Unlocking Durability: How Heat Treatment and Casting Defects Dictate Magnesium Alloy Fatigue Resistance

This technical summary is based on the academic paper "The Influence of Casting Defects on Fatigue Resistance of Elektron 21 Magnesium Alloy" by I. Pikos, A. Kiełbus, and J. Adamiec, published in ARCHIVES of FOUNDRY ENGINEERING (2013).

Keywords

- Primary Keyword: Magnesium Alloy Fatigue Resistance

- Secondary Keywords: Elektron 21, Casting Defects, Heat Treatment, Fatigue Life, Microstructure, Aerospace Alloys, Automotive Materials

Executive Summary

- The Challenge: High-performance magnesium alloys like Elektron 21 are crucial for lightweighting in aerospace and automotive, but their fatigue resistance can be compromised by casting defects and improper heat treatment.

- The Method: The study subjected sand-cast Elektron 21 samples to two different heat treatment procedures (ageing at 200°C vs. 250°C) and then performed a 1 million cycle fatigue test.

- The Key Breakthrough: The heat treatment aged at 200°C resulted in a microstructure that successfully endured 1 million stress cycles, whereas the treatment aged at 250°C led to premature failure in under 150,000 cycles due to detrimental precipitates and casting defects.

- The Bottom Line: For Elektron 21, controlling both the heat treatment parameters to achieve the optimal precipitate structure and minimizing casting defects like oxides and porosity are non-negotiable for ensuring high fatigue resistance in critical components.

The Challenge: Why This Research Matters for HPDC Professionals

In the relentless drive for fuel efficiency and performance, industries like aerospace and automotive are increasingly turning to lightweight magnesium alloys. Elektron 21 (Mg-RE) is a prime candidate, offering an attractive combination of low density, good castability, and high-temperature mechanical properties. However, its real-world reliability hinges on its fatigue resistance—the ability to withstand repeated loading cycles without failure.

This is where the challenge begins. Magnesium alloys are notoriously prone to oxidation during melting and pouring, leading to inclusions. They can also suffer from hydrogen-induced porosity. These casting defects, combined with suboptimal heat treatment, can create weak points in the material, drastically reducing component life. For engineers, understanding the precise interplay between processing parameters, microstructure, and fatigue performance is critical to unlocking the full potential of these advanced materials.

The Approach: Unpacking the Methodology

The researchers investigated sand-cast Elektron 21, an alloy containing Nd, Gd, Zn, and Zr. The material was divided into two groups, E1 and E2, and subjected to different heat treatments:

- Solutioning (Both Groups): All samples were solution treated at 525°C for 8 hours and then water-quenched.

- Ageing (Differentiation):

- Sample Group E1: Aged at 200°C for 16 hours.

- Sample Group E2: Aged at 250°C for 16 hours.

Cylindrical samples from both groups were then subjected to a uniaxial, cyclic tensile stress test. The test was designed to run for 1,000,000 cycles with a sine wave stress form ranging from a minimum of 9 MPa to a maximum of 90 MPa. Post-test analysis involved detailed investigation of fracture surfaces using Scanning Electron Microscopy (SEM) and microstructural analysis with Light Microscopy (LM).

The Breakthrough: Key Findings & Data

The difference in performance between the two heat treatments was stark and unambiguous. The results directly link heat treatment parameters to fatigue life and highlight the critical role of casting defects.

Finding 1: 200°C Ageing Treatment Delivers Superior Fatigue Resistance

The samples from group E1, aged at 200°C, demonstrated excellent fatigue resistance. As documented in Table 2, both E1 specimens successfully endured the full 1,000,000 cycles of the fatigue test without rupture. Microstructural analysis of these samples (Figure 3) revealed a clean structure with no microcracks, pores, or significant inclusions, along with a monochromatic grain structure indicative of beneficial coherent β" and semi-coherent β' phase precipitates.

