodology

Research Design:

The research employs an experimental design comparing a control group (AM60 alloy) against three experimental groups (AM61, AM60-0.2Ce, AM60-0.2La) to determine the effects of specific alloying additions.

Data Collection and Analysis Methods:

Alloys were prepared by melting at 720°C and cast using a 650 T HPDC machine. Tensile properties were measured from as-cast specimens. Corrosion resistance was quantified by measuring the volume of hydrogen evolution during a 7-day immersion test in 3.5 wt.% NaCl solution. Fluidity was assessed by measuring the flow length in a spiral die.

Research Topics and Scope:

The research is focused on AM60-based alloys for HPDC. The scope is limited to the effects of adding less than 0.2 wt.% of Mn, Ce, and La on the microstructure, mechanical properties, corrosion resistance, and fluidity of the alloy.

6. Key Results:

Key Results:

- The AM60-0.2La alloy achieved the highest mechanical properties: ultimate tensile strength (UTS) of 288.0±1.7 MPa, yield strength (YS) of 158.0±1.0 MPa, and elongation (EL) of 22.0±3.0%.

- The AM60-0.2La alloy demonstrated the best corrosion resistance, with a calculated corrosion rate of 0.29 mm/y.

- The AM60-0.2La alloy exhibited the highest fluidity, with a measured flow length of 465 mm.

- The performance hierarchy among the tested alloys for fluidity and corrosion resistance was determined to be: AM60-0.2La > AM60-0.2Ce > AM60 > AM61.

- The superior properties of the alloys microalloyed with Ce and La, particularly La, are attributed to grain refinement strengthening, reduced porosity, and a lower content of large shrinkage pores compared to AM60 and AM61.

Figure Name List:

- Fig.1. (a) Mechanical properties: (a1) Tensile stress-strain curve and corresponding mechanical property values of AM based alloys. (a2) YS, UTS and EL of various die-casting Mg alloys.

- (b)Corrosion property: (b1) hydrogen evolution volume-time curves; (b2) corrosion rate bar chart.

- (c)Macro-view photographs of fluidity test sample of AM based alloys: (c1) AM60; (c2) AM61; (c3) AM60-0.2Ce; (c4) AM60-0.2La.

7. Conclusion:

The investigation successfully developed an AM60-0.2La alloy by incorporating trace amounts of the RE element La into commercial AM60. This addition promotes grain refinement and reduces porosity. These microstructural adjustments lead to superior fluidity, mechanical properties, and corrosion resistance in the AM60-0.2La alloy. The minor addition of inexpensive La ensures the alloy remains low-cost, making it a very promising material for super-sized integrated HPDC automotive part applications.

8. References:

- [1] G. Wu, C. Wang, M. Sun, W. Ding, Recent developments and applications on high-performance cast magnesium rare-earth alloys, J. Magnesium Alloys 9(1) (2021) 1-20.

- [2] T. Chen, Y. Yuan, T.T. Liu, D.J. Li, A.T. Tang, X.H. Chen, R. Schmid-Fetzer, F.S. Pan, Effect of Mn Addition on Melt Purification and Fe Tolerance in Mg Alloys, Jom 73(3) (2021) 892-902.

- [3] M.S. Dargusch, S.M. Zhu, J.F. Nie, G.L. Dunlop, Microstructural analysis of the improved creep resistance of a die-cast magnesium-aluminium-rare earth alloy by strontium additions, Scr. Mater. 60(2) (2009) 116-119.

Expert Q&A: Your Top Questions Answered

Q1: What is the primary strengthening mechanism that makes the AM60-0.2La alloy superior?

A1: The paper explicitly states that the primary strengthening mechanism is "grain refinement strengthening." The addition of Lanthanum promotes the formation of a finer grain structure during solidification in the HPDC process. This, combined with a reduction in porosity and large shrinkage pores, leads to the observed significant improvements in both strength and ductility.

Q2: How does a small addition of Lanthanum improve corrosion resistance so effectively?

A2: According to the discussion, the improvement in corrosion resistance is multi-faceted. The addition of RE elements like La helps decrease harmful impurity content. It also leads to the precipitation of the Al11RE3 phase, which is believed to decrease micro-galvanic corrosion. Finally, by reducing casting defects like porosity, it removes potential sites for corrosion initiation, leading to a more durable material.

Q3: The paper shows that adding more Mn (to create AM61) degraded performance. Why did this happen?

A3: The discussion section suggests that the increased Mn content in AM61 leads to the precipitation of Al8Mn5 phases before the primary α-Mg solidifies. This precipitation increases the viscosity of the molten metal, which in turn reduces fluidity. The reduced fluidity and altered solidification behavior likely contribute to the formation of more ESCs (Externally Solidified Crystals) and pore defects, which significantly deteriorate the mechanical properties and corrosion resistance.

Q4: Why does Lanthanum improve fluidity more than Cerium or Manganese?

A4: The paper attributes the superior fluidity of the La-containing alloy to atomic-level behavior. It states that the diffusion coefficient of elements in the Mg melt follows the order of La > Ce > Al > Mn. A higher diffusion coefficient allows atoms to move more quickly, contributing to lower melt viscosity and thus higher fluidity. This allows the AM60-0.2La alloy to fill long, thin sections of a mold more effectively than the other alloys.

Q5: What makes the AM60-0.2La alloy specifically suitable for "super-sized" integrated components?

A5: The suitability comes from its exceptional combination of properties. Its dramatically improved fluidity (465 mm flow length) is the most critical factor, as it ensures the complete filling of very large and complex molds without defects like misruns. This is complemented by its high mechanical properties (UTS of 288 MPa, EL of 22.0%), which provide the necessary structural integrity for large components, and its enhanced corrosion resistance, which ensures long-term durability.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of producing large, lightweight, and cost-effective automotive components has found a promising solution. This research demonstrates that a minor addition of Lanthanum can transform the workhorse AM60 alloy into a High Performance Magnesium Alloy with superior castability, strength, and durability. For manufacturers, the AM60-0.2La alloy represents a direct path to producing next-generation super-sized integrated components with higher quality and reliability.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Low Cost High Performance HPDC AM60 Based Alloys for Super-Sized Integrated Automotive Components" by "Jing Wang, Jiangfeng Song, Bin Jiang, Fusheng Pan".

Source: The 75th World Foundry Congress, October 25-30, 2024, Deyang, Sichuan, China.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.