Eliminating Thin-Wall Casting Defects: How Mould Filling Simulation Prevents Cold Shots and Scabs

This technical summary is based on the academic paper "The Effect of a Thin-Wall Casting Mould Cavity Filling Conditions on the Casting Surface Quality" by A. Trytek, A.W. Orłowicz, M. Tupaj, M. Mróz, O. Markowska, G. Bąk, and T. Abram, published in Archives of Foundry Engineering (2016).

Keywords

- Primary Keyword: Thin-Wall Casting Defects

- Secondary Keywords: Grey Cast Iron, Cold Shots, Casting Simulation, Mould Cavity Filling, Surface Quality, Gating System Design

Executive Summary

- The Challenge: Thin-walled grey cast iron castings are highly susceptible to surface non-conformances like cold shots, scabs, and sand buckles, which compromise aesthetic quality and can lead to rejection.

- The Method: The study combined detailed metallographic examination using a scanning electron microscope (SEM) with advanced computer simulation (NovaFlow & Solid) to investigate the root cause of these defects.

- The Key Breakthrough: The research conclusively identified an incorrectly designed gating system as the primary cause of defects, which promoted turbulent flow and spattering of the liquid metal during mould filling.

- The Bottom Line: Proactive gating system design, validated by simulation, is the most effective strategy to prevent turbulent flow and eliminate the formation of cold shots and related surface defects in thin-wall castings.

The Challenge: Why This Research Matters for Casting Professionals

The push for lighter, stronger components has led to the increased use of thin-walled cast-iron castings as cost-effective replacements for aluminum alloys. However, manufacturing these intricate parts presents significant challenges. The higher mould pouring temperatures and liquid metal velocities required for thin sections increase the risk of mould erosion, sand buckles, scabs, and cold shots.

These surface non-conformances are not just cosmetic; they can indicate underlying process instabilities and are often unacceptable to customers. For engineers in high-performance sectors like automotive and aerospace, ensuring a flawless surface finish is critical. This research addresses a fundamental question: what is the precise mechanism behind these defects, and how can it be controlled? While this study focuses on furan resin sand molds, the fundamental principles of fluid dynamics and defect formation offer valuable lessons for all casting processes, including high-pressure die casting.

The Approach: Unpacking the Methodology

To pinpoint the cause of the defects, the researchers employed a two-pronged approach: physical analysis and virtual simulation.

- Test Material: The subject was a thin-walled casting made of grey cast iron with flake graphite, containing 3.3% C, 2.8% Si, and 0.5% Mn. The mould, made of furan resin sand, was poured at a temperature of 1340°C.

- Metallographic Examination: Transverse sections from an 8-mm thick casting wall were examined using a VEGA3 (TESCAN) scanning electron microscope. An INCA x-act adapter was used for chemical microanalysis to determine the exact composition of the defects and the surrounding material.

- Computer Simulation: The mould cavity filling and solidification process was simulated using NovaFlow & Solid software. The model replicated the industrial setup, including a wedge-shaped gating system, pouring from two ladles, and an air venting system, with a pouring temperature of 1340°C. This allowed the team to visualize the metal flow dynamics that were impossible to observe in the physical process.

The Breakthrough: Key Findings & Data

The combination of physical and virtual analysis yielded conclusive evidence linking the gating system design directly to the formation of surface defects.

