Paper Title From Billet to Breakthrough: Slashing Costs for High-Quality Forging Stock with Low-Pressure Casting

This technical summary is based on the academic paper "Low-Pressure Casting Technology Represents Step Change in Producing High Quality Forging Stock" by Ulf Tundal, Knut Omdal Tveito, Sigrun Sofie Berg, Lars Moen, Magne Boge, Arild Håkonsen, and Rune Ledal, published in Light Metal Age (2020).

Keywords

- Primary Keyword: High-Quality Forging Stock

- Secondary Keywords: Low-Pressure Casting (LPC), aluminum suspension parts, cost reduction in forging, scalp-free casting, AA6082, HyForge, aluminum casting technology

Executive Summary

- The Challenge: The traditional multi-step process for producing aluminum forging stock is complex and expensive, accounting for up to 50% of the cost of a finished forged suspension component.

- The Method: Researchers developed and validated a Low-Pressure Casting (LPC) technology to produce small-diameter billets with superior surface quality and internal structure.

- The Key Breakthrough: The LPC process nearly eliminates the inverse segregation zone at the surface, allowing the forging stock to be used directly without costly scalping and, in many cases, without a separate homogenization step.

- The Bottom Line: This technology enables the production of top-quality forging material at a substantial cost reduction—estimated at 20% on a material level—representing a major step change for the aluminum forging industry.

The Challenge: Why This Research Matters for HPDC Professionals

In the automotive industry, the demand for lightweight, high-strength components like aluminum wheel suspension parts is constantly growing. Closed die forging is a preferred manufacturing method for these parts due to the excellent mechanical properties it imparts. However, the value chain has a significant drawback: cost.

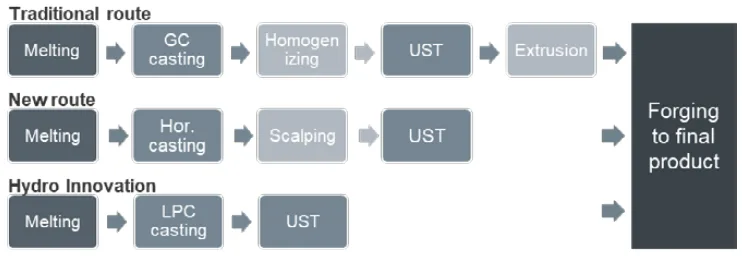

The traditional route to create High-Quality Forging Stock involves melting, billet casting, homogenizing, ultrasonic testing, and finally, extruding the material. A newer route simplifies this slightly by casting smaller billets but still requires a "scalping" step to remove the segregated surface layer. These multiple, complex steps mean the raw material cost can represent 50% of the final forged component's production cost. This high cost is a major barrier to the wider adoption of forged aluminum parts. The industry has been searching for a more direct, cost-effective method to produce forge-ready material without compromising on quality.

The Approach: Unpacking the Methodology

To tackle this challenge, Hydro developed and optimized a Low-Pressure Casting (LPC) technology specifically for producing small-diameter forging stock. The research involved a multi-faceted approach to validate the technology from simulation to physical trials:

- Advanced Simulation: An advanced computational fluid dynamics (CFD) model was developed to understand and optimize the critical start-up phase of casting small-diameter billets. This 3D model accounted for turbulent metal flow, solidification, and heat transfer, and was integrated with automation controls to maximize the process window.

- Pilot-Scale Validation: A pilot casting line at Hydro's Reference Center in Sunndal, Norway, was used to validate the numerical models. The setup included a furnace, launder system, SIR refiners, and a single module of the LPC casting unit. Experimental data, such as the metal level during filling (Figure 3), showed good agreement with simulation predictions.

- Material Characterization: Forging ingots of alloy AA6082 with a 90 mm diameter were produced using the LPC technology. Their surface roughness, microstructure, and grain structure were meticulously analyzed using optical microscopy and roughness measurement equipment.

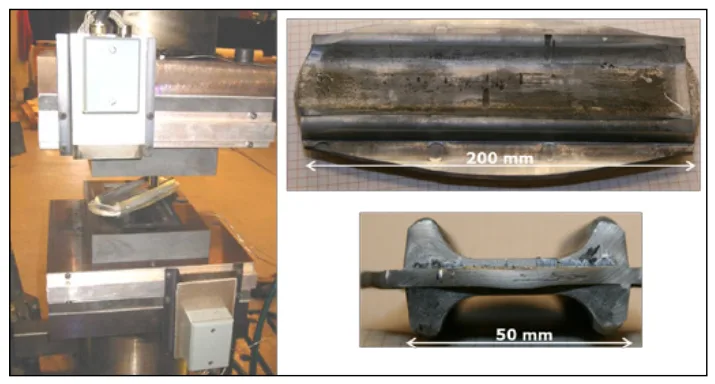

- Forging Experiments: To test performance under real-world conditions, the cast material was machined into 40 mm diameter bars and forged using an 800-tonne laboratory-scale press. The trials compared the performance of as-cast (unhomogenized) material against traditional homogenized material to evaluate mechanical properties and grain structure evolution.