Finding 2: 250°C Ageing and Casting Defects Lead to Catastrophic Early Failure

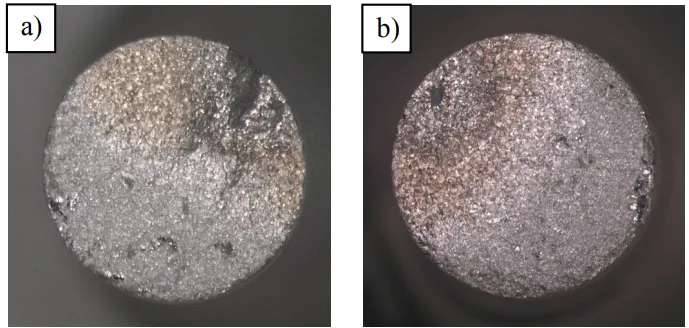

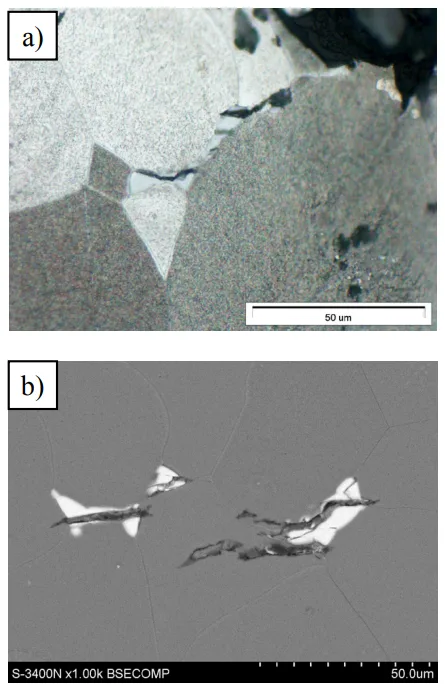

In sharp contrast, none of the E2 samples, aged at 250°C, completed the test. As shown in Table 2, the specimens ruptured prematurely at just 60,000 and 149,995 cycles. Fractographical investigation (Figure 1) revealed that the failures initiated at significant casting defects, such as large inclusions and porosity located at or near the specimen surface. The microstructure of E2 samples (Figure 4, 5) showed polychromatic grains, suggesting the presence of incoherent β phase, which deteriorates mechanical properties. Furthermore, numerous microcracks were observed, particularly in the brittle, massive phase on grain boundaries.

Practical Implications for R&D and Operations

This study offers clear, actionable insights for engineers working with high-performance magnesium alloys.

For Process Engineers: This study suggests that ageing temperature is a critical process parameter. Ageing Elektron 21 at 250°C appears to promote the formation of an incoherent β phase that degrades mechanical properties. An ageing temperature of 200°C is proven to be far more effective for achieving a microstructure conducive to high fatigue resistance.

For Quality Control Teams: The data in Figure 1 and Figure 2 of the paper illustrates the effect of casting defects as fracture initiators. Quality inspection criteria should prioritize the detection of surface and near-surface porosity and oxide inclusions, as these are the most detrimental to fatigue life.

For Design Engineers: The findings indicate that fatigue failure is highly sensitive to surface integrity. This reinforces the need for designs that minimize stress concentrations and for manufacturing processes that ensure a defect-free surface in critical areas of a component.

Paper Details

The Influence of Casting Defects on Fatigue Resistance of Elektron 21 Magnesium Alloy

1. Overview:

- Title: The Influence of Casting Defects on Fatigue Resistance of Elektron 21 Magnesium Alloy

- Author: I. Pikos, A. Kiełbus, J. Adamiec

- Year of publication: 2013

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING, Volume 13, Issue 2/2013, Published quarterly as the organ of the Foundry Commission of the Polish Academy of Sciences

- Keywords: Casting Defect, Mechanical Properties, Microstructure, Magnesium Alloy, Elektron 21

2. Abstract:

The Mg-RE alloys are attractive, constructional materials, especially for aircraft and automotive industry, thanks to combination of low density, good mechanical properties, also at elevated temperature, and good castability and machinability. Present paper contains results of fatigue resistance test carried out on Elektron 21 magnesium alloy, followed by microstructural and fractographical investigation of material after test. The as-cast material has been heat treated according to two different procedures. The fatigue resistance test has been conducted with 10^6 cycles of uniaxial, sine wave form stress between 9 MPa and 90 MPa. Fractures of specimens, which ruptured during the test, have been investigated with scanning electron microscope. The microstructure of specimens has been investigated with light microscopy. Detrimental effect of casting defects, as inclusions and porosity, on fatigue resistance has been proved. Also the influence of heat treatment's parameters has been described.

3. Introduction:

Magnesium alloys are promising materials for the automotive and aircraft industries due to their satisfactory mechanical properties, low density, good castability, and machinability. Elektron 21 is a magnesium alloy containing Nd, Gd, Zn, and Zr, which provide improved properties such as hardness, strength, grain refinement, and fatigue resistance at elevated temperatures. The addition of rare earth elements like Nd and Gd improves creep resistance and thermal stability via precipitation hardening. The microstructure typically consists of an α-Mg matrix with Mg12(Nd, Gd) and Mg3(Nd,Gd) phases. However, magnesium alloys are prone to oxidation during processing, resulting in oxide, carbide, and nitride impurities, and are also susceptible to hydrogen adsorption, which promotes porosity formation.

4. Summary of the study:

Background of the research topic:

Elektron 21 is an attractive constructional magnesium alloy for the aircraft and automotive industries due to its low density and good mechanical properties at elevated temperatures. However, its performance is highly dependent on processing conditions.