Finding 1: Metallurgical Analysis Confirms Oxide-Rich Defects

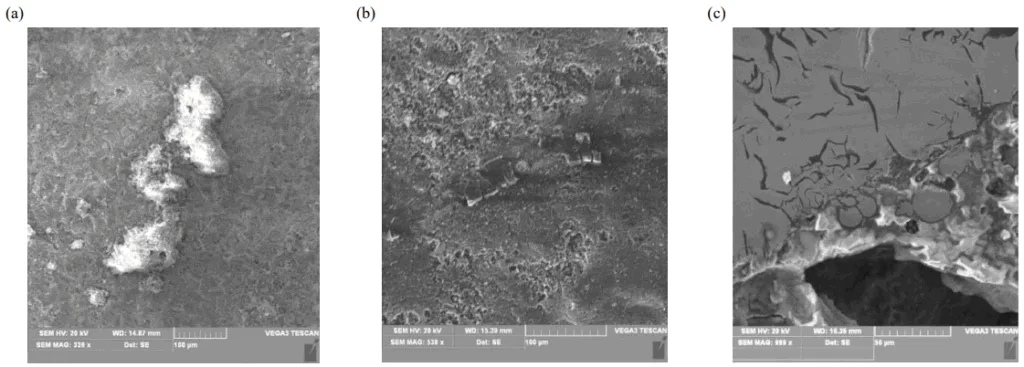

The SEM examination of the casting surface revealed non-conformances including scabs, sand buckles, and clusters of cold shots (Figure 2). A closer look at the transverse sections showed that these cold shots were distinct, spherical bodies adjacent to the casting surface, often with a characteristic halo and associated gas cavities.