The Breakthrough: Key Findings & Data

The research yielded significant results, demonstrating the LPC technology's potential to revolutionize the production of High-Quality Forging Stock.

Finding 1: Superior Surface Quality Eliminates the Need for Scalping

A primary benefit of the LPC technology is the dramatic improvement in surface quality. The process reduces friction between the ingot surface and the mold, which "nearly eliminates the inverse segregation zone." This results in logs with an exceptionally smooth surface.

As shown in Figure 5, the roughness values for a typical LPC cast surface are well within the requirements for forging ingots. The average roughness (Ra) was measured at 1.06 µm, and the mean roughness depth (Rz) was 6.4 µm, comfortably below the typical requirement of Rz < 20 µm. This high-quality surface means the material can be forged directly without the costly and wasteful scalping step required by other casting methods.

Finding 2: Unhomogenized Material Delivers Higher Strength After Forging

Perhaps the most surprising and impactful finding was the performance of the unhomogenized material. Traditionally, homogenization is a critical step to prepare the billet for forging. However, this study found it may not be necessary with LPC-cast material.

After forging and solutionizing, tensile tests were conducted on samples from different locations. The results in Figure 9 clearly show that the unhomogenized material (blue bars) consistently exhibited higher strength levels than the homogenized material (red bars). For example, in the "Transverse round" samples, the unhomogenized material achieved an ultimate tensile strength (Rm) of approximately 435 MPa, compared to around 420 MPa for the homogenized material. The paper suggests this is because, in the unhomogenized material, new dispersoids precipitate on dislocations during the forging and solutionizing process, creating a more effective barrier against recrystallization and thereby retaining more strength. This finding opens the door to eliminating the energy-intensive homogenization step, further reducing costs and lead times.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that for 6xxx series alloys, it's possible to eliminate both scalping and homogenization from the process flow. Furthermore, the research indicates that the solutionizing step can be combined with the pre-forging heating process, provided the temperature and time are sufficient to dissolve eutectic phases. This could dramatically simplify the production line.

- For Quality Control Teams: The data in Figure 5 and Figure 6 provides a new benchmark for as-cast surface quality and microstructure. The near-zero inverse segregation and fine, homogeneous grain structure (60-100 µm) are key quality indicators for LPC-cast forging stock that could inform new incoming material inspection criteria.

- For Design Engineers: The findings indicate that the LPC process produces a highly robust and consistent starting material. This reliability, combined with the potential for higher strength from unhomogenized stock, could allow for the design of more weight-efficient components or the use of forged aluminum in even more demanding applications.

Paper Details

Low-Pressure Casting Technology Represents Step Change in Producing High Quality Forging Stock

1. Overview:

- Title: Low-Pressure Casting Technology Represents Step Change in Producing High Quality Forging Stock

- Author: Ulf Tundal, Knut Omdal Tveito, Sigrun Sofie Berg, Lars Moen, and Magne Boge, Hydro Aluminum Primary Metal, and Arild Håkonsen and Rune Ledal, Hycast AS

- Year of publication: 2020

- Journal/academic society of publication: Light Metal Age

- Keywords: Low-Pressure Casting (LPC), forging stock, aluminum, AA6082, cost reduction, surface quality

2. Abstract:

Forged aluminum parts, particularly for automotive wheel suspensions, offer a desirable combination of lightweight design and high strength but suffer from high production costs due to a long and complex value chain. Traditional methods for producing forging stock require multiple steps, including casting, homogenization, and extrusion or scalping, which contribute significantly to the final component cost. This paper introduces a Low-Pressure Casting (LPC) technology developed by Hydro as a new, more efficient route. The LPC technology produces small-diameter billets with superior surface quality, nearly eliminating the inverse segregation layer and thus removing the need for scalping. Forging trials with AA6082 alloy demonstrate that this material can be forged directly, and even shows superior mechanical properties without the traditional homogenization step. By streamlining the production process and eliminating costly steps, the LPC technology is expected to provide a 20% material-level cost reduction, making forged aluminum components more competitive.

3. Introduction:

More car manufacturers are utilizing closed die forging for aluminum wheel suspension parts due to their excellent properties. However, the production cost is relatively high. The traditional process for producing forging stock involves melting, billet casting, homogenizing, ultrasonic processing, and extrusion. A more recent route involves casting small diameter billets followed by scalping to remove the surface segregation layer. Both routes are multi-step processes where material costs typically account for 50% of a finished forged component's cost. This article presents a third option: a low pressure casting (LPC) technology developed by Hydro. This technology produces logs with a very smooth surface, reducing the number of processing steps and allowing the material to be used directly in forging. This innovation is expected to provide a 20% cost reduction on a material level.