Status of previous research:

Previous work has established the role of alloying elements in Elektron 21: Zn for hardness and strength, Zr for grain refinement and reducing microporosity, and RE elements (Nd, Gd) for precipitation hardening, which improves creep resistance. It is also known that magnesium alloys are prone to forming defects like oxide inclusions and porosity during casting.

Purpose of the study:

The study aimed to investigate the influence of different heat treatment parameters and the presence of casting defects on the fatigue resistance of Elektron 21 magnesium alloy.

Core study:

The core of the study involved conducting fatigue resistance tests on sand-cast Elektron 21 samples that had undergone two different ageing treatments (at 200°C and 250°C). The performance of the samples was then correlated with microstructural and fractographical analysis to determine the causes of failure or success.

5. Research Methodology

Research Design:

The study employed a comparative experimental design. Sand-cast Elektron 21 alloy was subjected to two distinct heat treatment schedules (designated E1 and E2), and the resulting materials were tested for fatigue resistance under identical conditions. Post-failure analysis was conducted to correlate material properties with performance.

Data Collection and Analysis Methods:

- Material: Sand casting Elektron 21 magnesium alloy (2.6-3.1% Nd, 1-1.7% Gd, 0.2-0.5% Zn, saturated Zr).

- Heat Treatment: All samples were solutionized at 525°C±5°C for 8h followed by water quenching. Group E1 was aged at 200°C for 16h. Group E2 was aged at 250°C for 16h.

- Fatigue Testing: Uniaxial, cyclic tensile stress test was conducted according to PN-76/H-04325 and PN-74/H-04327 norms. A sine wave form was used with σ_max = 90 MPa, σ_min = 9 MPa, and σ_m = 49.5 MPa for 10^6 cycles.

- Analysis: Fractures were analyzed using an Olympus SZX9 stereoscope and a Hitachi S-3400N Scanning Electron Microscope (SEM) with a Thermo Noran EDS spectrometer. Microstructure was observed on perpendicular microsections using an Olympus GX71 light microscope (LM) and SEM after etching with acetic glycol.

Research Topics and Scope:

The research focused on the fatigue resistance of Elektron 21 alloy. The scope was limited to two specific heat treatment procedures and the analysis of resulting microstructures, casting defects (inclusions, porosity), and fracture surfaces.

6. Key Results:

Key Results:

- Samples heat-treated according to procedure E1 (ageing at 200°C) exhibited satisfactory fatigue resistance, successfully enduring the full 1,000,000 cycles of the test without rupture.

- Samples heat-treated according to procedure E2 (ageing at 250°C) did not exhibit proper fatigue resistance, rupturing prematurely after 60,000 and 149,995 cycles.

- Fractographical analysis of E2 samples revealed that fatigue fractures initiated at casting defects, specifically porosity and large inclusions located near the specimen edge. The fracture surfaces were mainly brittle and transcrystalline.

- Microstructural analysis showed a difference between the samples. E1 samples exhibited monochromatic grains, suggesting precipitation of coherent β" and semi-coherent β' phases. E2 samples showed polychromatic grains, indicative of incoherent β phase precipitation, which is known to deteriorate mechanical properties.

- Numerous microcracks were observed in the microstructure of E2 samples, primarily located on the massive phase at grain boundaries and within oxide inclusions. No such defects were found in E1 samples.

Figure Name List:

- Fig. 1. Examples of fracture surfaces, sample E2-1 (a), sample E2-2 (b)

- Fig. 2. SEM image of fracture surface, sample E2, porosity in area of fracture initiation (a), intercrystalline fracture in the close proximity to inclusion (pointed by arrow) (b), transcrystalline fracture surface with twins (pointed by arrow) (c)

- Fig. 3. Microstructure of sample E1, LM, black arrow points massive phase on grain boundaries, white arrow points Zn- and Zr- enriched zones

- Fig. 4. Microstructure and inclusions near the fracture in sample E2, LM

- Fig. 5. Microcracks in massive phase on grain boundaries, sample E2, LM (a), SEM (b)

- Fig. 6. EDS analysis of impurities, narrow points the area of analysis

7. Conclusion:

- Material E1, heat treated by solutioning (525°C/8h/water quenching) and ageing (200°C/16h/air cooling), exhibited satisfactory fatigue resistance, enduring 10^6 cycles of uniaxial stress.

- Material E2, heat treated by solutioning and ageing (250°C/16h/air cooling), did not exhibit proper fatigue resistance, with samples rupturing after 60,000 and approximately 150,000 cycles.

- Microstructural observations revealed differences between E1 and E2. The monochromatic etching effect in E1 suggests precipitation of coherent β" and semi-coherent β' phases, responsible for peak mechanical properties. The polychromatic effect in E2 suggests precipitation of incoherent β phase during ageing at 250°C, which causes deterioration of mechanical properties and contributes to insufficient fatigue resistance.