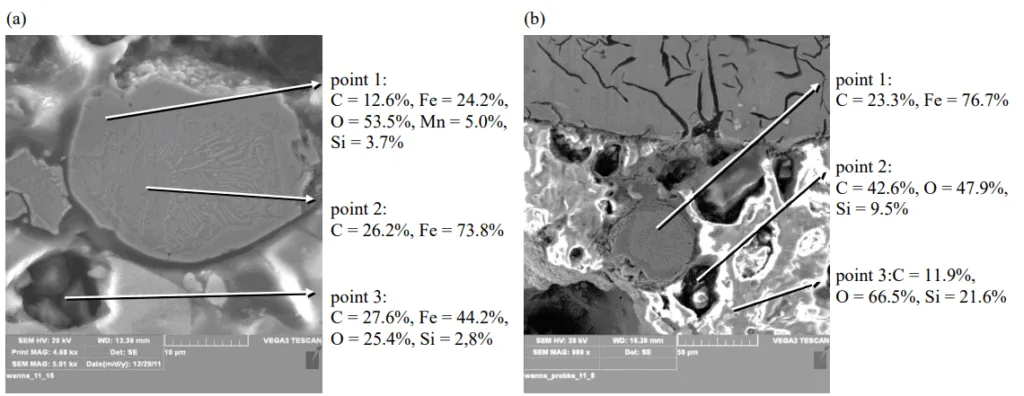

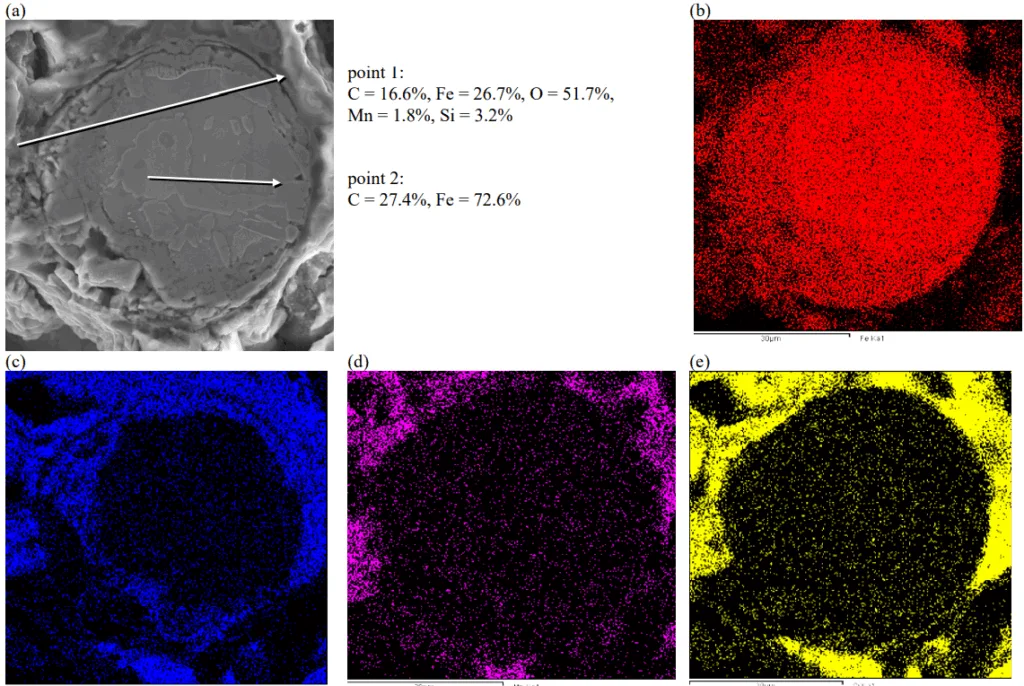

Crucially, chemical microanalysis of these cold shots revealed their true nature. As shown in Figure 4, the surface of a cold shot had an eminent concentration of oxygen (51.7%), along with iron (26.7%), manganese (1.8%), and silicon (3.2%). This composition confirms the feature consists of oxides, which formed an insulating layer that prevented the cold shot from fusing with the main body of liquid metal.

Finding 2: Simulation Reveals Turbulent Flow as the Root Cause

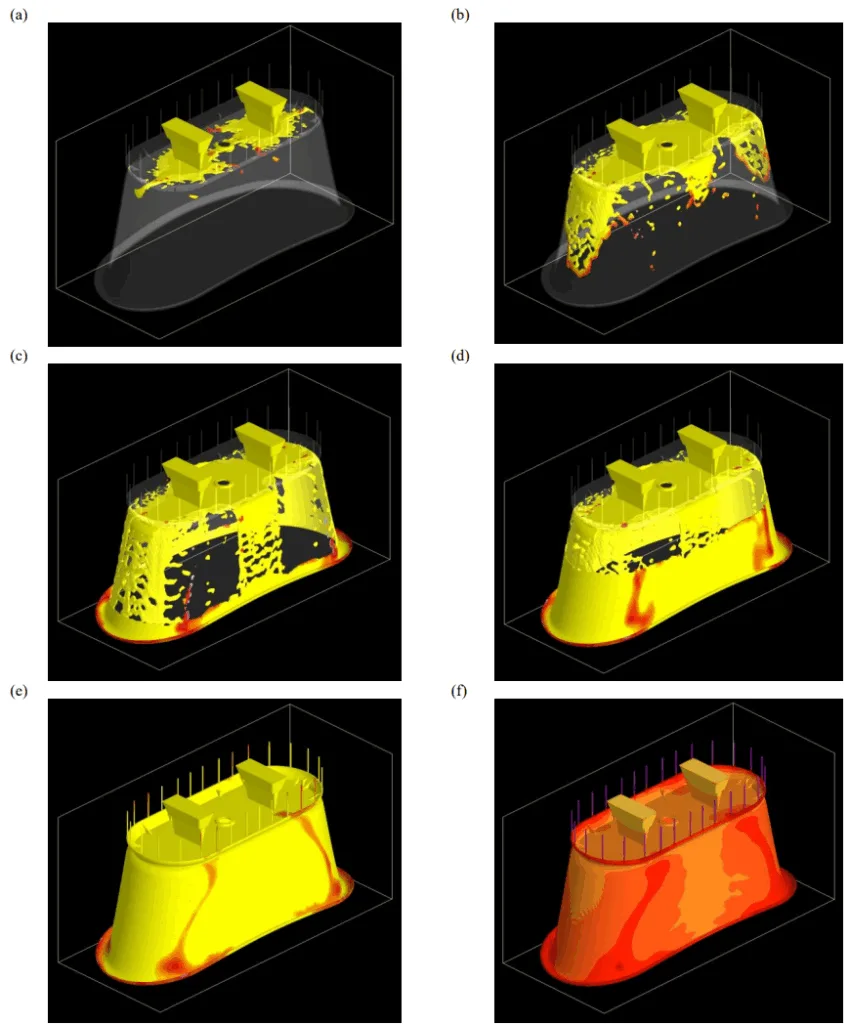

The computer simulation provided the "smoking gun." It demonstrated that the gating system design caused a highly turbulent flow as metal entered the mould cavity.