4. Summary of the study:

Background of the research topic:

The high cost of the existing, complex value chain for producing aluminum forging stock for automotive components.

Status of previous research:

Previous production routes involved either extrusion of large billets or casting of small billets followed by scalping to remove surface defects. A scalp-free alternative had been discussed but was limited in production.

Purpose of the study:

To introduce and validate Hydro's Low-Pressure Casting (LPC) technology as a new production route that significantly reduces processing steps and costs for high-quality forging stock.

Core study:

The study focused on optimizing the LPC process for small-diameter billets (90 mm) of AA6082 alloy. It involved CFD modeling to define the process window, pilot-scale casting to produce ingots, and laboratory forging trials to compare the microstructure and mechanical properties of as-cast (unhomogenized) versus homogenized LPC material. The goal was to demonstrate that LPC material could be forged without prior scalping or homogenization.

5. Research Methodology

Research Design:

The research combined numerical simulation with physical experimentation. An advanced computational fluid dynamics (CFD) model was first developed to optimize the casting start-up process. This model was then validated with measurements from a pilot casting line. Finally, ingots produced on the pilot line were used in laboratory-scale forging experiments to evaluate their performance under different pre-treatment conditions (as-cast vs. homogenized).

Data Collection and Analysis Methods:

- CFD Modeling: A 3D model considering fluid flow, solidification, and heat transfer was used to predict metal filling and temperature distribution.

- Physical Measurement: Laser sensors measured the metal level in the launder system during pilot casting to validate the CFD model.

- Material Characterization: Surface roughness of cast ingots was measured. Microstructure and grain size were analyzed using light optical microscopy with the linear intercept method.

- Mechanical Testing: Tensile samples were taken from various positions and directions of the forged parts and tested to determine yield strength (Rp0.2) and ultimate tensile strength (Rm).

Research Topics and Scope:

The research focused on the application of LPC technology for producing AA6082 forging stock in a 90 mm diameter. The scope included process modeling for industrial-scale production, characterization of the as-cast material, and an investigation into the feasibility of forging without homogenization and solutionizing after forging. The study also briefly touched upon the applicability to other alloys like AA7075.

6. Key Results:

Key Results:

- The LPC technology produces forging stock with excellent surface quality (Rz = 6.4 µm), eliminating the need for a scalping operation.

- The as-cast microstructure shows virtually no inverse segregation zone, a common issue in other casting technologies.

- Forging trials demonstrated that unhomogenized LPC material can be successfully forged and, after solutionizing, exhibits higher strength than material that underwent a traditional homogenization treatment.

- The grain structure after forging and solutionizing is robust with very little recrystallization, especially for the unhomogenized material.

- The technology is applicable to other alloys, with successful casting of AA7075 demonstrated.

Figure Name List:

- Figure 1. Alternatives for producing forging stock.

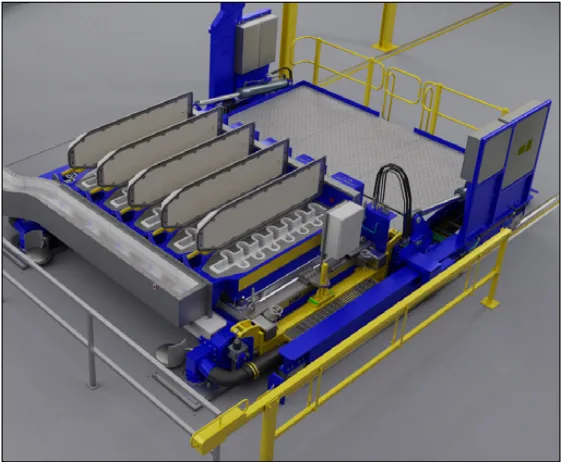

- Figure 2. The LPC vertical DC casting machine.

- Figure 3. Measured and predicted metal level during filling.

- Figure 4. Detail view of predicted filling of the molds (a) and temperature distribution in LPC casting mold during start-up (b).

- Figure 5. AA6082 cast forging ingots in 90 mm diameter (left) and a close-up of a typical surface with corresponding results from roughness measurements (right).

- Figure 6. Micrograph of a typical surface region of the LPC 90 mm diameter cast forging ingots in alloy AA6082 (left). Macro grain structure of an as-cast AA6082 forging ingot (right).

- Figure 7. Forging die used on the laboratory-scale forging press (left) and detailed pictures of a forged piece (right).

- Figure 8. Light optical micrographs showing the grain structures in forged and solutionized samples (560°C/20 min). Unhomogenized material (left) and homogenized material (right).