- Fractographical investigation of E2 fractures revealed numerous casting defects. Porosity and inclusions near the specimen edge were identified as fracture initiation sites. The fracture was mostly transcrystalline. EDS analysis identified impurities as magnesium and zirconium oxides. Microstructural analysis of E2 also revealed numerous microcracks.

8. References:

- [1] Piątkowski, J. & Binczyk, F. (2002). Properties and uses of the foundry magnesium alloys (in Polish). Archives of Foundry Engineering. 2(4), 426-433.

- [2] Nie, J. F., Gao, X. & Zhu, S.M. (2005). Enhanced age hardening response and creep resistance of Mg-Gd alloys containing Zn. Scripta Materialia. 53, 1049-1053. DOI: 10.1016/j.scriptamat.2005.07.004.

- [3] Kiełbus, A. (2008). The influence of long-term annealing on the microstructure of Elektron 21 magnesium alloy. Inżynieria Materiałowa. 4, 310-315.

- [4] Kiełbus, A. (2006). Casting magnesium alloy Elektron 21 - structure and properties. Archives of Foundry. 6(18), 173-178.

- [5] Bonderek, Z. & Rzadkosz, S. (2000). The phenomena of porosity in castings made of aluminium and magnesium alloys. Solidification of Metals and Alloys. 2(43), 51-55.

- [6] Kuffova, M. (2011). Fatigue Endurance of Magnesium Alloys, Magnesium Alloys - Design, Processing and Properties, Frank Czerwinski (Ed.), ISBN: 978-953-307-520-4, InTech, Available from: http://www.intechopen.com /books/magnesium-alloys-design-processing-and-properties/fatigue -endurance-of-magnesium-alloys

- [7] He, S.M., Zeng, X.Q., Peng L.M., Gao X., Nie, J.F. & Ding W.J. (2006). Precipitation in a Mg-10Gd-3Y-0.4Zr (wt.%) alloy during isothermal ageing at 250°C. Journal of Alloys and Compounds. 421, 309-313. DOI: 10.1016/j.jallcom. 2005.11.046

Expert Q&A: Your Top Questions Answered

Q1: Why were two different ageing temperatures, 200°C and 250°C, chosen for the study?

A1: The authors chose these two temperatures to create distinct microstructures. Ageing at 200°C (Sample E1) promotes the precipitation of coherent β" and semi-coherent β' phases, which are known to be responsible for peak hardness and strength. In contrast, ageing at 250°C (Sample E2) leads to the formation of the incoherent β phase, which the paper links to a deterioration in mechanical properties and, consequently, lower fatigue resistance.

Q2: What was the primary initiation site for fatigue cracks in the failed samples?

A2: The paper clearly identifies casting defects as the primary initiation sites. Specifically, fractographical analysis showed that failures in the E2 samples began at areas of porosity and large inclusions of magnesium and zirconium oxides. Crucially, these defects were located near the edge of the specimens, where stresses are often highest and where a defect can most easily propagate into a critical crack.

Q3: The paper mentions a "polychromatic grains" effect in the E2 samples. What is the technical significance of this?

A3: This visual effect, observed under a light microscope after etching, is significant because it serves as evidence for the precipitation of the incoherent β phase. The authors link this specific microstructure directly to the poor performance of the E2 samples. This suggests that the presence of the incoherent β phase, brought on by the 250°C ageing treatment, contributes to the material's insufficient fatigue resistance.

Q4: What specific types of inclusions were identified, and why are they so detrimental?

A4: According to the EDS analysis (Figure 6), the impurities were identified as magnesium and zirconium oxides. These oxide inclusions form during the melting and pouring process. They are brittle, non-metallic particles within the metal matrix that act as stress concentrators, creating localized points of high stress that can easily initiate microcracks under cyclic loading, leading to premature fatigue failure.

Q5: Were classic fatigue striations observed on the fracture surfaces?

A5: No. The paper explicitly states that "The striations, which are characteristic for fatigue fractures, have not been found in investigated material." The fracture surfaces were instead dominated by a brittle, transcrystalline character, with some intercrystalline and ductile areas near the main inclusion. This indicates that the failure was driven more by the rapid propagation of cracks from defects rather than a classic, slow-growth fatigue process.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a crucial reminder that for advanced materials, success lies in the details. The study on Elektron 21 demonstrates that achieving superior Magnesium Alloy Fatigue Resistance is a two-fold challenge: meticulous control over heat treatment to create an optimal microstructure, and rigorous control over the casting process to eliminate defects. The dramatic difference in performance between the 200°C and 250°C ageing treatments underscores how a single process parameter can be the difference between a component that lasts over a million cycles and one that fails catastrophically early.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "The Influence of Casting Defects on Fatigue Resistance of Elektron 21 Magnesium Alloy" by "I. Pikos, A. Kiełbus, J. Adamiec".

Source: DOI: 10.2478/afe-2013-0046

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.