As shown in the simulation sequence in Figure 5, this turbulence resulted in a "characteristic spattering of the liquid metal stream" (Figure 5a, 5b). Isolated drops of metal were thrown deep into the mould cavity ahead of the main flow. These drops cooled rapidly on contact with the mould surface—by as much as 150-200°C—and became oxidized. As the mould filled, these "frozen" and oxidized drops were enveloped by the hotter liquid metal (Figure 5c, 5d) but did not remelt, remaining as distinct cold shot defects on the final casting surface. The simulation showed that the areas with the lowest temperatures during filling and solidification (Figure 5f) corresponded directly to the locations where defects were most frequently observed.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that redesigning the gating system to ensure a calm, non-turbulent mould fill is the most critical action to eliminate cold shots, scabs, and related surface defects. Relying on simulation to validate gating designs before production is a key preventive measure.

- For Quality Control Teams: The data in Figure 4 provides a clear chemical signature for cold shot defects (high concentrations of O, Si, and Mn oxides). This can be used to definitively identify the defect during failure analysis and confirm that the root cause is related to metal stream breakup and oxidation.

- For Design Engineers: The findings underscore the profound impact of the gating system on final part quality. This research indicates that robust fluid flow simulation should be a mandatory step in the early design and process development phase for any thin-wall casting to prevent costly defects downstream.

Paper Details

The Effect of a Thin-Wall Casting Mould Cavity Filling Conditions on the Casting Surface Quality

1. Overview:

- Title: The Effect of a Thin-Wall Casting Mould Cavity Filling Conditions on the Casting Surface Quality

- Author: A. Trytek, A.W. Orłowicz, M. Tupaj, M. Mróz, O. Markowska, G. Bąk, T. Abram

- Year of publication: 2016

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING, Volume 16, Issue 4/2016

- Keywords: Thin-wall casting, Grey cast iron, Cold shots, Simulation

2. Abstract:

The paper presents results of metallographic examination of faults occurring in the course of founding thin-walled cast-iron castings in furan resin sand molds. A non-conformance of the scab type was Observed on surface of the casting as well as sand buckles and cold shots. Studied the chemical composition by means of a scanning electron microscope in a region of casting defects: microanalysis point and microanalysis surface. Around the observed defects discloses high concentration of oxides of iron, manganese and silicon. A computer simulation of the casting process has been carried out with the objective to establish the cause of occurrence of cold shots on casting surface. The simulation was carried out with the use of NovaFlow & Solid program. We analyzed the flowing metal in the mold cavity. The main reason for the occurrence of casting defects on the surface of the casting was gating system, which caused turbulent flow of metal with a distinctive splash stream of liquid alloy.

3. Introduction:

The progress in founding technology contributes to widening the scope of application for well-known casting materials. New technologies allow for the replacement of aluminium alloy castings with light-section cast-iron castings, reducing manufacturing costs while increasing strength. However, manufacturing thin-walled castings carries the risk of typical defects. They require higher mould pouring temperatures, which, combined with liquid metal stream force, can lead to erosion, dirt spots, sand buckles, and scabs. Preventing these defects involves correct selection of binding materials, special mould coatings, controlled compaction, and lowering the pour point.

4. Summary of the study:

Background of the research topic:

Manufacturing of thin-walled cast-iron castings presents a challenge due to the high risk of surface defects like scabs, sand buckles, and cold shots, which are undesirable from a customer perspective.