- Figure 9. Tensile results from samples taken from different positions and directions of forged pieces. Results from unhomogenized material is represented by the blue bars and homogenized by the red bars.

- Figure 10. Billet surface and sub-surface structure of an AA7075 alloy cast with the LPC technology in 152 mm diameter.

7. Conclusion:

The LPC technology is capable of casting small-diameter billets with a superior surface quality. Laboratory and industrial trials have demonstrated that this technology can shorten the process for making wheel suspension parts by eliminating the need for both surface scalping and homogenization prior to forging. With the start-up of large-scale production, it is expected that material costs for a forged part will be reduced by about 20%, significantly improving the competitiveness of forged aluminum suspension parts.

8. References:

- Jensrud, Ola and Ketill Pedersen, “Castforge: The synthesis for development of new technologies for manufacturing of aluminum automotive parts," 2nd International Conference & Exhibition on New Developments in Metallurgical Process Technology, September 2004.

- Forged Components, 2nd edition, Hirschvogel Automotive Group, 2014, p. 39.

- Wiel, Robert and Dr. Michael Muckelbauer, “Potentials in Aluminum Forging for Passenger Car Chassis Parts by Using Alternative Prematerial, or: Forging without Scrap," NEMU 2019, pp. 55-64.

- Håkonsen, A., J.E. Hafsås, and R. Ledal, “A New DC Casting Technology for Extrusion Billets with Improved Surface Quality,” Light Metals 2014, pp. 873-878.

- "SIR Inline Melt Refining," Hycast, www.hycast.no/products/sir.

- Mortensen, D., "A mathematical model of the heat and fluid flows in direct-chill casting of aluminum sheet ingots and billets,” Metallurgical and Materials Trans., Vol. 30B, 1999, pp. 119-133.

- Sintef, www.sintef.no.

Expert Q&A: Your Top Questions Answered

Q1: Why was an advanced CFD model so critical for developing the process for small-diameter billets?

A1: The paper explains that casting small-diameter billets on an industrial scale is challenging due to a narrow process window during the start-up phase. A large number of molds must be filled evenly and quickly. The CFD model was essential to simulate and optimize this critical phase, ensuring a turbulent-free surface flow and proper solidification to avoid freezing, which becomes more difficult as the diameter decreases.

Q2: Figure 9 shows that unhomogenized material is stronger than homogenized material after forging. What is the metallurgical reason for this?

A2: The paper proposes that this counterintuitive result is due to the precipitation of dispersoids. In the unhomogenized material, elements like Mn and Cr are in solid solution during forging. During the subsequent solutionizing step, new dispersoids precipitate directly at dislocations and shear bands. By "pinning" these dislocations, they act as a very effective barrier against recrystallization, thus preserving a higher level of strength from the deformation process.

Q3: The paper mentions eliminating the need for a separate solutionizing step after forging. How is this possible?

A3: This is achieved by integrating the solutionizing treatment into the pre-heating stage before forging. The paper states that it has become more common to preheat the forging ingot to a relatively high temperature and skip the separate solutionizing step afterwards. This requires that the pre-heating temperature and time are sufficient to dissolve the eutectic phases from casting and that the forging process itself is fast enough to avoid precipitation of non-hardening particles.

Q4: What is the key mechanism in the LPC technology that leads to the superior, scalp-free surface?

A4: The introduction states that one of the main benefits of the LPC technology is that "the friction between the ingot surface and the mold during casting is reduced." This reduction in friction is the key factor that "nearly eliminates the inverse segregation zone," which is the defective surface layer that must be scalped off in other casting processes.

Q5: How versatile is this LPC technology? Is it only suitable for the AA6082 alloy discussed in detail?

A5: While the paper focuses heavily on AA6082 for automotive suspension parts, it explicitly states that the LPC technology can be used to cast "almost any alloy in a quality that can be forged without any prior scalping of the surface." To prove this, Figure 10 shows an example of an AA7075 alloy billet cast with the LPC technology, demonstrating its versatility for other high-strength alloy systems.

Conclusion: Paving the Way for Higher Quality and Productivity

The high cost and complexity of the conventional supply chain have long been a hurdle for the broader use of high-performance forged aluminum components. This research demonstrates a clear and validated pathway to overcome this challenge. By leveraging Low-Pressure Casting, it is now possible to produce High-Quality Forging Stock that eliminates two costly and time-consuming steps: scalping and homogenization. The resulting 20% reduction in material costs represents a significant competitive advantage and a major step forward in lightweighting technology.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Low-Pressure Casting Technology Represents Step Change in Producing High Quality Forging Stock" by "Ulf Tundal, et al.".

- Source: Reprinted for Hycast AS with permission, ©2020 Light Metal Age.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.