Status of previous research:

Previous research has focused on preventing such defects through measures like selecting proper binding materials, using special mould coatings, controlling moulding sand compaction, lowering the pour point, and modifying the liquid alloy to improve mechanical properties.

Purpose of the study:

The objective was to establish the cause of cold shots and other surface defects on thin-walled grey cast iron castings by combining metallographic examination with computer simulation of the casting process.

Core study:

The core of the study involved analyzing the chemical composition of surface defects using a scanning electron microscope and simulating the mould cavity filling process with NovaFlow & Solid software to visualize the metal flow and identify the mechanism of defect formation.

5. Research Methodology

Research Design:

The study used a combination of physical examination and computational simulation. Defective thin-walled castings were physically analyzed to characterize the non-conformances, and a computer model of the casting process was created to investigate the dynamic conditions leading to their formation.

Data Collection and Analysis Methods:

Data was collected via metallographic examination of transverse sections using a VEGA3 (TESCAN) scanning electron microscope. Chemical composition was determined through point and surface microanalysis. The mould filling process was analyzed using results from a simulation run on NovaFlow & Solid software.

Research Topics and Scope:

The research focused on a thin-walled casting made of grey cast iron (3.3% C, 2.8% Si, 0.5% Mn) cast in a furan resin sand mould at 1340°C. The study investigated the formation of surface defects, specifically cold shots, scabs, and sand buckles.

6. Key Results:

Key Results:

- Metallographic examination revealed non-conformances on the casting surface, including scabs, sand buckles, and cold shots.

- Chemical microanalysis of the cold shots showed they were covered with a layer of oxides, with high concentrations of oxygen, iron, manganese, and silicon.

- Computer simulation of the mould filling process revealed that the gating system caused a turbulent flow with a distinctive spattering of the liquid metal stream.

- The simulation showed isolated drops of metal falling into the mould, cooling by 150-200°C, oxidizing, and then being enveloped by the main metal flow, thus creating the cold shot defects.

- The main cause of the defects was determined to be the incorrectly designed gating system.

Figure Name List:

- Fig. 1. An example microstructure of thin-wall casting. Note rosette pattern of flake graphite distribution and ferritic-pearlitic matrix. Etched with Nital (×100 magnification)

- Fig. 2. An example view of a thin-wall casting non-conformity: (a), (b) on wall surface; (c) a view in transverse section — a cluster of cold shots at the casting surface

- Fig. 3. Cold shots and oxides visible in the transverse section

- Fig. 4. Microanalysis: (a) point-like and (b)–(e) superficial

- Fig. 5. Simulation of filling a thin-wall casting mould when filled in: (a) 15%; (b) 30%; (c) 50%; (d) 70%; (e) 100%; and (f) in the course of casting solidification

7. Conclusion:

The study concluded that the main cause of non-conformances like cold shots, gas cavities, and scabs on the surface of the thin-walled castings was an incorrectly designed gating system. The observed cold shots developed at the beginning of the mould filling process, became surrounded by a layer of oxides, stuck to the mould surface, and remained unmelted by the inflowing liquid metal. To reduce or eliminate these defects, it is necessary to redesign the gating system.

8. References:

- [1] Fraś, E., Górny, M. & Kapturkieiwcz, W. (2013). Thin wall ductile iron castings: technological aspects. Archives of Foundry Engineering. 13(1), 23-28.

- [2] Fraś, E., Górny, M. & Lopez, H. (2014). Thin wall ductile iron castings as substitutes for aluminium alloy castings. Archives of Metallurgy and Materials. 59(2), 459-465.

- [3] Górny, M. (2009). Thin wall ductile iron castings as substitute for aluminium alloy casting in automotive industry. Archives of Foundry Engineering. 9(1), 143-146.

- [4] Vasková, I., Fecko, D. & Malik, J. (2012). The Dependance of Castings Quality Produced into the Clay Moulding Mixtures from the Properties of Binder on the Montmorillonite. Archives of Foundry Engineering. 12(3), 121-126.

- [5] Mocek, J. (2003). The process of erosion of sand moulds prepared with water glass binding. Archives of Foundry. 3(10), 23-30.

- [6] Mocek, J. (2001). Influence of selected technological factors on erosion of sand moulds poured with cast iron. Archives of Foundry. 1(1 2/2).

- [7] Mocek, J. & Samsonowicz, J. (2011). Changes of gas pressure in sand mould during cast iron pouring. Archives of Foundry Engineering. 11(4), 87-92.

- [8] Chojecki, A. & Mocek, J. (2008). Erosion phenomena in sand moulds. Archives of Foundry Engineering. 8(spec.1), 49-52.

- [9] Mocek, J. (2002). Erosion of the sand moulds during filling by liquid cast iron. Archives of Foundry. 2(5), 100-105.

- [10] Falęcki, Z. (1991). Analysis of casting defects. Kraków: the script AGH No. 1283.

- [11] Fras, E., Podrzucki, Cz. (1978). Cast iron modified. Kraków: the script AGH, No. 675.

- [12] Murgas, M. & Pokusova, M. (2007). Grafitizacno ockovadlo pre sinteticku liatinu. Sbornik vedeckich praci. Vysoka skola banska Technicka Universita v Ostravie. 50(1), 173-178.

Expert Q&A: Your Top Questions Answered

Q1: Why was computer simulation necessary when the defects were already visible on the physical casting?

A1: Physical examination can identify and characterize a defect, but it cannot reveal the dynamic process that created it. The computer simulation was essential to visualize the mould cavity filling process, showing exactly how the gating system's design led to turbulent flow and metal spattering. This allowed the researchers to establish a clear cause-and-effect relationship between the process and the defect.

Q2: What specific evidence points to oxidation as a key factor in the cold shot defects?

A2: The microanalysis shown in Figure 4 is the key evidence. The analysis of a cold shot (point 1 in Fig. 4a) revealed an oxygen concentration of 51.7%. This high oxygen content, combined with silicon and manganese, confirms the presence of a significant oxide layer on the surface of the droplet, which acted as a barrier, preventing it from properly fusing with the surrounding liquid metal.

Q3: The paper mentions the gating system was the problem. What specific aspect of its design caused the turbulent flow?

A3: The paper identifies the "wedge-shaped gating system" as the source of the issue. The simulation results in Figure 5a and 5b visualize the outcome: a "turbulent nature with a characteristic spattering of the liquid metal stream." This indicates the design did not properly control the velocity and direction of the metal, causing it to break apart into droplets instead of filling the cavity smoothly.

Q4: How significant was the temperature drop in the "cold shots" before they were enveloped by the main metal flow?

A4: The simulation provided a quantitative estimate of this temperature drop. According to the paper, the isolated drops that spattered onto the mould surface cooled to a temperature "lower than the pour point by about 150-200°C." This substantial cooling, combined with rapid oxidation, ensured the drops became "frozen" and could not be remelted by the subsequent flow of hotter metal.

Q5: What is the paper's primary recommendation for eliminating these thin-wall casting defects?

A5: The conclusion is unambiguous: "To reduce or eliminate non-conformances occurring on surfaces of thin-wall castings of cast iron with flake graphite, it would be necessary to redesign the gating system." The study pinpoints the gating system as the root cause, making its redesign the most direct and effective corrective action.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear and actionable insight into the formation of Thin-Wall Casting Defects. By combining detailed metallurgical analysis with powerful flow simulation, the study demonstrates that surface non-conformances like cold shots are not random occurrences but a direct result of turbulent mould filling caused by a suboptimal gating system. The key takeaway is that prevention through intelligent, simulation-validated design is far more effective than reactive quality control.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "The Effect of a Thin-Wall Casting Mould Cavity Filling Conditions on the Casting Surface Quality" by "A. Trytek et al.".

- Source: https://www.archives.afe.pl/40_4.pdf

- This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.